Media | Articles

Inventing a New ICE in an EV Age: The Waissi Engine

I admit to being a bit of a romantic when it comes to inventors, particularly independent ones who are pursuing their dreams without the resources of a large corporation, government agency, or university. There’s something special and quite human about seeing a connection that others don’t see and keeping at it. Clessie Cummins made more than 3000 prototypes while developing his fuel injector for diesel engines.

Sometimes the story ends up in failure and obscurity, other times in generational wealth and celebrity. More often than not, the success lies not in business or fame but rather in increasing human knowledge. Of course, sometimes you learn that something simply doesn’t work. For most inventors, that’s not a reason to give up but rather to consider alternative solutions. Like Thomas Edison said, “I have not failed. I’ve just found 10,000 ways that won’t work.”

About 50 years ago, engineering professor Gary Waissi was teaching a course in physics, and during his lecture he doodled a sketch of a disc mounted eccentrically on a shaft and realized that a piston could push directly on the edge of that disc, converting linear motion to rotational motion. Eliminating connecting rods and much of the crankshaft would have advantages in terms of reducing friction and weight in reciprocating-piston combustion engines, possibly making an engine based on the concept more efficient than conventional designs.

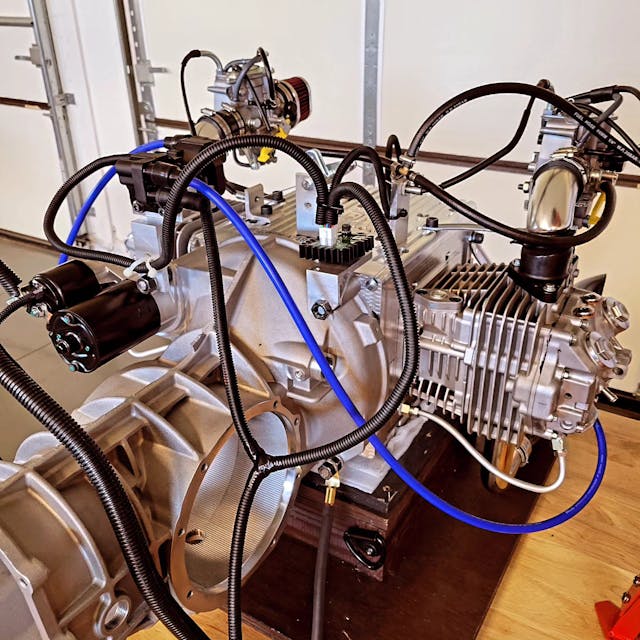

In the mid 1990s, then at Arizona State University, Waissi started working in earnest on the engine concept, based on a horizontally opposed two-cylinder design. The two pistons are linked together and move in tandem as they push on the disc and it rotates. Compared to a conventional engine, where forces from the connecting rod tilt the piston at an angle to the cylinder walls and create friction, the ganged pistons travel perfectly parallel to the cylinders. Later refinements put a circular ring around the “crankdisc,” upon which the pistons acted and within which the crankdisc spun. Additional development determined that flattening the sides of the annular ring that are in contact with the pistons further reduced friction.

You can read Waissi’s technical description at bottom.*

Marketplace

Buy and sell classics with confidence

To be honest, it’s easier to understand it with drawings and animations, but the bottom line is that it’s a very elegant idea.

