Media | Articles

Reinventing the Ford Model A four-cylinder

Is your Ford Model A crying out for emergency underhood attention? Thanks to a Campbell, California, entrepreneur, you can now update your car’s powerplant with 21st-century design features created using the latest engineering and manufacturing methods.

Enter Terry Burtz, a retired Lockheed mechanical design engineer and 60-year Model A enthusiast. “I believe Ford Model As are the backbone of the antique car hobby—a pastime I definitely want to endure,” he says. After rebuilding several Model A engines, Burtz identified their many weaknesses, including the materials they were originally made of. By inspecting engines that had been modified for oval track competition and Bonneville speed record attempts—plus a few used to power aircraft, where reliability means the difference between life and death—Burtz was able to develop major design improvements.

“Over the years I discovered that only one in twelve Model A engine cores are suitable for rebuild because of rust, water jacket cracks, and/or poor machining by past rebuilders.”

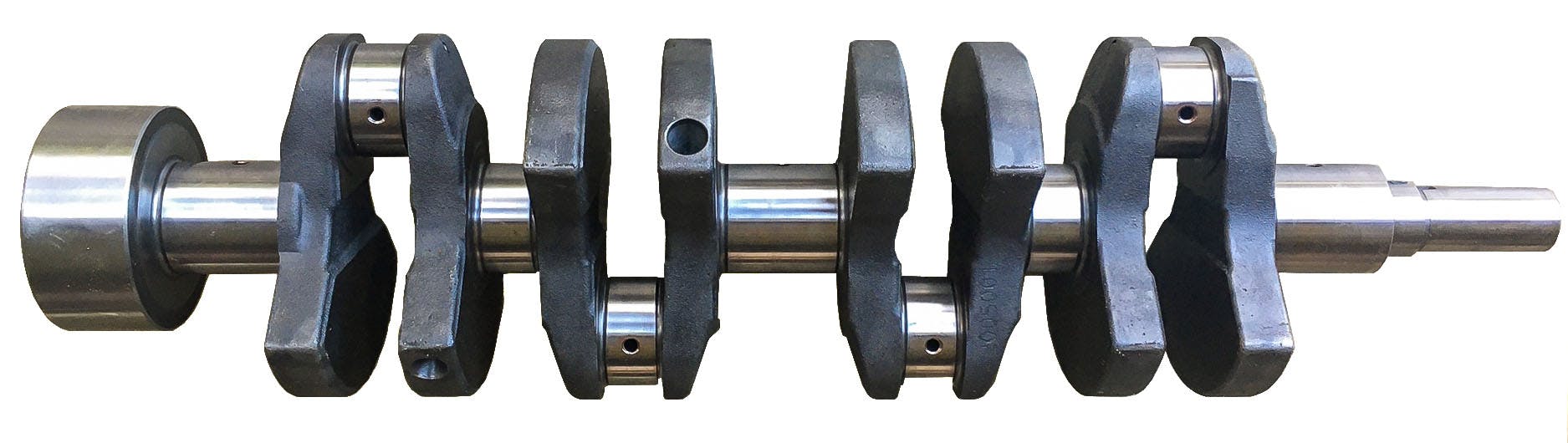

Burtz currently owns half a dozen Model As, and he takes great pride in his $4000 upgrade kit, which consists of a fully machined block, new connecting rods, and a crankshaft incorporating features Henry Ford never dreamed of.

