Media | Articles

9 roadside repairs that tested my DIY limits

If you’re tooling around close to home in a vintage car, breakdowns aren’t really that big of a deal. Your Hagerty or AAA coverage will probably tow the car home for free or close enough, and you can fix it there. But if you’re road-tripping a car, breakdowns are a much bigger deal. Even if the cause is something you think you can fix, you really don’t want to be in a situation where you need to be under a car when trucks are whipping past only 10 feet away. Anything you know is wrong with a car that is likely to put it in the breakdown lane really should be fixed before a trip.

That having been said, breakdowns happen, and when the cause is obvious and easily addressable, roadside repairs get made. To be clear, whenever possible, don’t literally repair it roadside—if you’re on the highway, limp the car to an exit and find a parking lot instead. Cooling system and oil pressure issues, however, carry a special urgency, as failure to act immediately can result in a cracked head or a lunched engine.

When a roadside repair is ingenious or difficult, it turns into the stuff of legend. I’ve heard stories about broken fan belts in Volkswagens being addressed (or undressed) by convincing a female companion to surrender her panty hose and fashioning a belt out of it (likely a relationship-cementing or a relationship-ending event). One South African friend told me a story about engine failure in a remote area and a weeks-long process of walking miles and hitchhiking while carrying a cylinder head to and from a machine shop. And I witnessed two good friends of mine replace a BMW 2002’s blown head gasket in a hotel parking lot in under an hour and a half.

Now, nothing I’ve done approaches these feats. But after 47 years of wrenching, these are the roadside repairs that stand out above the usual wiring-up of hanging exhausts, reseated distributor caps, “your alternator won’t charge without excitation current from the battery warning light” fixes, and getting a car to start by tapping on the positive battery clamp, the starter, or the electric fuel pump, then going “Ayyyy” like Fonzie.

1. Water pump failure in the Triumph GT6+

In high school, I had been a bicycle guy—riding bikes, fixing bikes, pulling bikes out of the trash and rejuvenating them with parts from other bikes. The summer before college, I was planning on cycling cross-country, which scared the bejesus out of my mother. She blatantly bribed me by offering to buy me a car. I took the bribe and bought the then-six-year-old 1970 Triumph GT6+, easily the worst car I’ve ever owned.

The first of many failures occurred when the car overheated in the hill country north of Amherst, Massachusetts. I limped it to that night’s destination, a friend’s father’s house. I didn’t know much about cars, but knowing bikes, to me the car was just another mechanical system. I could see that the part where water was streaming out had a pulley and a belt on it, and deduced that it was the water pump. I made a few phone calls, found a shop in nearby Hadley that had one, hitchhiked there, and bought it … and the gasket … and the sealant … and the antifreeze.

My friend’s father had enough tools for me to do the job. I had my first taste of the joy of getting myself out of trouble. There were other more devastating mechanical failures to come, and of course the requisite Lucas electrical system problems, but if anything is ground zero for me becoming The Hack Mechanic, it was this.

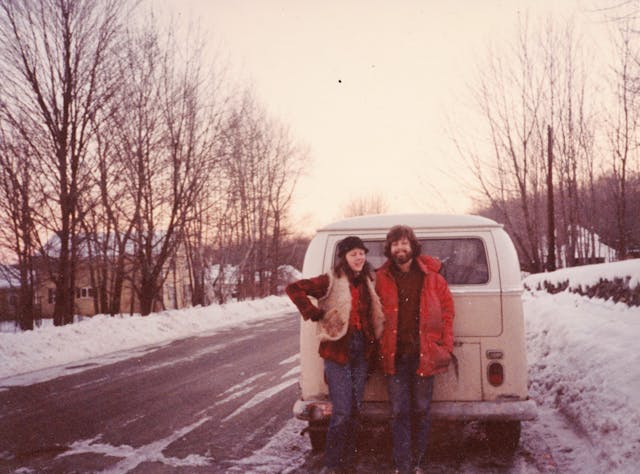

2. Points closing up in the VW Bus

In early January 1982, my then-girlfriend and now-wife Maire Anne and I moved from Boston down to Austin, Texas, in her rotted 1971 VW Bus with no heat. After surviving an ice storm in Pennsylvania, we finally made it to warmer climes, but somewhere in Arkansas, the bus lost power and sputtered into the breakdown lane. As the de-facto mechanic of my girlfriend’s car, I’d read John Muir’s classic How to Keep Your Volkswagen Alive: A Manual of Step-By-Step Procedures for the Compleat Idiot cover-to-cover. This was my first “it’s almost always the points” experience—due to pitting on the point faces and wear in the little nylon block that runs on the distributor shaft, the point gap had closed up until it no longer triggered the coil. I pulled the points, filed them, did the trick of gapping them with a matchbook cover (which is about the 0.016-inch needed), and voila. I think this is why Maire Anne later married me.

