Media | Articles

Project Goblin: It was right, it was wrong, it was a Christmas miracle

I’ve maintained an Internet presence (of sorts) since 2006 because of my dogged insistence to never stop being published. And yet, even with those intentions, I’ve neglected to sufficiently inform you about Project Goblin, one of the coolest endeavors I’ve had the honor of experiencing. That ends today, hopefully making this a very special Christmas holiday for everyone reading.

Let’s play catch up: My neighbor Brett is building a DF Goblin kit car from a donor 2009 Chevrolet Cobalt SS in his garage, just a few houses away from my humble abode in Houston, Texas. Last March, weeks before the pandemic, both of us got new gigs that allowed us to work from home. Project cars suddenly became a more palatable proposition.

By September 2020 he had stripped the donor Cobalt, scrapped it, and was eagerly awaiting his goodies from DF Kit Car. In the meantime, Brett spread some cheer for Cobalt owners by offering the Cobalt SS’ bumpers and Brembo brakes on Facebook Marketplace, which quickly netted $450 for his coffers. (Everything else of value eventually found a buyer, but we’re getting ahead of ourselves.)

In mid-October 2020, with a trailer in tow, Brett hopped in his minivan (yes, really) to pick up his goodies from DF Kit car. The haul included DF’s Stage 1 (everything to make a chassis with a running engine) and Stage 2 (everything to make a rolling chassis) kits. By the end of the month, Brett had the tube-frame chassis powder-coated locally (in a charcoal color) and ordered his 18-inch wheel/tire combo from a late-model Mustang parts specialist. Having all the bits secured was great, but November 2020 was when things really got cooking.