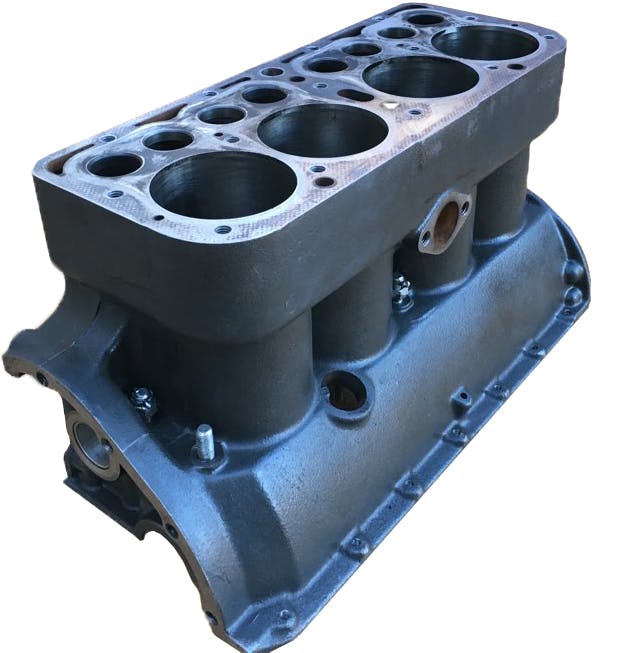

Using computer-based design imaging called Solid Modeling, Finite Element Analysis to measure stress and strain, 3D printing to make core patterns, and CNC machining methods, Burtz created a replacement cylinder block and various internal parts incorporating this wish list of modern features:

- 5 main-bearing supports instead of the original 3

- Larger, 2-inch-diameter crank and rod bearings

- 5 bearing journals to support the camshaft

- Shorter-length bearings to facilitate a stiffer crank configuration

- Commonly available bearing inserts to replace the antiquated poured Babbitt bearings

- Replaceable cam bearings

- A fully pressurized lubrication system with drilled oil galleries feeding 17 main, rod, cam, and thrust bearings—and the ability to add a full-flow oil filter

- 8 crankshaft counterweights to provide primary balance

- A new radial-lip rear main seal

- Thicker block webbing and sidewalls for improved rigidity

- Larger streamlined intake ports for better breathing

- Steel exhaust valve seats to increase longevity

Burtz’s simulations proved his design tough enough to provide 150 hp at 5000 for hours on end. In a 2020 road test, a 5-window Model A powered by the new engine ascended 1700 feet of elevation in just over 7 minutes on a five-mile Colorado mountain run.

In his efforts to improve the A’s engine, Burtz was careful to replicate Ford’s original factory appearance with its exterior. “Having judged at several Model A national conventions and other events,” he says, “I learned that no owner wants an engine or component part at odds with original appearances.” Furthermore, this new gray iron block is machined with all the interfaces and dimensions needed to bolt on original factory components.

Premium materials, including a modern alloy for the cylinder block, forged connecting rods, and a nodular iron crankshaft and camshaft, combined with induction hardening, help assure high-mileage longevity in tough applications such as trailer towing and mountain climbing. “Model A owners want enough power to accelerate well on freeway entrance ramps and sufficient cruising speed to avoid impeding traffic,” Burtz says

“Another notable discovery of mine was that a new Model A engine cannot be affordably made in the USA. I learned the hard way that West Coast foundries are not up to the complex block casting process. Like several OE brands selling vehicles in the U.S., we turned to China for this engine project.”

Burtz’s strategic partner is John Lampl of Leesburg, Virginia, who brings over 30 years of Asia-based manufacturing and product development to this project. Burtz and Lampl shook hands in 2019 to begin collaborations. Lampl had already successfully created a remake of the four-cylinder engine built by Willys and Ford for WWII and postwar Jeep use. Using that experience and the same Asian manufacturing operations greatly accelerated the fruition of the new Model A engine project.

The new parts are being produced in several factories that combine an entrepreneurial spirit with modern manufacturing methods. To date, more than 460 “New Engine” kits from several production runs have been delivered.

In addition to the $4000 block, crank, and connecting rod package, Burtz offers new 30-pound flywheels for $375, cylinder heads with a 6.5:1 compression ratio for $400, and replacement camshafts for $400. All parts are covered by a 1-year limited warranty, so long as they’re not used in motorsport or aircraft applications.

“Our combination of quality, reliability, price, and factory appearance means that we have no direct competitors,” Burtz says. If you’re looking to keep your Model A humming sweetly, now you know where to look.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

The US really needs to get it’s stuff together when we can’t even cast an (understandably modified) Model A block on home turf. Folks have excuses longer than my arm on how great this global economy and ambiguous origin of manufacture situation is, but I suspect like a lot of things, by the time we figure out it’s a bad idea it will be too late

It’s astounding to think that it is economical to ship anything across the ocean so much cheaper than it can be made on home soil.

