Media | Articles

What Happens When a Supercharger Becomes a 105,000-rpm Grenade

Steve Morris knows his way around V-8 drag race engines, especially those with forced induction. He’s developed his own engine blocks and heads for the fastest drag-and-drive cars in the world. His company’s big-block-Chevy-based engines can produce more than 3,000 hp and survive events like Hot Rod Drag Week and Sick Week that involve hundreds of miles on the road and a dozen passes down the strip. It’s safe to say he’s spent lots of dyno time developing engines for his customers. In his 25-year career as an engine builder, he’s never seen a mechanical failure as bad as the one he just had. The video he posted to YouTube highlights the carnage.

Steve and his customer, former NBA first-round draft pick and FIBA gold medalist Tom Hammonds, have been working on an LS-based engine to take on the NMCA Xtreme Street class. After his NBA career, Hammonds made a name for himself as an NRHA Pro Stock driver before moving to his current car, a beautiful 1969 Camaro with a Jerry Bickel chassis powered by an 8,000-rpm, 6.0L LS V-8. His car runs more than 150 mph in the eighth mile, which requires a delicate balance due to the class’s small tires.

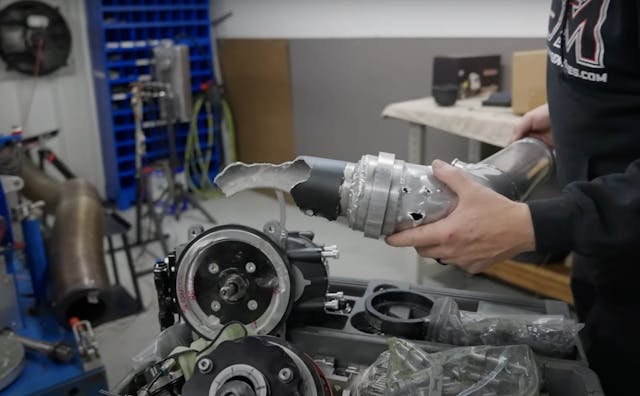

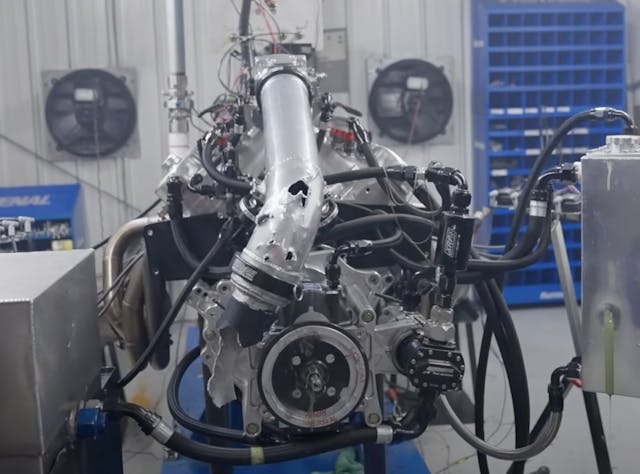

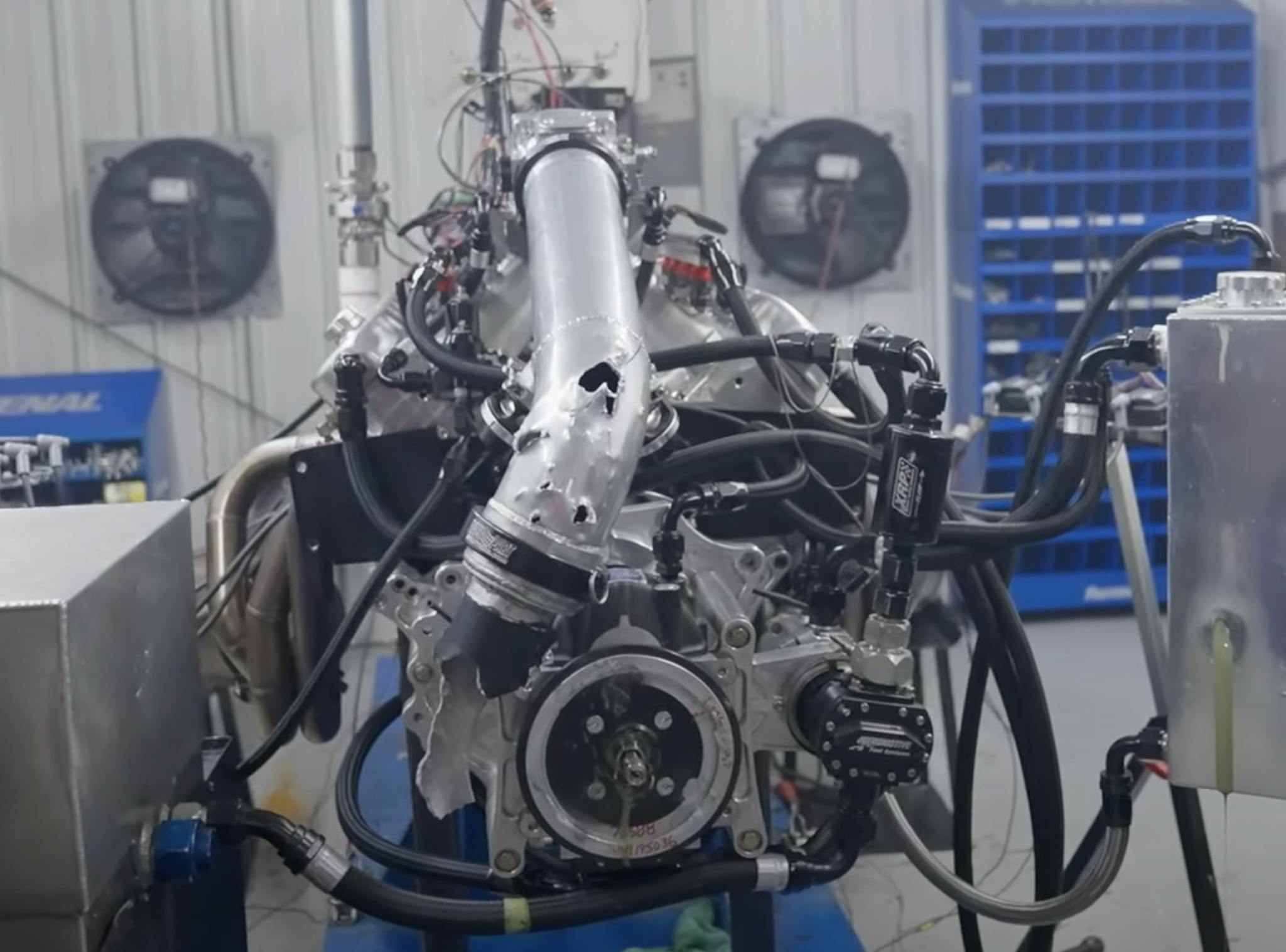

Morris and Hammonds were at the dyno console testing the nearly 2,000hp engine when a mechanical failure caused its centrifugal supercharger to explode and send bits of cast and billet aluminum flying through the dyno room. A chunk of the centrifugal supercharger flew almost straight forward and blew through the polycarbonate window, heading right between Morris and Hammonds, neither of whom was seriously harmed during the violent event.

We think of aluminum as a light material, but only because of its strength compared to heavier metals. In truth, it’s denser than concrete. Imagine the energy behind those sharp pieces of aluminum shrapnel, and you quickly understand why engine builders clear the room when dyno testing powerful engines to their limit.

The aluminum pierced the drywall, the engine’s fabricated aluminum intake tube, and the dyno’s oil and fuel tanks. Aside from the piece that flew between Morris and Hammonds, other chunks flew straight through the ceiling and the door to the dyno room. It wasn’t just the engine, the dyno machinery itself took a lot of damage.

