Media | Articles

The long, winding road to EFI

In the 1950s, auto engineers began to ditch unruly carburetors in favor of the fuel injection that winners and losers alike had successfully employed in WWII aircraft. Mercedes-Benz was first to bat in 1955 with a direct-injection system—squirting fuel into each cylinder instead of mixing it with air in the intake manifold—on its spectacular 300 SL sports car. Of course, the Americans had other (some say better) ideas.

Instead of employing bulky and expensive injection pumps originally developed for diesel engines and refined in aircraft applications, GM and Bendix Aviation devised two innovative approaches: simpler mechanical injection for Pontiacs and Chevrolets, followed by the world’s first electronically controlled fuel injection for select AMC and Chrysler models.

Fundamental injection patents date back to the 19th century and the dawn of the diesel engine. The world’s first V-8 engine built in France for speedboat and aircraft use was so equipped. Fuel injection is required in compression-ignition engines to assure that combustion doesn’t occur until the dickens is squeezed out of the incoming air. In 1935, Mercedes-Benz diesel cars, trucks, and buses began using pre-combustion chambers fed by fuel injection pumps. Practically every WWII aircraft engine maker employed similar technology because carburetors failed miserably at altitude compensation.

Post-WWII developments

Stu Hilborn’s mechanical injection system developed on the Bonneville salt flats showed up on Meyer-Drake Offy engines at the 1949 Indy 500. Bosch in Germany and Bendix in the U.S. began simplifying aircraft systems for automotive use. At GM, the aggressive and innovative Ed Cole put his engineering staff, the Rochester Products Division, and Zora Arkus-Duntov (Corvette’s patron saint) to work developing a mechanical injection system later called Ramjet. Having created the seminal small-block V-8 for Chevrolet, Cole’s second mission was making that engine exemplary in performance and efficiency.

Gasoline will not combust with air until it’s converted from a liquid to atomized droplets, which vaporize when heated. The amount of heat must be carefully regulated to avoid vapor lock (blocked fuel flow) after the engine reaches its normal operating temperature. The second challenge is distributing the ideal amount of fuel to each cylinder.

Marketplace

Buy and sell classics with confidence

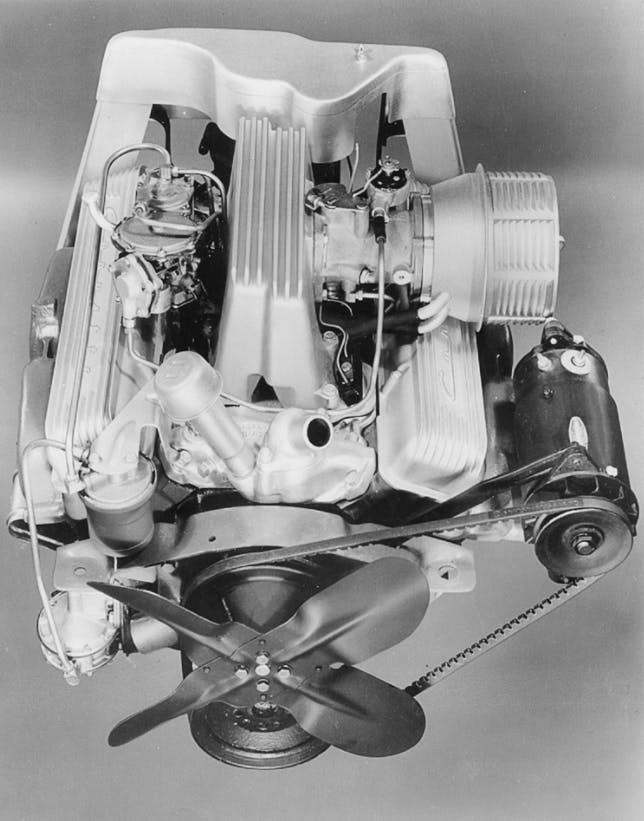

GM’s Ramjet was a continuous-flow injection system with atomized fuel squirted toward the back of each intake valve. A necked-down port called a venturi, positioned between the air filter and the intake manifold, measured the mass of the incoming airflow. The venturi’s air pressure signal operated a control diaphragm in a fuel chamber, fed by a small pump that drew fuel from the car’s tank. The diaphragm moved to regulate fuel delivery to the cylinders in proportion to the incoming airflow. Ramjet’s air-fuel ratio was calibrated at 15.5:1 at light loads and up to 12.5:1 at full throttle.

Fuel delivery nozzles attached to the intake manifold and aimed toward the intake valves had openings approximately 1/64-inch in diameter. Filtered air mixed with the fuel near each nozzle enhanced atomization. Long intake ports ducting air from a plenum atop the manifold to each cylinder used the kinetic energy of the flow (momentum) to raise the pressure of the air reaching each cylinder above atmospheric, a phenomenon called dynamic supercharging.