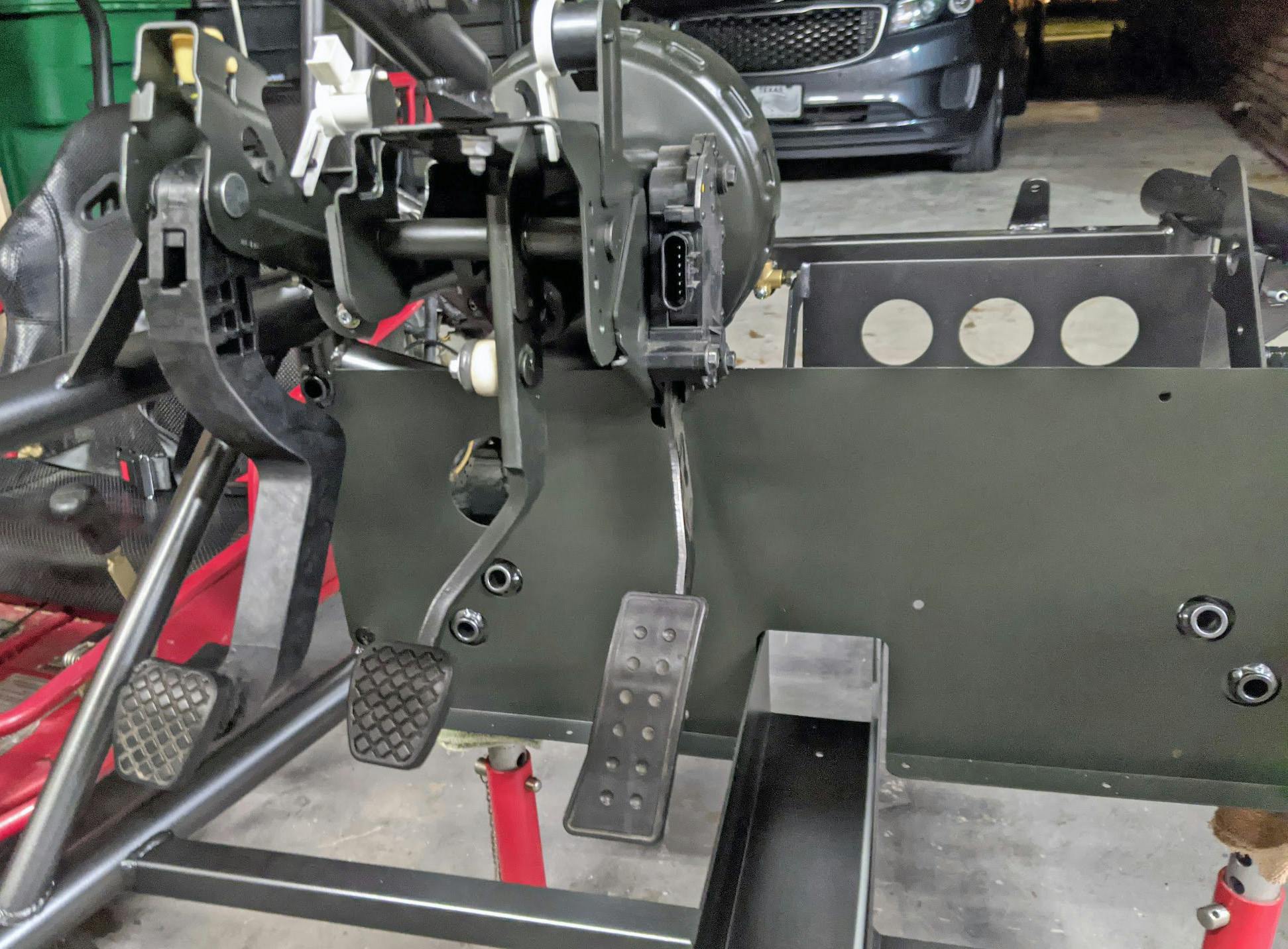

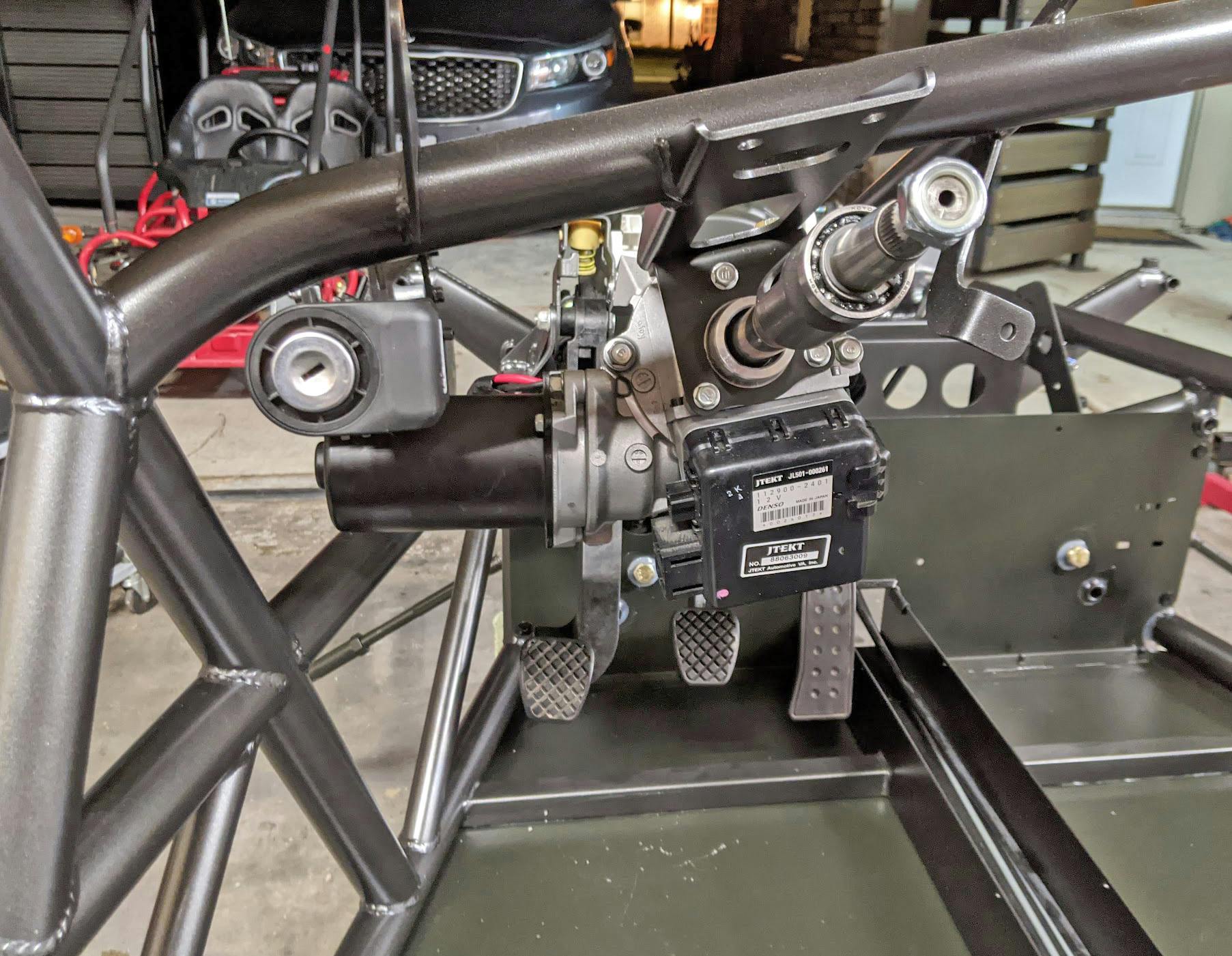

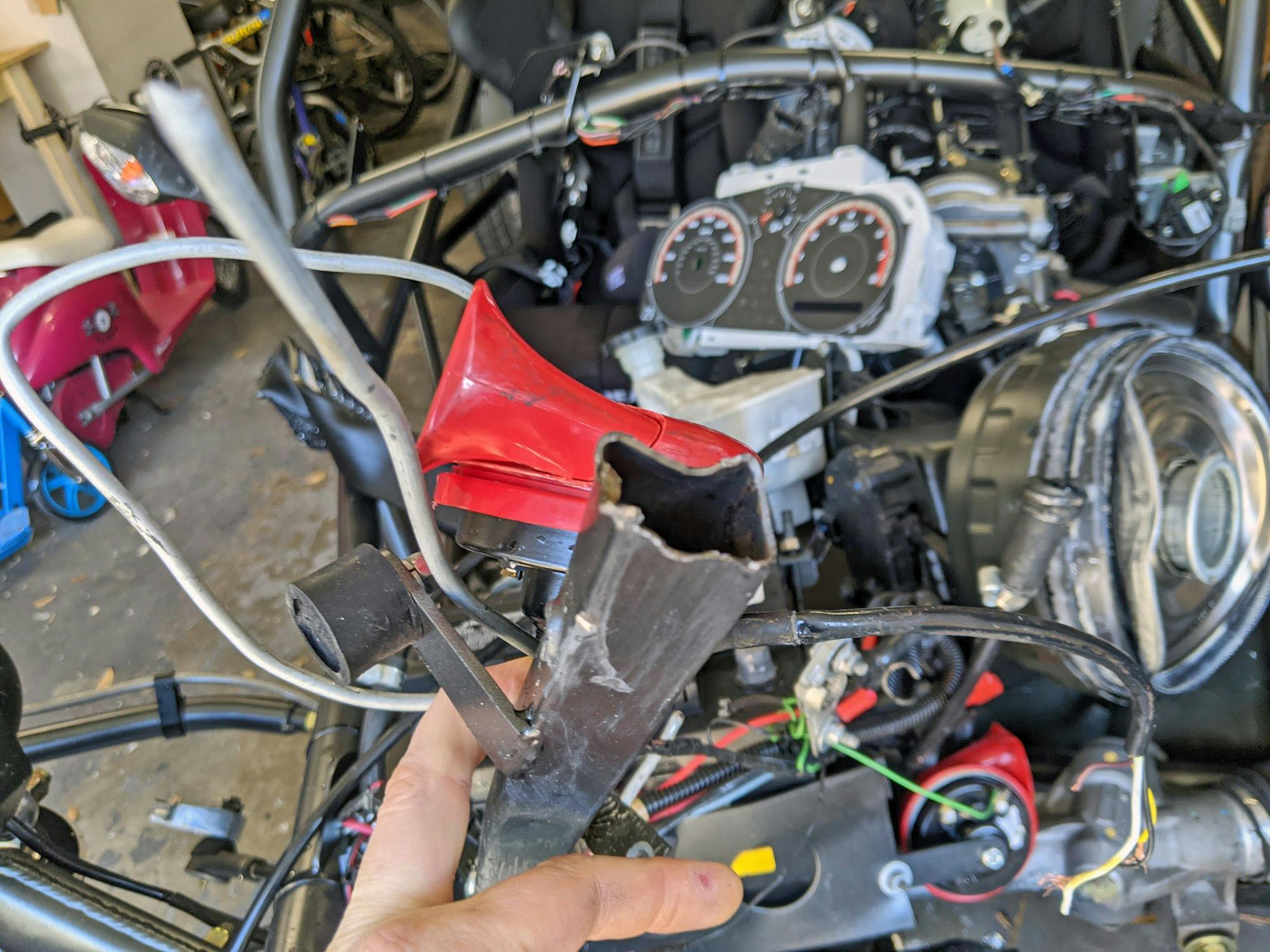

While I was busy growing my “Movember” facial hair and not working on Project Valentino, Brett spent the first week of November 2020 assembling Project Goblin’s front firewall, brake system, clutch master cylinder, pedal box, fuel tank, steering systems, intercooler plumbing (remember this is a turbocharged Cobalt), and did the most painful aspect of Goblin kit car assembly: pulling coolant hoses through the frame tubes and installing the radiator.

Marketplace

Buy and sell classics with confidence

And you thought using soapy water to get a hose on a metal tube was a chore! Try getting that hose in a tube, for the entire length of a vehicle. The next week of November 2020 included cleaning up the engine wiring (remove A/C and secondary fan wiring) to mate with the soon-to-be decluttered Cobalt chassis harness, sourcing new MAP sensor wiring (from an S-10 truck) after mistakenly discarding it, installing Goblin front control arms, and installing the Cobalt radiator overflow bottle. A set of replacement front hubs were machined to spec, the Ecotec’s