Media | Articles

Understanding Relays, part 4: Let’s not forget the solenoid

I thought after three stories I was done with relays, but I realized that there was the unfinished business of the starter solenoid, which is where this whole relay business started, bad pun aside. Now that you know everything you need to know about relays, the workings of a solenoid (a starter solenoid, in particular) can be framed in the appropriate context.

In the past several installments, I’ve explained that a relay is nothing more than a remote-controlled switch where a little electromagnet (a coil of wire wrapped around an iron core) is used to pull together a pair of switch contacts. Using the DIN standard nomenclature, powering the electromagnet on terminal 86 and grounding it on 85 energizes it, which pulls switch contacts 30 and 87 together, causing current to flow to whatever device is connected to terminal 87.

When an electromagnet is employed in this way, it is fixed. No parts of the electromagnet itself are moving. It is instead used to make something else move, in this case to pull the switch contacts together.

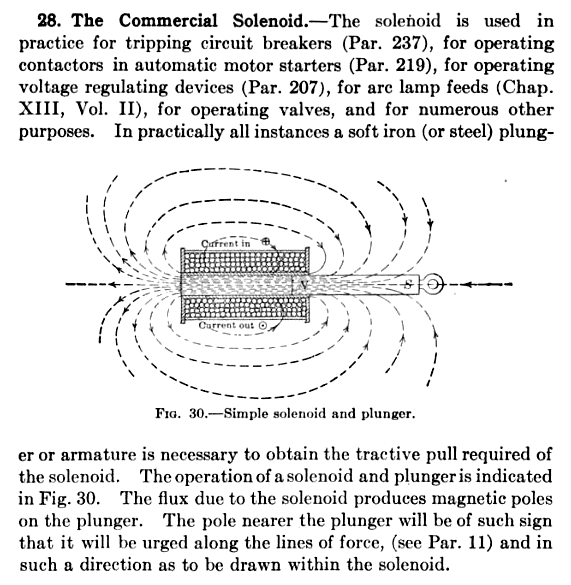

But there is another way that an electromagnet can be used: as a “solenoid,” which is a kind of linear actuator. If the iron core in the middle of the coil of wire—instead of being fixed in place—is free to move back and forth through the coil, the principle of linear induction will cause the iron core to be pulled through the coil when voltage is applied to the coil and current flows through it. In this configuration, the iron core is a plunger with one end protruding, and an internal spring is typically employed to keep the plunger retracted when the solenoid is unpowered. The solenoid was invented about a hundred years ago, and the idea that electricity could not only spin something around (as it does in in an electric motor) but also shove something forward was fairly revolutionary in its time. Solenoids have been used for a variety of linear actuation applications ever since, including all kinds of pinball machine parts.

Marketplace

Buy and sell classics with confidence

A number of things on cars have long worked by using solenoids as linear actuators, from the starter solenoid (which we’ll get back to), to electronic fuel injectors (the moving core opens and closes the injector valve), to those little aggravating solenoids mounted on the firewall of early emission-controlled cars that opened and closed vacuum lines at certain engine load and RPM conditions. They’re all examples of solenoids being used as linear actuators.

When a solenoid is used in this way, there are typically only two terminals on it: Power and ground. Apply power to one terminal and ground the other, and it causes the plunger to extend and do something useful, like open or close a valve. Remove power and the spring causes the plunger to retract.

With this in mind, let’s get back to the starter solenoid, which, since it’s the biggest and best-known solenoid on a car, is what we mean most of the time when we say “solenoid.” (If, for example, we mean “fuel injector,” we typically say “fuel injector.” The fact that an injector internally employs a solenoid is usually not part of the spoken description; we typically don’t say “fuel injector solenoid.”)

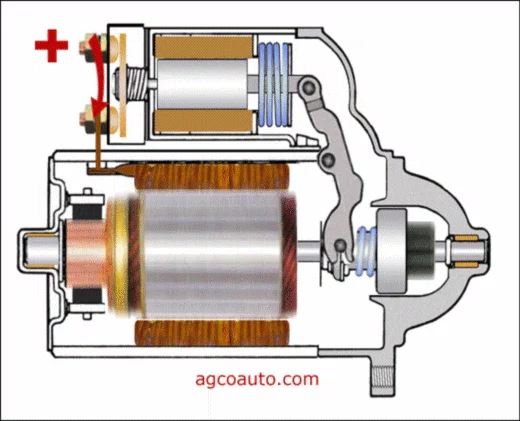

The starter solenoid is a wonderful example of a solenoid that is both a linear actuator and a relay. Here’s what’s going on. When the solenoid is unpowered, it is in a retracted state with the pinion gear disengaged from the flywheel, and the pair of electrical contacts between the battery and the starter motor are open.

Then, when you apply power to one side of the solenoid’s coil and ground the other, it causes the plunger to extend, which does two things:

- It closes the switch contact that connects the fat cable from the positive battery terminal to the windings of the starter motor itself. Because the starter is grounded to the battery through the engine, this causes current to flow, and the starter spins.

- It moves a lever, which in turn pushes the pinion gear outward so it can engage the gear on the flywheel.

Together, these two things cause the starter motor to spin your engine, which is, of course, the whole idea.

In this way, the starter solenoid performs its trick of letting the starter spin the engine, while also acting like a relay and keeping the hundreds of amps of current isolated between the battery and the starter and solenoid, and not having them flow up to the ignition switch.

It also explains why, when the battery is low, you turn the key and hear that dreaded click. You’re hearing the plunger in the solenoid snap forward without there being enough juice in the battery for the starter to spin the engine.

Although the starter solenoid is most definitely a type of relay, it doesn’t exactly follow the DIN standard relay terminal numbering. The functions are identical, however, once you think them through.

- On the low current (control) side, instead of having a terminal 86 on the hot side of the coil of the electromagnet, there is only terminal 50, which is the 12V input from the ignition switch. There is no terminal 85 for the ground side, since the solenoid and starter are grounded by their physical connection to the engine block.

- On the high current (load) side, terminal 30, the big threaded post on the solenoid is the same as terminal 30 a standard relay, as it is the source of voltage that you want to remotely switch on. There is no terminal 87, though, as the output of the solenoid (what would be terminal 87) is typically hard-wired to the starter motor itself.

Hopefully I’ve de-mystified the starter solenoid for you, and placed it in the larger context of relays in general. And now, when you hear the dreaded click, you know exactly what it means.

***

Rob Siegel has been writing the column The Hack Mechanic™ for BMW CCA Roundel Magazine for 30 years. His new book, Ran When Parked: How I Road-Tripped a Decade-Dead BMW 2002tii a Thousand Miles Back Home, and How You Can, Too, is available here on Amazon. In addition, he is the author of Memoirs of a Hack Mechanic and The Hack Mechanic™ Guide to European Automotive Electrical Systems. Both are available from Bentley Publishers and Amazon. Or you can order personally inscribed copies through Rob’s website: www.robsiegel.com.