Media | Articles

The Dead Car Road-Trip Adventure (Part 2 of 3)

The story thus far: In early 2017, I’d recently lost my job and was struggling to piece together income from being a self-employed writer along with some engineering consulting work when I committed to buying a decade-dead 1972 BMW 2002tii with no title sight-unseen in Louisville, KY. I got the go-ahead from both my incredibly supportive wife as well as from a sense that the universe was telling me that this was what I should be doing. But it was pretty crazy.

As I laid out last week, no matter how much you may want to buy a dead car, drop in from the sky, pit your knowledge against it and make it bend to your iron will to get you home (okay maybe that’s just me), a certain amount of preparation is necessary. Really, what you need is a nearby garage and a spare bedroom, or at least a driveway and a couch. And if you can get advanced intel on the first layer of the car’s needs, so much the better. All of these materialized in the form of Jake, a fellow I’d met exactly once for ten minutes at a vintage BMW event the year before. He lived in Louisville, had seen the car, offered space for it in his pole barn, and said that I could stay with him and his wife while I tried to resurrect it. I cannot overstate what an enabling factor this was. It was the thing that made the entire adventure possible.

Jake towed the car (which I named “Louie” due to its Louisville connection) to his pole barn and gave it a quick evaluation. In a Facetime session, he showed me that the engine wasn’t seized, but the brakes were—the pedal moved a bit and the car rolled but the brakes did nothing. A visual inspection of the undercarriage showed that not only was the giubo (the rubber flex disc between the transmission and driveshaft) was cracked, but the rubber carrier for the driveshaft center support bearing was completely detached. The alternator was visibly cocked off-axis due to deteriorated rubber bushings. And the clutch pedal was limp, likely due to a dead slave cylinder.

But as valuable as the Facetime session was, I kept thinking how much more I would know if I was actually there and able to lay eyeballs and hands on the new purchase. It was, however, winter, not the best time for a road trip, particularly in a rust-prone recently-long-dead car.

Three things happened to make me hit the go button. The first was that Jake said “You know, you could come down, check out the car, try to get it running, and if it’s too big of a project, then arrange to ship it back.” I hadn’t thought of it that way. The second was that a friend of mine who is part of the same Louisville-Cincinnati BMW community as Jake posted on Facebook “Looks like winter has been cancelled.” Sure enough, there was a 10-day forecast for unseasonably warm weather from the mid-Atlantic coast up through New England. The third was that a three-month-long slug of consulting work from my former engineering job, possibly the last of my career, was likely to start up in March.

Marketplace

Buy and sell classics with confidence

I looked at all this and thought “You’ve been going on and on about how you want to have this buy-and-revive-a-dead-car-and-road-trip-it-home adventure. You now own the car. You’ve been offered a place to work on it and a place to sleep. You have a break in the weather. WHAT THE HELL ARE YOU WAITING FOR? Do this right freaking now or shup up about how you always wanted to do it.”

Well, all right then.

I went into logistics mode. If I flew down, I’d need to ship my tools and parts. Loading them in my daily-driver 2003 BMW 530i would make for a swift and enjoyable drive, but I’d need to get the car back home. Driving my other 2002tii down made a certain amount of sense as then I’d have a whole car from which I could swap spares, but then I’d have two 50-year-old BMWs to get back. The best solution was to rent a car. That way, if I was successful in Louie’s resurrection, I could just drop off the rental, and if I wasn’t, I could drive it home with my tail between my legs and my tools and parts in the back. Hell, if I rented a mid-sized SUV, I could even grab a U-Haul auto transporter and tow Louie back. It was perfect.

As far as the legality of driving the car back, I could insure it with Hagerty, but there was no way to get a Massachusetts plate without a title. To my stunned surprise, a BMW Car Club member I’d never met who read about my plans on Facebook contacted me, said he’d been reading my column for decades, and offered to loan me a plate from his dealership in South Carolina. First Jake, then this fellow. I was blessed with help.

Let me digress for a moment. If you’re reviving a long-dead car, here’s the Cliff Notes version of the steps you should go through. Skip them at your peril.

- Verify that the engine rotates by putting a wrench on the crankshaft nut.

- Change the oil and make sure there are no mouse nests in the air filter.

- Verify that there’s even compression in all cylinders.

- Verify that the fuel system is leak-free and pressurizes to spec (crucial on fuel-injected cars).

- Check that there’s spark.