timing chain bolts needed attention, the engine was married to the chassis, and a OTTP short throw shifter met the Goblin’s increasingly more complex chassis. This is all standard fare for assembling a kit car, but Brett went a step further by using horse stall mats as floor linings for maximum heat management.

Week three of November 2020 brought the Goblin closer to rolling chassis status, with a quick release steering wheel, rear suspension, half shafts, brakes and a new rear lower control arm and ball joints. Before December rolled around, Brett was cleaning, prepping and painting all relevant components before installation. Quite frankly, I lost track of how many times I walked over and saw parts hanging around his garage sporting a fresh coat of semi-gloss black.

With a fresh set of tires, adjusted shifter linkage, and a fully assembled cooling system, Brett’s DF Goblin finally put rubber to Mother Earth on December 3, 2020. The thinned-out Cobalt SS chassis wiring harness arrived from DF Kit Cars five days later, and after addressing a burnt fuel pump circuit on the fuse box (a casualty of re-energizing the pump to flush the tank), the Goblin had its first start on the 12th.

And yes, after all those months of preparation, this was a big deal for all involved.

December 19, 2020 was the Goblin’s first drive up and down the street. After that, a few more little details needed attention before the Goblin’s true maiden voyage. Work included a bikini top for the roll cage’s top hoop, parking brake adjustment, and a Christmas Eve surprise: the race seats and five-point harnesses arrived and were quickly installed with the help of Brett’s Dad.

There’s a gas station adjacent to our neighborhood, so after adding a few gallons of go-go juice, Brett took the Goblin for a spin to give himself a quick gift for the holidays. And that’s when it happened. On Christmas Eve at approximately 5:00 p.m., Brett took the Goblin to a neighboring industrial office zone, accelerated in second gear, felt the rear end get loose, and was unable to countersteer out of the situation before hitting a Dodge Intrepid parked on the street. The collision pushed the Intrepid off the road and Brett’s Goblin suffered terminal frame damage after completing a 180-degree rotation and coming to a rest in a parking lot in the unpopulated industrial zone.

Or so we assumed.

