Media | Articles

Wrenchin’ Wednesday: Simple air-powered fluid pump for nasty diff oil

Everyone who’s ever serviced their differential knows how much of a joy it is to work with gear oil. It’s pleasant smelling, easy to clean and … who am I kidding? This stuff is among the worst mechanical substances ever. When cold, it’s like a gelatinous skunk spray. Even worse, differentials are filled from the side through tiny plugs and, since the whole apparatus is tucked up into the chassis, the opportunities for spillage are plentiful. Today, we’re going to break down the principal behind another cleaning tool and create our own air-powered fluid pump using the bottle in which the diff fluid originally came.

You could easily replicate this with any jar or container that has a sufficiently large lid, but stay away from anything made of glass. Metal and plastic containers are ideal. Even a thin-walled two-liter bottle can hold around 150 psi safely (they’re often used in hobby planes and rockets as flyweight air tanks), so the thick plastic sides of the diff fluid jug will be just fine.

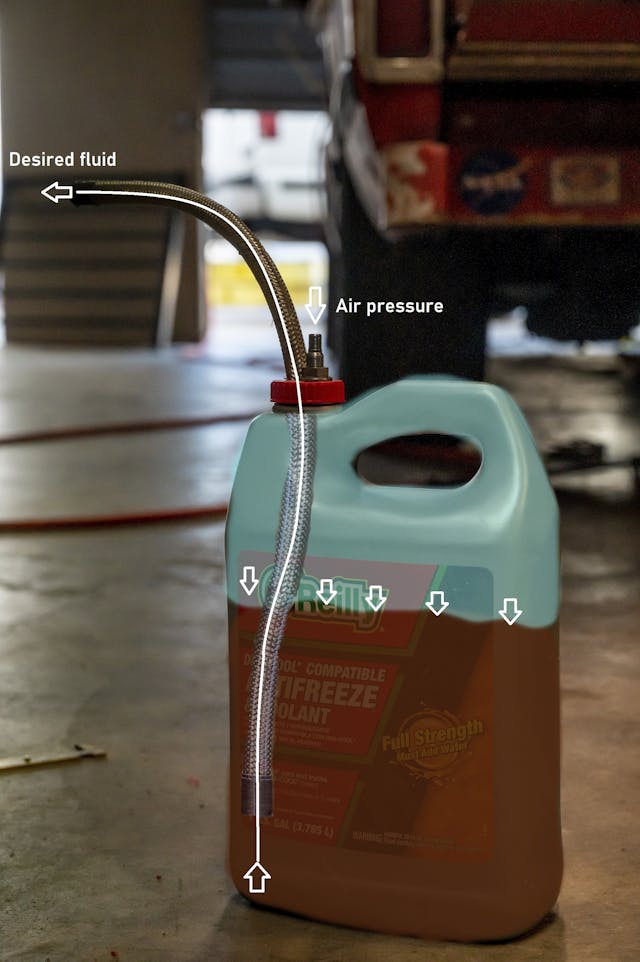

Real simple: Drill two holds in the cap. One for an air fitting, the other for the hose that will feed fluid into the diff. I used a bolt-in valve stem because it made the act of securing and sealing the fitting easy, even if the hole had to be elongated to get the best final fit. A standard rubber stem works fine, too. Alternatively, you can simply drill a hole against which an air chuck can seal. The advantage of a valve stem is that its orifice is small enough to slow down the rate at which air is sent inside the container, thus keeping flow very well controlled. With an air chuck, you’ll just need to practice trigger discipline.

The hose here is simply wrapped in duct tape where it passes through the bottle. The tape acts like a grommet, but a perfect seal isn’t 100 percent necessary. If the cap isn’t wide enough for both holes (if you’re using a quart bottle, for example), you can also simply drill a hole in the side of the container as close to the neck as possible for your air supply. Then, just seal your output hose to the open container with duct tape. As long as the air enters above the fluid, and the hose’s pick-up is at the bottom of the fluid, you’ll get the desired results. Just make sure the hose is long enough to tap the bottom of the container and still reach the diff.

We’re essentially recreating a solvent sprayer, using compressed air so that the fluid is forced to exit through the hose into ambient air as it’s displaced. This is dirt cheap, and you can build it in less than 10 minutes.

Marketplace

Buy and sell classics with confidence