Marketplace

Buy and sell classics with confidence

Morris tried to uncover the cause of the destruction, which seems to have stemmed from the engine shearing the flywheel bolts. The engine, running at full-throttle and suddenly finding itself with no load holding it back, immediately revved to 11,800 rpm. That led to the supercharger, rated to run at a max rpm of 65,000rpm, to exceed 105,000 rpm. It’s no wonder the thing came apart.

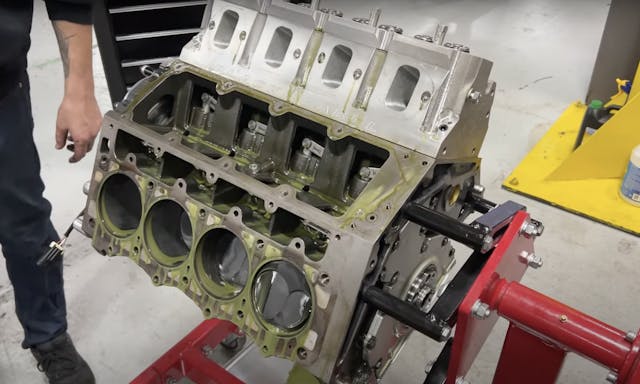

The engine teardown showed that the valvetrain remained intact, with the rockers where they’re supposed to be. Unfortunately, there were pieces of supercharger where they definitely weren’t supposed to be, including inside the intake ports and the cylinders. It appears that the block and heads will survive to race another day, but plenty of parts will need to be replaced just to be safe.

We’re sure Morris and his team will have his dyno up and running again shortly, and Hammonds will soon be back with an angry LS V-8 that churns out nearly 2,000 hp. This video reminds us that it’s not easy to run on the bleeding edge of performance and that horsepower can turn ugly when it escapes in sudden and violent ways. Stay safe out there.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters

It’s understandable it did what it did, however I’m surprised it wasn’t designed to contain the failure. In the turbocharger world they are purposely designed and tested to failure to make sure the housing contains the compressor or turbine wheel when it explodes.

Sorry, but this isn’t consistently true.

I’ve personally seen compressor impeller blade shrapnel in the intake of engines.

If it weren’t running on methanol, it would’ve had an intercooler to contain all the shrapnel.

This could almost as easily have been a tragic disaster. I’ll bet that window gets an upgrade to something ballistic.

Would have been cool to see a closer video of the explosion. Glad no one got hurt.

Thicker Lexan for the window, and cover the inside of that wall with a layer or two of 3/4″ plywood just to be safe.

It’s amazing that all of the ceiling lights survived.

Bullet-proof glass for the window. Starts at $50 a square foot. While the idea of plywood under the sheet rock is a good one, steel plates might a better one.

Wow!! Gotta tell ya, nothing blows up quite as nicely as a Chevy LS.