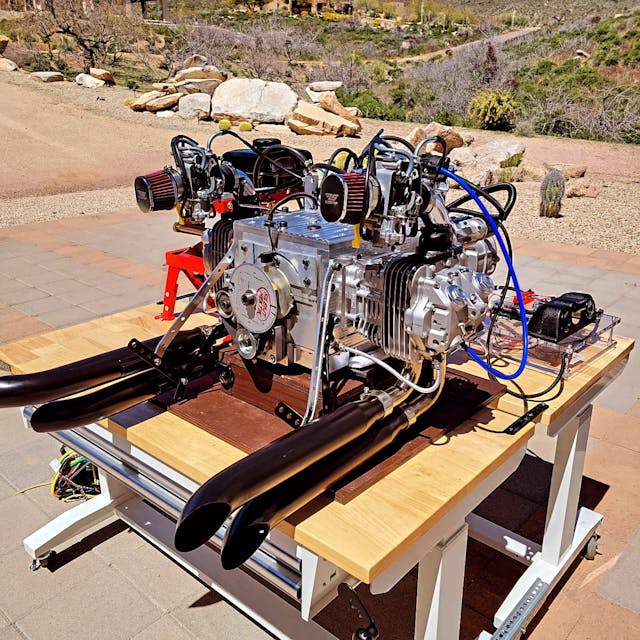

Ten years ago, Waissi came to the Society of Automotive Engineers World Congress, where he displayed drawings, animations, and some engine parts, but the engine had not yet run outside of the digital domain. Since then, he’s built two running versions of the engine, with the current motor, which Waissi describes as “Version 1.9999 repeating,” being the sixth-generation design. That engine is now on display at this year’s SAE convention, and I got a chance to discuss the project’s progress and trajectory with the professor.

The concept will work with both spark (gasoline) and compression (diesel) ignition. I didn’t ask but I’m guessing it will work with Atkinson as well as Otto cycles.

The project has been pretty much self-financed and now reaches into six figures. Waissi Engines is a two-man operation. Gary Waissi is now retired from teaching and devotes much of his time to the project, with son Robert, also an engineer (who works in audio by day), helping. Gary says that the annual outlay has been between $10,000 and $20,000 a year, depending on what components they need to have made.

Anyone who has owned a Honda motorcycle or a car with an air-cooled OHC engine will recognize the cylinder barrels and heads on the prototype. As a matter of fact, that’s what drew a Honda engineer to the Waissi booth, texting photos of the motor back to Hamamatsu. Engineers from Ford, General Motors, and a handful of Chinese automakers also expressed interest. The overhead valves are operated via chains driven by auxiliary shafts geared to the main shaft. The animation above also shows some counter-rotating weights, also on auxiliary shafts, which Waissi said were intended to prevent rocking of the engine but in practice were found to be unnecessary.

As shown by the use of production Honda components, the Waissi engine is compatible with current automotive industry manufacturing and assembly methods. There are no exotic materials used, and all components unique to the engine can be made with conventional manufacturing processes.

Waissi says there have been “nibbles” from major manufacturers. Beyond its applicability as a primary powertrain component, because of its compact size and light weight, the Waissi engine could see duty as a range extender in a hybrid system.

Personally, I think he needs to put it in the back of a vintage VW Beetle as a publicity stunt. Waissi has given some thought to possibly powering a VW-based dune buggy with the opposed-piston “V-180 degree” twin. With just 677 cc of displacement, the 175-pound engine is calculated to put out about 80 horsepower, though that figure remains to be tested on a dyno. Eighty horsepower out of less than 700 cc displacement is impressive in terms of specific output. What I found even more impressive is the fact that the engine can run at 10,000 rpm or higher.

While the Waissis have not yet run emissions or fuel-efficiency tests, it’s still a piston-based, overhead-valve engine with a more or less conventional combustion chamber, so unlike thirsty and relatively dirty Wankels, it should be as clean and at least as fuel efficient as conventional piston motors. Even if those specifications are only equivalent to conventional engines, it would be cheaper to build, as it has fewer parts to assemble.

Since the most powerful engine that VW put in the Type I weighed 244 pounds and put out just 60 hp, a Waissi-powered Bug or dune buggy should probably scoot pretty well. Actually, a production version of the Waissi engine would likely weigh even less than 175 pounds, as the prototype crankcase is milled from a big rectangular billet of aluminum, with no attempt made to reduce the finished weight.

The Waissi engine isn’t the only new take on piston-driven combustion engines to have been displayed at the SAE World Congress in recent years. Nautilus Engineering showed a novel compression-ignition engine with multiple combustion chambers, intended to improve the emissions performance of lawn equipment, but the company appears to be defunct, and the domain name for the company website is for sale.

