Media | Articles

Trying to Get My Armada’s A/C System through the Summer (Part I)

I’m going to delve into some of the issues of the air-conditioning system in my 2008 Nissan Armada—the vehicle I love to hate, or at least to intensely dislike due to its apparently never-ending needs. Just to be clear about this, I’m not a pro, so don’t take any of this as vetted advice. It’s just me describing what I do.

I’ve done a lot of A/C work over the decades, with a concentration on retrofitting or resurrecting the A/C in my older cars. I wrote a book about it called Just Needs a Recharge: The Hack Mechanic Guide to Vintage Air Conditioning. In it, I define “vintage air conditioning” as a system that may have originally had R12 refrigerant in it instead of the newer R134a; that likely had an old-school upright compressor instead of the newer smaller rotary-style ones; that may need improvements to blow cold if it’s converted from R12 to R134a; and—most importantly—is not part of a climate-control system where there are a bazzilion sensors and the heater core and the A/C evaporator core are co-located inside the same box and a blend door is used to mix cold and hot air to achieve a certain cabin temperature.

This last bit is crucial. On a functional vintage A/C system, when you twist the knob to turn it on, that sends power directly to the compressor. As long as there is more or less the right amount of refrigerant in the system and there isn’t a blown fuse or any broken wires, there are typically only two things that can prevent the compressor from switching on and pumping refrigerant to create cold air. The first is the pressure switch screwed into the receiver-dryer that cuts off voltage to the compressor if the system pressure is either too high or too low. This is intended to save the compressor if the system either leaks catastrophically or has a blockage, but in practice, on vintage cars, I often run without the pressure cut-off switch because it’s a potential source of leakage. And besides, if a hose blows or a connector breaks, you usually know it immediately from the refrigerant cloud and smell. The basic electrical layout of a vintage A/C system is shown below in this illustration from my book.

Typically, there’s also an anti-icing switch in the thermostat that cycles the compressor off if it senses that the evaporator coils are freezing, but my experience is that when those fail, they usually fail in the “on” position. (In a great bit of automotive trivia, A/C-equipped AMC Ramblers between about 1962 and 1966 had a “Desert Only” setting on the dashboard that bypassed the freeze-up switch if you were driving in ultra-low-humidity environments.)

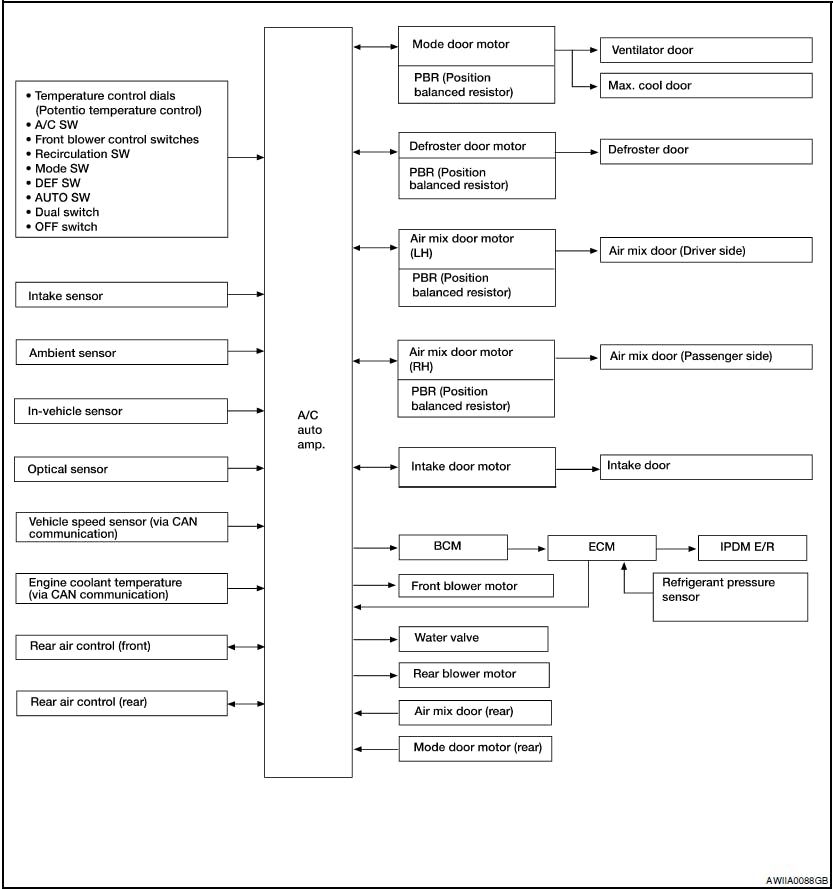

In contrast, on a modern climate-controlled vehicle, particularly a large one like the Armada, with its three separate zones (driver, passenger, and rear), the block-functional diagram is seizure-inducing. In the center of the one for the Armada, there’s the oddly named “a/c auto amp”—the brain of the climate-control system.

