Media | Articles

Lada 111 Tuning: The toughest horsepower that was ever earned, Part 2

Will it ever get easier? Perhaps you remember how we left off in Part 1: Spending the afternoon at Customs. The great big pile of Russian speed parts resting in my driveway. The suspicious neighbors on their evening strolls, staring into my car and wondering: What kind of nefarious activities could he be doing alone, inside his car with a laptop. All that was a cake walk compared to what was coming following the long-anticipated dyno date and five-hour-drive. In only a matter of days, the remaining parts needed to be in the car and more or less functioning, lest I miss my appointment with my virtual German teacher, Marco Degenhard of the Halle 77 YouTube channel. Alright, into the garage we go!

I wasted no time in installing getting the exhaust. And it didn’t have to—the fitment was almost perfect and the entire system from header to tip was right where it needed to be in under two hours. It knocks on the tow bar, but that’s nobody’s fault. A quick start-up and test drive confirmed a decent uptick in power and a sound that’s both blatty and raspy, yet muted. Like the right bank of a glass-packed Ford Y-block spun twice as fast and smothered with a pillow.

At this stage, the motor now could spin to 7500 rpm, but it was totally out of breath due to the lazy factory cams. Enter new bump sticks. My selection criteria were the following: must work with stock valvetrain and be somewhat drivable in town. Lumpy idle a plus. 8000 rpm a must. One hasn’t lived until they’ve over-cammed a car and then needed to live with that decision. Having been there before, I selected my dream cams and subtracted 20 degrees of duration as part of my continued quest for maturity.

