Media | Articles

For My LS Engine Build, Planning Makes Perfect

Remember my Corvette? The sad, 1985 grand tourer that I just couldn’t stop myself from buying last fall? If you’ve forgotten, I forgive you. For most of the winter, I forgot about this poor car, too. It’s been a cold one this year and, despite my heated garage, progress on the Corvette’s LS engine swap has been glacial and very opaque—but there has been progress.

For once, I decided to take my own advice and break the project into stages. Like any long-term project there will be fun stages and frustrating, wow-I-wish-I-could-have-skipped-that-part phases. Finding the beauty in big projects like this lies in the ability to enjoy both the sweet and bitter moments (like a coffee snob, perhaps). In the interest of building lasting momentum and excitement within a year-long project, I’ve chosen to start with what I am most prepared for: Building the engine.

First came the reading. Lots, and lots, and lots of reading. And watching, if I’m being honest, though I found that YouTube videos often failed to capture the information that forum threads and Facebook groups were able to share. Understanding a process often required piecing together a tidbit here, another from somewhere else, and a third source just to be sure. Lots of LS parts are talked about as if they are Lego blocks that all simply click together, but I’ve built enough Lego to know even those tiny plastic bricks aren’t always what they seem.

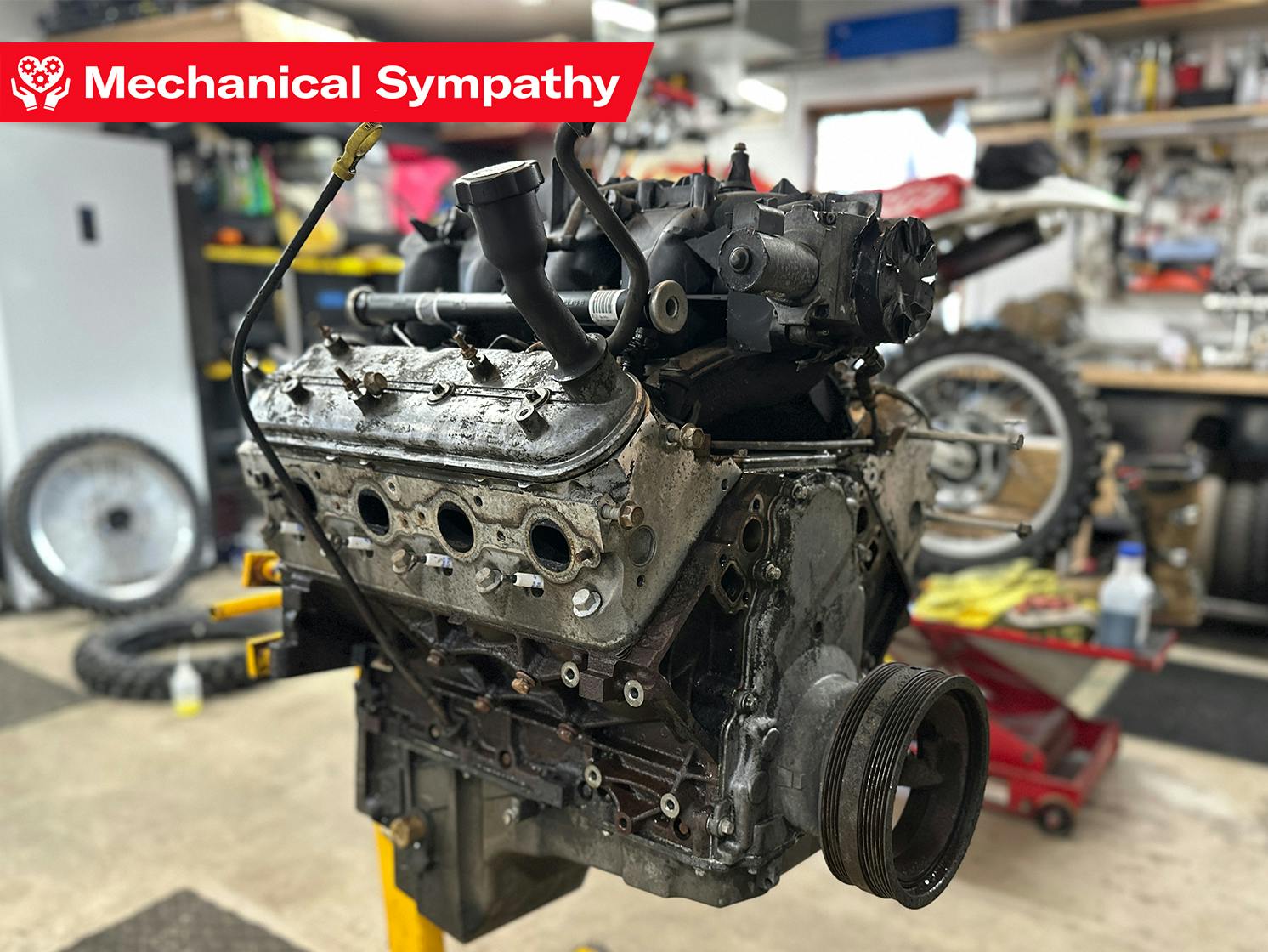

The 364-cubic inch V-8 sitting on my engine stand was carefully divorced from a 2003 GMC Yukon. Those who speak LS Engine Code will recognize it as an LQ4. Simply removing the wheezing L98 small-block from the Corvette and putting in this aging modern truck engine would give me a nice bump in horsepower and torque, but where some is enough, a little more is just right. Thus, this 140,000-mile V-8 is getting a refresher before settling into its new sports-car home.

