Media | Articles

I breathed life anew into my 1970 MGB thanks to hard work—and rattle cans

I first saw this MG in The Washington Post classifieds, for $750. My parents took me to meet the owner at a Howard Johnson’s in Arlington, Virginia, and I (or, more precisely, my mom) ended up driving it home.

Through two years of high school and then to college, this was my regular car. I would drive it home and back to Clemson—about 12 hours round trip—for the holidays. When I graduated, though, I started not to use it as much. Career. Life. Eventually, the car was placed in a storage unit in southern Delaware. It sat there for close to 20 years.

I got married nine years ago, and our house had a three-car garage. My wife encouraged me to bring the MG back to New Jersey to get it on the road again. I rented a trailer and got the MG. I had this desire to bring it back to life again; I felt guilty that I had pushed it away.

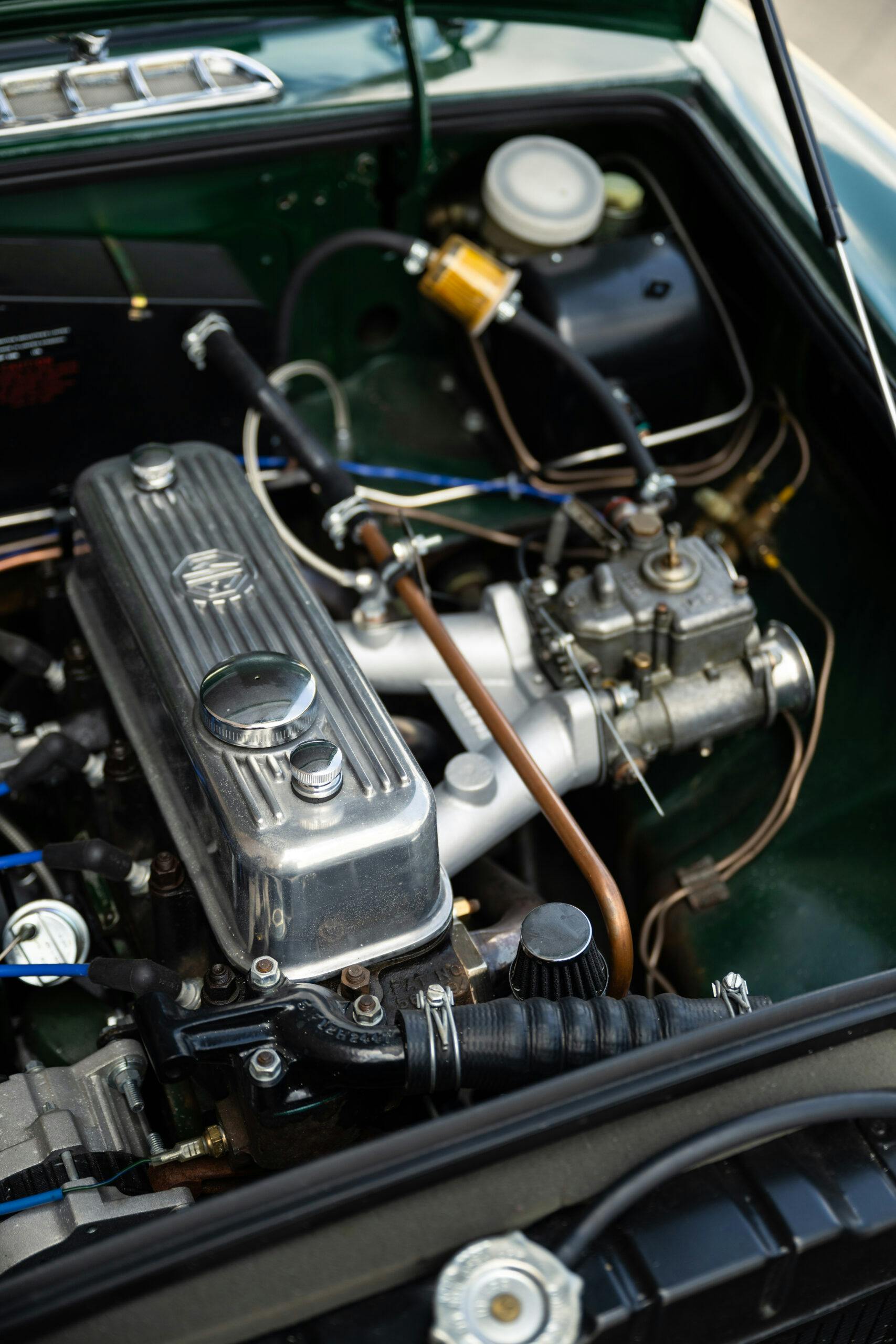

I started slow—small jobs like restoring the steering wheel—but particularly during the early days of the pandemic, I dived deeper. Over time, I replaced everything in the car except the block, the head, and the suspension. After almost two years, the car drove down the street, but the instruments didn’t work. We discovered rain had come through the windscreen seal and had rusted the gauges. A previous owner had chopped up the wiring harness, so now I needed a new electrical harness. I removed the seats to get better access under the dash. I knew I was in trouble when the first fastener I pulled out was a machine screw. I rolled back the carpet, and, lo and behold, I could see the garage floor.