3. Fixing the 2800CS in the middle of a busy intersection

In 1988, I looked at two BMW 2800CS E9 coupes from a salvage yard north of Boston. One was a wrecked picked-over parts car, but the other surprised me by being rusty but whole, and starting and running. I bought them and decided to drive the good one home, use it as a winter beater, and part it out the following spring (I had two other E9 coupes). A few days later, Maire Anne drove me over to the junkyard in our 1983 Volvo 245GLT wagon. I slapped a plate from my daily driver on the 2800CS, jump-started its doornail-dead battery with the Volvo (incredibly foolish—I should’ve brought a fully-charged battery from another car instead), verified that no fluid was gushing out from under the engine compartment, and off we went. Through traffic. At rush hour. Ah, youth. When I was trying to get through the very busy intersection of Rt. 28 and Memorial Drive, I didn’t feed enough gas coming off the clutch, and the car stalled. Since the battery was dead, there was no re-starting it.

So, there I am in the middle of a city intersection at rush hour in a dead, rusty, uninsured, unregistered old car that looked like Beatrix Kiddo in Kill Bill II when she escaped from being buried alive. With it nearly impossible to position the Volvo nose-to-nose to the 2800CS to jump it, I motioned Maire Anne to drive the Volvo to the curb. I ran over, popped open the Volvo’s hood, yanked out its battery (also foolish, as doing so on a running car risks blowing the diodes in the alternator, but necessary), wrapped the positive battery cable in a glove so it wouldn’t short to ground, said to Maire Anne, “Whatever you do, don’t stall,” ran into the intersection with the Volvo’s battery, threw it in the 2800, started it, and drove home. Certainly not one of my smarter moves, but a good story.

4. Reconnecting the half-axle on the Vanagon

Before I began my serial relationship with Suburbans, I had Vanagons. They were weird cars but cavernous inside. I think I went through half a dozen of them before we finally bought the Toyota Previa, which also was weird but was more reliable. When I bought the first Vanagon, the clutch was slipping badly. I dropped the engine (very similar to the old VW busses—support it on blocks, unbolt the bumper, unbolt the engine, roll the bus forward) and replaced the clutch. A few days later, my sister needed to borrow the Vanagon to pick up a piece of furniture. That afternoon, I got a call from her from a payphone (this was pre-cell-phone days) saying that the Vanagon began making a loud rumble, then very loud whacking sounds came from the back.

She and the car were a few miles away. I shot over there with my tools and found that one end of one of the half-axles was flopping in the breeze. Apparently I hadn’t torqued down the ring of Allen-head bolts holding it to the flange on the transaxle. I crawled under the car, tightened things up, and sent my sister on her way. Some 35 years later, she will still sometimes needle me, “Remember when the axle fell off the Vanagon you leant me?” I, of course, will correct her and say, “It wasn’t ‘the axle.’ It was one of the half-axles. And it didn’t fall off—one end just got loose. And I came immediately and tightened it back up, didn’t I?” The funny thing is that, looking back on it, I can’t remember why I had to detach the half-axles at all. Maybe there was some reason why I needed to pull the engine and transaxle together.

5. Unadjustable fan belt on a 635CSi

I had a 1985 BMW 635CSi that had been gifted to me by my son’s girlfriend’s father. He was mainly a Mercedes guy, and his Mercedes mechanic couldn’t figure out why the 635 wouldn’t start. It turned out to simply be a bad distributor cap. That, an air flow meter, and new injectors got the car running well, but it was by no means well-sorted, and the young man who bought it from me surprised by saying that he wanted to join my convoy on the 2000-mile round trip to The Vintage in Asheville. I warned him that this was risky. He said that he understood that I wasn’t his traveling mechanic, but I couldn’t help but feel a sense of responsibility for both him and the car. Sure enough, on the drive down, the car’s temperature began creeping up and eventually headed for the red zone.

We took the next exit. I found that the belt was slipping even though there was no audible squealing, and the slippage resulted in the water pump not continuously spinning. I tried to adjust the belt, but the bolt in the adjuster track was at the end of the slot, indicating either that the belt was wrong to begin with or had stretched. I was afraid that, if he drove the car hot, he’d crack the head, and I was about to search for the nearest auto parts store when I noticed that next door to the convenience store we’d pulled into was a machine shop where we were able to borrow a round file. I removed the bracket, and Jordan (“the kid”) did the hard work extending the adjustment slot (hey, it was his car). It worked like a charm. We later found a shorter belt, but never needed to install it.

