Media | Articles

In the garage, sometimes less is more

After a short hiatus of hands-on projects, I’ve been returning to the garage to deal with a few tasks that have been sitting on my back burner. Top of the list is sorting through the various parts and pieces that have accumulated in the 10 years since I moved to Michigan and began to hoard the parts and pieces that will certainly get used one day.

The sad theme of my cache? Stripped nuts and bolts.

Most of it is OEM Honda hardware. I can still buy it, but I fear the day I won’t have that option. I could replace all of it with socket-headed cap screws—the threads are standard metric—but the flanged head with the hemispherical dent in its center is a touch that I like on my bikes. It’s the correct stuff, and a good build deserves it. Sadly, the previous owners of the motorcycles I’ve bought didn’t have such respect for the little things.

Many of the bikes’ nuts and bolts have rounded-off corners or are otherwise damaged in a way that suggests an inconsiderate mechanic rather abuse on the road or trail. With my thrifty (read: cheap) nature, the bikes I bring home rarely come from loving homes. The last one, an ’86 Honda XR250R, came from a dirt lot adjacent to a house whose roof had collapsed. I think the 14-year old who sold me the bike was squatting in it.

Humans have advanced to the point where we’ve made so many tools that one person could never own them all if they tried. The sheer number of available tools has made it easy for users to reach for the wrong one. If it kinda works, it becomes their go-to.

Marketplace

Buy and sell classics with confidence

That doesn’t make that tool the right choice.

Allow me to present an example, which happens to be a personal pet peeve: 12-point sockets.

Go to your favorite local hardware store and look into the bins of nuts and bolts. Then put your car on jack stands (if it’s already there, I’m sorry) and spend five minutes poking around and noting the hardware that holds the thing together.

Just leave this window open in your browser. It’ll be here when you get back.

I promise.

What did you find? Most of those fasteners have six sides with six tidy corners. What isn’t a hex-, Torx-, or Phillips-head is likely hexagonal in shape and would fit perfectly into a six-point socket. It would also fit in a 12-point socket—but poorly.

