Media | Articles

Peek under the skin of a Spec Trophy Truck and discover off-road ingenuity

When I traveled to Baja California to tag along with the Polvoorde Racing Team and see my first-ever Baja 1000, I was overwhelmed by the sights and sounds of the race. There was so much to take in: the history, the wide variety of classes, the sheer warfare that is racing across more than 1200 miles of punishing desert … It was too much to grasp in the few days surrounding the race, so Christopher Polvoorde, driver of the Optima Batteries/Steel-It/Ford Racing Spec Trophy Truck, invited me to his team’s shop, where I got to see the truck with all of the body removed and many of its trick components on display.

Here are some of the interesting tidbits that I found most interesting and that you might use to inspire a future off-road build.

The foundation

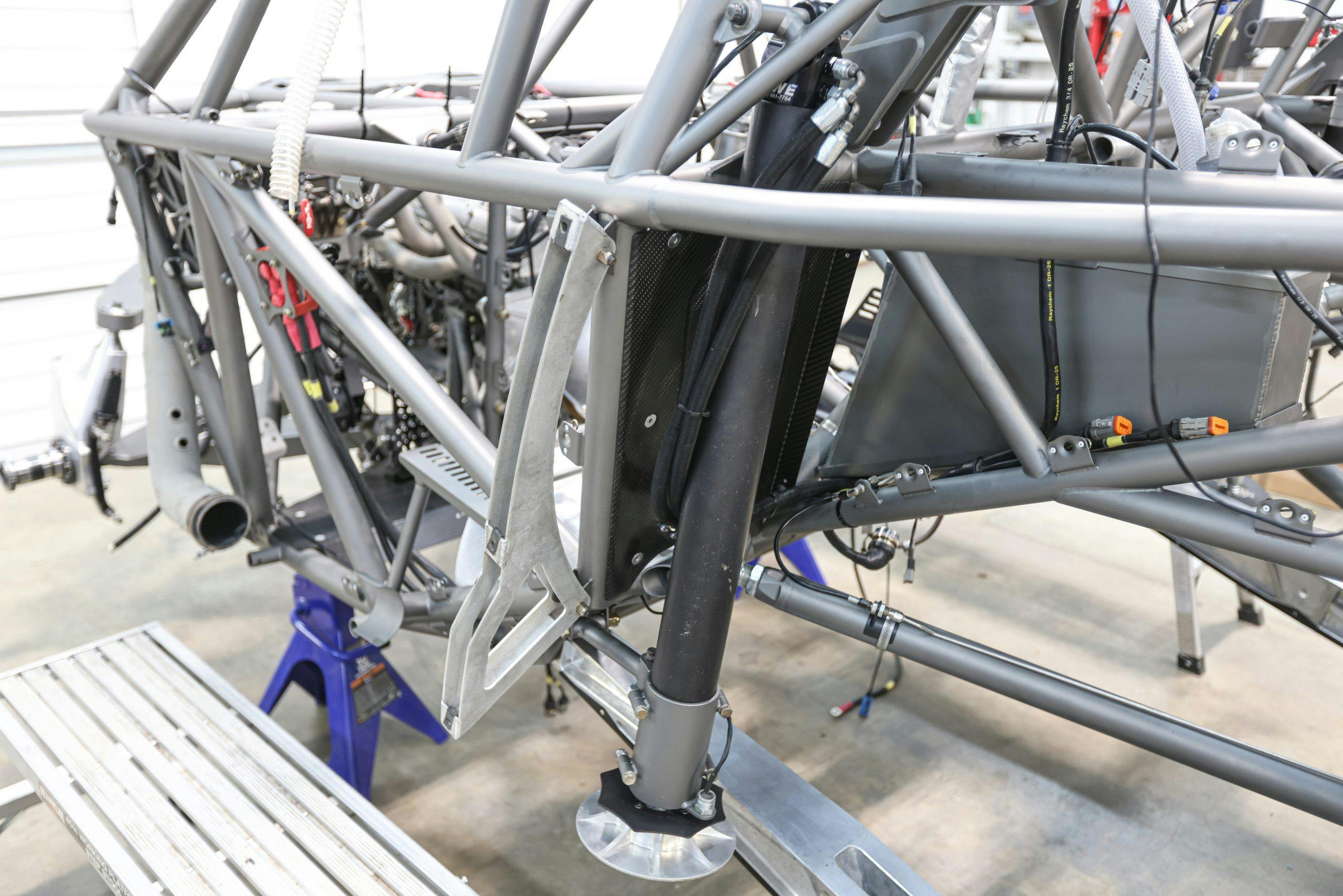

The chassis of Christopher’s truck was built by Mason Motorsports in Lake Elsinore, California, one of the nation’s premier builders of Trophy Trucks that typically sells turn-key vehicles. For this build, the Poolvorde Racing team wanted to be more involved, so they got a nearly completed truck to which they added some custom flourishes. Aside from the engines and transmission, which are specified by SCORE, Spec Trophy Trucks are just like their Trophy Truck brethren, so while they’re not as powerful, they are in a very competitive class and their suspensions are still at the bleeding edge of technology, just like that of all-out Trophy Trucks.

As per class rules, the driver compartment is made from 2-inch DOM tubing and the forward and aft sections are made from 1-and-3/4-inch tubing. Because the design uses a wall thickness of one-eighth inches, the joint between the various sections is neat and clean. The welds throughout the chassis are gorgeous and flawless.