Marketplace

Buy and sell classics with confidence

Simply to engage the Armada’s A/C compressor, there is a labyrinth of gating functions that go far beyond turning it on, unless there’s a pressure issue. Wrap your head around this description from the Armada factory manual of the decision tree for sending voltage to the compressor clutch:

“When the A/C switch is pressed, or the mode switch is turned to the defroster position, the front air control outputs a compressor ON signal to Body Control Module (BCM). The BCM then sends a compressor ON signal to the Engine Control Module (ECM), via CAN communication line. The ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sensor signal, throttle angle sensor, in-vehicle temperature sensor, ambient temperature sensor, optical sensor, intake sensor, etc). If it judges compressor can be turned ON, it sends compressor ON signal to IPDM E/R, via CAN communication line. Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate compressor.” Sheesh.

When I bought the Armada, it was winter, so I couldn’t tell whether the A/C system was working or not. I could tell that there was a rhythmic clicking sound coming from under the dash. I assumed correctly that this was from one of the actuators trying to move one of the blend doors in the climate control box, an issue I’ll circle back to later. In late spring, the weather got warm enough that I began sussing out the A/C system. To my delight, I found that it had refrigerant in it. I shot one can of R134a into it and it began to cool. Another can and cool transitioned to cold.

And, of course, it didn’t last.

If you haven’t figured it out, the Just Needs a Recharge title of my book is a joke (like Ran When Parked, the title of one of my other books). An A/C system NEVER “just needs a recharge.” A/C refrigerant isn’t used up like engine oil. If it needs a recharge, it’s because the refrigerant leaked out. The leak needs to be found and fixed. Part of my whole vintage-car A/C rejuvenation mantra is that if you leak-test the evaporator assembly by pressurizing it before you install it under the dashboard (the hardest part), then procure all-new components, make new hoses, and leak-test the entire system before you charge it up, it simply comes up working and stays that way. And if it does leak, the leaks are typically easy to find due to the simple nature of a vintage system and the amount of space in the engine compartment. But on a modern system in a large vehicle with rear air, due to the number of components, with how tightly things are packed in, and with the amount of plumbing required, finding a leak can be far more difficult.

But with it sort of working, I can just keep topping it up to keep it working, right?

Well . . .

Despite certain reports to the contrary, it is not in any way illegal to top off the refrigerant in a car’s A/C system. If it was, anyone buying a can of R134a, particularly the expensive ones with the integrated hose and gauge, could be followed home, surveilled, and arrested. (What is illegal is intentionally venting A/C refrigerant into the atmosphere—e.g., pressing down the little valves in the middle of the service ports.) If you pay a dealership or a qualified A/C shop to test your system, what they’ll do is pump all the refrigerant into a pressurized container and compare its before-and-after weights. It’s from there that they deduce whether the system was low on refrigerant, infer the presence of a leak, try to find and repair it, and recharge the system with the proper amount of refrigerant. Most DIY-ers, including me, don’t have this kind of suck-it-out-and-weigh-it equipment, so we rely on either doing it from scratch with an integral number of whole cans of R134a that add up to the total system capacity, or by topping off a system while looking at a set of manifold gauges to make sure the low- and high-pressure sides are within some reasonable range (about 20 to 45 low and about 150 to 275, respectively), all while measuring the vent temperature with a thermometer or simply feeling the crack of cold air with our hand.

To me, there’s a clear and consummately practical line between topping off a slightly leaking system and hopelessly emptying $12 cans of R134a into it as if they’re Axe deodorant before an out-of-your-league prom date. The crucial issue is whether the A/C system has any pressure left in it at all. To determine this properly, don’t just take a matchstick to one of the service valves and see if it spits (illegal, remember?). Do it correctly with a manifold gauge set. Make sure the knobs on both gauges are rotated closed, then hook up the low- and high-side hoses to the vehicle’s service ports. The gauges should read the resting (ambient) pressure of the refrigerant. While there’s no strict metric relating resting pressure to whether the system is under-charged or over-charged, I’ve always used the rough rule of thumb that the resting pressure reading in psi should roughly match the air temperature in °F (e.g., 90 degrees out, 90 psi). The exact number, though, is unimportant. The issue is whether the resting pressure is zero, because if it is, there’s a major leak that does need to be fixed first, and unloading every can of R134a from the shelves of AutoZone into it won’t change that. But if it’s got a good amount of resting pressure, whatever leak it may have is small, and you may get away with topping it up. For a while.

