Media | Articles

This 1-Valve-Per-Cylinder Rotary Engine Could Never Go in a Car

Internal combustion engines are a relatively new development in terms of human history. A lot of people still alive today were a part of the wild first half-century of experimentation and development that landed us at the engines and drivetrains that currently propel us so casually down the highways and byways as we go about our business. While many of the engines popular today are engineering marvels, the designs and ideas of years past can be even more interesting engineering case studies. Case in point: the Gnome Omega rotary engine.

I know some of you have already skipped to the comments to show how much smarter than me you are, but if you kept reading or have just returned after leaving said comment, thanks for the chance to explain how this is a rotary engine with pistons and valves. You are correct that significantly more well-known Wankel design rotary engines are of the “flying Dorito” type that utilizes a triangular rotor that compresses and exhausts fuel and air through passages cast into the engine block. It’s the traditional arrangement where the outside of the engine is stationary and things inside spin. Solid design, but what if you turned it all inside out?

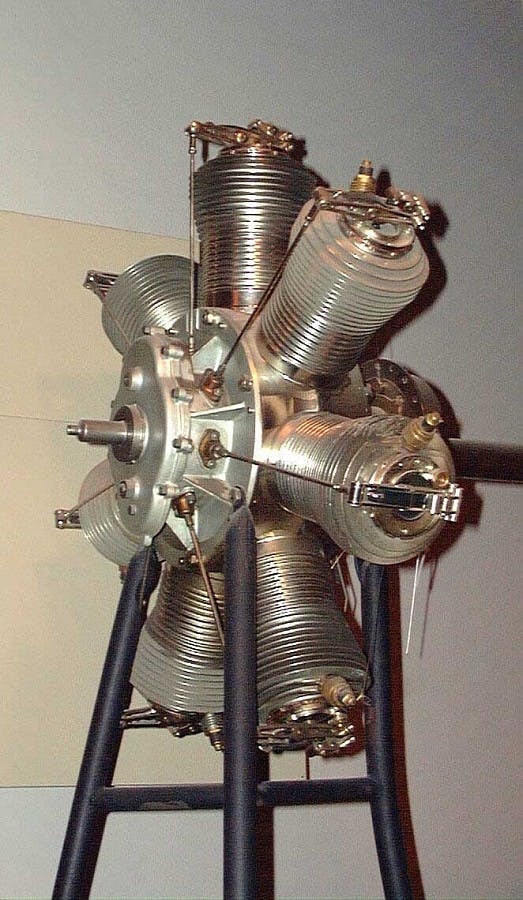

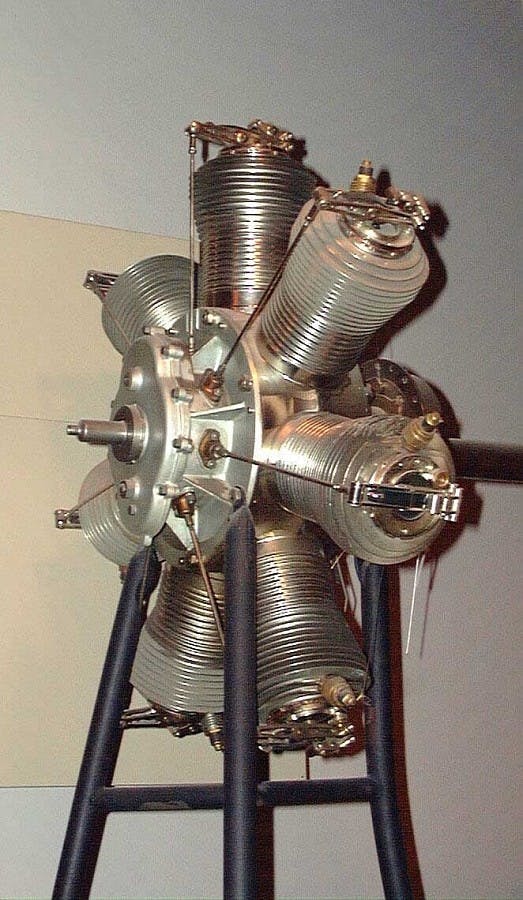

![Gnome Omega No. 1 Rotary Engine (A19990069000). [2008-13964]](https://hagerty-media-prod.imgix.net/2024/08/NASM-Gnome-rotary-engine.jpg?auto=format%2Ccompress&ixlib=php-3.3.0)

That’s more or less the concept behind this rotary engine. It is a “monosoupape,” or single valve, design that was mainly used for aircraft. After looking at the design it’s clear why it was never attempted for anything else. For the Gnome to make power, the crankshaft is fixed to the airframe while the entire crankcase, along with the cylinders, rotates. The crank pin for attaching the connecting rods is located slightly off center and creates the reciprocating motion. I needed to see it in motion to understand it. This video I found on YouTube was a great explainer of the system.

