Media | Articles

Piston Slap: Sealing threads in ported heads?

Michael writes:

What is the best way to seal a steel rocker arm stud in an aluminum head when the threads open to the intake port?

Sajeev answers:

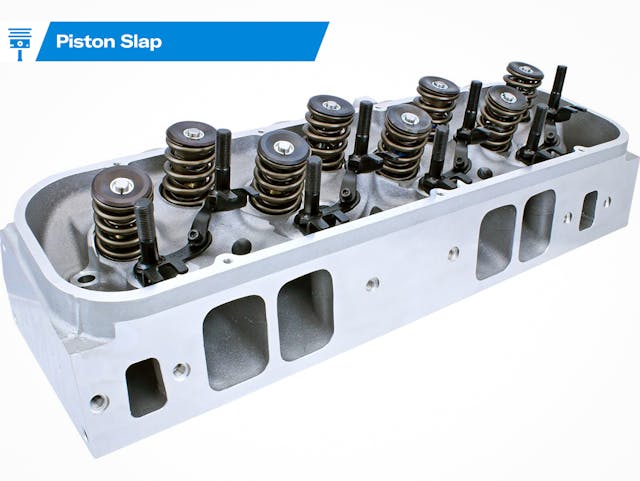

I’m tempted to suggest that only someone with experience building the engine in question can answer this, but odds are there’s general information that applies here. And to insure that we’re all on the same page, here’s a graphic representation of the issue, using a cutaway of a GM LS-series engine.

Basically, if you port these heads, you will see threads. And exposed threads, when met with engine vacuum, might create contamination between the incoming air and the crankcase air (between the cylinder head and the valve cover). Simply put, the threads must now also be air tight.

Marketplace

Buy and sell classics with confidence

Your best bet (only bet?) is to use a thread sealer on the rocker arm’s studs. As mentioned in this forum post, using a thread locker like the ones from Permatex or Loctite is the way to go, not to mention you might already have it in your toolbox. The blue thread locker is good for 300+ degree temperatures and is easily removable. The red thread locker is a lot stronger, but you’ll need a lot of muscle (or heat from a torch) to get the studs off again. And, while I mistakenly assumed red is mandatory, the general consensus is that blue is adequate here.

That said, this might be a good time to discuss torque specs. If the aluminum head in question is a factory part (like the LS head, above) the specifications listed in the repair manual are probably fine. If these are aftermarket heads, it behooves you to call the tech support line from the manufacturer to see what torque spec is needed, especially because of the exposed threads (presumably from porting).

Too bad I have no experience in this matter, only tangential knowledge gathered from watching other people soup up small-block Ford and Chevy mills. So, Hagerty Community, if you have firsthand knowledge, we’d love to hear from you!

Have a question you’d like answered on Piston Slap? Send your queries to pistonslap@hagerty.com, give us as much detail as possible so we can help! Keep in mind this is a weekly column, so if you need an expedited answer, please tell me in your email.

You’re right on Sajeev. Blue loctite or the new orange loctite will work perfectly. The torque figure is whatever the factory or the fastener manufacturer says it is. 🙂 I’ve also used liquid pipe sealant for these applications and cylinder head bolts that got into water. It works perfectly.

Thanks for this, especially for the recommendation of liquid pipe sealant. Sounds perfect for this application!

I been using the new Orange Permatex thread locker. Great stuff. Best of both worlds