Marketplace

Buy and sell classics with confidence

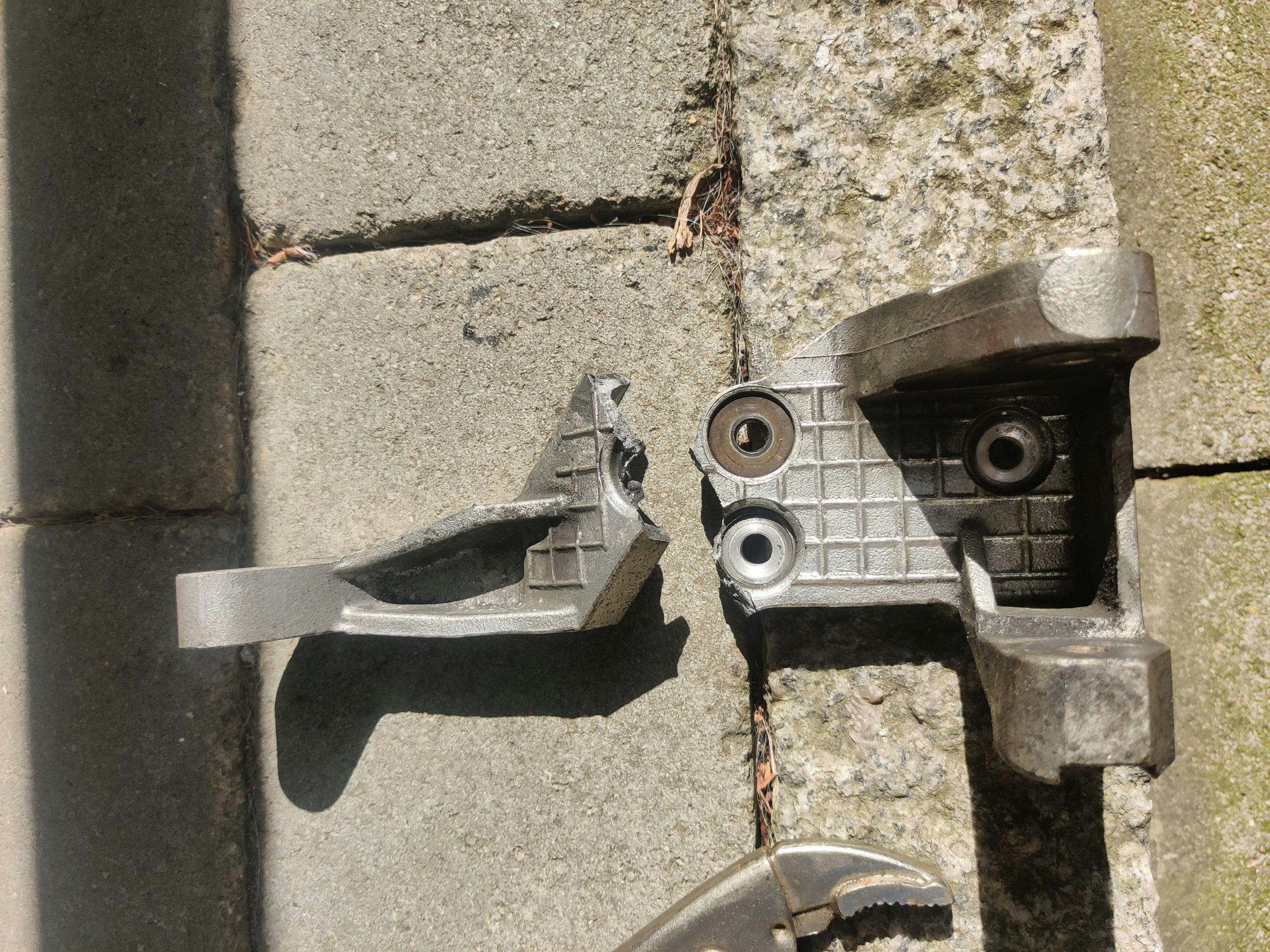

During the cam install investigation, I was also determined that the alternator bracket had broken completely off. I can’t even tell you why the alternator was still on the car. But I can say that it sounded like a woodpecker.

A few calls and two trips to Stuttgart later, I had my big aluminum montage back in my hands thanks to some absolute TIG legends at a local machine shop.

The cams are held in by a big cradle and once you find the right place to smack it with a hammer to release it from the head, the job can be done in 30 minutes. Hydraulic lifters means no measuring and swapping of shims. After the install, it (shockingly) fired right up and idled. Amazing! I borrowed an Innovate air-fuel measurement box from a friend, jammed an oxygen sensor in the tailpipe, and started making adjustments to keep the air-fuel-ratio at around 13.25:1. From idle to 7800 rpm it was now dead-on. Using my Windows 3.1 Cyrillic Edition calibration software and trusty Google Translate, I was able to log more air mass data and gradually optimize the cam timing. Ideal overlap and advance also yielded a light chop at idle, so I was satisfied. For good measure, I also ordered and installed a catch can to catch more of the oil droplets blown out under duress.

On my way back in from a tuning session, my neighbor informed me that the Lada was smoking. Between the German willingness to tell you exactly what they’re thinking and slightly rich idle, I figured that this was a superfluous critique. Then again, said neighbor ownd a two-stroke Wartburg, so he knows a thing or two about smoke.

The next morning, a sunny and cool Sunday, a follow-up test drive with a short high speed Autobahn run would prove him right. As joggers and bikers were being blanketed with a dense blue fog, it occurred to all of us that something was very much amiss. I sheepishly pulled back into my driveway as my neighbors gawked, luckily most of them laughing. I don’t split hairs between “with” or “at” at this point. A quick look to the outside of the car painted a grim picture with my inner fender wet with oil and lubricant bleeding out of my turn signal and trim. Now THAT’S some blinker fluid!

Clearly, my newfound higher revs were causing problems. Did it blow it up? I started pulling things apart to confirm. In a moment of immaculate revelation, looking through a parts microfiche, I noticed that one of rotten hoses that had crumbled in my hands actually was plumbed from the valve cover to the oil pan. Hmm. I had plugged both those holes. Perhaps that was dumb. As it turns out, this gigantic crumbly hose had a purpose. Design-wise, all the oil that can’t find its way down through the passages in the head and block was delivered back to the pan via rubber log flume. Or onto the ground via disintegrated pipe. Now it was still ending up on the ground, albeit with a more exciting journey through the valve cover, catch can, intake manifold, and turn signal.

After all this, we are now roughly 24 hours before dyno go time, which is five hours away in Dortmund. I needed a plan and fast. The option of using stock parts was out. The remains of the oil return pipe were swept off the floor hours ago, and even a new one wouldn’t be adaptable as the old port on the valve cover was blocked. With a rough idea of a workaround, I ran to the junk yard and dug through a huge bin of old radiator hoses. I snagged two or three that had at least one of the compound bends I needed. After that, I sprinted to the home improvement warehouse and raided the pool plumbing section, coming up with a 38mm barb fitting with 3/4NPT threads. I threw a bottle of epoxy and a 3/4NPT plug in my basket for good measure. Back at the house, I pulled the valve cover and nervously drilled the end of it to the very last notch on my step bit. I roughly cut the NPT pipe plug into a tap and—with care never before used in a vehicular project of mine—gently tapped the massive nearly 1.5-inch hole in the cover. With the enormous brass pool pump fitted in place, I epoxied it all up and mounted it back on the motor. Now, looking at the plumbing situation with the manifold off, I was bestowed a gift by the god of poorly constructed cars. The wonderful fiber-reinforced VW Passat radiator hose fit without any modification. Praise be! I got the wine opener out of the kitchen—not to celebrate, but to extract the huge cork I jammed in the oil return. It’s back together, yes, but the clock reads midnight, and that’s too late for a potential fire. To bed I went, sans test ride.