6. Cracked fan on a Euro 635CSi

I was driving my ’79 Euro 635CSi on the return trip from The Vintage—the same trip where I fixed the kid’s unadjustable fan belt. During a rest stop, I opened up the hood to check the oil and was stunned to see that two blades had flown off the belt-driven cooling fan. The 635CSi’s six-cylinder M30 engine was used in BMWs from 1968 through ’95, but it went through three different water pump, fan clutch, and fan configurations, and new parts are no longer available for anything other than the final configuration. I put out the call to friends on Facebook, but unless someone had an old fan, I’d need to replace not just the fan but also update the water pump, the fan clutch, and the pulley.

I removed the fan lest it lose another blade and slice open a coolant hose. This required removing the radiator, which in turn required dumping the coolant. Fortunately I was able to send one of my road trip companions to a nearby Autozone for a catch basin and a few gallons of antifreeze. Driving without a belt-driven cooling fan is usually fine when cruising at highway speeds, but if there’s not enough air flow over the radiator at low speeds or in traffic, it can send temperatures into the red and crack the head. I made a quick wiring mod that allowed me to run the electric pusher fan that’s in front of the A/C condenser without turning on the A/C, and let the car idle in the parking lot to test it. The temperature seemed to top out at about 3/4 of the way up the gauge, so I felt pretty good about making a run for it.

In the meantime, a friend about 150 miles north and on the way home messaged me that he had every part to do the full water pump/clutch/fan/pulley upgrade. We made it to his garage without incident, where I installed the newer-style cooling components. The car’s cooling system was fine until…

7. Leaky heater hose on the same car

A few years later, again on the way to The Vintage and driving the same ’79 Euro 635CSi, I had another cooling system issue. The irony was that, having experienced cooling system issues the last time I road-tripped the car, I wanted to be certain everything was copasetic, so I inspected the cooling system. I found a heater hose that was obviously ballooned and soft. The hose was listed as no longer available from BMW, but I found one as new old stock (NOS) on eBay. I clicked and bought it, but wasn’t certain it would arrive in time, so I hunted around on my parts shelves for a replacement. I found what appeared to be a perfectly good used heater hose. It was clearly better than the ballooned one in the car, so I installed it.

When the NOS hose arrived, I tossed it in the trunk as a spare. On the way to The Vintage, the car’s temp crept up, but did so slowly enough that I thought it was just due to the outside temperature increasing as we headed south, combined with the car rolling up and down the Blue Ridge mountains, but when it tickled the red, I pulled over. I-81 is one of the most heavily trucked routes in the country, so I made it a point to get the car as far off the breakdown lane as I could. Sure enough, the engine was peeing coolant … out the hose I’d just replaced.

Fortunately, I had the NOS hose in the trunk. While I was waiting for the engine to cool down, I sent my travel companions for antifreeze, at which we all had a serious déjà vu, as the same thing happened with the car and the same people three years prior. It was yet another reminder how much easier these things are when you’re not trying to act like a lone wolf.

8. High beam stalk disintegrates on the Merritt Parkway

The Merritt Parkway is a windy two-lane road north of New York City with a lot of elevation changes. When I was younger, I used to love the Merritt for that reason, but in my dotage I find it stressful due to the 85-mph traffic, the sudden squeezing of two lanes down to one due to construction, the lack of illumination at night, and the repeated experience of coming over one of the rises and having to jam on the brakes due to the sudden sea of red lights. As such, I usually avoid it, but sometimes I’ll just do whatever Waze says, and if it takes me via the Merritt, so be it. Such was the case on one of my trips to The Vintage in a 2002tii.

It was night. Traffic was light to moderate, so there was a lot of toggling the stalk between low and high beams. During one such flick, the stalk fell apart in my hand. What’s the big deal, you might say? Did it fail in the low or high beam position? That was the problem. Neither—my headlights went completely out. With the Merritt Parkway’s lack of lighting, I was abruptly plunged into darkness. I slowed down while fumbling with the stalk to see if I could restore lighting. Fortunately I found one fragile position where the lights came back on, but they went out if I deviated in the slightest. I drove very carefully that way—one hand on the wheel, the other on the stalk—until I came to a rest area. On road trips, I always pack a roll of wire, a variety of connectors, and a crimping tool, so I had no question that, if necessary, I would wire the lights directly to the fuse box, but I thought that I’d first try fixing the stalk. I took the upper and lower panels off the steering column to expose the stalks and found that the potted metal tabs holding the Bakelite back of the stalk in place had broken off.

