Media | Articles

You (Nearly) Picked a Fine Time to Leave Me (Again), Loose Wheel

Part of my stock in trade in writing these columns is that, as your favorite automotive everyman, I’m willing to admit to doing things that most folks would deep-six, like the prom pic of you sporting a mullet, or the fact that you dug Night Ranger in the ’80s. I’ve never changed my oil and then backed over the catch basin, but if I had, I would write about it without hesitation, which then would give you folks cover to say “Okay, yeah, I did that too, but at my wife’s parents’ house, and the wave of oil hit my mother-in-law.”

I mention this because about four years ago, I wrote a piece titled “That time my wheel feel off and rolled past me on the street.” In it, I described how, nearly 40 years ago, after swapping my winter wheels onto a ratty BMW 1600, I was driving home at low speed on local roads, heard a rapidly-increasing whubba-whubba-whubba noise, and before I knew what was happening, BANG! the left rear brake drum was skidding on the snow-covered asphalt. The number of comments it received was astonishing. What I thought was weird negligent gonzo livin’-on-the-edge Hack Mechanic stuff was far more common than I ever imagined.

While I never again actually lost a wheel, I had two other ones loosen (one on local roads, the other on an interstate), and thus have become acutely aware that, when driving slowly, you may only have 20 or 30 seconds from that first whubba-whubba to chaos. On the highway, it may be more like only 10 seconds. Having lost one wheel and nearly losing two others, I became hyper-vigilant about always torqueing down lug nuts after swapping wheels.

So imagine my surprise and self-loathing when it nearly happened again.

Here’s the story. The day before Boston’s first predicted winter weather, it was delightfully mild outside. I set out to put the winter shoes on both of the daily drivers—my wife’s 2014 Honda Fit and my 2003 BMW 530i. Since the garage was fully occupied by my ’73 BMW 3.0CSi and both Lotuses (yeah, my life is hell), I did the swap on the sidewalk in front of the house. So, no mid-rise lift, no air tools, just a floor jack, a jack stand, a breaker bar and socket, a torque wrench, some Scotch Brite, and anti-seize compound. To make things quick and easy, I used the lightweight aluminum jack that I bring on road trips with me. The downside is that it doesn’t have enough reach to jack up the nose or the rear—you need to do one wheel at a time.

Marketplace

Buy and sell classics with confidence

I did the Honda Fit first. Each wheel has one special keyed anti-theft lug nut, so I needed to dig through all my wife’s crap in the glove box to find the keyed socket. But the swap went quickly, as the car’s little 14-inch wheels are small and light and easy to throw around. One corner at a time, wheel off, Scotch Brite on the hub center, Scotch Brite on the center bore of the wheel that’s been sitting under the back porch for eight months, anti-seize on the bore, wheel on, torque it, second and third and fourth verses same as the first, boom, done.

Next was my E39 530i. I toyed with the idea of not swapping to the winter wheels, as a) the Craigslist Toyo snow tires have plenty of tread but the sidewalls have so much flex that it absolutely kills the car’s handling, b) I could probably leave the three-season low-profile rubber on it and just drive the Nissan Armada if it’s slippery out, and c) the alloys are not only cheesy aftermarket, but mismatched cheesy aftermarket. Every winter I imagine the car saying to me “Really? You say over and over that I’m the best daily driver you’ve ever owned and here it is, another winter, and you make me wear this crap again?” But then I remembered that my driveway slopes down, and when it snows, without proper snow tires, the E39 becomes immobile. Plus, my oldest son uses the car quite a bit, and I wouldn’t want him to be driving it on summer shoes if weather moves in. So onward with the swap.