- Try to start the engine.

- Verify that the engine warms up without fuel, coolant, or massive oil leaks.

- Verify that the engine runs smoothly.

- Move and stop the car in the driveway to check the brakes and clutch.

- Drive the car around the block, then check for leaks.

- Verify that the car stays cool in traffic and runs well at highway speeds.

- Verify that the car is safe and ready for a road trip in the predicted weather.

Part of my reason for listing these is that everyone does the Young Frankenstein “IT’S ALIVE!” thing when a long-dead engine springs back to life, but that in no way means that the car is ready to hit the highway. My trying to do this in borrowed space while sleeping in someone else’s house a thousand miles from home meant that these steps were about to get compressed into the smallest amount of time possible, which meant that I needed to be utterly merciless about what was and was not essential.

Also, although I write a lot about “The Big Seven” things likely to strand a vintage car (ignition, fuel delivery, cooling, charging, belts, clutch hydraulics, ball joints), that assumes the car is already running and driving. On a car that hasn’t moved in years or decades, brakes are often seized, shift linkages can be frozen, on and on.

Lastly, although I and others joke about the whole “ran when parked” thing (the fact that the condition a car is in now is far more important than whether it did or didn’t actually run when it was parked), there’s usually a reason why a car was parked, and it’s often because it needed some big expensive repair. Two owners down the road, that information may be lost, and you may not find it until you try to get the thing running and driving and go “uh oh.”

Here we go.

Departure

On February 18th 2017, I loaded up the rented SUV with tools and parts including the usual retinue of plugs, belts, and filters, a fresh battery, a water pump, a full set of hoses, a pair of rebuilt front calipers, new flexible brake lines, a new fuel pump and rubber fuel line, spare fuel injection parts, alternator bushings to repair the cocked alternator, shift platform bushings, and a driveshaft on which I replaced the center support bearing, as this requires a bench vise and a torch, and set off to meet my dead-car-road-trip destiny. Tools were more than just the usual road-trip box, as they included an aluminum floor jack and stands, torque wrench, timing light, a power brake bleeder, a section of brake line and a flaring tool, a hose I’d made that could be threaded to a tire that I could use to blow fuel lines out, and a good deal more. I stopped overnight near Pittsburgh at my friend Paul Wegweiser’s house (he who roped Sam Smith into buying the Weissrat).

Day 1: Introduction

I knocked out the last 400 miles, made it to Jake’s pole barn outside Louisville in time to begin wrenching, and came face to face with Louie. I gave the car a “let’s see who you are” walk-around. Jake had warned me that the car’s tires were badly cracked and dry-rotted, and that if I revived the car and drove it home, they’d need to be replaced. He was right.

The other thing I noticed was that the bushings at the tops of both front shock towers were cracked. If these break away completely, they hit the underside of the hood, but they didn’t appear close to failure. Which was good, because I didn’t have spares or a spring compressor with me.

I drained and changed the oil. It came out looking as thick and black as you’d expect of something that was rode hard and put away wet ten years ago, the perfect example for why you don’t simply jump-start a long-dead car like you see people do in videos, at least not if it’s one you care about. I then yanked the spark plugs, squirted in some fresh oil, and rotated the engine by hand a few times. We then went back to Jake’s house where I met his generous and supportive wife Liz.

Day 2: Fuel and engine start

The goal for the day was getting the car started. I did a back-to-front fuel system cleanse which included draining and cleaning the tank and replacing the electric fuel pump, every rubber fuel line, and the fuel filter. I’ve seen fuel tanks that look like they have a pot roast stewing in them, and components choked with rust. This one wasn’t too bad, just some sediment. I then cracked the key to ignition to pressurize the system, looked at the Kugelfischer injection pump on the engine, and saw fuel spurting out the top. This wasn’t wholly unexpected—the o-rings on the top that seal the delivery valves often leak on 2002tiis that have been sitting. I’d brought a set with me. I replaced them and retested. The fuel system was tight, and fuel pressure was about right at 27psi.

I did a quick compression test that verified basic engine health, installed fresh spark plugs and points, topped up the radiator with water (I was going to flush the coolant later anyway), and then, with a fire extinguisher at the ready, went for it. After a few tries and some starting fluid, Louie’s engine rose from the dead, which you can see (along with hearing my cackles of joy) below.