The suspension, which is a Mason Motorsports proprietary design, features 24 inches of travel in the front and 29 in the rear. The front suspension uses long control arms that are mounted near the center of the chassis. The longer arms allow for a longer arc of travel, which means the wheels and tires don’t tuck in as much when they reach the bottom of their travel. That attitude helps keep the vehicle stable at high speeds.

Marketplace

Buy and sell classics with confidence

Driver comfort

The Baja Peninsula can cook up a hot, dusty racing environment, and a comfortable driver is much more effective than one who is fatigued. To keep drivers hydrated, Polvoorde Racing has installed insulated water reservoirs that feed through the same quick-connect fittings that pump the helmets with filtered, air-conditioned air. The electrically powered air-conditioning units are mounted at the top rear of the cab. When the driver needs a drink, a press of a button on the steering wheel activates a repurposed windshield-washer pump—Christopher’s crew chief swears it wasn’t plucked from a junkyard—to deliver a sip.

Navigation and instruments

During the 27 hours it took to complete the Baja 1000, Christopher shared driving duties with Dale Ebberts and Steven Eugenio. Their codrivers helped navigate from the passenger seat with help from a larger version of the Lowrance navigation system mounted on the driver’s side. The codriver gets their own MoTec dash to monitor engine vitals. Christopher also uses an iPad that prompts him with detailed notes taken during a pre-run of the course and gives him prompts for turns 15 seconds before he gets there. The truck has antennae for the two Lowrance units, a push-to-talk satellite phone, and a GPS for the iPad.

Seriously strong parts

The constant whoops and jumps of Baja mean that the rear tires go from free-wheeling in the air to grabbing traction, one of the worst-case scenarios for driveline and suspension parts. To keep everything under power, sturdy pieces are used throughout the build.