The E39 has developed a steering wheel shudder on braking. I replaced the front rotors a few years ago, and that cured it, but it’s back. This could be due to either rotors or to a suspension component like lower control arms. One way to tell is to jack up the car and spin the front wheels. If there’s no rhythmic binding of the rotor against the pads, then the rotors are true, but if there is binding, then the rotor isn’t sitting flat against the hub, or has deposits on it, or in rare cases, is warped. While I had the E39’s front wheels in the air, I checked this. The right rotor ran true, but the left one did exhibit some oscillatory rubbing against the pads. I didn’t want to take the time to investigate further, as it would’ve meant pulling the rotor, but I made a mental note of it.

True to forecast, the following day brought cold temperatures and some morning flurries. I was glad the snows were on the E39, as my son borrowed it to go to the gym.

That afternoon, I needed to run to the hardware store to buy some fasteners. On the way back, the E39’s steering vibrated noticeably when I hit the brakes. Initially I thought it was the less-than-true rotor I was already aware of. But as I continued to drive, the sound was no longer only on braking. And it was getting louder. I thought, “Well, it can’t be the lug nuts because I know I was out there with a torque wrench and checked them all on both cars.” I initially thought that I could make it the two-ish miles back home and look at it then, but even at my 20-mph pace on local roads, the sound got louder quickly enough that I realized I had no choice but to stop.

I pulled over on a small side street, turned on the hazards, got out, grabbed the wheel at 12:00, and rocked it back and forth. The lug nuts clearly were loose. Damn, how did I get this wrong?

Well, no matter. BMWs come with a tool kit. There’s a lug wrench in the trunk. Snug these errant puppies down and I’ll be on my…

No tool kit.

And then I remembered. For reasons unknown, this E39 is missing its trunk-mounted tool tray. I have no idea why. I bumped into this when the alternator died. I needed a rollback tow home, and I couldn’t find the towing eye that screws into the bumper. I had made a mental note to find a used factory tool tray, but forgot about it.

While this was hardly a dire situation—I could’ve called an Uber, or seen if my wife or one of the kids was home, or just walked to the house if necessary—it was inconvenient, and a little embarrassing.

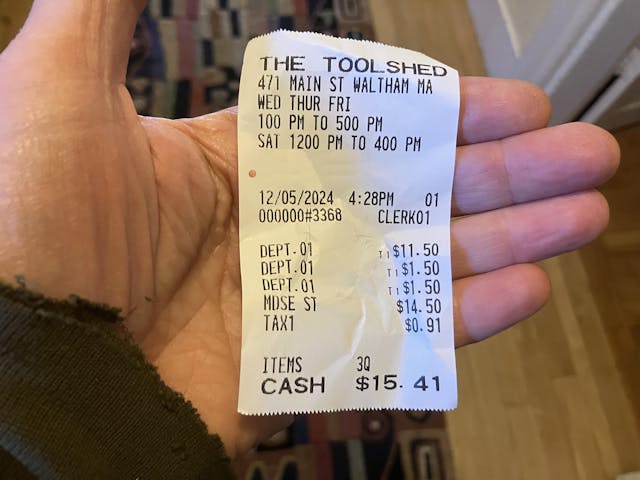

Then I remembered. I was maybe a quarter of a mile from The Tool Shed, a delightfully old-school little store in a little strip mall where a guy sells used tools. His prices aren’t give-away, but they’re very fair. I hoofed it up there, went inside and said, “I’ve bought stuff from you many times over the years, I’m parked just around the corner with a wheel that’s about to fall off, can I borrow a breaker bar, a 17mm socket, and an extension? I’ll be right back with them.”

“Sure, he said. He grabbed the stuff off the shelves and handed them to me. The whole thing probably took 15 seconds.

“I’ll be right back,” I repeated.

“I know,” he said. “I trust you.”

I hoofed it back to the car and snockered down the renegade lug nuts. All five of them were completely loose. I checked the ones on the other three wheels. They all were fine.

I walked back to The Tool Shed. The owner put out his hands to receive the breaker bar, but I said, “I’ll just buy it.”

“You don’t have to,” he said.

“I want to,” I said.

“Really,” he said, “You don’t have to. You probably have five at home.”

“Really,” I said, “I have two at home, but I want this one to live in this car.”

