Media | Articles

Redline Rebuild: Chrysler Slant-Sixes Done Mild and Wild

Engines don’t always get a second chance at life. Many are assembled, dropped into a chassis, and then driven until they cannot drive anymore, fixed, driven to the point of failure, fixed again, and repeated until the cost of the repair is no longer rational to the owner. Lucky engines never hit that point. But really lucky engines lie in wait until Davin Reckow and the Redline Rebuild team come to the rescue. The latest rescue mission was a Dodge two-for-one worth watching.

The Chrysler slant-six is an engine that you likely know from its role as the butt of a joke. The facts aren’t laughing though. With 170-,198-, and 225-cubic inch variants and a production run that spans decades, the “leaning tower of power” is an attraction worth seeing. The first to appear in this Redline Rebuild is sourced from a Dodge Lancer station wagon wearing all of the grime from a life well lived.

After swapping the automatic transmission for an engine stand, the oh-so-rewarding teardown can begin. Davin will even admit that while disassembly is not his favorite part of the process, it’s up there. “You get to see the engine so completely, its always interesting to try to figure out its history.”

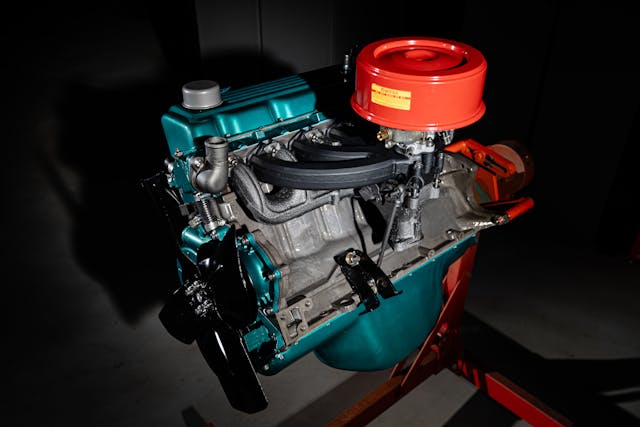

And this engine got cleaned up and went back together faithful to that history. The turquoise paint really dressed up the cast iron block and cylinder head, even though we thought they were beautiful right out of the machine shop too. Right when that stocker went off to get sized up was when slant-six number two arrived in the shop, this one a little rougher starting point. By the end, this one got a host of performance touches, including bolting on a Torqstorm supercharger. We aren’t saying the restored stock engine isn’t as lovely, but something about that four-barrel pressure fed by that belt driven blower is just extra attractive.

Marketplace

Buy and sell classics with confidence

Hidden inside the wild build are some pistons that required Davin to do some machine work of his own. He needed to ensure the piston-to-valve clearance would be acceptable after the increase in camshaft size and bump in compression from replacement pistons. A little off the top made the compression just right for the additional air and fuel the blower will be pushing in. Davin made sure the path to the cylinders would be a smooth one also by doing plenty of grinding to the intake and cylinder head, slowly adjusting the shape to maximize the flow.

Davin said it was fun to build the same engine twice for once, proving that even just the second round is enough to say “not my first rodeo” and, ahem, dodge some small catches and particular tips pertain to the Chrysler slant-six specifically. He was tight lipped about which engine will be going back into the Lancer, or even if either were. He seems to always have something fun up his sleeve, so we think it might be best to click subscribe to the Hagerty YouTube channel and watch for the next Redline Update.

I will never forget the kid in high school that drained the oil and Dr over his slant duster home. He filled it and it kept running. Till the rain would knock out the ballast resistor.

That’s not your run of the mill cast iron block – if I’m not mistaken that Lancer block is the relatively ray ALLOY block – obvious not only by the colour but the “open deck” design!!!!!

My first car – 67 Barracuda – had a 225 slant 6 that I rebuilt. Drive through a big enough puddle and the distributor (low on the passenger side of the block) would get wet and it would refuse to move. I would simply remove the cap AND the whole distributor on the side of the road, dry everything off, clean the points, reinstall it and be on my way in 15 minutes. Drove it seven years and 100,000 miles, never left me stranded.

Yes… a one year old 67 Barracuda notchback was my second car and second Slant 6… It went to the Army with me and was trouble free for over 100k miles. A collision finished it. I never knew the horsepower of either one…. and yes again the distributor did get flooded out a few times. We also used to wash the engines at the ”quarter” car wash.

Thank God for dis huh!

My granddaddy had a 65 Dodge D-100 with slant six and 3 on the tree. I could “bark” the rear tires going from low gear to second if I shifted without the clutch. Great truck, great engine. I drove it to school some and around the farm feeding his cows. Never gave any trouble despite my teenage antics.

You forgot about the Australian Hemi heads for the slant 6

Two totally different engines. There are no “HEMI” heads for the slant six.