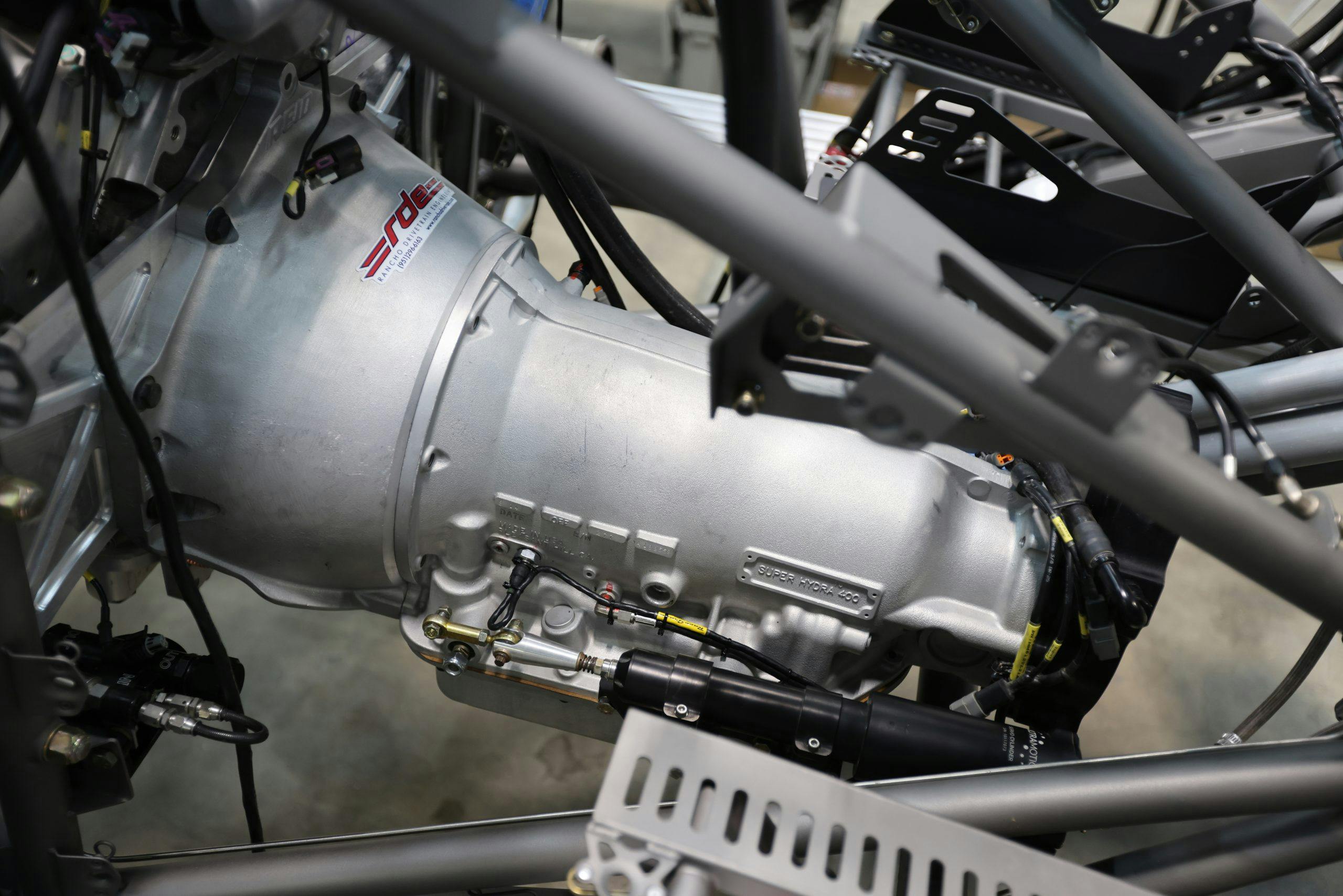

The front suspension uses a billet knuckle with Uniballs to handle the extreme range of travel. The rear suspension uses a billet-aluminum control arm with steel skidplates. The Spec Trophy Class mandates a Turbo 400 transmission, which has a well-earned reputation for dependability, but even then, parts and assembly factor into the gearbox’s performance. Polvoorde Racing relies on a transmission built by Rancho Drivetrain Engineering. Because of the tall tires, a steep final-drive gear ratio would be necessary. That would mean a small pinion gear—a potential weak spot.

Instead, Christopher’s truck uses an underdrive gear at the back of the transmission. The four gears are a lot like those in a quick-change rear axle, since their ratios can be changed quickly. The rear axle has large gussets and a carbon-fiber-reinforced third-member. It’s patterned after a Ford 9-inch, but the ring gear actually measures 10 inches. The rear 300M axles measure 2 and 1/16 inches in diameter and are gun-drilled. We placed a dollar bill and a Sharpie next to it for scale—have a look.

Sharing the load, redundancy, and spares

Even with tough parts and excellent planning, things break. The Polvoorde Racing team builds redundancies into the truck and looks for way to make swapping parts on the side of the racecourse as easy as possible.