This means it is a reciprocating rotary engine. Yeah, weird stuff. The camshaft is also centrally located in the crankcase and still runs at 50-percent crankshaft speed but only actuates one valve per cylinder, something that even when this design was born in 1913 was either very adventurous or very curious. The single valve design works because the air and fuel enter from a port at the base of the cylinder, where a fuel nozzle sprays constantly to enrich the air as it is pulled through the hollow crankshaft and pushed into each cylinder via crankcase pressure as the whole thing rotates. Exhaust gases are pulled out through the single valve which also helps to scavenge and assist in pulling the intake charge into the cylinder.

Marketplace

Buy and sell classics with confidence

Early designs featured attempts at speed control by throttling the amount of fuel being fed into the intake charge, but it proved largely ineffective. A similar idea attempted to alter the camshaft timing but proved too complicated. The most reliable iteration was a simple ignition cut switch that made the engines essentially an on-or-off proposition.

For all the drawbacks, the Gnome design won fans around the world. It was praised as “one of the greatest single advances in aviation” by Sir Thomas Octave Murdoch Sopwith, which is very high praise from a man whose company produced over 18,000 aircraft for the Allied forces in World War I.

The engineering and mechanical understanding required to produce an engine like this with the tools available in 1913 is amazing. This was a full five years into the mass production of the Model T Ford and most internal combustion engines were of a poppet valve design, yet it was still viable to at least attempt and refine such an interesting design. What a fascinating piece of engineering, even if it would never work if swapped into a car.

There were once a lot of creative engine ideas out there, and a few others have cropped up from time to time, but what kills them all is emissions… more specifically not keeping the lube oil out of the combustion process. Pretty much anything that uses a port-style intake will suffer this fate.

TG, ’emissions’ were such on the rotaries that it is well documented that the pilots suffered from loose plumbing from all the castor oil fumes they breathed in the raw slipstream! It was considered a preventative/remedy for the Rotary’s Revenge to imbibe plenty of blackberry brandy (what? It was France, after all!) which I’m sure they all did! Must have been a relief for the Yank flyboys when they finally traded in their Gnome/Rhone Nieuport pursuits for the Hisso SOHC V-8 powered SPADs! “Debrief me after I’ve been to the latrine, sir!”

Adams-Farwell did the impossible.

Daniel: Awww… I thought I’d be the first to drop this tidbit of true nostalgia! Never say ‘Never’!

PS/ Up at 2:10 am? Night job or new baby? Ha!

As did Balzer. in 1894.

Megola did it in a motorcycle. The gyroscopic forces were notable in airplanes, turning a motorcycle wheel with a rotary engine in it would be interesting (for observers–not so much for the driver).

I distinctly remember a magazine article in the 1970’s that featured this type of engine installed horizontally in a car, as a test bed, and proof of concept. I don’t believe it proved more than how you could keep an air-cooled engine cool under the hood without a

separate fan.

There’s a rotating model of this very engine in the Air Force museum in Dayton, Ohio

For anyone interested in aviation this is a must see museum.

Every other year at the Air Force Museum there’s a “Dawn Patrol” event, where folks fly in (mostly 3/4 scale replicas) of WW I aircraft–usually powered by VW or flat 4 Subaru engines. Several years ago someone brought in a Le Rhone-Gnome rotary engine mounted on a stand, and ran it for all to see. Absolutely fascinating to watch, and try to figure out how the spark plugs got their spark, how fuel reached the cylinders etc.

All that rotating mass is what made the Sopwith Camel (Snoopy not withstanding) so difficult to fly. The rotating engine tried to turn the rest of the aircraft in the opposite direction.

The Adams-Farwell used a 5 cylinder rotary recip engine, mounted horizontally behind the driver. Wonder if the gyroscopic effect of those rotating cylinders helped its handling; probably not given the car was basically a motorized buggy with tall, skinny wheels.

Mike:

Actually Billy Bishop and the other allied pilots flying Sopwith Camels discovered that the best way to beat a German Fokker on their tail was to “right turn them to death” utilizing that reverse torque of the rotary engine which made the Camel instantly do a tight right turn and suddenly be right of the tail of the pursuing Fokker. Later the British SE5 and SPAD 7, both used the Hispano Suisa V8, and I happen to have a beautiful wooden propeller from one. SPAD 7’s were flown by the Lafayette Esquadrile , as the Amercan pilots who flew for

France were named. A famous one was Eddie Rickenbacker who was later famous for racing cars.

Numerous adventurous shops, including one American whose name has faded into aero-motive twilight, converted these monsters into radials, but not successfully; they disappeared even faster. Didn’t even make it into Herschel Smith’s A HISTORY OF AIRCRAFT PISTON ENGINES (1981, Sunflower U. Press) many times reprinted classic. From the Manly Balzer to the Porshe pancake-six; a ball to read and re-read! I M Humble O.

Afterthought: maybe is isn’t ‘breathing’ the fumes, but at least absorbing them; very moving experience, it seems!

The rotary was light, made very good power for it’s size, and not too expensive to build in mass. Legend hath it that American grease-monkeys with the USA Air Service theorized that drilling holes around the base of the cylinders would provide extra port area for the exhaust (don’t ask me!) and that in dusk or dawn light, the things looked like a Fourth of July pinwheel when turning over.

