Media | Articles

The work and life of the man who “invented” horsepower

The timeline of the automobile goes back to prehistory and the first wheel, but that line also runs through 18th-century Scottish inventor James Watt. While Watt is widely thought of as the inventor of the steam engine, that honor really goes to Thomas Newcomen, who developed the device that Watt later improved, primarily to pump water out of mines. It was Watt, however, who made the invention more practical and thus applicable to more industrial uses. In doing so, he kicked off the industrial revolution and created technological legacies that carried into the modern automobile.

Today we associate steam power with locomotives and electrical generating plants, but those machines operate on high-pressure steam. In the 17th and 18th centuries, metallurgy had not advanced enough to support the construction of high-pressure boilers. The engines of Newcomen and Watt were atmospheric: Where a modern steam engine uses steam pressure to motivate a drive piston, atmospherics work by filling a sealed cylinder with steam, then quickly cooling that cylinder, forcing the steam to condense.

Since water in gas form occupies roughly 1700 times more volume than it does as a liquid, rapid condensation of an atmospheric’s steam created a vacuum. Introducing standard atmosphere to the other side of the piston created a pressure differential, which in turn caused the piston to move. In Newcomen’s case, the piston was connected vertically to a pivoting beam, which in turn moved a chain. That chain then drove a pump suspended into the shaft of the flooded mine.

Watt’s initial innovation, said to have arrived while taking a walk, lay in the addition of a separate condensing chamber where the steam could be cooled, preventing the need to cool the cylinder itself. That made Newcomen’s engine much more efficient, reducing the amount of coal it needed as fuel. (Watt’s 1769 patent for the separate condenser was in fact titled, “A new method of lessening the consumption of steam and fuel in fire-engines.“)

In a later development, Watt made his engine double-acting, using automated valves to alternate vacuum and atmospheric pressure on each of the piston’s two sides. Surprisingly, this dual-action engine was only two-thirds as powerful as Watt’s original single-action engine, but it used half as much coal, making it even more fuel-efficient—a detail of supreme importance to mine operators. To get the funding to properly develop his invention, Watt took on as partner an English manufacturer named Matthew Boulton. Their partnership became the manufacturing firm of Boulton & Watt.

Marketplace

Buy and sell classics with confidence

By the 18th century, Britain was mining minerals like tin, copper, iron, and coal. The deeper the mines went, the greater the need for engines to pump out the groundwater that filled them. That was a substantial economic opportunity, but Boulton and Watt realized that the market for their engine was larger than just mine operators. Mills, producing grain and textiles, dotted the British countryside, adjacent to the rivers and streams needed to power their waterwheels. The rapidly growing iron and steel industries needed mechanized hammers to crush iron ore into powder, and they needed bellows to blast air into smelting furnaces. Watt’s original engine produced, through its beam, a reciprocating force that was fine for operating pumps, hammers, and bellows, but waterwheels produce rotational force, more widely useful in industrial applications.

To expand their market, Watt had to come up with a means of converting reciprocal motion into rotational motion. There are only so many ways to do this. Boulton & Watt first developed a crankshaft, linked to the engine’s beam with a connecting rod—likely the first such arrangement in an engine. (If you drive an internal-combustion vehicle not powered by a rotary engine or electric motor, it contains a crank and rods.) Unfortunately, James Watt didn’t think that arrangement, used for grinding stones and other applications since antiquity, was novel enough to patent. In an early example of industrial espionage, the crank-and-rod setup was taken by machinery maker Matthew Wasbrough, who patented it, preventing Boulton & Watt from using the arrangement commercially.

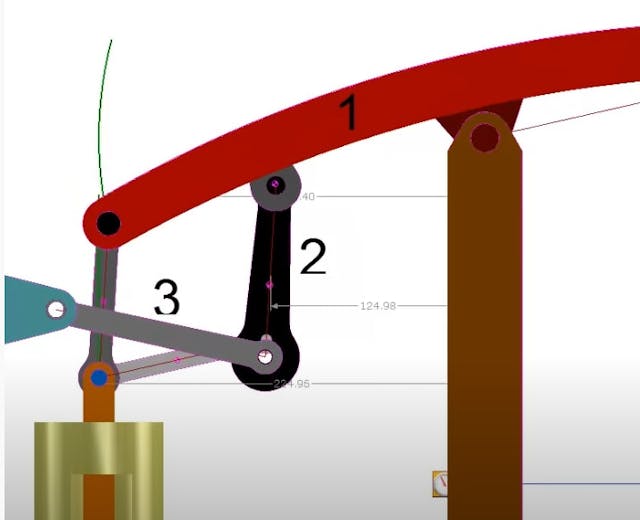

Out of necessity, Watt replaced the crankshaft with a sun-and-planet gearset, likely invented by his associate William Murdock (Murdoch in the original Scottish). One end of the connecting rod was attached to the engine’s reciprocating beam, while the other end held a planet gear. That planet gear meshed with a sun gear. The sun gear was fixed to the middle of a large flywheel. As the beam’s connecting rod reciprocated, it drove the flywheel, which could, in turn, be used as a source of rotational power.

Piston engines need help to both maintain continuous motion and smooth out their power strokes. In this case, the flywheel’s inertia kept things moving when the connecting rod reached the “dead” spot at its extremes of travel. If your car or truck runs on liquid fuel, it has a flywheel. If your vehicle has an automatic transmission or a hybrid drive, it uses planetary gears.