Fifteen bucks. You gotta love old school.

So, how did it happen? I’m not entirely certain. Since I was jacking and changing the wheels one corner of the car at a time, I believe that I was torqueing them one at a time as well. Some might think that’s a bad idea, and perhaps it is, but I’ve been working on the recently-purchased Lotus Elan +2 and doing things like shimming one tie rod or replacing the U-joint on one half-axle. These things have required removing one wheel, so when it goes back on, I torque it down. If two wheels are off, I put them both back on, then torque them both. On the E39, I don’t know if I got interrupted—a text, my wife coming out of the house—or whether I forgot to do the left front wheel because I was examining the runout of its brake rotor, but it’s likely that I was torqueing each wheel as I set it down, which may be a more fragile process than walking around the car and doing all four.

I posted this event to social media, and a number of people said that when they swap wheels, they leave a torque wrench on the driver’s seat. I’m not certain that alone would’ve saved me. I had a torque wrench on the front steps and somehow managed to miss a wheel. Plus, when I swap wheels on the sidewalk in front of my house, I need to move the car at least once in the process so I don’t step in my wife’s garden (one wheel at a time on the right side can be accessed from the cement in front of the steps to the porch). I think that the issue is more that I need to use a sequence where I swap all four wheels, then torque all four, instead of torquing them one or two at a time.

Another friend commented that sometimes, if a wheel is put on the hub slightly cocked, and if there’s corrosion on the hub and/or the center bore of the wheel, it may seem that the lug nuts are torqueing down, but the wheel isn’t properly seated, and won’t be until the car is driven and bounced around. I did experience this the first time I dismounted and mounted the wheels on the Armada, but I caught it, as one wheel was loud the moment I moved the car in the driveway. Others say that their routine is to torque all four wheels, drive the car around the block and hit the brakes a few times, then torque the wheels again. Even though I think that this was operator error on my part, not a cocked-and-therefore-unseated wheel, I am now vowing to adopt this torque-em-all, drive the car, torque-em-all-again procedure.

The whole Kenny Rogers song parody, “You picked a fine time to leave me, loose wheel” thing is funny, but this really wasn’t. It was jarring. My son was driving this car just a couple of hours before I was. This could’ve happened to him. It could’ve happened to my wife. I absolutely cannot let this happen again.

So when you see a person systematically walking around a car and torqueing all four wheels, then doing it again, it’s not a glitch in The Matrix. It’s me.

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon here. His other seven books are available here on Amazon, or you can order personally inscribed copies from Rob’s website, www.robsiegel.com.

Take extreme care mounting wheels that use flat washers, they just don’t bite like bevel (“acorn”) nuts. Cragar S/S’s are a classic example. These must be retorqued after putting a few miles on them whenever they’re mounted.

I quit stopping in to The Tool Shed when I realized I always bought something I didn’t need. Great little shop though.

And there ain’t nuthin’ wrong with enjoying Night Ranger, or any good quality metal from the 80’s.

I learned that lesson with the Cragar S/S wheels when I could finally afford them. In fact, my tire shop guy (who installed them) made me swear to come back after first 25 miles and then after an additional 25 for a re-torque. He’d been in business a long time, and apparently, he thought not getting sued was a good business practice.

At risk of upsetting some younger (than me) dudes and dudettes out there, I’ll not comment on the use of Night Ranger and “good quality metal” in the same sentence.

I had an old Mopar once, back when I was young and stupid. Went out in it one night with a few friends and a few beverages and decided to do some donuts, which resulted in a melted drive wheel. We stumbled out and managed to change the tire, who knows how we managed, an off I drove.

I had an old Mopar once……

Crisis averted thankfully. Yeah I always check the lugnuts again after a quick ride around just in case.

I’m so glad I read this story. After 45 years of minor-league wrenching, for the first time ever, I left the nuts loose on my son-in-law’s car. Now, I like him just fine, but my grandchildren ride in that car, so I felt extra guilty – to the point of swearing off wheel removal on anything but my own car. Now maybe I can be a little easier on myself.