The engine idled remarkably smoothly, but there were three issues. The first was that the exhaust smoke was oil-burning blueish. Whether this was from stuck rings that would free up over time or worn cylinders remained to be seen. The second was that the temperature gauge pegged as soon as the ignition was turned on, so I couldn’t judge actual operating temperature. The third was that there was a leak from the back corner of the valve cover that was dripping oil onto the exhaust manifold. I tightened the nut on the stud, but it and the stud just spun, indicating that the threads in the head that held the stud were stripped. This minor-sounding problem would vex me for several days.

Day 3: Driveshaft and clutch

The bad slave cylinder was stuck in the transmission bell housing due to corrosion of dissimilar metals. Heat, penetrating oil, and twisting eventually freed it. I installed a new cylinder and hose, filled the reservoir, bled it, and verified that the pedal now felt firm. This was good, because the flaccid pedal could’ve been due to a bad master cylinder, which I did not bring with me.

Next, I replaced the driveshaft and giubo, for which the exhaust had to be dropped. Fortunately, its old rusty fasteners came off with penetrating oil and leverage. I could see that the original giubo was cracked, but I didn’t expect it to come out in pieces. While the driveshaft was out, I replaced the shifter bushings, as the shift lever was functional but comically loose. This was one of a small handful of “not strictly necessary but it was quick and it made me feel better” repairs I made.

I put the driveshaft back in, started Louie, and moved it two feet back and forth in the garage to verify that the clutch was operational. It was technically its first drive in a decade.

Since things were looking good, I dealt with tires for Louie’s little 13-inch wheels. Jake knew someone who had a BMW specialty shop who also did tires, and he was taking his wife’s 2002 there for new rubber anyway. While I was there, I asked about a valve cover gasket, which segued into the stripped stud issue. Zach handed me a Time-Sert kit. I was astonished and grateful, as I know what it means for a professional shop to loan out tools. “What do I owe you for all this?” I asked. “I’ll bill you,” Zach laughed. “I know where to find you.” Again, what I did in this life to deserve such generosity is a mystery to me.

Day 4: Brakes

I began the day by installing the Time-Sert in the stripped stud hole. Unfortunately, that did not stop the oil leak from the corner of the head. Further, while the car was idling, it began spitting coolant out the overflow tube. However, I put both of these aside to deal with the brakes.

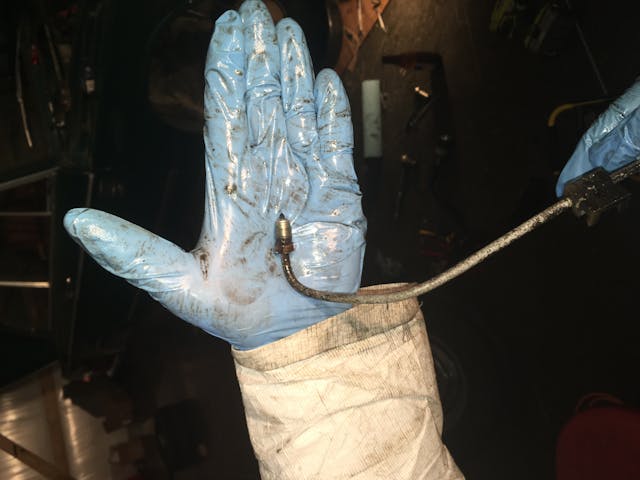

A firm brake pedal with no action at the calipers means that either the calipers are seized, or the flexible brake lines are plugged, or both. I came with both, and installed them. But while bleeding the brakes, I got no fluid out of the right front caliper. Methodically moving backwards, I found that the metal lines leading to the caliper were blocked. I found the same issue on the left front caliper. By stomping hard on the pedal, I pushed little rubber “brake turds” out the ends. This was alarming, as it was possible that these were deteriorated rubber seals from the brake master cylinder, I didn’t have a spare one with me, it was Thursday and past next-day ordering time, meaning that it was possible I couldn’t get one until Monday.

That evening, several of Jake’s friends came down with pizza, beer, and ice cream. Chris, the fellow who sold Louie to me, made an appearance as well, and was thrilled to see the car running and mobile. But I’d worked myself to the point of exhaustion, and the brake and oil leak issues were threatening to derail the drive home. I wondered if declaring victory, renting a U-Haul, driving the now-operational car onto it, and towing it home behind the rented SUV wasn’t such a bad idea.

