Media | Articles

What I learned from testing the limits of an “idiot-proof” design

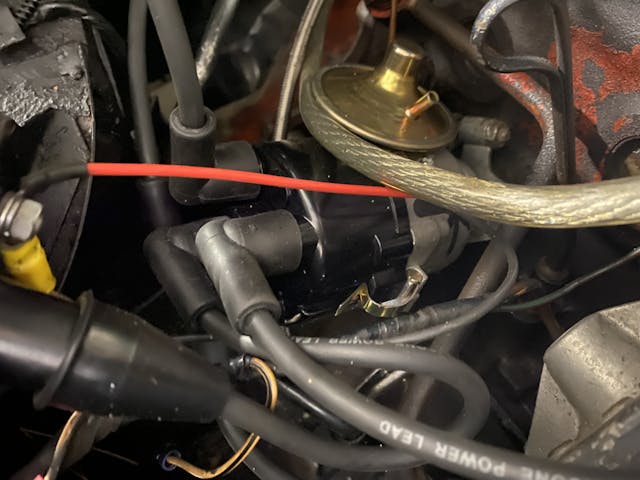

After my Austin-Healey’s BMC A-series engine had left me stranded two times in as many weeks, I discovered that the points were more charred than a well-done steak at Golden Corral. So I sat down and ordered some parts and prepared myself for the task of playing with the ignition timing. That meant reading every manual I could find—I even dove into YouTube and absorbed everything I could regarding how to properly set up a new distributor.

I know what you are thinking, dear reader: Why is he replacing the entire distributor when all he needs is a set of points? Also, didn’t Rob Siegel talk about this like two weeks ago? You are correct on both fronts, but hear me out. This article isn’t an explanation of my choice to upgrade to an electronic distributor, or the exact how and why of the install. No, these are my thoughts about a word I used to describe the design of the BMC A-series distributor drive—“idiot-proof”—and how it came back to bite me.

Ignition timing was something I remained intimidated by for years after I began to play with vintage cars. Having seen the results of incorrect timing, and without a firm grasp of ignition system intricacies, I left well enough alone on my first few cars. I’ve now grown to understand what is going on inside a distributor cap, and that is why, for my little Healey, I chose to ditch the points ignition system in favor of a Pertronix setup. My goal for this car is to have a fun little roadster, one whose keys I can toss the keys to anyone I know and tell them to go have fun with it for a weekend, or month, without any worry.

Here is the part of the story where I got in trouble. I looked at the distributor drive on the Healey’s engine and said to myself, “Wow, this is pretty much idiot-proof. You can’t screw it up.” There must have been a conflict between the two sides of my brain that day: One side was remarking how easy this was, and the other was actively sabotaging me.

You can’t put the distributor in wrong; that much is true. What you can do wrong, though, is mark where the number one cylinder plug wire should be. With the engine on the workbench, I got lazy when determining top dead center for the front cylinder. Instead of carefully checking and double-checking, I hand-rotated the engine until a soft copper wire I put down the spark plug hole showed the piston to be at the top of its travel, then marked which direction the distributor’s rotor was pointing and did the swap.

Marketplace

Buy and sell classics with confidence

My error was two-fold. First, I had already disconnected and removed the plug wires. If those were still installed as a reference, it would have been clear I was on the exhaust stroke, since the rotor would have been pointing at the wrong terminal on the dizzy cap. Second, since I had the spark plugs out, I could have taken the extra step to pull the rocker cover to confirm both the intake and exhaust valves were closed as the piston traveled up in the cylinder, confirming compression not exhaust.

Instead, I relied on my feeling of You Can’t Screw This Up. In the process, I proved that, while engineers spend hours laboring over drafting tables in pursuit of an idiot-proof design, we—the idiots in our garages—continue to find new ways to be idiots. I can safely predict that this battle will never end.

Ironically, though a simpler design may be more intuitive, it often leaves more room for error. Take the process for adjusting hydraulic lifters, for example. Modern cars no longer have a specification or measurement that the mechanic can reference when adjusting the lifters. Most assemblies are “just tighten the bolt” affairs: Once the rocker is torqued down, the lifter will be preloaded with the precise amount needed. The trouble here is that system still leaves room for some inventive character to misassemble or improperly tighten it. (With this new configuration, we’ve also lost the ability to adjust for wear or tune based on real-world conditions.) Even the “improved” system can still be assembled with errors.

There will likely never be a fully idiot-proof car, so we enthusiasts must try to slow the arms race between the idiots and the designers. Let your shop manual be your guide as you dive into a project, and allow experience to guide you when those shop manuals leave you scratching your head in confusion. Accept that one day you will be the idiot that manages to defeat the idiot-proof design. It happens to all of us.