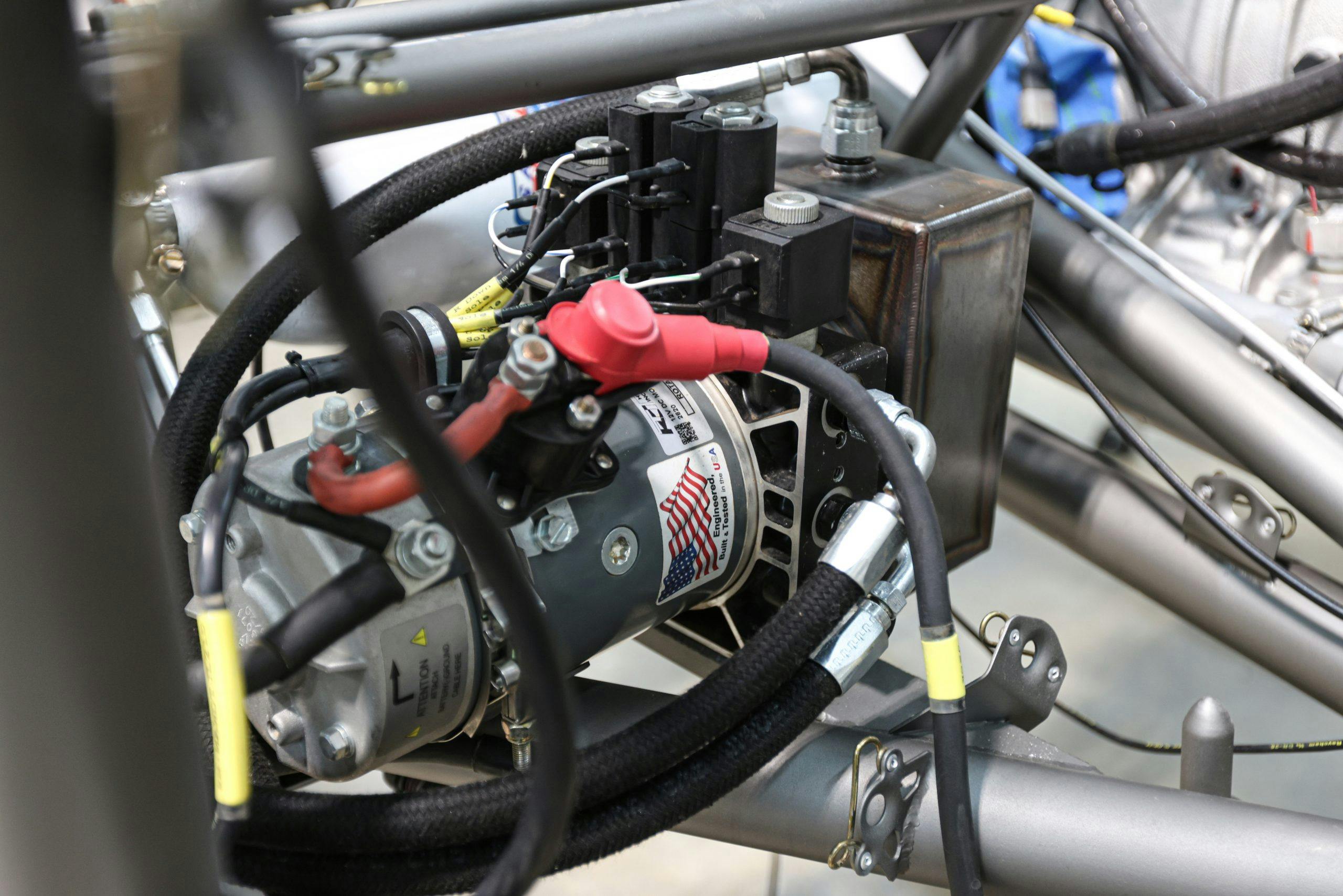

Take the hydraulic lifts as an example. The lifts on some trucks are powered by the power-steering pump, but it’s guaranteed that you’ll need to lift the truck to change tires during the race, and failed power steering means you’ll be sidelined. Instead of stressing the power-steering pump, Polvoorde Racing chose a separate hydraulic pump for the twin rams that will lift each side of the truck for tire changes. If the rams or the pump fail, there are jacks on the pit trucks. If either component fails when the truck is between pits, there’s a scissor jack mounted to the truck. There’s even a spare breaker bar socket-pinned and safety-wired to the chassis, right next to some duct tape wrapped around a chassis tube.

