Media | Articles

Wrenchin’ Wednesday: Quick and cheap heat shields

Heat is thy enemy.

It really doesn’t matter what you’re looking to improve in your project—from performance to comfort, heat management is one of those unspoken secret sauces to building a bulletproof machine. As a byproduct of energy production, be it from dead dinosaurs or buzzing electrons, heat is inescapable. While there’s a bunch of aftermarket solutions to keeping heat where it’s supposed to be, sometimes you just need to protect just a tiny, weird little thing on your project for which no one builds a heat shield. Hell, even when they do, why spend the money?

Today’s Wrenchin’ Wednesday is all about knocking out a cheap and effective heat shield that attaches with hose clamps and requires no special tools to form. I’ve built these for all sorts of components—notably, to protect starters from burning up next to headers—but this particular heat shield will protect my A/C system’s accumulator from the heat of my 1996 Suburban’s downpipe. Plus, the new HX35W didn’t fit the original heat shield for the downpipe, so I needed to fabricate something to help prevent the A/C system from overheating as EGTs rise over hill climbs and in Arizona’s 120-degree summers.

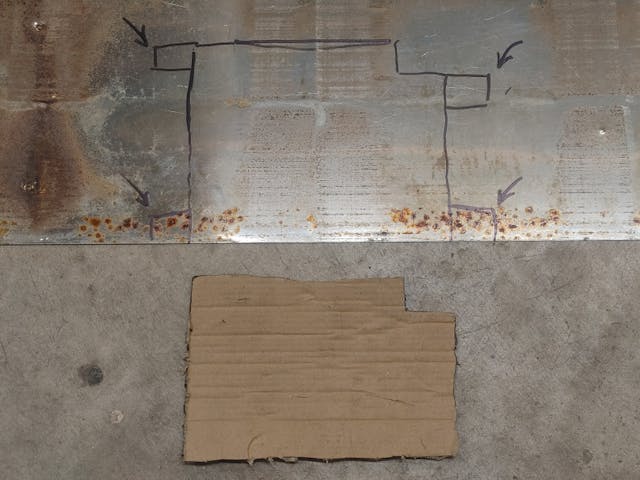

Starting with a little CAD, a simple template was cut out of cardboard before transferring the shape to a roll of sheet metal. Steel or aluminum both serve fine; you just need it to be thin enough to easily form and manipulate.

What we’re going to do for attachment is create a set of tabs that will wrap around a hose clamp. So, while mocking up your CAD template, take note of where the tabs will need to be to properly situate the heat shield on your part.

Marketplace

Buy and sell classics with confidence

The fresh-cut heat shield had its edges cleaned up with a flap-wheel before I shaped it to the accumulator’s profile and flipped the tabs over. I used a little piece of sheetmetal like a ruler to get a clean edge in the bend, but you’ll want there to be a small gap—a few millimeters—between the tab and the rest of the heat shield through which the hose clamps can fit. This will also build up the all-important air gap created behind the heat shield, which creates the insulating barrier in combination with the metal absorbing or reflecting heat energy away itself.

With the hose clamps surrounding the accumulator with modest pressure, the tabs keep the heat shield locked and centered between them. And there’s no reason to drill into the component you hope to protect, so parts warranties and durability won’t be affected by newly-created bolt holes or attempts at welding.

Looking to stay cool? Well, now you know.