While peak power gains over a four-barrel carburetor were modest in initial development tests conducted by Arkus-Duntov, performance gains did come from fuel injection’s more consistent fuel-air mixtures. To obtain maximum benefit from fuel injection, various compression ratios, cam designs, and intake runner lengths were evaluated. Also, the location and aim of the injection nozzles were varied in testing. Duntov personally drove test Corvettes at Pikes Peak and at Daytona Beach.

Introduced on the 1957 Corvette and Bel Air, Ramjet fuel injection cost $538 and delivered exactly one horsepower per cubic inch—283 hp (gross) at 6200 rpm. While Chrysler had already demonstrated similar specific output in its 1956 Hemi V-8s, the lighter Corvettes outran the heavy 300Bs to sixty mph in 5.7 seconds and to a top speed of 132 mph.

GM’s Rochester Products also supplied its mechanical injection systems for installation on a few Pontiac Bonnevilles. Those V-8s, which lacked Ramjet-style intake manifolds, delivered 315 hp at 4800 rpm from 347 cubic inches.

Bendix Aviation’s Electrojector

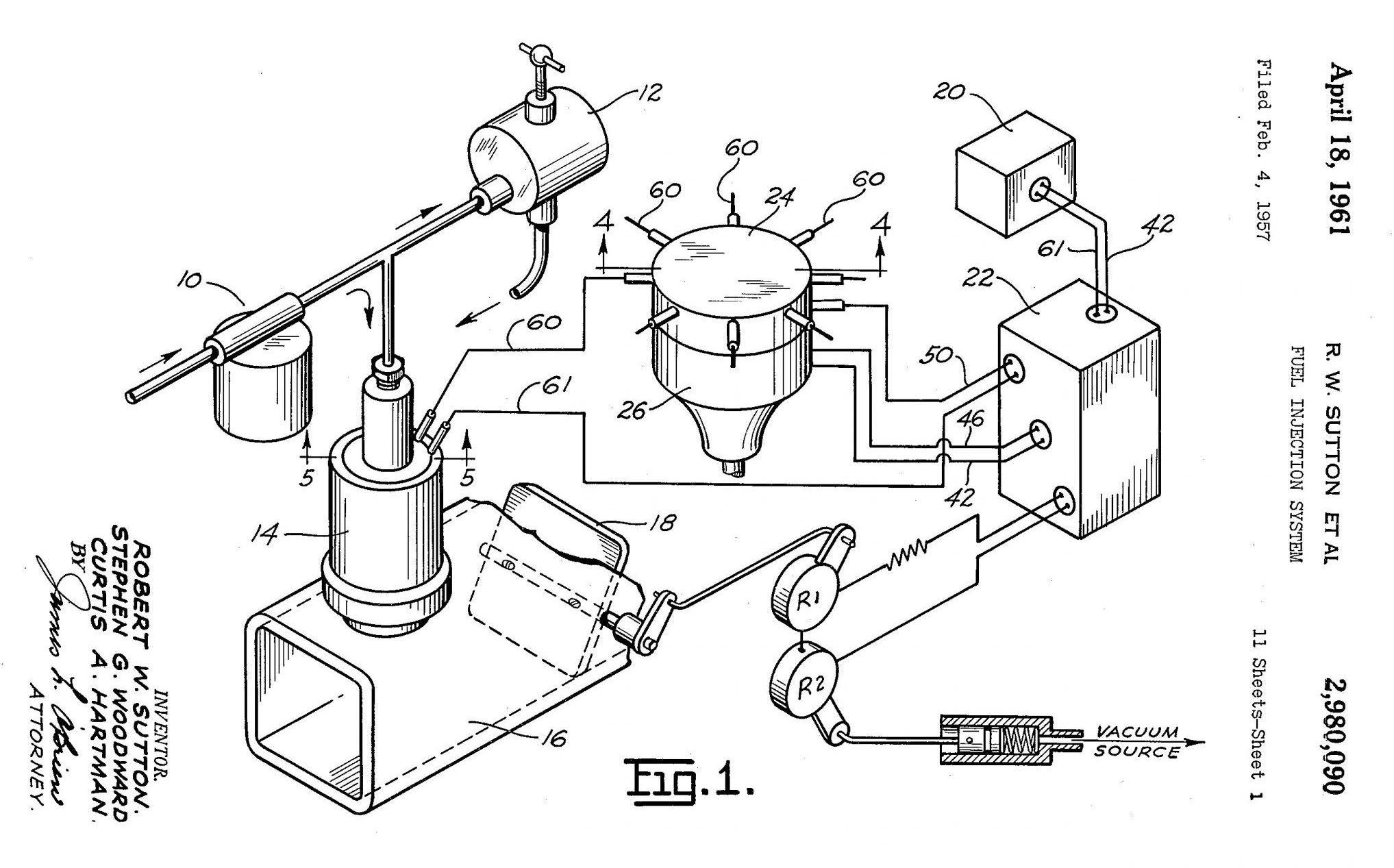

Concurrent with GM’s development of mechanical fuel injection, longstanding auto industry supplier Bendix began working on its own system in the early 1950s, adapting Korean War technology. The notable difference with that what Bendix called Electrojector was the first attempt at regulating fuel delivery with electronically-controlled, electrically-activated port injectors.