Up the next morning, I readied my laptop and tuning interface for 3-4 hours of optimization. Instead, I made it 400 meters and the throttle body fell off at the bottom of the hill. Great start. I quickly secured, it but then cut myself and had to go to the hospital for some stitches. I thought about taking the Lada, but I decided to just walk to make sure I get there before bleeding out. My valuable test and tune time ticked away in the waiting room. After a little fleshy knifework from kind professionals, I’m was bandaged up and departure was on the brain. My wife and I quickly loaded our bags, Lukas the dog, and tools before hitting the road. I was sweating and dreading this trip at this point, sure that it would end with us on the side of the A81 with a rainbow-colored oil slick expanding out from under the car.

We hit the Autobahn north on the way to meet my buddy Greg and his wife in their Daihatsu Charade. With roughly 40 miles of intensely scrutinizing every noise and smell coming from under the hood, we arrived at the rest area meeting point. While the ladies walked around the parking lot with Lukas, Greg and I did a last-minute nut-and-bolt inspection and while trying to skirt police scrutiny. Back on the highway, the car was running like a top. Aside from the dog vomiting deep into the seatbelt buckle hole in the back seat, sheets of rain, and endless construction zones, there was nothing to report in the 5-6 hours it took to reach our hotel in Dortmund. Dinner, a beer, and a quick walk-around happily punctuate a stressful yet gratifying day.

The next morning, we headed to Halle 77. It’s loctaed in a nicely wooded industrial park. The parking lot and “Hof”, or central parking area of the shop, were totally packed with European Classics and a Dodge Daytona. Hello, unexpected tickle of homesick feelings! After a brief ogle, it was time to put the cars on the rollers. The Daihatsu pumped out a respectable 94 horsepower and screamed all the way up to 7800 rpm, with the tachometer sweeping backwards for reasons unknown. Greg was in no way disappointed. The Lada did me proud, too. But best to watch the video for the full effect. (Transcript is below the clip if you’re following along and not a German speaker.) As for Halle 77, this place deserves an article of its own; a couple of paragraphs wouldn’t do justice the service Marco and his Youngtimer wonderland bring to the automotive community. Stay tuned.

Ultimately, I have a lot of faith in the car now. I glow with excitement when I think about this trip and the huge push it took to get here. Though after a brisk run to the Alps and back last week, the clutch is now slipping. That shouldn’t be a hard job—the clutch is already on order with a few other things to make it go smoothly. Like anti-seize, Loctite … and a Torsen limited-slip diff, 4.3:1 final drive, close ratio gear set, rebuild kit, and case extension carrying a sixth gear. Maybe it’ll never get easier. I really hope not, anyway.

Full transcript of the YouTube video. Our performances start around the 11:00 mark.

Marco: And we’ll grab the next car and then you’ll understand why I say we have so many curious cars here today.

People, I’m telling you, seriously. Old cars—awesome … Old cars and curious cars. Where would you see such a car except here on our dyno? When I say I don’t want new cars like the latest Golf, Opel Astra, whatever new Mazda, new Honda, or whatever other makes—you see them all the time on the street. Have you ever seen one of these?!

Cameraman: No but do you know what it reminds me of? It’s like an Audi RS2 that’s been stretched a bit taller.

Marco: What?!

Cameraman: But, from…

Marco: What from an RS2?

Cameraman: From the back, around …

Marco: No, boy, that’s a strike. Complete strike. No. If someone would say SEAT Cordoba, I could say maybe there are some similarities. But I need to talk to the owner. (to me) Come on over here. First thing, you’re from America, right?

Me: Yeah, exactly.

Marco: And you chose a Lada 2111 because it’s so extremely rare. That is really curious. When you first look at this car, it looks completely stock, right?

Cameraman: Yep.

Marco: And it had 94 horsepower from the factory?

Me: Yes, right, 94.

Marco: Ok, 94 horsepower stock. Can you pop the hood and show us around?

Marco: I wanted to quickly introduce this thing to you all. There are very, very few of these and I definitely have never seen one. Most of them are probably in Russia. Most of these are in Russia, right?

Me: Yeah, yeah, yeah. In Russia and the former Soviet Union they’re everywhere and there is very good support from a parts perspective. So, I ordered all of the parts from Moscow and got everything through customs and so forth. That was an unbelievable amount of effort in order to obtain all of the parts. So much with Google Translate.

Marco: This motor is no longer stock. Micha (cameraman) come on up here. This already looks different. The base motor is still original, right? 94 horsepower? And you built in a freely programmable ECU? Is that right?

