Media | Articles

Piston Slap: Ditching V Belts in a Serpentine Search

Roger writes:

I’ve had it with V belts on my 1962 Fairlane with a later-model 302 V-8. Don’t get me wrong, they’ve worked (2 of em) very well for last few years. But I lost my first V belt as I turned on busy corner, heard a thwack, thunk, and in my rear view I saw what looked like a snake I’d run over. A kilometer later, I glanced at the gauges and my water temp was trying to leave the right side of my gauge! Went back, got the tattered belt, and after a teen behind the parts counter asked, “’62 Fairlane V-8, is that a foreign car?” and I ended up with a Toro tractor belt that seemed to work fine. But that’s enough for me.

Other than spending $2,000 Canadian for an aftermarket serpentine belt setup, my Chevy buddy popped the hood on his Monte Carlo, showing me his serpentine setup that he found at the local U-pull it yard for 70 bucks! (Off a S-10, I think he said)

I was looking up junkyards, and one I spoke with said “1962 Ford Fairlane with a later model 302, eh? Nope, can’t help ya. Ford changed so much of the related hardware I wouldn’t know where to start. Now, if it was a GM model, no problemo.”

So, is this true about Ford? Am I screwed before I go digging? Do I have to pick 6 Ford models to get the parts I need? (I don’t mind, eh.) Oh, by the way, I’m running an alternator, water pump, and a KRC power steering reservoir. (KRC is a thing of beauty, with jets to tune the steering feel.)

Marketplace

Buy and sell classics with confidence

I don’t mind digging through different models, I’ve heard F-150’s for this and Crown Victoria serpentine setups for that. One guy even told me an Edsel serpentine system bolts right in! (Sure, I’ll head over & pick thru the Edsel line of cars at the junkyard.)

Sajeev answers:

You’d think this would be an easy answer for a Ford enthusiast with a 5.0HO-swapped Mercury Cougar in his garage, but no, the same issues you are experiencing are a brick wall for me.

Take, for example, the rotation of the water pump: it changed direction sometime in the Malaise Era (I think) so you might need the water pump from the donor Ford vehicle to ensure it all works correctly. And the timing cover might vary because of that water pump. That’s the extent of my knowledge of the pitfalls to your serpentine belt conversion on an unknown vintage small-block 302.

Luckily CVF Racing makes you answer the tough questions to ensure you get the right stuff from their company. This will also help in your junkyard scrounging.

1) Is your lower radiator hose going to be on the passenger side or driver side? This tells us if your water pump is 5.4″ or 5.7″ tall.

2) Do you have 3 or 4 bolt damper? This tells us what offset it could be in addition to what the bolt pattern is.

3) Is your damper factory or aftermarket? (Aftermarket 4 bolt dampers are shorter and usually require a spacer)

CVF Racing

Their info on water pump rotation is also quotable:

Standard rotation water pumps should have a 1.75” bolt circle, reverse rotation water pumps should have a 2.06” bolt circle.

Another way to try and identify the rotation of the water pump would be to look at the belt(s). A v-belt water pump pulley should be a standard rotation pump. A serpentine belt water pump pulley with ribs should be a standard rotation pump. A serpentine belt water pump pulley that is smooth or without grooves should be a reverse rotation pump.

CVF Racing

But all the questions and armchair analyzing ain’t gonna help if local junkyards are the only place you will get the parts. And that’s not hate, because I would do exactly the same thing.

With the water pump/timing cover/etc knowledge you now have, I recommend you inspect an entire donor car/truck at the junkyard with this in mind. You should take everything from the water pump, the timing cover, and everything forward. If you don’t need it, it becomes scrap metal in the future. But for now, you need everything.

The Falcon isn’t the biggest Ford out there, so it’s possible that the Crown Vic or F-150 setup won’t fit. (Unlikely, but bear with me as I play devil’s advocate.) The most compact setup came in the 1995-02 Ford Explorer 5.0, as that SUV’s cramped Ford Ranger engine bay made it tough to slam in a small block with all the goodies (like air conditioning, etc).

In theory, the Explorer is best because it’s so compact and slick. But there’s a good chance you aren’t working with a fuel injected, later model engine block. If you have an older 302, the Crown Vic setup might work better, as they have a twin serpentine setup that likely has more flexibility for your application. But my favorite might be the F-150 setup, as it has one belt that varies in size depending on the number of options you have. (Power steering, A/C, etc.)