Labor costs are often cited. Taxes, fees, and other regulated compliance are a huge factor. You make something in the USA or Canada you have to follow all sorts of rules the “competition” may not.

To my knowledge, goods from countries with lacking standards are not tariffed when imported to balance the competition.

Consumers would revolt of course, as costs would skyrocket on even the simplest things like cutlery. Though if the tariff was rebounded into tax breaks to consumers maybe it could balance out better.

That at the end of the day is the real problem. Folks want a living wage, but don’t want to pay for a living wage in their products… can’t have it both ways for long

Consumers are the ones who pay the tariffs, not foreign countries. The best way to rebound tariffs with tax breaks is not to charge a tariff in the first place.

It’s the consumer that pays… depends on what you buy. I won’t be paying any tarrifs on a Porsche because I’ll never buy one. Understand that FOREIGN countries have heavy tarriffs on American goods and they aren’t stopping any time soon. When it comes to tarriffs, they can’t be all one sided.

shipping has become ridiculously cheap in the last few decades with the growth of cargo ships to ridiculous proportions. it’s almost free. moreover the chinese manufacturers will make things not just cheaply but faster and more effectively. their manufacturing economy is much stronger. need a mold modified? need a new circuit built? need a new source of iron for your castings? there’s fifty vendors fighting for your money.

meanwhile, try finding an electrician for hire in the USA these days, or a decent technician. the military is the only reliable source. we shipped our industrial base overseas in the name of shareholder value, and now we’re paying the price.

Correct

Entrepreneurial spirit in this country went to the grave along with Henry Ford!

This guy’s problem is using foundries in California or Oregon. Try the upper Midwest. Anyone who would attempt to build an engine in California with their regulations deserves what he gets.

We are building 2 of the Burtz Blocks at the same time. The quality has been great and it’s been really fun. Terry Burtz thanks for helping the Model A hobby.

I don’t think the issue probably is that foundries in the us CAN’T cast the block. Its that they can’t cast it at a price that makes the project affordable. I’ve run in to this several times myself.

Exactly! I’m confident that there are US foundries that can make whatever casting challenge is given to them-but it’s at what price, especially in the relatively low quantities given here.

Actually, foundries in the US and Canada have these capabilities, it is just a matter of being willing to pay more for the processes. $4000 for these parts is something that hobbyists may accept, $7500-$10000 would be much less appealing. Its our consumers, not our industry.

I think Joe Strauss hit the nail on the head — there are no SMALL foundries in the US that can profitably cast something the size of an engine block. All the foundries capable of casting something of that size and complexity are large and the volume required to make it economical just isn’t feasible.

I was very interested in the Burtz block until they got around to mentioning that it was made in China. When you do business with China you’re doing business with the CCP, and a portion of your money goes to pay for weapons pointed at Americans. I won’t be contributing.

Many valves are cast in Asia. U.S. regulations have made it difficult to keep foundries open here. Send the smog overseas – it’s the green thing to do. 🫤

Well china is more competitive on price.

Odds are that in 2 years the Chinese will be duplicating the entire Model A and shipping it back here.

History tells us: “that when you dine with the devil, you bring a long spoon”

Yep,

The Chinese will ripoff Burtz’s design and start cranking parts out at 1/2 the price to drive Burtz out of business.

Burtz can certainly sue the Chinese for copying, but that won’t stop them from running him out of business.

One day they’ll be talking about Chinese manufacturing as modern day slavery.

I am all for this, but I won’t be buying one until they fix the current leaking issues. They currently leak profusely!!

And how is it still an antique car with this engine? It seems some people these days don’t want an old car. They just want something that looks like one. Is original now a dirty word?

What are you on about? Vintage and classic cars are huge investments for the vast majority of people who enjoy them. Lots of those people want to actually drive their vintage car rather than merely staring at it. Modern traffic is not getting any more vintage car friendly, so some of us prefer to make subtle (and some not so subtle) changes in order to keep using the car as it was meant to be.

