Media | Articles

DIY: “While I’m in There” syndrome is a slippery slope

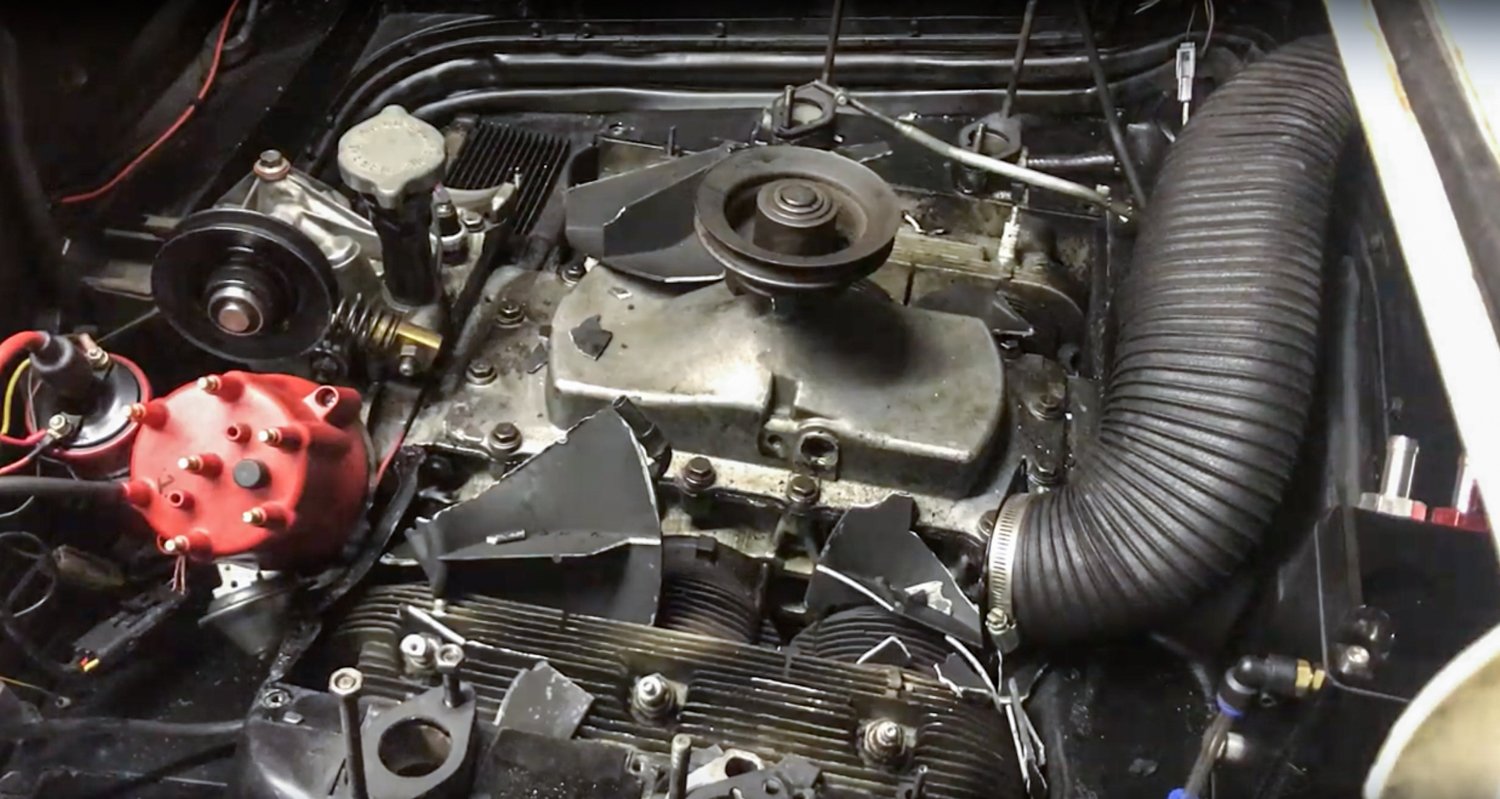

My 1965 Chevrolet Corvair has been an ongoing project for 18 months, but the latest fix was was unplanned. For that, I have a failed 50-year-old cooling fan to thank. The last article I wrote about my Corvair lamented the extent of the damage that a lone cooling fan hell-bent on destruction could impose. The magnesium fan seemed to pick no favorites and instead broke everything it could reach—the dispassionate force of entropy. I got the engine compartment apart, then moved onto ordering parts.

While repairing the damage from the fan demolition, I came down with a certain… ailment. More of a syndrome common to the DIYer. The medical term is “While I’m in There,” and if you’re reading this, there’s a good chance it could affect you or someone you love.