After sensing intake manifold pressure, engine rpm, ambient air pressure, and temperature, the all-knowing Electrojector controller sent timed pulses to solenoid-type injectors fed by a 20-psi fuel rail. The controller was programmed to regulate air-fuel ratio, provide start-up enrichment, a faster idle when the engine was cold, and total fuel cut-off during deceleration to diminish exhaust emissions. Each injector was held closed by a spring until its solenoid coil received a pulse from the controller. A major distinction from Rochester’s approach was that Electrojector was a timed system with fuel injection in sync with each intake valve opening.

A set of breaker points added to the engine’s ignition distributor provided the rpm signal. For applications where distributor height was a concern, a separate shaft-driven speed sensor was employed. A simple electronic sensor reported intake manifold pressure to the controller. Another sensor enabled altitude compensation.

Bendix originally intended to use vacuum tubes in its controller until engineers discovered they required a few seconds to warm up. That prompted a shift to new-fangled transistors which also lowered the electrical current draw to just a few amps. The width of the electrical pulses dispatched to each injector determined the quantity of fuel delivered to each cylinder.

Bendix tests revealed a 10 percent power gain over a carburetor-equipped V-8. Fuel economy gains ranged from 0.5 mpg at 45 mph to 2 mpg at 70 mph.

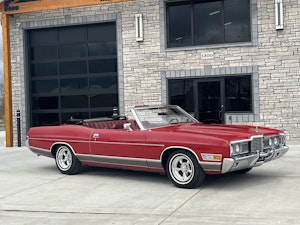

AMC and Chrysler both took the Bendix bait. AMC planned a 1957 Rambler V-8 application but teething problems during development—such as hard starting in cold weather—resulted in no cars reaching the buying public. Chrysler offered Electrojector systems on its 1958 300D, DeSoto Adventurer, Dodge D-500, and Plymouth Fury. Factory records show that 54 cars were equipped with this $600 option.

Alas, the day of electronically controlled fuel injection had not yet arrived. Electrojector suffered from two fundamental flaws. The wax-paper-wrapped capacitors failed as a result of temperature and humidity changes. And AM radio station transmitter signals occasionally caused Electrojector V-8s to rev up, surprising the driver. When customers complained, Chrysler had them return their cars to the dealer in order to replace the troublesome injection system with a proven dual four-barrel-carburetor setup.

The Chrysler 300D owned by Per Blixt, a faithful employee at Jay Leno’s Burbank, California, garage, is a rare car that escaped with its Electrojector system intact. True to form it ran poorly, so Blixt spent a decade tracking down spare OE parts during his fastidious restoration. Though only a few Bendix parts survived his rebuild process, Blixt’s 300D does run powerfully and dependably.

EFI development in the 1960s and ‘70s

Lacking the patience to fix the Electrojector’s flaws, Bendix packed up its research documents and patents for sale to Bosch in Germany. It re-emerged as Bosch’s D-Jetronic EFI the 1967 Volkswagen 1600 Type 3. Several other automakers bought the improved system from Bosch and it enjoyed a fruitful life of more than a decade in production.

Bendix re-entered the EFI game with 1976 applications on Chevy’s Cosworth Vega and two Cadillac V-8 engines. Digital controllers began supplanting slower analog computers in 1979. In 1986, a modern-style fuel injection armed the Fox-body 5.0-liter Mustang GT with a potent 200 (net) hp worth of kick. Mitsubishi introduced direct injection for gasoline engines in 1997.

Today, automotive carburetors exist only on vintage cars and in museums. EFI will reign as standard operating equipment as long as internal combustion holds the fort against the inevitable electrification attack.

I need two rare vintage Hilborn four injectors with four baffles for The ZZR restoration; and two matching linkages for those Hilborn four injected horizontal scoops used in top drag racing in early 1960’s. Yes, this a Barris Kustoms Car: The ZZR; in “Out of Sight” from 1966 Universal Motion Picture; that hasn’t been seen in 58 years. I’m the Technical Adviser. I have pictures, without the body. $300 worth of rare George Barris Movie Pictures; from his 1947 German camera. I bought them Brett Barris his son, in Long Beach, CA.