Media | Articles

My XR250R wrenching philosophy: I’ll cross that Bridge(port) when I get there

The process of building my Honda XR250R into racing shape has been more of a task than I anticipated. Despite budgeting fifty percent more time than I hoped to need, fifty percent more money than I thought I’d spend, and a thousand percent more frustration than I expected, this project is still stumbling when it should be striding towards the finish line—or, in this case, the starting line.

This is a tough update to write for a couple reasons. The first is that there are no sexy progress photos to share. The bike looks about the same as it did last time. What’s especially frustrating is that the project took a big step forward only to take one immediately backwards. The frame was tidied up months ago, with the trick Race Tech suspension bolted up, and even the faded plastic was polished and ready for glamor shots. So when the boxes started arriving from Millennium Technologies, I was all too excited to assemble the engine and bolt it into the frame.

There was extra excitement with each box because the crankshaft, cylinder, and cylinder head arrived separately, each in a state that could only be described as better than new. Not that I ever expected to write that. Late last year, this engine blew up in a magnificent way: The crashed valve broke off, launched itself at the cylinder walls, and proceeded to make mincemeat of the combustion chamber. Short of casting a new head, how could anyone really bring this back? I contacted the Wisconsin-based crew at Millennium Tech earlier this year, however, and they were completely unfazed by the carnage. Their solution? Lots of welding and CNC machining.

The shop stripped down the head and then welded it up before affixing it to the CNC machine. A cutter removed the built-up weld to restore the original shape of the combustion chamber and cut the pockets for the valve seats. As those new valve seats got pressed in, the valve guides also met their press-fitted homes. High-performance valves and springs rounded out the package before Millennium Tech boxed everything up and shipped it back across Lake Michigan.

The crank and cylinder were less involved, but no less spectacular to see in their finished glory. The crank was a simple job: Press apart, install new rod kit, press back together. The cylinder got plated with nickel silicon carbide, which puts a paper-thin layer of extremely hard, extremely durable barrier on top of the soft aluminum. Millennium Tech claims this addition decreases friction, improves heat transfer, lowers weight, and ultimately yields more horsepower. I’m always open to having more horsepower.

Marketplace

Buy and sell classics with confidence

The case assembly went quickly, though I obsessively referenced the factory manual for every bolt torque and assembly diagram. Then the piston and cylinder slid on, and all hell broke loose.