Listen to anyone talk about modifying LS engines for a few minutes, and you’ll find the formula is pretty simple, especially when it comes to transforming this LQ4 from truck to sports-car engine: Leave as much as you can alone while increasing airflow. (The formula is no different than it was when first-generation small-block Chevys were popping up under hoods half a century ago.) The cylinder heads on the LQ4 are actually pretty good, but almost every LS build you hear about includes a cam swap, and for good reason; the factory camshafts leave plenty of power and personality on the table. I’m still making the final decisions regarding the exact cam and supporting valvetrain modifications, but the formula for my build is making progress even with the engine still together.

Marketplace

Buy and sell classics with confidence

A beautiful thing about the LS-series engines is that their shared architecture makes it simple to swap parts between engines. Because the LQ4 is a truck engine, the compression ratio is just 9.4:1 due to the dished pistons and the design of the 317 cylinder-head casting. Cylinder heads are easily interchangeable, meaning a simple swap to different heads would potentially raise the compression ratio with no other downsides. A pair of 706 casting heads went onto my shopping list, as they have a relatively small (61.15 cc) combustion chamber that, while small, yields a full point of compression ratio. That’s without any work, too. Sure, I could mill down the 317 castings that are on the LQ4, but why pay for machine time when I found a set of decent looking 706 heads on Facebook Marketplace for $50? There are other, “better” options in the LS-sphere, but it would take free parts to beat that deal. Finally, the 706 casting will support my power goals just fine.

Other parts of the engine are similarly interchangeable. To increase airflow, and to upgrade from a 78mm to a 90mm throttle body, I’ll be replacing the stock LQ4 intake with the “NNBS” one from the Trailblazer SS. A set of long-tube headers, specifically designed for an LQ4 in a C4 engine bay, round out the set of fun-to-talk-about parts.

When I finally cut myself off from sourcing parts, it became clear that I would reuse the rotating assembly, and not much more. It seems like there is a lot of work to wrap up before I can swing out an engine crane to extract the Corvette’s original engine. In the interest of keeping as many projects as mobile as possible, I’m keeping it running with its factory TPI engine as long as I can. Additionally, despite my best efforts, I still need to consider interest rates in the future planning of this project.

Much like the first mile or two of a marathon, these first bits of progress on the Corvette feel like a cakewalk. They should; they’re mostly research and opportunistic parts purchasing. The real challenge, after laying out a plan, is following the plan at the planned pace. I intend to have the LQ4 on a stand and running—or close to it—before pulling the engine out of the Corvette. This week’s planning and research should now allow me to check off next month’s to-do items at a regular rate. Just like anyone who has experienced the wall at mile 21 will dutifully settle in for the first half of a marathon behind a pace-setter while still checking their watch, I am wise to continuously evaluate my budget and my effort levels.

While my legs are unlikely to cramp up during an engine swap, my wallet likely will. Breaking down the project into stages will hopefully allow me to focus more and to make measurable progress without actually touching the Corvette. The end goal may be to put a different engine under the clamshell hood, but there is a lot of ground to cover between now and bolting in this LS. Also, as regular readers will expect by now, I have other things that will distract me along the way. Tackling only a portion of the larger puzzle at a time will make it a lot easier to pick up where I left off. Or so I hope.

I fully expect this engine swap to take the better part of a year before the car is drivable again, and even then the LS likely won’t be sorted out to the degree I would like. Even with that mountain to climb, I’m excited to actually start turning wrenches now rather than piling parts and information. The next installment of Project Corvette will be what I find inside the engine and if the simple heads, cam, and intake build I have in mind will be enough.

We make lots of money on LS builds.

Here is what you do.

New heads and bump the compression to over 10/1.m

Replace the intake for a better glow yet keep it under the hood.

Upgrade the rockers from stock.

Headers are fine if they fit. Good C5 or 6 manifolds do well and will not catch the car on fire.

Put on the Summit 2501 SFI balancer and pin it.

Cam Brian Tooley Racing has a good selection. Don’t go too big if a street car.

Also don’t go yo big on TB. Too many Ho so big it bogs.

The key is to match the parts and make sure they work together for what use you have planned.

If your intake glows you got problems 😂

Not if your intake is a turbo. Let is glow, let it glow! 😁

I bought a 85 with a Greenwood body kit for 300$, right place , right time, knowing it needed an engine swap. A buddy had a 1970 4 bolt main 350 block that he donated, another had a set of rebuilt heads he sold me cheap. I forged for a new Edelbrock Rpm intake and 650 cfm carb. Sold the original parts and computer for 500, reused the headers , rad etc and had a fun machine for 1500$ total. I sold it for 9k .

Will you need to smog that car?

I will not, no.

Ha! I’m in the process of replacing my 225k 2002 Avalanche Z71 5.3L I bought new in Anchorage 2002, live in Fla now. Drove across US coast to coast 3x moving, on my 3rd 4L60e trans, and 4th rear end & 1 front axle rebuild over the years I’ve owned it, t-case still holding up just fine.

Hope all all goes good for you!!

Ha! I’m in the process of replacing my 225k 2002 Avalanche Z71 5.3L I bought new in Anchorage 2002, live in Fla now. Drove across US coast to coast 3x moving, on my 3rd 4L60e trans, and 4th rear end & 1 front axle rebuild over the years I’ve owned it, t-case still holding up just fine.

Hope all all goes good for you!!

Hot Rod Magazine did an article (many years ago now) called Iron Maiden. 6-Liter iron LQ4 like yours. As I recall, 430 horses with a pretty mild build.

I have a BTR camshaft waiting patiently to be installed in my LS (L33 aluminum 5.3), I selected the Truck Torque cam. Stabbed into an LM7 (iron-block 5.3), it was good for ~390hp/390tq. The L33 has more compression, so the possibility of 400/400 out of 325 cubic inches is there. Should be fun in a 3,000lb truck.