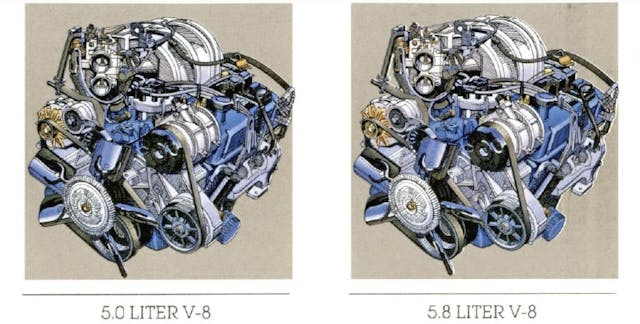

From what I see in the picture above, looking for a 1986(?)-up Ford truck with the 5.0 or the 5.8 might be best. You may be able to cobble together the bits to modernize your Falcon, though this could all be wishful thinking on my part.

But I remain optimistic, as I have a feeling you enjoy a junkyard scavenge just as much as yours truly. I’ve learned from these adventures that the 2.3-liter Ford Rangers from 1992-94 have a wonderfully modular serpentine belt setup for other four-banger Fords. Grabbing one from the junkyard netted me fancy aluminum brackets and a low-slung 3G alternator. It all ensures my turbocharged Ford Sierra project will one day have everything it needs from that belt. And the new alternator location means I can clean up the intake’s path from the Sierra’s front-mounted intercooler to the throttle body…that’s a discussion for another day, but it did suggest that Ford’s parts bin may offer a solution even if it’s not commonly known among pickers.

Good luck in your junkyard hunting. Go get parts from a discarded Ford truck and give them a new lease on life!

I work in the performance aftermarket. Converting is not easy or cheap with junk yard parts.

You may loo at a March system and try to copy it as a pattern. You can also get them in many cars unpolished in black for a lower price.

To be honest there is nothing wrong with V belts. The cone off for two reasons. One they are not in alignment or two you have too big of a belt. You need to buy by size not application. Get a shorter belt that will tighten up.

We ran v belts racing even high RPM. Never a problem.

I think you just need to fix the problem you have vs creating a new one.

^agree with Hyperv6.

Size both belts correctly. Then buy spares that are in the trunk and the tools you need to change them on the side of the road.

It sounds like no matter which way you go, it will be a head-scratcher at the parts counter. I would recommend doing some research on v-belt sizing. Most of the major manufacturers have the thickness and length of the belt integrated into the part number. Once you know what your correct size belt is, you will be able to order it anywhere

I typically dislike going against Sajeev’s advice (after all, he gets paid to provide it), and I feel he’s pretty fearless when it comes to parts adapting within the FoMoCo world, but reading his responses about possibilities with pumps, pulleys, timing covers, etc., etc., etc. just made me think: all that to basically replace a v-belt? I’m in line with others commenting here – I’ve run v-belts on engines since the mid-sixties in all sorts of applications from street cars to off-roaders to semi-trucks to drag racers to farm equipment, and in all those years, I think I’ve had two issues (and one was really more of an idler problem than the belt). As others have suggested, there’s a reason that a car throws a belt, and once you isolate and correct that, the simple thing to do is just continue to run what the factory intended.

Your points are both valid and likely stronger than mine.

No need to worry about disliking my advice, as I get paid to start conversations. I am not here to be the final say in anything, or some guru who is never to be questioned. That’s too much pressure for me!

The only reason I am pushing harder on doing the serpentine belt setup is that sometimes the right vehicle in the junkyard manifests itself. I still needed to get a new alternator for the Ranger setup on my Ford Sierra project, and LKQ charged me way, way, waaaaay more than I expected from this junk. But the end result that bolted up to my new engine was worth all of that mess.

To measure you can use a string at both extremes of the adjustment. Look at the belt alighnment this is what tosses most belts. It needs to be straight. You may need to shim or replace a pull.

Average v belts are same v for most automotive.

The trouble going Ford is they did many variations of the same thing on many different vehicles and few adapt easily.

To do it efficiently takes a very deep understanding of the parts and changes. Then having the luck to find them.

Yes the serp is a nice idea but buying the aftermarket kit would save time and possibly money and frustration.

When it comes to Chevy many years we’re the same parts in many cars. As time went on that began to change.

I see people trying to make changes and struggle enough on v pulleys that are easier.

I only speak from a point of experience. I see tge struggles and issues and found they are not simply don on their own.

You may do a web search for a formula of success on what parts to use. Then see how easy to find the parts needed then how much. Often that March price is much lower.

Also like many Canadians ship it to the states near the boarder. It can be cheaper.

One more note finding parts in Canada can also be difficult due less cars and models offered in many cases.

Just things to consider. Seen these struggles before and most do not work out easy or cheap.

I want to know more about the Sierra setup you mentioned.

I haven’t done much with it since the pandemic, but you can get caught up on it here. One day I will get back on it.

On my 65 falcon with 289, I used the setup off a v8 fox body mustang. Whilst everything bolted up, I needed a new timing cover, harmonic balancer, and a switch to an electric fuel pump