This video shows how the sun and planet gears operated:

Watt also developed a governor to automatically control the engine’s speed. An opposing pair of weighted balls were mounted on a spinning linkage driven by a belt running off the flywheel. As engine speed increased, centrifugal force moved the spinning balls farther apart, changing the angle of the links, which were connected to the throttle for steam. If the engine ran too fast, that linkage would cut the throttle.

This governor is generally agreed to have prompted the phrase “balls to the wall” (think about it for a minute). My Honda has a rev limiter that cuts power to the spark plugs at the engine’s redline. That rev limiter is by no means the same technology, but it is ultimately descended from Watt’s device.

Interestingly, Watt didn’t consider his improved steam engine to be his greatest accomplishment. He was exceptionally proud of his method for keeping an engine’s piston traveling in a straight line, despite the fact that this piston was connected to a beam whose motion transcribed an arc. That semi-circular motion could rock the piston against the cylinder walls, increasing friction and reducing efficiency. Watt came up with an elegant, three-link solution that restricted motion to a vertical plane. You can see how it works in the video above.

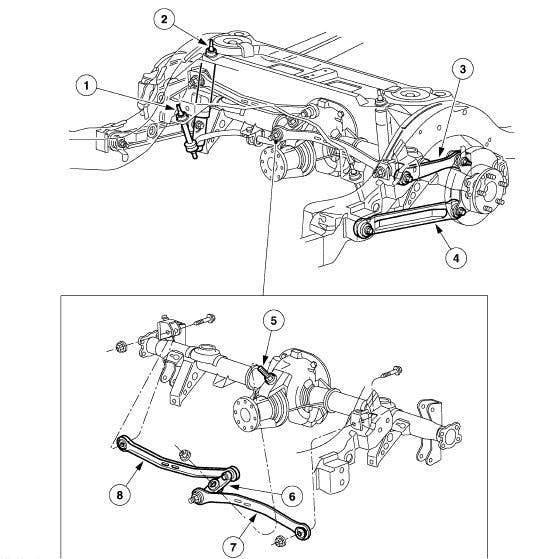

If this sounds familiar, remember muscle cars: What is today known as a Watt’s linkage, or a Watts link, is still used in the rear suspension of live-axle vehicles. The device is an improvement over the simpler but equally common Panhard rod, which doesn’t permit true vertical motion.

Watt had been scarred by what he perceived as Wasbrough’s theft of his crankshaft design. As a result, he was particularly concerned with protecting intellectual property. His 1784 patent also included the use of a piston-driven conveyance that used “the elastic force of steam to give motion.” A self-propelled vehicle, in other words.

It’s not clear if Watt was familiar with Frenchman Nicolas-Joseph Cugnot’s 1769 steam-powered Fardier à vapeur, the world’s first self-propelled vehicle, but Watt and Boulton were undoubtedly familiar with the experiments of their associate William Murdock. Murdock focused on steam propulsion, and he even developed a small-scale, self-propelled, steam-powered vehicle that he intended to patent. (Boulton talked him out of securing rights to the idea, and Watt kept him busy with the firm’s work.)

Some describe Watt’s patenting of a steam driven vehicle as an early version of “patent trolling,” securing IP rights to prevent others, in this case Murdock, from developing those ideas. However, the historical record shows that Watt, a master fabricator with strong connections to iron/steelmakers, had genuine concerns about the safety of high-pressure boilers. In any case, Murdock didn’t seem to mind. Watt respected the man greatly, and Murdock continued to work for Boulton & Watt, eventually being named partner in the firm.

Perhaps James Watt’s most lasting automotive legacy, one that will exist as long as there are cars, is the word “horsepower.” While Watt was, of course, interested in measuring the power output of his engines for practical purposes, his use of that term and his codifying of its measurement was driven (no pun intended) by how Boulton & Watt were paid for their engines. The bulk of the firm’s early revenue, off the work for mine operators, came from royalties. Watt’s original single-action engine could do two to four times the work of a Newcomen engine when given the same fuel, and W&B’s royalty arrangement ensured that the company received one-third of the mines’ resultant financial savings.

In this case, that calculation birthed a new term. The two engines could be compared by the amount of “duty” they could perform, measured as the number of pounds of water that could be lifted one foot after the engine had burned one bushel of coal. That figure was suitable for comparing two steam engines pumping water, but as Boulton & Watt expanded to power other industries, Watt needed an accurate and fair way of comparing his engine to other power sources, like waterwheels or animals. With that in mind, he measured the amount of pressure an engine could develop, then recorded the effective load that could be lifted in a standard period of time using beams of standard length and weight.

The calculated result was termed “horsepower.” The term had already been in use informally, comparing the amount of work done by waterwheels, which could be measured fairly easily, with that done by horses.

Power equals force times velocity. Philosopher (and Isaac Newton assistant) John Desaguliers postulated that a single horse could lift 27,500 pounds a distance of one foot in one minute. Based on his own measurements, Watt substituted 33,000 pounds, which works out to 550 foot-pounds of work per second, a figure still in use today, as is the man’s name. Outside the automotive world, power is usually measured in Watts, to honor the great inventor.