On the lighter side, Google “Ron White Sears tires”. Absolutely hilarious. Viewers are cautioned for strong language.

Last two sentences apply to ANYTHING by Ron White, do they not? 😛

I did not lose a wheel, but the experience was never the less frightening. Several years ago, maybe 2007, my son had an audition across the state, a 300 mile drive. Our ’98 Volvo S70 GLT had been in the shop for a service that I don’t remember now. We completed the round trip without incident, most of it driving in eastern Washington where driving at 80 mph is common. I don’t recall now why I elected to check lug bolts, but I did. I found that most of the lug bolts on one front wheel were finger tight. I was amazed and grateful that we did not lose a wheel! I did share this with the shop and they were very apologetic. I still use them for two of my vehicles. I think my guardian angel was along for that ride.

Try losing a wheel at speed on I-77 with a sailboat trailer with a 2500 pound racing, keel boat on it. That will increase your pucker factor and cause you to cut a donut in the seat of your vehicle.

Lessons learned: 1) Bearing buddies are your friend; keep them greased; and 2) Do an annual check on the condition of the bearings and wheel studs.

Man, I puckered right here in my easy chair just imagining that while reading your post!

rob, i thought you meant the tv show ‘night rider’, not the group ‘night ranger’. thank gawd i didn’t have a tv at that time!

anyway, i make sure all lug nuts are started and not cross-threaded. next, i run them fully seated with my impact gun at lowest torque setting, then, i lower the car on the tire/wheel with just enough weight to keep it from turning when torquing the lug nuts. and, torquing them in a star or cross pattern, depending if 5 lug or even number. i then retorque all lug nuts at this time. at least 2 will turn more.

also, i don’t grease the threads – studs or lug nut. i make sure the threads are clean. it’s rare for me to find rusted threads. if i’m worried about rust, i’ll spray on wd-40 or equivalent. grease with a high shear strength can affect the true amount of torque.

also, over-torquing can cause rotor warpage. and once warped it might stay warped, even after loosening & properly retorquing. and, believe it or not, over-torquing can also cause the lug nut to loosen. i read about a certain model vehicle where the wheels sometimes fell off. believe it or not, the cause was determined to be excessively over-torqued lug nuts. a recall followed where the lug nuts were to be removed, reinstalled, and then re-torqued.

I’m gonna get yelled at here (or at least chastised politely), but I’ve never used a torque wrench on wheels. I rarely work on anything modern, but typically just use my air impact or 18″ breaker bar (if I don’t feel like messing with air hose — like one wheel). Never had a wheel come off. As someone mentioned, just a few “whackas” with the air impact. I’ve had to stand on the breaker bar with a cheater to get lug nuts off after some moron at the tire place put them on until the air impact wouldn’t go any more. One or two where my impact wouldn’t break them loose — but then it was an older model I’d picked up used — probably WHY it was sold (was getting weak). I’ve had a lug BREAK OFF because it was too tight (noticed several days after new tires were put on). I can

t blame that entirely on the shop — the car was 30 years old, had been run hard by the last owner (or two?), and I was in my late teens and not taking it easy on it either. Nowadays many tire shops use those torque limiting extensions. I probably need to get me a set for tires. But real good snug has always been “good enough” for old 60s US built iron — just like they used to do it in the old days.

” just like they used to do it in the old days.”

What are you talking about? Torque wrenches and specifications date back over a century. Just randomly tightening lug nuts is dumb and dangerous. Over-tightening can be just as bad as under, and lug studs can snap (as you acknowledged) while driving due to being stretched too much.

Just because you haven’t had a significant failure yet does not mean your idea is safe. It’s people like you that give the vintage car community a bad reputation with your unsafe practices.

Oh Randy, let’s not cloud the issue with logic. Sometimes it’s best to let nature sort things out for us. It’s clear you’re entering a battle of wits with the unarmed, and I think there is something in the Geneva Convention about that being illegal.