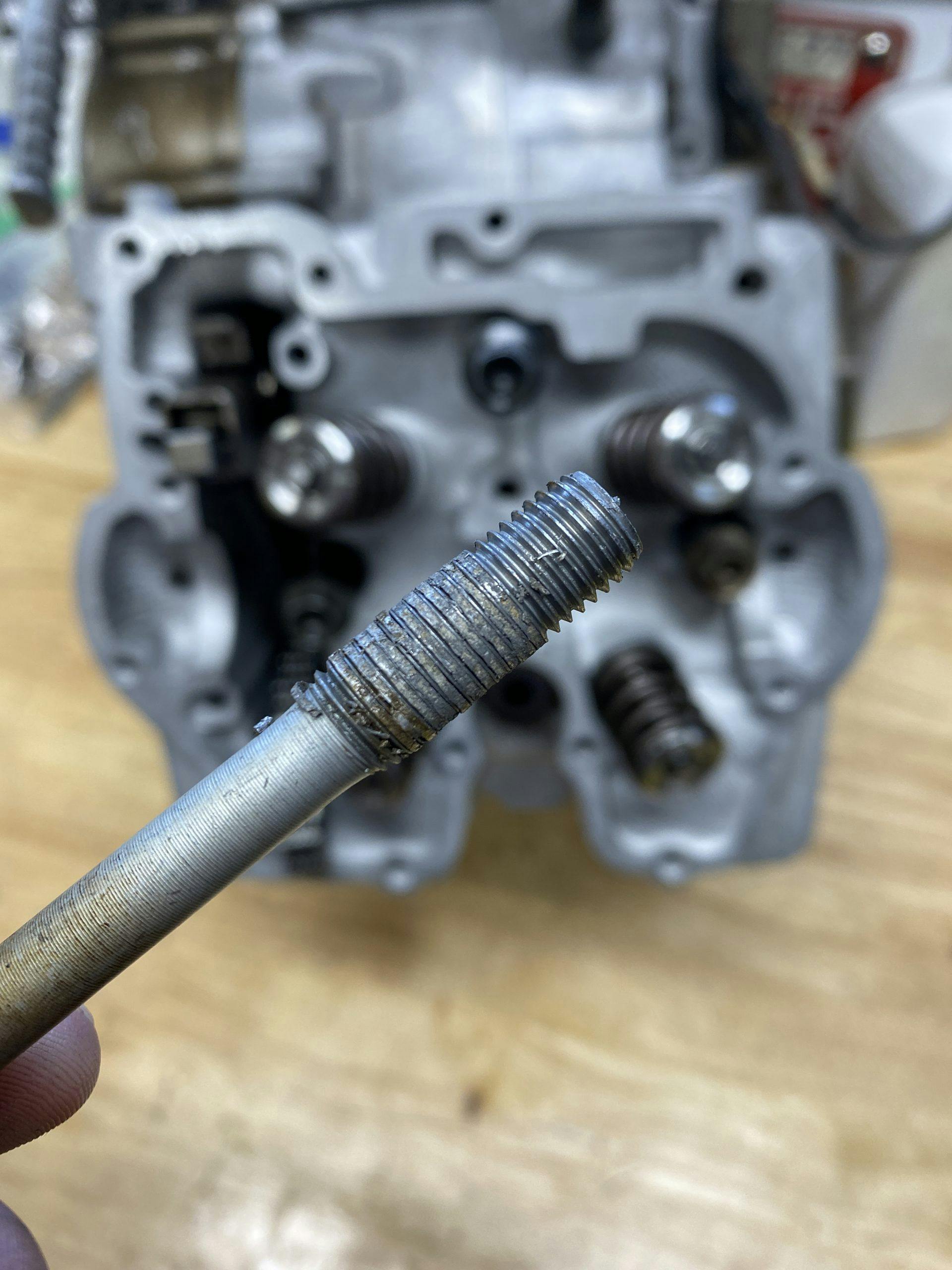

To be clear, this is not the first time I have disassembled and assembled this engine. True, I had reused a few questionable parts during my “budget build” that took place last spring, but the cylinder hadn’t given me any trouble. This time around, as I happily bolted the cylinder head down, two of the bolt simply refused to take torque. The aluminum threads pulled right out.

This wouldn’t be such an issue if it wasn’t for two other tasks I had already decided to delay indefinitely. When I first refreshed this engine last year, one exhaust stud broke off in the head. I hack-repaired it, knowing I would need to properly fix the stud one day. Then there was the spark plug debacle. In all the fresh machine work done to the head, the spark-plug hole was welded up and recut, but not to match the factory 12mm threads. Instead, 14mm threads led into the combustion chamber. What plug is the correct one now? It’s up to me to find out.

I took the time to install three Heli-coils into the cylinder. This was an easy fix for the pulled threads. A dash of Loctite to keep things where they should be, and problem one was solved. Problem two got out of hand quickly. The exhaust studs do not thread very far into the head and in my attempt to drill out the previous mistake I discovered something inside the head—something harder than my drill bit and high enough to prevent a Helicoil from seating properly. The spark plug hole was empty.