“While I’m in There” involves performing a necessary repair and then replacing parts that are not truly, immediately necessary because you’re already “in the neighborhood,” so to speak. Indulging this torrent of maintenance saps all the DIYer’s energy and drags the whole project to a halt. Quick action can prevent your project from becoming something for Barn Find Hunter to discover in 20 years.

My Corvair has had trouble containing its engine oil the entire time I have owned it. I have worked to seal up all the leaks from underneath, but despite my efforts it only seemed to quell the fine mist of oil covering the engine compartment for about 200 miles of driving. Even with the PCV properly set up, oil covered the engine compartment.

Marketplace

Buy and sell classics with confidence

I likely would have never figured out the dipstick was reading one quart lower than it should have, meaning I would have run the engine a quart over full for most of my ownership. But thanks to the fan’s destruction, I was forced to install a new dipstick tube which ultimately corrected the problem. (The last person to assemble this flat-six did not press the tube completely into the aluminum engine block, rendering it wildly inaccurate.) Removing the broken tube was a pain, requiring heat from a MAPP gas torch and use of the longest set of needle-nose pliers I own. Driving the new in was an exercise in patience; I had to make sure it drove in straight and completely.

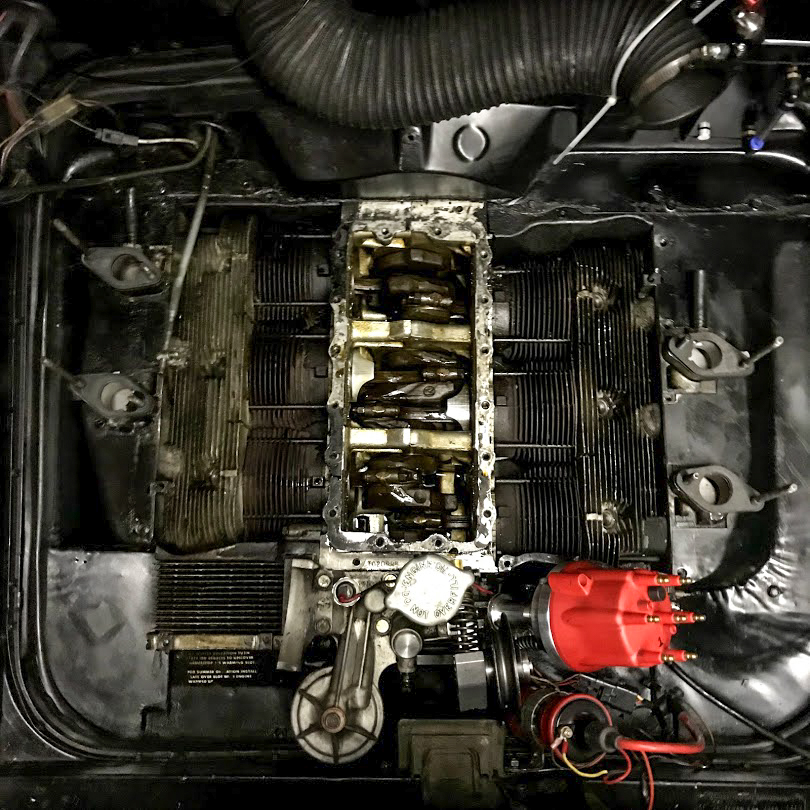

But that song and dance was something that I had to do. Removing the top cover of the crankcase just to re-gasket it against leaks it didn’t already have was, well, more ambitious. Yet I there I was, doing it anyway.

The top cover of the crankcase is a fairly common leak point, and it could have eventually leaked oil in the engine compartment, but there were no signs of a leak when I got everything taken apart. I was spending time fixing a non-existent problem, because “While I’m in There” is sneaky like that. I also sandblasted all the parts I took off, applied fresh paint anywhere I could, re-tuned the spring-loaded fanbelt tensioner, new hard lines for the fuel system, and swapped the perfectly functioning secondary carburetors for untested units. Many hours of unnecessary work.

Even with years of experience turning wrenches, “While I’m in There” had me ordering parts and taking things apart before I could catch myself. If you enjoy wrenching on your car, it can be quite dangerous to turn a small project into something larger. When someone says they are starting a small weekend project, I advise caution. That’s how full-blown restorations start.

As it sits right now, the engine is 90-percent back together. It could be started, but I went ahead and prepared the car for storage since it’s winter in Michigan and it won’t be driven till spring. I also need to finish the interior that was started in September, since that got derailed when the fan exploded. There is a whole list, but for now I’m just trying to finish the ongoing projects before starting any more—and making sure that none of them snowball out of control when “While I’m in There” eventually recurs.