Would you rather see every Model A Ford parked forever or have some still driving around with these engines? Also add in the fact that if Ford could have built them this way new… He probably would have. Exacting restorations have their place, but there are likely thousands of MAFCA restoration Model As. Turning some into reliable drivers is not going to hurt anyone.

100% agree

A modern four will do that, and much cheaper. Stick a Lima 2.3L or even a Duratec four in if you want a more traffic friendly driver. Ford didn’t make a side valve or OHV four in the US past 1934 (Model B engine) as far as I can discover, with the exception of European Fords. They used small sixes in the US instead (as small as 144 inches, 1960 Falson six). Other make engines would be less acceptable for many owners, but they are possibilities. Of course you’d have to adapt the transmission/driveshaft/rear axle to the new engine or use some of the newer components and adapt to the car. So less Model A… This approach has been done, but many prefer to keep closer to the original, and I understand that. It just costs more…

You counter your own argument by bringing up how much work it would be to actually install one of those engines you say is so much cheaper than this Burtz. Also, who needs a Model A Ford with 166hp? That’s what a Duratec makes from the factory. I’ve driven enough Model As to know 60hp is a sweet spot that makes for a very driveable, no nonsense car. There is zero chance that adapting a modern four into an ‘A chassis is in any way cheaper or easier than using a Burtz engine. Happy to be proved wrong though.

Agreed, Volkswagen hobbyists have been doing this for years. Hardly anyone drives a 36-hp Beetle or Bus anymore; they plug in a later-model engine so they can keep up with traffic.

You hit the nail on the head, Mitchell overdrives, Burtz engines (not to mention it’s cast in China)… Why even bother trying to keep it original. Thank God some of us still try to keep cars true to the original driving experience, good or bad. My 28 standard Phaeton was last restored in 1990 and it has been driven at least once or twice a week since then… Just as long as the roads are dry. The old girl has never been in rain since she’s been restored. Could it go faster, hell yes I’m an engineer and Machinist coming from the glass mold industry. For me I get a much more authentic experience if I take the grandkids out on two lane country roads doing 40 miles an hour. When I’m driving the model A I’m not in a hurry and that’s just the way I like it

You make a fair point, but just because the way someone else enjoys their car is different than yours does not make it incorrect. The original driving experience is great–hence why my Model A is also fairly close to stock–but there is a little hot rodder in me that like the idea of an easy swap that looks correct-ish and gains me horsepower and drivability. Swapping in anything else will be quite involved, but this is drop in and very easily reversible horsepower gain that allows more people to feel comfortable driving vintage iron or keeps cars on the road in general due to the cost of this compare to rebuilding a stock long block. My motor has no shims left on the babbitt, and I won’t be getting rid of that engine, but the idea of swapping some parts over rather than sending it all out for fresh babbitt is appealing.

What sort of leakage do these new blocks have? Coolant? Oil? Both?

Both of my Burtz block leak, so what. Terry won’t acknowledge it. But it’s a huge advance forward in this hobby.

I’m impressed with building a new “stock “ engine with today’s technology and materials. However, I am having a hard time with driving this up curving roads and them talking about being able to get on freeways and not impede traffic. Even when I was 16 I couldn’t imagine driving driving that fast and trying curves like that. Brakes, steering, suspension, tires, and the rest of the drive train would really need some upgrades. At 35-45 mph the model A I had was OK , but still needed hydraulic brakes to make it a little safer. I just see more needing upgraded but then how do you make it all original looking as some of these enthusiasts want

Very cool thing to see this motor being made today. Sad to see it is not being made in the USA like the original.

Having come down a hill at a bit over 45 mph, and the babbitt disappearing from the rods and crank, necessitating a 25mph drive from Desert Center AZ, into Phoenix AZ, I appreciate that the new configuration is with 5 main bearings, and modern shell bearings instead of poured babbitt. Also an electrical problem with the 12volt upgrade, along with new headlights. Needs a relay for the lights – the bulb on the bottom of the steering column containing the light wiring burst into flame when I pulled into the High School parking lot so many years ago, when I still had the car. Definitely miss it!