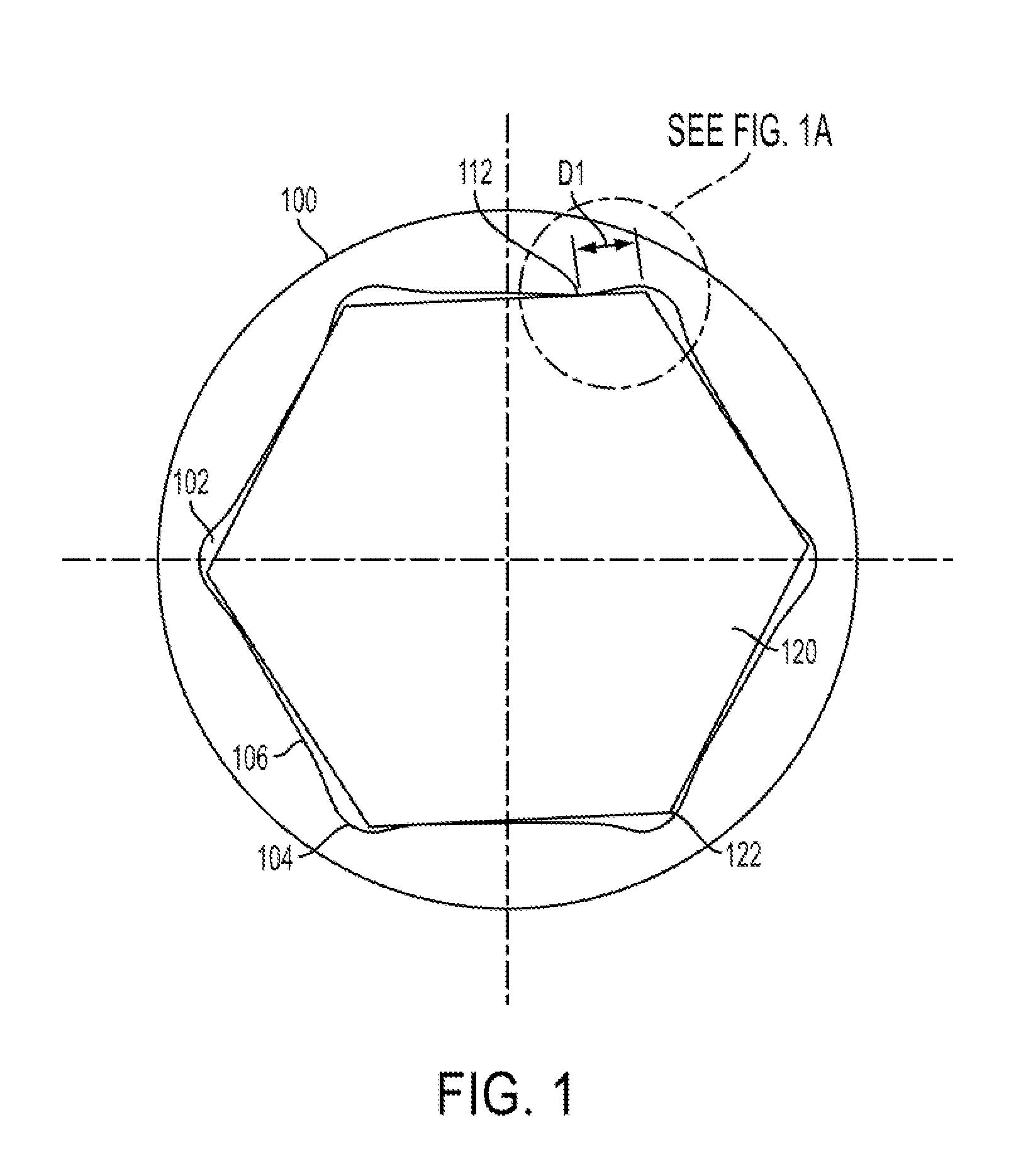

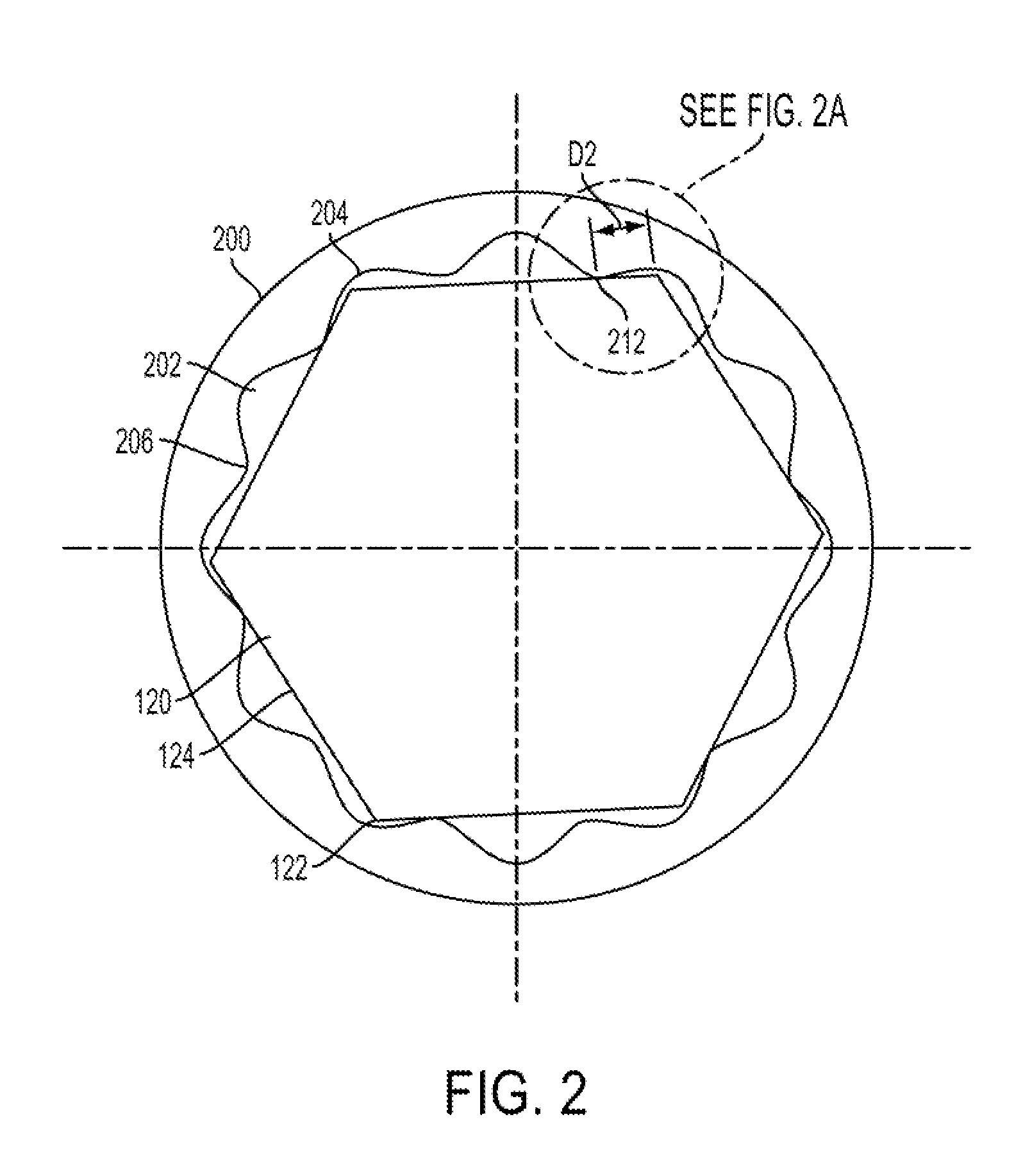

I can state this as fact because science backs me up. Look closely at the two sockets, of the same size, side by side. Notice that the six-point socket has thicker walls than the 12-point one. Also, look at the facets inside. If you have a quality set of sockets, these surfaces won’t actually be flat; instead, each section will have a slight arch to it.