Nope……Aussie Hemi was NOT a slant, completely different engine, nothing interchange. Never been any hemi heads or even aluminum heads for the slant 6, unfortunately.

I drag raced a 67 Dart for many years with a 225. Ran high 12’s in the 1/4 mile.

Good times

Sadly in this day and age with alot of people as soon as their is a bit of engine trouble the vehicle is discarded in the junkyard.

Today’s engines for the most part can’t be rebuilt. Plus cost to replace is too high (some engines are $10,000+). People got rid of their cars in the ‘old days’ just the same as today when they quit running or became too costly to fix. I remember my first car, ’69 Chevelle with 307 that I paid $1100 in 1979. It was one owner but an oil burner after I flushed out all the STP that the dealer filled it with. I pulled the engine and did a ‘refresh’ (ring, bearing, valve and cam/lifter job) that cost as much as I paid for the car by the time I was done. Not many have $ laying around to spend a lot to fix things. You can get a ‘cheap’ loan to buy a new car but putting $10,000 on your 28% credit card is NOT a good idea.

Best slant 6 story. I had a friend with an old duster broke a rod off at the crank journal. there was a hole in the block just in front of the starter. He wrapped a wire around the rod hanging down from the piston and tied it to the starter. Stuffed rags in the hole and drove the car for weeks on five cylinders. Gave me a huge Ford guy a lot of respect for that motor.

That’s crazy. I thought I heard all of the slant 6 stories.

A high school friend had a 60s station wagon with a slant 6. He put a rod thru the block and drove it 35 miles home. He figured get as close as possible for the shortest walk but made it all the way.

The supercharged one does have that extra bit of cool. Both looked great!

I always remember the slant 6 being the most reliable gas engine I’ve ever known. Slow and lots of valvetrain tick, but they went on forever. Cab drivers loved them and would run them past a million miles. It would be interesting to see how they hold up with a performance build.

The stop-motion disassembly and rebuild video was excellent……very entertaining 🙂

Went to my ’74 High School Prom in Dad’s ’67 Dodge Coronet with a 225 Slant Six = Happy Memories.

That engine provided 22 mpg and over 150,000 miles of operation. It was easily maintained by driveway mechanics. My Dad taught me the basics on that 225. Lessons that later saved my life… but that’s a longer story…

It doesn’t surprise me as I read about new found interest and appreciation in and of the slant sixes.

My first impression of these engines came to me as they were introduced into the market. One of the dads in my Boy Scout troop had a new 1960 Dodge Phoenix. This character ran the socks off of that car…it was often more than just competitive with other V-8’d cars, and I think he passed up no opportunity to display that.

Even though I was eleven years old I recognized that this ride was something new. I didn’t understand what the difference was, but it was quite impressive to me.

As I emerged into the work world and started working in gas stations ( a veritable haven of happiness for someone like myself who enjoyed cars and meeting people) I paid some attention to the vehicles we were always seeming to work on, and of course, the ones we just sold gas to.

My thought has long been that we can neglect and abuse anything into submit, but in general those slant sixes just ran, and ran, and ran some more.

I believe that a big part of the success is in the crankshaft suspension. There are a few other engines that share that sort of reliability and longevity… the Volvo 122’s , Cummins 5.9 Diesel to name just two.

And now I am watching one of Grandsons as he is developing his 1974 Valiant. First of all, I am totally pleased and proud that he appreciates the old iron and chooses persue that era of car while utilizing some of the newly developed options made available.

Secondly, I am intrigued to see how far he takes it . At this point my only disappointment is that the turbos, superchargers, intakes, exhaust systems, ignition upgrades, and fuel management systems weren’t around when I was young enough to play in that pool!

… just another “perk” of getting old, I guess.

Thanks Hagerty for running this story, I look forward to following the build on You Tube.

American manufacturers never really utilized the Inline 6 for high performance like the Japanese and Germans did. Truly a shame because they are so smooth and generate amazing torque.

Don’t forget the Pontiac OHC-6 Sprint from the mid sixties.

It was a performance machine with a four-barrel carburetor, hot cam, high compression ratio, large valves, stiffer valve springs, and a split exhaust manifold.

I see PontOHC6guy responding below so he knows straight six performance 🙂

My mother had a Dart with a slant six and to say that was a good driver would be a lie. She once drove a car that only 25,000 miles for two days with the oil light on, it finally seized up. That car was an Oldsmobile Jet fire. As hard as she tried she couldn’t kill that 6 cylinder. Although I did have to put brakes on it about every 3000 miles. Left foot braker.

I grew to love the old 6’s: Ford, GM, AMC and MOPAR in my ‘old age’. Base cars or small V8’s are what I like (even the foreign econoboxes have merit). I can appreciate now the full size 4 door land barges too. When compared to the expensive SUV’s today, I would much rather have an old daily driver that you can actually repair in the comfort of your own garage.