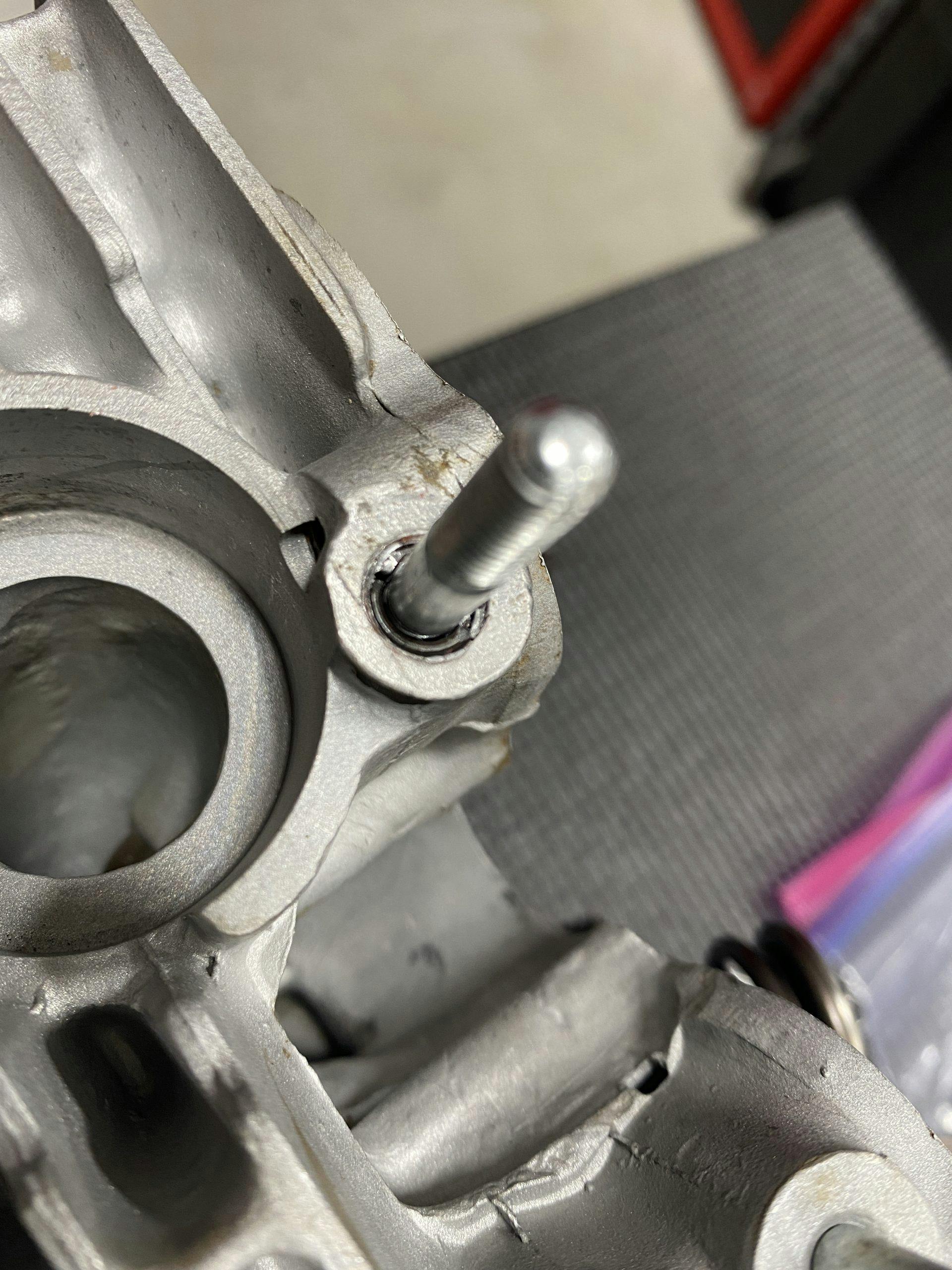

Toss in the fact that I am exactly one week from pointing my loaded-up truck south to go racing and I knew it was time to call in the big guns. Davin has always generously helped me repair things that I’ve butchered, but I am still surprised he picks up my phone calls. Within minutes of my dropping by the Redline Rebuild garage, he had the head chucked in the Bridgeport and was pecking out the leftover steel in the stripped hole with an endmill. Once the hole was clean, we prepped it for a Time-sert style repair. This meant drilling an even bigger hole and threading in a piece that had both external threads and the internal M6 threads needed for the exhaust stud.

The spark plug was a more entertaining adventure. My favorite Tuesday afternoon activity is dropping random parts on the Thirlby front desk. I then watch the team banter its way through problem-solving whatever random issue is currently afflicting me. This week, we stared at the head a bit and measured the correct factory plug before one of the guys picked up the phone and called NGK. The company had a plug that matched my needs closely—but not exactly. I needed a threaded-top version; NGK only had one with a solid top. A simple change to the plug boot would solve this conundrum—and that’s the only thing preventing me from starting the bike right now because, of course, the specific part I need is not in stock.

No matter. The bike is together. Simply seeing a whole bike again after five, nearly six, months of sporadic wrenching is invigorating. The sparkplug boot arrives tonight and with any luck the next update will have the bike running. Either way, you’ll hear about it—and, come what may, I will be headed to Kansas for the AHRMA Motofest. Stay tuned early next week to find out if this adventure will be a last-minute thrash or an enjoyable jaunt.