Media | Articles

Webb Motorworks is building an all-electric small-block “Chevy”

Canada’s Webb Motorsports has built a unique hybrid: an electric motor the size of a torpedo keg, in the shape of a Chevy small-block. The trick part about Webb’s design is how it looks like a typical mouse motor from the outside, complete with stock Chevrolet bell housing and Chevy motor mounts. Beneath that veneer, however, is a High Performance Electric Vehicle Systems (HPEVS) AC35X2 motor and the pair of controllers needed to throttle it. The project is the brainchild of British Columbia’s Chris Webb. Webb’s “V-8” is currently a one-off prototype, but his goal is to build a kit that drops into most vehicles without major modification.

View this post on Instagram

One of the greatest shifts in automotive modification over the past decade has been the increasing practicality of electric drivelines. But while electric swaps can be hugely appealing, the parts involved can diminish the visual impact of certain vehicles, especially hot rods. There’s just something about a proper tower of power that sets the right attitude—and a cable-laden electric motor rarely carries the same presence.

“If you wanna go electric,” Webb says, “you’re ruining the look of your engine compartment.”

After a conversation with his daughter, Emily, Webb landed on the idea of engineering a traditional V-8 to hold an electric motor. “She had seen a YouTube video on this electric VW van,” he says. “She was all excited. Originally being a gas-engine guy, I thought, That’s kind of corny, whatever, but kinda neat. And then she kept pushing me to do it.”

Marketplace

Buy and sell classics with confidence

The elder Webb had relevant experience—he had recently developed a series of cast-aluminum parts to disguise a small-block Chevy as either a flathead Ford V-8 or V-12. “It really was a natural progression, to use his knowledge from creating shrouds to replicate the flatheads,” Emily says. “It was probably just over a year ago when I had the idea for an electric engine. Shortly after that, it was a no-brainer to build one.”

Webb’s block starts as four main castings that are then welded together. Due to the HPEVS motor’s size, Chris decided to have new parts cast for his project, instead of coring out an original small-block. The block, heads, and intake manifold are all purpose-built, but they share bolt patterns with the stock small-block, allowing front-drive accessories and even standard headers to bolt on. He used the pattern-making skills he’d honed with his flathead conversions to design the castings he needed.

Besides the old-school aesthetics, one big advantage of Chris’ design is its ability to use stock engine-mount and transmission bolt patterns, making it a drop-in solution for countless vehicles. Depending on the cooling system fitted, his motor is capable of over 300 hp and 400 lb-ft, but Chris is configuring his first install, an old family pickup, for a more conservative 126 hp and 257 lb-ft on 96 volts. That might not sound like much, but Chris plans to pair the motor with a four-speed manual, using gearing to take advantage of the available torque. The motor’s dyno curve looks like a quarter-pipe, with peak twist coming in a flat line from zero to 3000 rpm. The battery pack will consist of 30 3.2-volt lithium cells. The motor’s controllers—the electronic devices that pass for an EV’s throttle—will be mounted to a custom water block that ports coolant through a stock-location thermostat and water-pump housing. A faux intake manifold will hide a cooling fan.

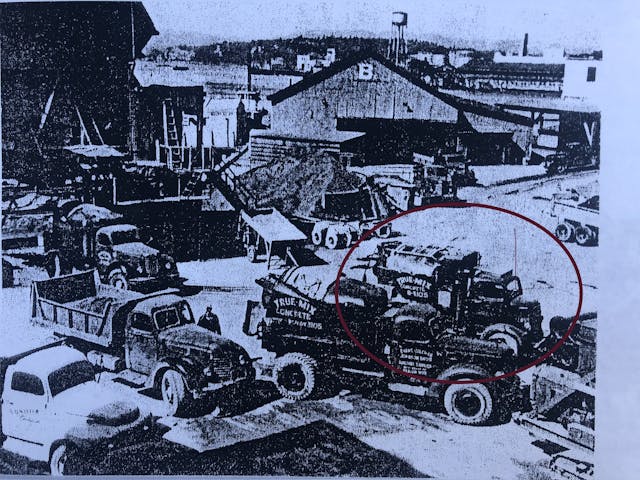

“The Square Truck”

The patinated red Hayes pickup featured in Webb Motorworks’ YouTube series is a family jewel. Chris’ grandfather bought the Hayes as a cement mixer around 1955 and eventually converted it to a general farm truck with a fifth-wheel hitch. Family legend holds that the original Mack truck chassis underneath was built to support the construction of the Hoover Dam before being rebodied with a Hayes cab and sold to Chris’ grandfather. The truck was later put out to pasture, sitting for decades before Chris inherited it at 16.

“I used to play in that truck when I was five or six years old,” he says. “It was in the yard with a bunch of old International trucks, and I’d always go with my cousins and my sisters.”

An auto-shop student, young Chris managed to get the Hayes’ old engine running, and he began driving it. When he founded Webb Motorworks, the truck became testbed for his flathead kits, eventually serving as a kind of rolling billboard. Chris says he plans to continue using the Hayes as testbed for his EV driveline.

If you listened to a certain crowd a few years ago, you might think electric vehicles would be the death of hot-rodding. Thankfully, innovation and curiosity have underpinned the hobby over its long existence, and talented people will always find ways to implement challenging new technology. We suspect we’ll see more “double-takes” like this as EV technology becomes more accessible. If you want to follow along with Webb Motorworks’ progress, check out their YouTube page for a video series on the build.

I’d like to know more on the small block Chevy electric motor housing. Do you have the Chevy flywheel adapter also.