One has to wonder whether the optional 30 pound flywheel (presumably lighter than stock) is compensating for the 27 pound heavier crankshaft. If so, why optional? Valid point about upgrading and increasing engine performance but not addressing braking nor handling. More reliable components are, of course desirable but more power upsets the balance. Remember ’60s muscle cars? Dropping big car engines into smaller car chassis resulted in great acceleration and lousy braking and cornering.

Why should lighter flywheel be optional with the Burtz block? Because the buyer may have their own already. Same with the head.

Back in the ’80s, I was told that GM’s 2.5 Iron Duke blocks were being cast by John Deere for $33.00 each.

Although the volume here is completely different, and these are not 1980s dollars, There’s gotta be a foundry in the US that could do this economically. I wonder if Dart Machinery and other aftermarket race parts manufacturers outsource overseas as well.

I believe, other than Edelbrock, most aftermarket companies out source their casting. Nearly all do their final machine here in the U.S. but, the casting may not be done here. I do believe World Products does at least some of their casting in the U.S. and the same is true of Blueprint Engines, but others, like Weiand, AFR, Trick Flow etc, may not have the facilities to do that.

John Deere was probably making a whole lot more of them. These are a low-volume item and that drives up the cost per piece.

What sort of leakage do these new blocks have? Coolant? Oil? Both?

A lot of relatively small companies like foundries went out of business when the tariffs on metals put in by the last administration made the cost of materials too high for them to survive.

The cost of machine work in the USA is out of control! I’ve had the same part done at the same machine shop since the early 90’s price has just about doubled in cost, but I am “old school” trying to buy American, unfortunately, most of the rest of the parts I buy are made overseas! Glad to see that the improved parts are available. How many original Model A’s still have the original 4 banger in them? Most have been “rodded”

More power only leads you to the next weak point. Improving upon the next weak point leads to the next and so on. Projecting into the future, can we expect in a couple hundred years or so, (maybe in 2228, the 300th anniversary of the first model year Model A,) an all new and improved, bulletproof, Model A that will potentially operate indefinitely on a drip of fuel, and a quart of oil every 20,000 miles?

By that time old folks in gated communities, (who as of this writing have not been born,) will have long since tossed their GEM golf carts and taken up driving around in modern reproduction Model As, tooting their claxons at one another.

Kudos to Terry!

Lately I have been having the hotties for a 1930 – 5 window coupe, and thought of installing a 4 Cyl. Volvo engine and whole Volvo power train. There is this Volvo performance shop in New Mexico who can get almost 200hp. To it. After reading this article I now know where to go. Excellent, congratulations for your passion!

D. C.

Not that this comment will get read and cared about. I love reading hagertys email. We are so divided in this country, family politically, many other things, and on to the cars. Us car loving folks love burning gas and hauling ass. Then the ev car lovers love thinking they’re saving the world buying a bad investment. I have gotten to have little to no opinion on anything anymore. Why can’t we all as humans just live and enjoy. We are only here for a minute then it’s time to hop off the train and leave it with the next generation. It’s too bad we can start up our own businesses and cast blocks or make many other parts here in the USA, USA, USA, (oops small chant) and add to the fun and enjoyment of what is in our times. We are taxed, inflated, regulated to death!!! If we don’t give our son our old truck and teach him how to own, operate, and care for it the minute we croak it’s for sale. Look how many estate sales are selling off “grandpaps collection” I see that and roll my eyes every time. The fact these parts for cars that made the USA what it is had to be made in a country you couldn’t pay me to visit is very sad. Yes I buy Taiwan parts for my 66 Chevy 2, yes I buy across the pond parts for my 71 c10, AND I HATE EVERY PURCHASE!!! the poorly paid people making our parts don’t even know what they go in or get to enjoy an old cool car with their family and friends! What are we to do besides ACCEPT IT ? I’m 40 when I’m 60 (hope I am one day) what is the car market going to be….. ?

That’s not a Model A engine. Save $6000, go to a junk yard and pop in a Honda 4-cylinder. There, problemsolved.tr

Very few Model A Fords made it through WW II with their original engines, and most were dragged protestingly out of junkyards after the war to meet the automobile shortage caused by five years of having no new cars. This talk about this not being a Model A engine is nonsense.