I carefully put the stalk back together, held it together with zip ties, re-attached it, and tested it. It held. For the rest of the trip, I flicked the stalk very carefully lest it fall apart again, but it’s now eight years later, and those zip ties are still in place.

9. J-B Welding a cracked head

I’d say that I’m saving the best for last, but I already wrote about the time that I J-B Welded a cracked cylinder head in a lot of detail here. It almost doesn’t count as a roadside repair, as it didn’t technically fail on the road, and as it certainly wasn’t fixed roadside—I was in a first-class repair shop with the advice of a seen-it-all mechanic—but it was still enormously satisfying to stop the dripping of oil out a crack at the top of the head onto the exhaust manifold using J-B Weld and be driving home a few hours later.

How about you folks? What was your favorite roadside repair? Wipers pulled back and forth with rope? Throttle controlled with a hand-yanked cable? Tell me what you’ve got.

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem is available on Amazon here. His other seven books are available here on Amazon, or you can order personally-inscribed copies from Rob’s website, www.robsiegel.com.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Marketplace

Buy and sell classics with confidence

While driving through Toronto’s east end years ago in a 1979 Plymouth station wagon with my wife and baby suddenly the temperature light came on. It was dark and only two lanes open with no place to pull over. Luckily I found a spot to get to the side and not stop traffic. I pulled the hood an by the light of the small factory lamp Chrysler had installed there I saw a twisted up belt snarled in the fan. I fished it out and found that the pulley driving the water pump had broken away at the bolts and was just a ring laying there on the water pump. The other two belts were intact on the 360 engine. The water pump was free so no bearing damage. I let the car cool for a few minutes and figured I would start it and limp along to an exit and get off. The engine fired right up and we pulled back into traffic. Amazingly the temp light never came on and I realized that the air through the radiator was turning the water pump. We drove another 60 miles that way to my parents home and only when I stopped in town did the light come on. Phew we made it! Next day I got a replacement pulley at a wrecking yard. Someone was behind me on my shoulder that night. Thank you!

Bob, you do know the difference between a BMW and a porcupine, right?

I do indeed.

1984. Charlotte, NC.

While driving up the spiral entrance ramp in the BB&T bank building, the timing belt on my Volvo 242GT snapped. The car immediately stopped blocking the ramp. I removed the sparkplugs using the toolkit that always carried and used the starter motor to pull the car off the ramp by leaving the car in 1st gear. I coasted down the parking deck and into a parking space. At lunchtime, I went to the NAPA store and purchased a new timimng belt & valve cover gasket. That afternoon after work, I replaced the belt. Took about 30 minutes from start to finish.

I love those B21F engines. Not a lot of power but they run forever.

“It’s almost always the points.” In the 1980s I was an a 1,000 mile trip from San Jose to the Northwest when my 68 Fiat 850 Sedan (rare in the U.S. even then) died on I5 in Northern California. A quick examination revealed that the distributor cam rubbing block on the points had broken off. Since it wasn’t my first Fiat rodeo, I had the used set of points from my last tune-up in the car, along with a basic tool kit. Five minutes and one matchbook cover later I was back on my way, something that could never happen with any of the cars I own today.

The nylon-block–on-the-points-falling-off thing has become more and more common with the poor quality of new points.

Zip tie moment. 1970 Cougar. the ignition switch came apart like your headlight dimmer did. I actually made the field repair with some wire I found by the road pulling the 2 halves back together. That got me and the car home. I then used zip ties for a long term repair. Several years later I found a replacement switch. I think I still have the zip tied one in my parts collection,

In 1971 the right rear axle bearing went out in my 64 vette on a Friday night at 1AM. Got a new bearing from a dealer that was open on Saturday 35 miles away and changed it out in the Moose Club parking lot next to lake Erie. No press, beat the old one out with a small sledge.

In the 70’s we were doing a 600 mile trip down the East Coast of Australia in our unrestored 1936 P2 Plymouth Hearse. Early in the trip, the head gasket blew. We took the bonnet off and put it in the back, removed the radiator cap too. Could open the throttle just so far until water spewed out, so drove watching the radiator filler for the next 500 miles, dropping down the gears on the many hills. In Sydney I removed the head, had it surfaced and replaced it on the side of the road. It was .013 warped. Nice simple old flathead!

As a man who knows his own limitations and therefor calls AAA for everything, these are some amazing repairs. Reminds me of the song “Real Men” (Can Fix fix the car) from Tom Demarest’s 2009 CD Tune Ups, Tunings & Car Tunes. Mr. Siegel, you are a real car man.