Day 5: Cooling system

I tabled the brake turd problem to go back to the cooling system. I ran the car with the radiator cap off, and saw something troubling—coolant would surge up and out like a geyser. I pulled the water pump and found its impeller badly corroded. I installed the spare water pump I’d brought, but it made no difference. I posted the problem to my Facebook brain trust, and several folks said “You’re fooling yourself if you don’t think it’s a cracked head blowing exhaust into the coolant.” Fortunately, the problem turned out to be that the badly-cocked alternator was allowing the belt to asymptomatically slip. When it grabbed again, the coolant would surge. I didn’t think the alternator bushings were on the critical path, but they were now. I replaced them, got the alternator to stay aligned and keep the belt tight, and the problem went away.

I dealt with a few minor electrical issues, then took the car for its first actual test drive on the dirt road that led to the pole barn. It was immediately obvious that the braking wasn’t right—soft pedal and the car pulling left, consistent with my being unable to bleed the right caliper. I tried bleeding it again, found another brake turd, again forced it out, and the system bled like it should. A second test drive revealed correct braking. Whew!

Unfortunately, coolant began streaming from the heater box onto the accelerator pedal, indicating a leak in the heater core. I bypassed the core, but also checked out other functions of the heater box, and found that the blower fan didn’t work, the defroster vents were stuck shut, and the footwell vents were stuck open. So there was no way to direct air to the windshield to defrost it, and there was going to be a constant stream of cold air at my feet. Great. This was a direct consequence of the compressed time frame and things like heat not being on my list of what was necessary for either reliability or safety.

I was very close. In four and a half days, I had taken a decade-dead car and turned it into a running, driving, stopping car. But was it really ready for a thousand-mile drive home?

[Next week: The decision.]

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon here. His other seven books are available here on Amazon, or you can order personally inscribed copies from Rob’s website, www.robsiegel.com.

One of my daughters – a psychology major at the time – once pointed out to me that “car guys have a habit of using the words ‘supportive wife’ to describe what is in reality an ‘enabler'”. 😂🤣😉 Either way, Bless their hearts, one and all.

Great story so far, Rob, and truly you were blessed to have the folks around you – like Jake – that made this such a cushy recovery (that pole barn makes a lot of our garages look like a disaster area). I’m sure I’m not alone in being impressed with the relative thoroughness of what you packed in the back of that SUV. You darned-near thought of everything. I’m likewise sure I’m not alone in having set out into far worse conditions armed with little more than a screwdriver, some channel-locks, and a set of questionable jumper cables, so I encourage any newbies to the dead-car-rescue-scene to go back and re-read your lists and cautions!

Anxiously awaiting Part 3!

I very rarely read books. But due to enjoying Rob’s articles here I have purchased a few of his books. The car in this article was the subject of his “Ran When Parked” book that I found very enjoyable.

👍

👍👍

Careful! Rob’s books are gateway drugs into a whole wide world of reading…

I recently bought three of his books because he tells a story so well. Looking forward to reading about his adventures in automotive endeavors.

“‘supportive wife’ ” ? I’m ever so lucky. My dear wife lets me bring home any car I can sleep in!

Time to buy a nice VW Bus or Vanagon with a factory Westfalia camper kit.

This saga is inspiring. I hope to do this one day, but with a car one of my friends buys. That keeps me insulated from the cost-sink but still lets me live the adventure.

Smart thinking.

Being a member of the group the shows up at a not running car with a bent screw driver, pair of pliers and a set of cables, I am over-whelmed! I’ll never do that again. Amazed and inspired at your foresight and attention to detail. Almost makes you decide to stop looking at a non-running project. Great article and looking forward to the next chapter. Amazing work. Many thanks for sharing.

I am enjoying the ride so to speak, so now the next chapter is the ride… or not? Tune in next week…

Fabulous story! You’re an inspiration.

I remember a car I DROVE home. My wife was so overwhelmed she didn’t say a word for three days and then couldn’t stop talking about it.

Just bought your Car Wiring Book and like your stories is a joy to read. Can’t wait for the decision.

Why so many bushings? Is it to insulate the cabin from noise and vibration?

The opposite of this story – buying a car you think will have no problem being driven home 700+ miles, and then discovering you made the trip in one piece thanks only to the graces of whatever entity you pray to – can also be enlightening and entertaining…..if not a little horrifying. 😉😹

As you are well aware, 25% of Louie had to be repaired or rebuilt.

Of course there was no way to know ahead of time which 25% it was.

Jim B