This concave surfacing helps the socket engage the fastener farther towards its center, on what’s called the fastener’s flank. Together, the six-point’s superior rigidity and optimal contact point transfer torque more evenly from the socket to the fastener. This design also deflects less twisting power during high-torque situations, like those produced when you’re wrestling with a corroded or very tight piece of hardware.

According to a patent filing by Snap-on tools, the goal of a socket design is to “engage the flank of the fastener at a distance of about 30 to 60 percent of half a length of the flank away from the corner of the fastener.” This prevents the fastener’s corners from being wiped off by the socket, leaving you with a stressful evening of dealing with a newly round bolt.

Before you say it, yes—I will happily admit that there are three parts to this equation: Tool, workpiece, and user.

Think about all the times you’ve heard people complain about modern “cheese-grade” hardware. This is the stuff that is unmarked and made of an alloy that seems to be heavy on the sugar and spice but has none of the nice carbon, zinc plating, or heat treatment found on grade-five and above hardware.

Low-grade hardware commonly found on budget-focused products, combined with a less-than-conscientious user who selects a sub-optimal tool is a recipe for failure and frustration. It is up to the user to select the proper tool for the job.

Often, the perceived ease of engagement offered by a 12-point socket is traded for greater risk of rounding off hardware and creating even more of a pain.

So, I propose a rebranding of 12-point sockets in your mind: They are speciality tools.

There are twelve-point fasteners and, of course, that means you should be prepared for them. An 8mm 12-point can stand in for the special XZN hardware found on Volkswagen Auto Group cars, just as one example. That’s a pretty narrow use case, though. Oh, and I have to mention ARP bolts, along with the other aftermarket hardware that surely exists. Heck, I could swear I’ve seen factory-installed connecting-rod bolts with 12-point heads.

Twelve-point sockets always seem to be around, though. Look in any one of the starter toolkits at your local hardware store, and you’ll find a matched set of six- and 12-point socket duplicates.

I chalk this up to two reasons: It is handy to have two sockets of the same size if only because you might lose one or need two in order to separate a nut-and-bolt union. Also, notice how so many of those kits are sold on tool count: high number of tools for a low price. Just $250 for 290 tools, and these kits often go on sale around the end of the year for close to $100, even.

That tool number is a big part of the manufacturer’s value play. The reality is that duplicates—and the practice of counting each screwdriver tip that can be inserted into the single screwdriver included in the kit—builds value in the customer’s mind. It also means that we view each tool in those sets as something we need and must use. That’s just not true, though. Even with these toolkits.

Look, in most situations, a 12-point will do the job. But if a fastener gets tight, rusty, slightly rounded, or otherwise damaged, why take the risk of starting with an inferior tool and hoping that the proper one can save you if things go wrong?

The sales pitch that double the points is handy for when a bolt is slightly hidden or tough to get to is backwards. Yes, a 12-point socket can engage a six-point bolt every 30 degrees of rotation, but if you’re are unable to rotate a 6-point socket to get settled onto a bolt, how are you going tighten or loosen the bolt once the socket’s engaged? Should the inferior socket damage the hardware, you can only hope that a six-point can save the day. Even if it does, you’ve now wasted time doing the job twice. Just use the right tool the first time and save yourself the stress of having to replace rounded bolts.

Or don’t. I fully recognize it’s your shop, your tools, and your hands. You can take the risk if you want.

But if you are the person who rounds off hardware with a 12-point, uses a six-point to remove it, and then just goes ahead and reinstalls it … would you please stop selling me motorcycles?

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I couldn’t agree more on the importance of using 6 point sockets, especially when trying to loosen a stubborn bolt. If the 6 point socket is not engaging at an ideal angle for leverage, just rotate the socket 90 degrees on the breaker bar. Voila! Now you have an angle available with a 12 point.

I work on ✈️ airplanes. Almost all of the jet engines, P&W,Rolls-Royce, Honeywell and GE use 12 point fasteners (bolts and nuts) to hold them together. I’ve worn out many Snap-on, and MAC sockets working on Jet engines. Granted, some of the fasteners are titanium or stainless steel, depending on where on the engine they’re found (hot and cold sections) 12 point is the only way to go.