That appeared to be the case with the Armada, because, unfortunately, a few weeks later, the A/C seemed to go intermittent. My assumption was that enough refrigerant had leaked out quickly enough that it rocked back over the line into non-functionality, so I tried to find the leak. I used Big Blu soap bubble solution as well as sniffing with a refrigerant detector. Neither found anything. I usually don’t regard dye as a go-to solution, but I shot in a can of R134a with dye in it. This, along with a U/V light, revealed a leak at the joint between the condenser in the nose and the receiver-dryer. Unfortunately, on this vehicle, those two components are integrated, so to fix it, the condenser must be replaced. As in nearly every car, the condenser is in the nose in front of the radiator, so the radiator has to come out first. On one of my vintage cars, this is maybe 20 minutes of work, but on the Armada, it’s a bear, and I’m hoping I can put it off until September.

So, I find myself trying to do what I joke about in the title of book. And, again, for a while, the additional can of R134a seemed to be all the system needed.

Unfortunately, last week, it went intermittent again. Specifically, I’d turn it on and it would blow cold, but then after driving for a bit, it would get warm in the cabin. The light on the A/C switch would still be on, but when I stopped and looked under the hood, I could see that the compressor wasn’t engaged (the pulley was spinning, but the nose wasn’t). The odd thing was that the next time I drove the Armada, the problem repeated—the A/C initially worked fine, then got warm. So it didn’t seem to me that the system was simply low on refrigerant—it seemed that something was shutting off the compressor. Nor did it seem that the compressor was “short-cycling,” which is normal if it’s low on refrigerant. The length of its on and off cycles seemed much longer. On my vintage A/C-equipped cars, I’d simply hot-wire the compressor to the battery as a test, but the Armada’s compressor connector is very difficult to reach and separate.

The Armada and other Nissan factory service manuals are available online. I found that the manual has an exceptionally thorough climate-control troubleshooting guide, but its level of complexity mirrors that of the illustrations above. It would take me forever to step through it all. If I had diagnostic software that pointed me to the source of a fault code, that would be much faster, but I haven’t bought or appropriated the Nissan CONSULT factory diagnostic software or purchased a good scan tool with access to Nissan-specific diagnostics.

So I was thrilled when I learned that the vehicle itself has some diagnostic capabilities that are accessible on its console display via a Byzantine process of starting the car and then, within 10 seconds, holding down the “settings” button while twisting the radio control back and forth. I continued to be joyous when I located the climate-control diagnostics and heard and felt the actuators and fans being put through their paces. But then it mysteriously reported nothing other than the outside ambient temperature readings going wonky. I read up on the Armada forum (clubarmada.com) and learned that the error codes are actually flashed in the temperature field. I wrote them all down, came inside, pored over the factory manual and the forum, and learned that my car, for reasons unknown, had posted three codes whose meanings aren’t listed anywhere. So much for the in-car diagnostics.

I read more on the forum and saw a hail of posts describing symptoms remarkably like mine that were fixed by a $60 easy-to-replace resistance-based temperature sensor that sits up under the dash in the inlet of the evaporator assembly. The posts said that the sensor usually works, or else is shorted (low resistance), or is open (infinite resistance). I checked mine in both hot and cold water with a multimeter, and it basically seemed to work, with resistance decreasing with increasing temperature as it should, but it did seem to be off from the table of values in the factory service manual. And it made sense that, when comparing the evaporator temp to the cabin temp, erroneous data would cause the compressor to be shut off, right? I’m usually willing to try one of these “maybe it’s this” things, so I ponied up the 60 bucks, ordered it online, waited for arrival, and installed it.

And it made no difference. Whenever I drove the Armada, it continued this frustrating behavior where the A/C would initially work, then mysteriously shut off, then come back alive the next time I used the truck. Oh, did I forget to mention that this Armada is black with a black interior? Combined with a hot summer in Boston with stretches of 95-degree heat, it made me think that I couldn’t rely on the Nissan if I needed to actually use it for anything. Not that I really was, mind you (and that’s a larger story of the folly of my having bought it in the first place), but the entire scenario just added to the way that the thing glowered at me in the driveway. My wife certainly wouldn’t ride in it with me knowing that it could turn into a sweat lodge at any moment.

