Media | Articles

Wrenchin’ Wednesday: Opening oil filters on the cheap

Most installments of Wrenchin’ Wednesday share trick tips that don’t require trick tools, and today’s is no different. We’ll be looking at how you can inspect the inside of an oil filter without resorting to a $50–$100 cutting tool.

Why would you want to peek inside an oil filter’s can? It’s a quick way to evaluate the health of an engine’s rotating assembly. Worn-out bearings and damaged components will eventually find their way into the oil pan before getting sucked up by the oil pump and passed through the oil filter. Examining an oil filter is a handy habit for regular oil changes, but it’s also a common process used to diagnose mechanical noises; rod knock and other damaged components will often leave warning signs in the filter medium well before catastrophic failure.

Instead of buying a glorified pipe cutter, finesse filters open with a beer can and a cut-off wheel. The idea is to use the can, or any other solid object, to set the height of the cutting wheel so that the blade can skim along the base of the filter. For this particular filter, GM’s do-it-all unit for classic blocks (small- and big-block, Detroit diesel, etc.), the beer can worked perfectly, but if you can’t find something that works, the lifting pad of a floor jack works just as well when locked into the height you need.

The secret sauce here is light pressure: Let the cutting wheel skim across the oil filter as you rotate it by hand several times. Sparking off the filter should be minimal; if you use too much force and create a shower of sparks, you risk filling the filter with cutting debris and contaminating your inspection.

Marketplace

Buy and sell classics with confidence

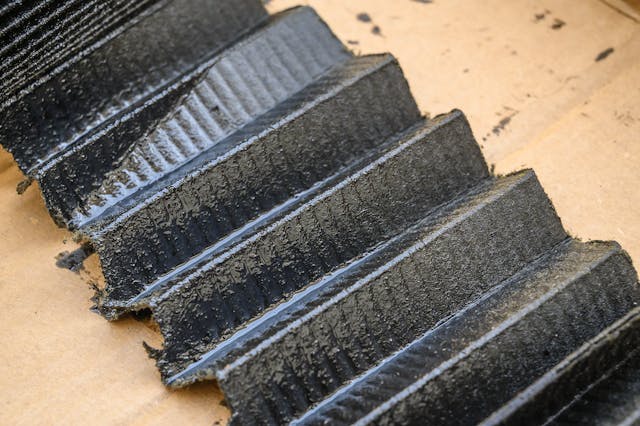

Once you’ve split the oil filter’s case, you can remove the filter cartridge and cut along its edges to free the pleats. This will get messy, especially if the filter has been used recently, so cardboard and gloves are ideal.

With the filter medium removed from the cartridge, you can pull it apart and look for metallic glitter and other missing pieces from the engine. The dreaded shimmer, caused by either copper- or silver-colored particles, points to bearing failure. Small chunks of aluminum are often broken chunks of pistons. More impressive finds include pieces of needle bearings from failed roller rockers and sloppy overflow from RTVing parts. Either way, an oil filter is a litmus test for the mechanical health of an engine. Now you know how to read the petroleum tea leaves.

Find anything real odd in an oil filter before? Tell us in the comments.