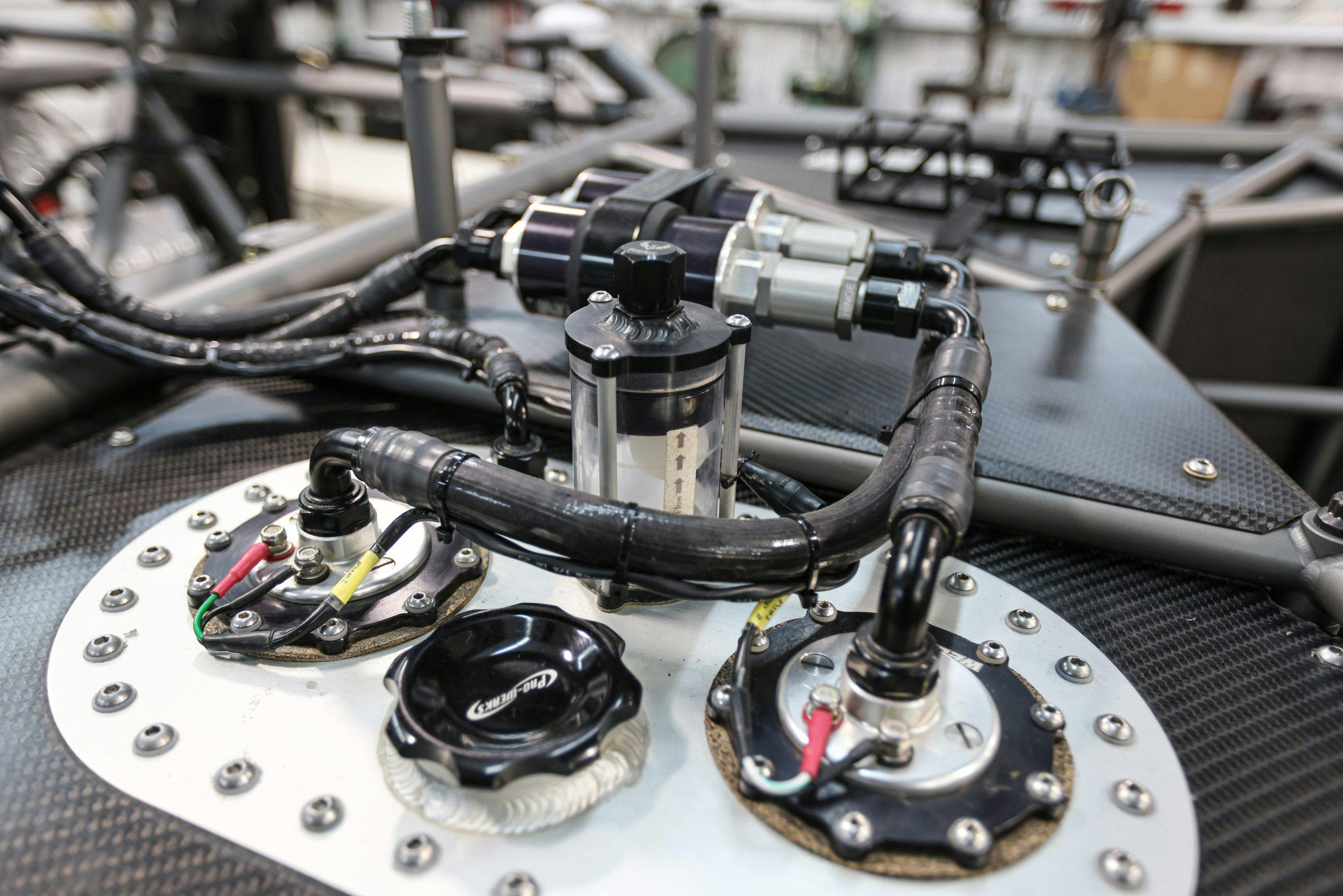

Other redundancies include fuel fillers on either side of the truck for pitting on either side of the track, dual in-tank fuel pumps, and a spare driveline tucked up under the truck, an easy reach from where you’d be if you were fixing a broken driveshaft.