What do all of these have in common? Foreign car.

Driving on the 401 near Cambridge Ontario and my 1981 Lada 1500 started sputtering and I could smell gas. I saw that there was a rest stop about a mile ahead and the car completely stalled then. I kicked it in neutral and coasted to the rest stop fortunately although there was some tooting that I was going too slow (no kidding). Popped the hood and began the inspection. I noted the fuel line had popped off at the carb due to the end being somewhat rotted. Got out my knife and trimmed it and added a hose clamp and put it back on. Back in business with about 20 minutes lost on the trip.

Made a panic stop in my ‘69 SAAB 96 while driving from DE to AZ. Worn engine mounts let the engine lurch forward and the fan chewed a hole in the radiator. Had a used radiator in the trunk for a different model SAAB, wired it to the outside of the grille, bought some long coolant hoses and some antifreeze, and continued on my way. Fan proved unnecessary for the remainder of the trip.

I cannot help but notice that almost all of these involve German-made cars.

In high school I built a Model A street rod. After graduation in ’72, my brother and I drove the A to Ann Arbor MI from Dayton,OH where we used to live. We stayed with friends and drove back and forth to Detroit for the Street Rod Nationals. The roads took their tole on the recored radiator and at was leaking badly. I drove it to a gas station that I used to work at, borrowed some tools and removed the radiator. I walked thru downtown Ann Arbor carrying the radiator and getting plenty of weird looks. A couple of hours later everything was good and we enjoyed the rest of the trip.

I had two incidents with the same 1969 Corvair. The first was more of a “shade tree” repair. I had a lower cylinder stud pull out of the block. That was also used as the fulcrum for the rocker arm. Fortunately, it wasa on the exhaust side, so I pilled the spark plug and drove it to where I worked, an AM transmitter site in the middle of a corn field. There, literally under a tree, I pulled the head and cylinder, helicoiled the stripped hole and put it all back together, all in about 8 hours. The second was when my clutch cable broke on the way to that same transmitter site. When it was time to go home, I started the engine to warm it up, then shut it off and put the transmission in first gear while using the starter to get the engine going. On the way home, I had to learn how to match revs to minimise clashing when I shifted. I couldn’t avoid several traffic lights, so I used the first gear and starter procedure to get the car going. At the time, the local Chevy dealer still had some Corvair parts in his inventory, so I was able to replace the cable from a local source.

This article really hit home with me. Twelve days ago (September 30th), five hours into a 7+ hour trip from Connecticut to Virginia, the fuel pump on my 79 Camaro 350 small block failed. It was a Carter and only 2 1/2 years old, but it failed none the less.

I got off the highway and coasted into a diner parking lot. I broke down near 3 auto parts stores, but nobody had the correct fuel pump. My car has the three-line set up with the large cup/bottom, while only one of the stores had a two-line pump with the small cup/bottom. The other two stores had nothing on the shelves.

The stores could have ordered the correct pump in, but it would have been a day or two, which would put a big delay into our vacation plans, so I really couldn’t wait. Not to mention avoiding having the car hauled somewhere on a flatbed.

I had to buy a flare nut wrench and I had a small tool kit with me, so tool wise, it wasn’t too bad.

I also ended up blocking off the third (return) line by clamping a bolt inside it.

The other issue was the steel line from the pump to the carburetor was too long and I had to bend it a bit to make it fit.

It was a success in I was able to complete the trip, including driving through Shenandoah National Park via Skyline Drive all 105 miles, followed by an 8+ hour drive back home.

Once home, I was able to install the correct pump and restore the car back to normal.

It was an adventure, and my wife was a trooper and waited patiently while I secured and installed the part.

I figured I owed it to the diner to eat dinner there since they did not bother me and let me do what I needed to to get the car going.

The oddest thing on top of all this was a gentleman went to the diner to eat dinner with his wife and asked if I needed assistance. I told him I believed I had it under control but thanked him. He said if I wasn’t done by the time they were done eating, he would help me.

Well, I finished the repair, road tested the car, and returned, noticing he was no longer in the diner window. When my wife and I went inside, he was on his way out and congratulated me on the repair. He then proceeded to say he was impressed and wished to by me a beer while attempting to hand me money.

I said, “Wait, you’re tipping me for fixing my own car?” He said yes, I worked hard, got it done, and therefore deserved it. My wife insisted I not argue with him and insult him, at which point he gave me a ten-dollar bill.

There still are nice people in the world.

THAT is awesome.