So, how do you proceed? Is there a middle ground between a nosebleed-level repair bill at a dealership and hot-wiring the damned compressor to the battery?

I’ll talk about that next week.

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon here. His other seven books are available here on Amazon, or you can order personally inscribed copies from Rob’s website, www.robsiegel.com.

Ah, the joys of getting a vehicle to non-ambient temperature.

I recently was worried about nothing with my ’86 Mercedes. I did all the work (new compressor, drier, pressure switches, condenser, and any O-rings I could reach)

Yet, the auxiliary fan wouldn’t come on. The wiring had been messed with previously. But after reading the factory schematics, in Mercedes’ infinite wisdom, the Aux fan will only activate when it sees high pressure (north of 220psi) or 105c coolant temp.

Well my A/C system never reaches that pressure and the car has never ran hotter than 85c it’s entire life. So it looks like I have an ornamental fan out front and less cooling sitting in traffic. The joys of vintage cars!

Side note on A/C. In Canada, it is illegal to refill a system without some kind of repair. Refrigerant is controlled (you require an Ozone Depletion Prevention certificate, which I have, to buy it) and only comes in 30lb containers.

Funnily enough, I can order the small cans from the states without issue, so long as I don’t resell them.

Lastly, A/C resting pressures will always be the same at rest whether you have 1oz or 38oz in the system. Running pressures are your biggest clue to how low the system is.

This reminds me of an issue I used to have with my Volvo V50. Once the compressor got hot, after the next cycle off it would not reengage until it cooled off. No codes shown but thankfully this was well documented in the forums. It turned out to be the clutch gap got too wide on those Denso units. This made it harder for the coil to pull the clutch in when hot. Removed one of the shims and problem solved.

Definite possibility that it is the clutch coil. Nippondenso used to be notorious for that. What happens is that as the clutch heats up either a short that reduces the number of coils receiving electricity too low to produce a strong enough magnetic field, or an open which of course prevents any magnetic field from occurring. So that cool coil works fine until the magic temp is reached and then it stops working. I had a Crown Victoria with such a clutch and I found that if I got on the freeway and stayed at speed there was a combination of enough air flow and low clutch usage that it would work for hours. Pull of the freeway and sit at a light for a minute and boom no A/C. Sometimes enough time back on the freeway with AC turned off would get it to work again, but it often required a full cool down.

Ah this is like the Tom Hanks movie Money pit.

Love the “desert only” switch bit included in the article.

Rob, it is summer, should you not be shaking down some of the fleet from the warehouse? They will be salting the roads in a few weeks so you will miss out exercising the fleet and addressing issues with each member of the collection.

I am one of a very rare set of individuals who has not desensitized myself to normal ambient summer conditions with the ‘convenience’ of air conditioning. Of my 6 vehicles, 4 are air conditioning capable. Only one (my newer long-distance car) actually has it working, and I generally only use it on the highway.

In my fleet mechanic days, I ran across a lot of variations on air conditioning ailments, and two that were more troublesome to detect were clogged expansion valves (which would cause high pressures to be too high and lows to be too low) and clogging or airflow problems in evaporators causing actual freezing conditions. In this day and age with cabin air filters, clogging of evaporators is not terribly common but not impossible… particularly if someone decided to delete yours and now the evaporator is full of acorns and pine needles

I meant to add that having a relay in there is a great thing for diagnosis. No need to figure out how to jump power and ground at the compressor. A couple of inches of wire to jump from the power in terminal to the power out and the clutch should engage if the clutch and wiring back to the relay is good. It is also useful for telling whether or not the computer has decided that turning on the compressor is indicated and acceptable. If the relay clicks when you unplug or plug it in then the computer is energizing the relay. Or you can test for a signal from the computer at that point. Either way the relay is somewhere in the middle of the circuitry and thus a good point to start diagnosis.

As you’ll read in next week’s piece, the relay isn’t a plug-in module but instead is an integral part of another assembly and thus can’t be separately accessed.

I was afraid that could be the case, but you did say relay, so I was thinking that it was a separate plugable relay, not one soldered into a module.

Rob, You always have the most interesting articles!

I recently had a similar AC complaint. I bought a 30 year old Civic last year. The seller said the AC works “sometimes” – I thought, “yeah right – that means it doesn’t work” – at least that was my assumption when deciding whether or not to buy. Well, I did buy the car, and it sat for a year (another story – bad capacitor took out the ECU, which took me a while to diagnose – and took 4 used ECUs from eBay to find a working one).