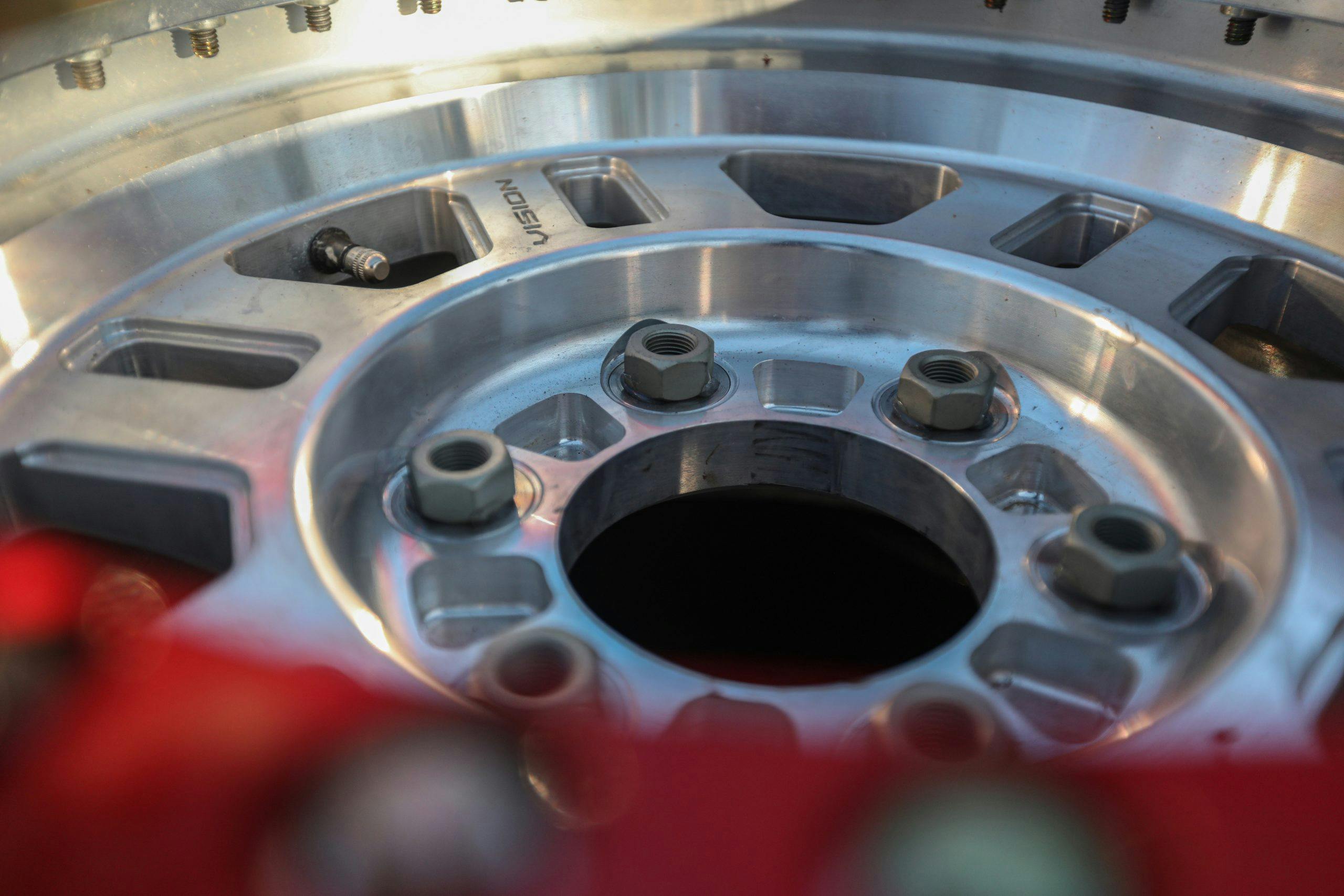

We also noted that the spares mounted in the rear of the truck have lug nuts glued in place, NASCAR-style, for quick tire changes. Also facilitating the swap are rollers mounted on the tire mounts to help wrangle the wheel/tire assembly into place. That’s got to be really helpful when you’re trying to locate more than 125 pounds of tire and wheel. Extra lug nuts are mounted to a stud that’s hose-clamped to the chassis.

Finally, you can’t expect to finish a 1200-mile race without needing some zip ties, so you might as well make them accessible. The bracket for mounting spare bottles of fluid is also worth noting.

There’s much more to explore on this truck, and hopefully, we’ll get to see more of it when Christopher and the rest of the Polvoorde Racing team campaign it across the desert southwest and into Mexico in 2022.

Hi Guys, Steven from Rugged Routes here. I really like the way you guys are fittinghte lowrance units in there. However, I think you can make even better use of those screen with a few integrations that I’m working on including but not limited to engine and transmission data.

Reach out if you want to have a chat.