Me: Yes, exactly. It’s called a Janvar 7.2 and it’s an open ECU from Russia and the entire tuning interface is in Russian. Therefore, I need to take my cell phone … with my camera … and look at all the parameters through Google Translate. It’s very difficult, for example, to find the rev limiter. It’s a ton of effort. I calibrated everything and measured the air fuel ratio with an Innovate lambda box in a couple of days, and yeah, as I said, I only finished it last night.

Marco: Last night you finished this and today you drove this thing up from Stuttgart to put it on the dyno.

Me: Yeah, exactly.

Marco: That’s what I mean. I get goosebumps from this community. Micha, go around to the other side. There you see something else interesting. Here you see adjustable cam gears. That means you’ve also put new cams in it and calibrated the whole thing quickly last night in order to run it on the dyno today.

Me: Yeah, but I had played around in the ECU earlier, just without the new cams. Just with the intake manifold, new exhaust, and air fuel measurement. And then I installed the new cams and recalibrated a little bit, made air mass measurements, and then changed the cam timing a bit more.

Marco: And you programmed it all yourself?

Me: Yep, yep, yep

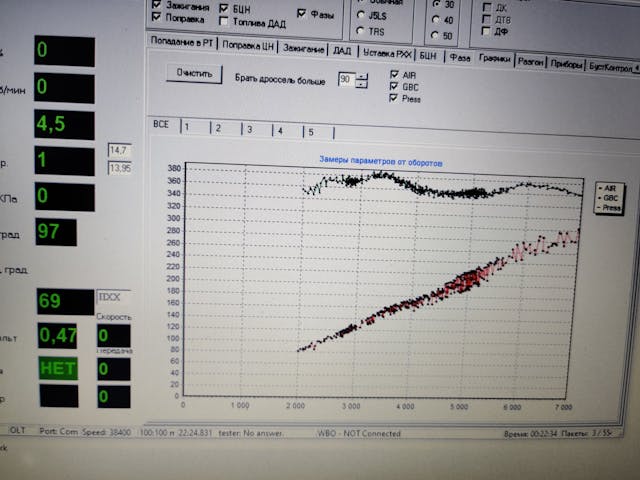

Marco: And with the air mass measurement, you can calculate a power output, right? What kind of power did you calculate?

Me: 136 horsepower at 7400 rpm

Marco: At seven and a half and that’s the peak power. So that means we need to pull to the rev limiter?

Me: Yep, just spin it.

Marco: Laughing Super, super, super curious story and that’s what I mean. This is now the real deal. You really never see that … and the stories behind it, you also never see. Except here on our Channel with old and Youngtimer (German term for ’80s cars) cars.

Run 1 from rear

Run 2 from front

Marco: Laughing The most awesome story … the really, most awesome story. First, I want to tell you that we ran it in fourth gear. One of the fastest. It’s got a five-speed gearbox but we ran it in fourth. 228 kilometers per hour, in fourth gear … an actual, validated 228 kph it did. We ran it to 7400 and into the rev limiter. And the good man said that he had calculated it—how much power did he calculate?

Cameraman: 136.

Marco: Yep, something a bit over 130. Have a look. Awesome, right? Now we’re going to go over to the owner and talk it all over. More curious it simply doesn’t get. We even just discovered that this thing also has an LPG system installed on it! For when you want to save a little money. Now, if I may ask … what do you do for work?

Me: I’m an engineer.

Marco: Ok, that explains everything because to build something like this is really wacky. And you said you had made a power calculation. Where exactly must it land?

Me: 136 horsepower at 7400 rpm.

Marco: This is cool. You made 131 horsepower at 7400 rpm. That is really true.

Me: Huh!

Marco: How you calculated that—it’s giving me goosebumps right now. This is so cool, when someone knows exactly what they’re doing. So you did cams, free programmable ECU, and the intake manifold …

Me: And the exhaust manifold, too.

Marco: And I believe that with a shorter gear ratio it would do even better. Because in fourth gear, I looked, and we were doing 228 kph. And that’s really, really long. And I think with this car, you don’t really want to go 230kph, do you?

Me: No, no.

Marco: But does it do it anyway, from an engine power perspective? No, right? Can it go over 200?

Me: Yeah, yeah, it will go about 210 kph.

Marco: Before it can’t overcome the wind resistance? Thank you for bringing us this car and the huge ride you took to get here in order to show our community your car. Because that is the “ober-hammer” (absolute best). This really made me happy, thank you. Have a lot of fun, great that you were here, have a walk around and check things out. Great story. Really, super, super awesome.

Me: Definitely! Bye!

Marco: Ciao!

***

Matthew Anderson is an American engineer who relocated to Germany a few years ago for work. In his spare time, with reckless abandon, he pursues a baffling obsession with unexceptional Eastern Bloc cars. We don’t ask him too many follow-up questions.