Anyway, summer rolled around and the seller was right – the AC works sometimes! Specifically, it works great when it is cold out (not very useful), and then for a while when it’s hot. I printed out the factory wiring diagram and monitored various points in the 2 circuits that control the system (one going to the ECU with an AC request and the other coming from the ECU with an AC command) and eventually diagnosed the issue.

Turns out the AC clutch was worn after 30 years. It would work great at start up and when cold out, but after the 200 degree air from the condenser (which is directly in front of the AC compressor) blew on the compressor for a while, it would get hot, the clutch parts would expand and then the clutch wouldn’t re-engage. So it would work fine for a while. Then the anti-freeze switch in the evaporator would do its job and switch off the compressor because the AC was working so well. However, when the evaporator warmed back up and the anti-freeze switch / ECU requested the compressor to turn back on, the current got to the clutch but nothing happened – the clutch gap was now too large for the electromagnet to overcome the spring pressure. When this happens, the definitive check is to smack the clutch with a broomstick and the clutch will reengage (there are plenty of YouTube videos of this diagnostic approach). The factory service manual also has a max clutch gap you check with a feeler gauge. At cold, mine was at the upper limit. After running the AC for a while, the gap was one or two mils over the max value.

Honda sells an AC clutch shim kit for $5 (miraculously since every single other part for the car is discontinued) – but it was on national back order for a month. Fortunately, McMaster had a shim that got the job done. I only had to remove 6 bolts to get the splash shield off and removed one nut on the AC compressor – which was good since I had just had shoulder surgery and removing the 6 bolts was excruciatingly painful.

So the AC is fixed… except that it wasn’t. There is a much more intermittent no work condition that happens when the car bakes in the sun for a while. Troubleshooting that revealed the AC button / switch in the dash has an intermittent open when it is extremely hot. So the switch is currently shorted with a wire with alligator clips on the end and I am gloriously cold all the time. When my shoulder heals, I’ll pull the climate control unit out of the dash and do a proper fix – fortunately I grabbed an extra climate control unit at the pick and pull yard for one of my other Civics about a decade ago and never got around to installing it.

Congrats on your sleuthing. That’s the kind of thing I seem to be facing. Jumping ahead to part II, it doesn’t appear to be the clutch, but something else is terminating the signal to it.

The joys of rust belt used car ownership. What can wrong today?

Had a similar problem with my ’93 Pathfinder – went nuts looking through the wisdom of the interwebs & FSM, which led to a temp-control in the dash, which wasn’t the solution – took it to my “AC guy”, who eventually found a loose fuse in the dash, which returned the blissful feeling of Things Working Properly. Now my low-mileage ’89 GMC (R-12) Dually has a similar problem, but I’ve moved 8 hours away in the interim and need to sort it myself if possible.

I had a rental car that would start up and cool great for about 20 minutes. The cabin air filter was completely plugged up and would ice up the evaporator causing warm air. Took out filter, all worked fine.

Buy a 150 W power inverter (12V DC to 110 AC) and bungee cord a through the window air conditioning unit out the rear hatch. ( There’s currently a clearance sale at Walmart, $14.00- $399.00 ). Save the packing foam, included in box, shave, fill any openings and duct tape as necessary. Remove and store A.C. in fall or winter depending on your location.

“Blows COLD! It will drive you out of there!”

Some spray-foam and Bondo can almost make it look like it belongs there. Go for a sort of tail fin.

My 2003 Expedition had the dreaded air-door flapping. Of course it’s a high end model with dual controls in the front and a rear control (like your Armada). It didn’t bother me at first, but then the door started hanging open (or closed?) and blowing hot air out the vents on the driver’s side. Not warm air, HOT! If I shut it off and started it back again it would work for a while, and sometimes it would just correct itself for no good reason. Well, I got enough of that and talked to a local mechanic who knew how to fix it without removing the dash. Removing the dash would have been an $850 bill, not removing it turned out to be just under $600. He used to work at a Ford dealer and the guys figured out that if you cut a duct and moved it you could get to the upper air door to replace it without removing the dash. Then you duct tape the duct back together when done – with the good mylar tape, not the common “duct tape” (which was invented for ducts, but if you’ve ever used it for that you know it doesn’t last more than a few years…).

I love those kind of repairs. If I recall correctly, there was one done on Saab 9000 heater boxes that involved cutting the plastic open with a hot knife to avoid removing the dash and the box.

Who would use the A/C on the highway? That’s when you would need it the least. When you’re sitting still is when you need it the most!