Media | Articles

Wrenchin’ Wednesday: Clean-cutting hole saw for silicone couplers

Dear OSHA: I am sorry.

In a previous installment, I had to wrap up a HX35W swap in my 1996 Chevrolet Suburban K2500 by connecting the new turbocharger to the rest of the intake system. The factory air box has been great for keeping the filter safe from water and sand, but to keep it, it took a little hunting to find the right selection of couples that could route between the compressor housing and battery. To add to the subtle complexities, the PCV system needed to be ported into the intake too, where it could take advantage of the drop in pressure created by the turbo inlet to pull crankcase fumes out of the block.

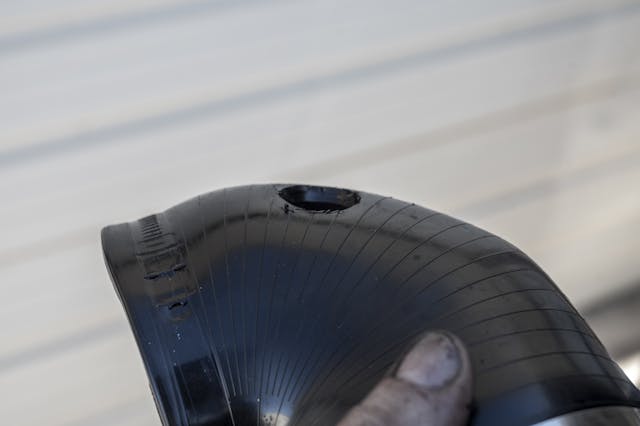

Cutting silicone couplings can be tricky, as the soft and gummy material is often just ripped open by hole saws, and many couplers have an inner weave of fibers to help reinforce them, which can also fray. Today’s Wrenchin’ Wednesday will introduce a method to get clean cuts through silicone that creates little to no mess.

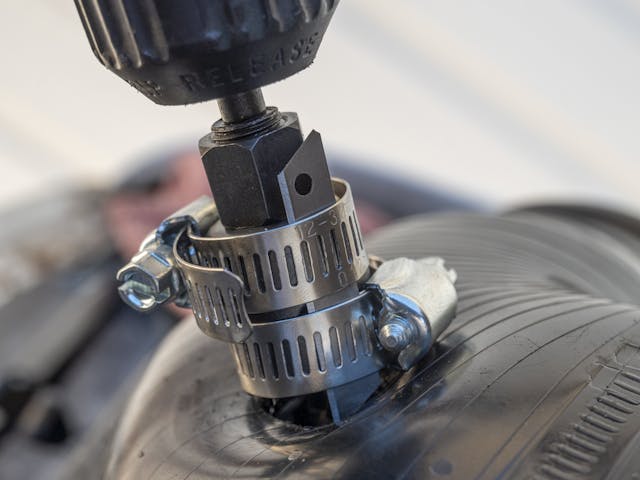

Start off by grabbing a utility blade and breaking off a piece that’s long enough to be held by a pair of hose clamps while still protruding enough to cut through the silicone. A piece that was a bit over an inch worked well enough for me. Then, while wearing gloves, I attached the blade to the hole saw to give it a fixture.

A pilot hole can be drilled with a separate bit, or the centered bit in the donor hole saw. This must be done before the utility blade begins its cut or it’ll just dig in and walk the hole saw across the part. The trick here is to have the drill bit in the hole saw already in the pilot hole with utility blade cutting at a slow RPM, as if you were dragging the blade by hand in a tiny circle. Let the blade do the work, you shouldn’t need to give it a lot of pressure. If the coupling still wants to collapse, back it with a piece of wood—don’t hand-hold this!

Marketplace

Buy and sell classics with confidence

Once through, you get a small disc in the drill bit, leaving behind a cleanly-cut void behind it. With the low cutting speed, the coupler isn’t melted away, and the single-point cutting action created by the utility blade keeps shaving at bay. Like all drilling and cutting tools, use the appropriate safety equipment and precautions. Always consider where the tool is going to jump in an accident, or where it’s going to end up after the job is finished.