Well Frank, I think you are wrong on two points: 1) that “it hasn’t happened yet so it’s good enough” is good enough, and 2) that you might be “chastised politely”.

Middle of the Golden Gate Bridge northbound to Marin County, height of the rush hour, 40mph, 4 of 5 lug nuts on the L rear of our ’65 Mustang decide to abandon ship. Fortunately the 5th hangs on for dear life, the wheel (barely) stays attached, enough to make it to a safe spot at the north end of the bridge. Damages: one Torque Thrust D wheel toast, 5 studs toast, bodywork fine, pride in my mechanical prowess, toast. Operator forgot to torque the lug nuts after wheel change.

Any issue on a bridge at rush hour is the worst. I was once on the approach to the George Washington in NYC towing a boat when someone began honking at me and motioning me to get off. I thought he saw that something near-catastrophic was about to happen, like a loose wheel. I got into the right lane and grabbed the last exit just before the bridge (the Bronx? I forget), found a place to park, and discovered that all it was was that the directional light had broken off its bracket and was dangling by the wire. For THIS someone spiked my blood pressure?

If you’ve got an emergency and need to get off of a bridge immediately, what better than to be towing a boat? 🤔

I’ve had two B-body Mopars with left-handed threads on the driver’s side wheels. Tire shop employees never understood that the factory built them that way.

Hey man, Night Ranger is great.

I don’t know how they are gonna prank you at the vintage, but it’ll probably involve lug wrenches 🙂

Oh geez.

I do one wheel at a time usually as well. I use my electric impact (1/2″ drive) at slow speed to snug the lugs in a star or cross pattern with the wheel in the air, then set it down and tighten in a pattern to 3 whackas, then use the torque wrench set to the factory spec and go around the pattern 3 times (I usually still get some rotation on the second time around). I then move the jack, impact, and torque wrench to the next wheel and do the same. When I think I’m all done, I go around the car with the torque wrench and check the lugs in the pattern one more time. Once or twice during the final check, I’ve found one wheel I thought I had done but all the lugs were just snugged to 3 whackas (which varies depending on the battery strength) and not torqued. As a caveat, I’ve found through experience that 3 slow whackas with my electric impact is snug, but below the factory torque spec so I’m still getting the proper torque, not over torquing anything.

In 1976 I pulled all four wheels off my first car, a Volvo 122S, and used a cutoff wheel to take about 2 coils out of each coil spring. I bolted everything back together and decided to take it for a run through the neighboring canyons to see if I had transformed the handling. But it was low in gas so I headed to the nearest gas station when I heard and felt that sound just as I was pulling in. First (and only) time but I knew what it was. I asked the mechanic (like I said, this was 1976) if I could borrow a lug wrench and he just pointed at the sign “NO TOOLS LOANED”. So I walked next door to the HW store and bought a 4-way lug wrench for $2.99. I still have it. Never use it, but I keep it on the wall of my garage as a reminder.

Since you own 2 of them, you must know that the plural of Lotus is not Lotuses.

Yes, according to Lotus, the plural is “Lotus.” But that just doesn’t strike my ear or my eye as correct. Besides, “Lotuses” you can imagine Sean Connery pronouncing as “Lotushesh,” which is way funnier.

I thought Sean only knew how to say Aston Martin! You must be thinking of Roger Moore…

I prefer “Lotii”. Like octopii

Know all about getting interrupted in the middle of a project. I installed a new 750 Holley on my Cougar’s 351. Screwed the fuel line fittings a turn or two by finger but before picking up a wrench to finish I got sidetracked by something (squirrel). I fired up the cat and thought “what a great job I did” so I went into the house to get my wife to see my handy work. We returned to the garage to smell fresh gas and see a spray of gas coming from the loose fuel line. Fortunately I got the engine shut down with no fire. My wife just shook her head and went back into the house.

Do ALL wives do that, or just yours and mine, Rock?