Marketplace

Buy and sell classics with confidence

Then, last year, I got Covid. It caused me to suffer a stroke. I was very fortunate to make it through, knowing that so many people had suffered worse than me during the pandemic. Fortunately, finishing the car became part of my therapy—literally. I would video myself moving nuts and bolts, grinding the floor joints, then I’d show it to my physical therapist. She would say, “Get on your knees,” or “Straighten your back.”

Since I’d gone so far as to redo the floor, I figured I might as well upholster it in style. I was obsessed with green carpet—found in early Jaguars. I found a little shop in England that made green wool carpet for MGBs. When the exchange rate hit $1.08 per pound sterling last year in August, I pulled the trigger.

Obviously, this project had snowballed. My idea at first had been simply to get it running. That morphed into redoing the wiring, then replacing the interior. So… why not paint, too? We started with just a few rattle cans for the front clip, which had a ton of rock chips. That looked so good that, well, we decided to do the whole car. Forty-four cans later (20 base coat and 24 clear coat), it turned out amazing. (Check out the end of the article for more detail on the process.)

It might sound as if I did this whole thing myself, but it’s not like that at all. I never could have gotten this far without the car community. First and foremost is Nick O’Donohoe. I had purchased a few parts from him at an MG show, unaware that he is the son of a British Leyland parts director. Lucky for me, he passed down all of his knowledge to Nick! Nick became interested in the fact that I wanted to do the work myself and helped me with some tougher bits, like welding. He also has a wholesale account with Moss Motors, to serve his business, British Car Company of Wayne, New Jersey.

Most important, though, he held me accountable. “Did you get that done? Can I come tomorrow?” He was like a teacher whom I didn’t want to let down. After I got Covid, when I really needed in my own head to see progress on the car, Nick would bring over three or four members of the Eastern New York MGA Club and spend a Saturday on the car. This gentleman spent countless hours helping me—and he refuses to take money.

There were others. Tim McNair, of GP Concours, the preparation specialist, told me exactly how to polish my paint. Sandra McPhillips at the upholstery shop in the U.K., PJM Motors, where I ordered my carpets, was super nice and helpful. And of course, my wife, Karen, who supported the project from start to finish and who works in automotive PR. After I had my stroke, she put the word out through the local Motor Press Guild to stop by our home and help me work on my car. And then there are the people I’ve never actually met but who were indispensable nonetheless: commenters on the MG Experience online forum and YouTubers.

So now the car is just about done, although it does still need a new front suspension, and the rear shocks are probably kind of on their last legs.

There’s always something else, right?

***

I really painted the whole car with rattle cans

The process is dead simple: prime, paint, and clear. The devil is in the details. For the base coat, don’t just grab a color off the shelf, especially if you’re planning to paint only a section (as I originally planned to). Instead, go to a paint-and-body supply shop and have them custom-mix an exact match to your car. They’ll also have the clear coat you need, the kind with hardener (aka 2K clear). It’ll give you a glassy finish. (Note the hardener produces some nasty vapors, so wear a mask.)

To make it shine like a “real” paint job—and remove debris that falls onto the surface as the paint dries—you’re in for a lot of wet sanding, with progressively finer grit: 3000, 4000, 5000. (I used an inexpensive dual-action sander from Harbor Freight.) Think you’re ready for polish? Nope. Sand more. A paint-thickness gauge can keep you from sanding through. Allow the finish to cure in the sun before polishing out the final swirls.

I learned the hard way not to cheap out on primer—it had a reaction with the base coat. Spraying even strokes takes practice. And the final result, admittedly, isn’t concours-ready. If you want that, pay a pro. But for a car painted outside with rattle cans? You won’t believe how good it can look.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Good story, good job, underscoring that it’s the quality of people that’s often the real boon to our years, decades with old cars. Congratulations.

Hats off. A really great story. Yes, you had some amazing help, but it was you and your wife that started the project, and you that persisted. A true up-lifter.