Turns out, there were dedicated employees nearby who left their Christmas Eve workstations to assess the situation outside. Someone called 911. While he doesn’t remember the spin, Brett didn’t totally black out when the collision happened. He managed to turn off the Goblin, release the five-point harness, remove the steering wheel, grab the roll cage and extract himself from the wreckage. He recalled a need to “encourage my left leg to move” and it wasn’t until he was a foot away from the Goblin that he realized he lost control of his left leg. One of the Goblin’s horizontal tubes bent inward on impact and likely was the source of Brett’s leg injury.

Brett called his family, who were a mere 1.1 miles away. The Houston Fire Department were the first responders on the scene, and as Brett put it, they were “nice enough to put a Band-Aid on a cut on my hand.” He clearly needed more medical help, as Brett likens the impact to that of an offset barrier crash test, and the resulting pictures suggest the same.

Once the paramedics arrived, Brett’s leg was put in a splint and he was transported to a small local hospital. Once the workup was completed, it was determined he needed a Level 1 trauma center to address a broken tibia, fibula, severed Achilles tendon, and fractured foot. Brett spent 2 weeks in the hospital, working and playing virtually (these being pandemic times) thanks to modern technology, including some long phone chats with yours truly. He was always in good spirits (even growing a mustache worthy of my Movember moment) and finally returned home in January 2021.

Brett was mostly bed-ridden for the next six weeks, but we had plenty of time to assess the Goblin’s condition both on the phone and in his garage. Most importantly, Brett emerged from the accident fully recovered, aside from some wicked-cool scars on his left leg. By the summer of 2021 he was hosting an event for the Goblin community (including Lonny, the owner of DF Kit car) in his garage to go over the wreckage and do a full recap of lessons learned.

For one, Brett never, ever made excuses for what happened. Instead he methodically sourced potential issues that caused the problem. Brett makes no bones about the possibility of driver error being an issue, not having wheel alignment fully dialed in, cold tires, and so on. In the end, though, the biggest factor contributing to loss of control was likely suspension play from the rear ball joints.

Let’s dig into that for a moment: Apparently the Turbocharged SS has a unique 20.5 mm front ball joint, and even the Supercharged SS uses the same unit (19.5 mm) as more pedestrian Cobalts. And while having a millimeter of play on the front of a Cobalt might not lead to a terrifying accident, slapping that subsystem to the rear of the Goblin can indeed create an issue. Again, Brett doesn’t make excuses for what happened, and he credits DF Kit car for making a chassis robust enough to handle such a torturous impact, and he insists that the five-point harnesses on his race seat saved his life. (That’s an extra cost option, as perspective owners can run the stock Cobalt seat and three-point seatbelt if so desired. Both of us highly discourage that route.) Brett went further with his advice:

“Do not get carried away test driving the car until it is fully vetted. Have other builders check it out and drive it. Have it inspected by a master mechanic and do not be afraid to ask for help with the alignment.”

That said, all is well that ends well. Even with supply chain shortages, Brett’s new Goblin is safer (using a modified frame design), more visible to threats in traffic (finished in a color worthy of his alma mater and employer), and is just plain better than the first iteration. More on Project Goblin v2.0 in a future update … much more in fact.

Incidents like Brett’s crash remind us that personal health can’t be replaced. Family, friends and a community of car enthusiasts always make the ups/downs of life more pleasurable/tolerable. To wit, Brett and I cannot thank Lonny at DF Kit car enough for his kindness, compassion, and the fantastic engineering inherent in his products. Risks are part of the deal when it comes to buying, building and driving a ANY kit car, but Lonny makes the experience feel highly supported.

Of course, no matter how intimidating something looks at first, having time, family and community on your side only improves the situation: Witness the fact that a member of the Houston-area Goblin community was en route to the accident site on Christmas Eve, 2020, to offer assistance and moral support.

A year later, to see Project Goblin in better shape than either of us could have imagined is a bit surreal. Christmas miracles do happen, but sometimes they require two Christmases to take. From all of us at Hagerty, we hope you enjoyed the story of Project Goblin, and we wish you a very Merry Christmas!

Well the old man in me thinks someone was probably in over his head on performance. Was he insured since he was just ”Test driving” it?

Sounds like a “Cars & Coffee” story!

Glad he is OK after that accident.