The crazy gyroscopic effect of that mass rotating one way was partially, it’s said, what made the Sopwith Camel so maneuverable in one direction — it worked against an evasive turn in the other, in compliance with Newton.

A number of late-model Nieuport fighters made it to CA, and ‘starred’ in many early aviation adventure films.

I always called the RX-7 type engine a ‘Wankel’ because I knew the ‘rotary’ had been taken. Ole’ Wick

Pontiac experimented with a rotary air cooled 4 cylinder engine in a 2 seat car. They had one prototype.

The engine was behind the seats and it used a modified A body platform.

Not sure of the valve set up but it was literally an aircraft like engine powering a car. It was featured in a magazine back in the late 60’s.

Apparently it was called the X-4, and there appear to be varying accounts of whether or not it existed

Hagerty… article?

It did exist as it was features in Popular Science back in the day with spy photos assisted by John Sawruck of Pontiac. It was his program.

It was also in Hight Performance Pontiac at some point.

One car was made and it was only a really advanced tech project that never came close to production. The car was a two seat car and it was mostly made of parts bin parts. The body panels were just on to cover the car. They were not styled for production.

Here is a story and photos of the car. John is in the photo, He let Jim Dunn the Detroit photo spy in to get some of the only shots of it. The car was destroyed but it did drive and did exist.

https://www.hemmings.com/stories/today-we-learned-the-fiero-wasnt-pontiacs-first-mid-engine-car/

All four-stroke radial engines (yes, a rotary is a radial) have an odd number of cylinders in each bank. They cannot be made to run with an even number.

I’ve seen video of the car hyperv6 describes but can’t find it now. I believe it was a triple.

A company named Anzani made a very popular three-cylinder radial engine from 1900 to 1915. Bleriot and Curtiss both used them in the early days.

It’s a cool aircraft motor. It is so ridiculously shiny and smooth.

The technology of the time couldn’t support boring cylinders, so all the cylinders were turned on lathes. Since the entire engine spins around, making the weights of everything was a real artform. The result is very pretty.

In WWI, similar engines were made by Le Rhone, Clerget, Bentley, and (on the German side) Oberursel. There were other makers as well.

The terms have become a bit ambiguous over time. What we typically call a rotary (Mazda) is really more correctly a Wankel even though it has a fixed crank. The engine shown here in general parlance would now be described as a radial.That design was used primarily on aircraft from WW-1 into WW-2. The ‘wa -wa -wa’ sound on WWI fighters landing does come from those engines having on or off speed control. Specifically ( I think ? ) rotary engines have have all their components, INCLUDING the block spin around a fixed crankshaft, where in a radial the cylinders may spin but the block doesn’t. Something like that. The X engine that Henry Ford wanted to use in the T replacement took something of its design from these radial designs but he couldn’t make it work. Hence the flatty on the cover of this Sep-Oct Drivers club whos design in truth owes more to Edsel.

With a rotary, the crankshaft is attached to the aircraft and the propeller is attached to the engine block. The crank is hollow and the carb is attached to the crank and is located inside the aircraft. A rotary is a type of radial engine, but not all radials are rotaries. The rotary came to be because the early technology couldn’t circulate oil well enough. They disappeared because there are limits to how big you can make one and aircraft needed more power than they could produce.

With the later radial engines, the crankshaft is attached to the propeller, usually through reduction gearing. The block and cylinders is attached to the aircraft. Intake, lubrication, and exhaust are all similar to automobile systems. One problem with the radials is that oil tends to drain into the lower cylinders and cause fluid lock. The solution is to pull the prop around several times with the ignition off. With the larger engines, this takes several people.

(ps) as a somewhat interesting side note ,or not , note. Confederate Motorcycles repurposed Pratt and Whitney radial ‘ double wasp’ cylinders for their Hellcat engines.

Early Stuart tanks also used aircraft radial engines.

George- You clearly know more than I do regarding these types of engines. I find it interesting that you mentioned the problem of fluid lock . As I referred to, it was one of the problems Henry had with the ‘X’ engine design if I’m not mistaken. As again another interesting, or not, side note. Confederate Motorcycles changed their name to Curtis (sp?) Motorcycles for Glenn Curtis. ( They’ve now gone electric in partnership with.. ) who, as I’m sure you know, was befriended by Ford and encouraged him to put one of his modified aviation engines in the Model T. So, what do you know about rotary valve engines?

I don’t know when Ford did this, but by 1914, Curtis was building water-cooled inline six cylinder and V-12 engines for their planes. Their OX-5 V-8 went into production in 1917. It would have been quite reasonable to put one of those into a Model-T, but I’m not sure the car could’ve taken the power.

As for rotary-valve engines, I just looked that up. I now know some of what you could find on the web.

It helps to own a copy of “Jane’s Fighting Aircraft of World War I.”

Some WWll Tanks used rotary diesels. The spinning engine could keep itself relatively cool without risking battle damage to a liquid cooling system.

I read that the Stuart engines had a small propeller to provide cooling air.