When Gary Waissi had his minimalist booth at the 2014 SAE convention, Scuderi Engine had a large and expensive open-floor display with a cutaway example of its split-cycle engine inside a plexiglass case and another version mounted in a midsize sedan. Scuderi Engine was founded by the children of refrigerant compressor pioneer Carmelo Scuderi about 20 years ago to develop and license the engine that he patented. Scuderi Engine released a video of the engine running on a test bed in 2012, but the company has been mired in legal difficulties with the Securities and Exchange Commission, and with Toyota’s Hino division. As yet, the Scuderi engine has not come to production. The company still exists, apparently to manage a portfolio of hundreds of patents. A related company, Scuderi Clean Energy, rebranded as ESG Clean Energy, is ostensibly in the business of selling power generation while putting a lot of emphasis on the carbon capture market. The combination of the lawsuits, the emphasis on patent management and licensing, and buzzwords like “carbon capture,” coupled with ESG never publicly showing a running version of the engine (to the best of my knowledge and research), have made a few people skeptical about the Scuderi ventures.

Compared to Nautilus, which had a team of engineers and backing, and Scuderi, which worked hard at selling stock, cultivating investors, and putting on an impressive show, Waissi Engine is a modest venture. The LLC doesn’t even have a website. At 75, Gary Waissi doesn’t seem to be looking to make a fortune off of his idea, but rather to make a working engine and prove his concept. At this point, he seems to be succeeding. Perhaps there’s a lesson to be learned from that.

Asked why he’s devoting his time and not insignificant amounts of his own money to developing a new internal-combustion engine at a time when the industry, amid considerable government pressure, is moving quickly to battery-powered electrics, Gary Waissi said that ICEs will still be around for a long while.

“We have to consider the entire life cycle of an electric vehicle and its total environmental impact (from mining to electric grid to use to heavier impact on roads to replacement of batteries to disposal, etc). I think the future will not be one or the other, but some combination of technologies, and the internal-combustion engine will be in that mix. Also, alternative fuels and their research (including hydrogen, etc.) show great promise.”

Words of Waissi

*GW: In the earlier version, we allowed the bearing ring (a perfectly circular ring) to slide under hydrodynamic conditions (oil pumped from inside the main shaft through channels inside the disk to under the bearing ring) on the top surface of the crankdisc. We noticed that allowing the bearing ring outer surface to slide/roll against the piston base created a higher-than-calculated (and expected) friction between the outer perimeter of the ring and the piston base. So we decided to change the outer perimeter ring shape to have a flat (or convex) surface against the piston base flat (or concave) surface and pump oil through the ring to that outer surface. This created a hydrodynamic condition between the outer part of the ring (non-rotating ring) and the piston base. This lowered the friction to the same level as friction inside the bearing ring against the crankdisc (to similar level and conditions as in the main journal(s) of a common crankshaft with cranks and piston rods). Theoretically, the inside surface of the bearing ring serves the same function as the big end of a piston rod; and, correspondingly, the outside surface of the bearing ring against the piston base serves the same function as the small end of the piston rod. The rigid piston structure does not allow the piston to tilt, and the piston side supports distribute the force against the cylinder walls over the combined length of the pistons, whereas in a regular combustion engine, the piston rod pushes the piston, in an angle, sideways against the cylinder wall. Our design significantly reduces all these main friction components.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

There are always problems that come up with any new technology. Look at the Wankel engines that were rumored to replace the ICE engines in GM were polluters. The air-cooled engines in Porsche are now water cooled because of emissions. The latest darling of the government pseudo-engineers, the EV, is a flash in the pan because of the expense of digging huge holes in the Earth to get the rare earth to build the batteries, and the problems when they need to be disposed of.

I believe that “Fairbank- Morse” used something very similar in submarines and other things back in WW2

I’d volunteer to put it in my Bugeye Sprite

I’m surprised no one’s talked about that “Tomahawk” engine which was featured in Motor Trend. This is a radical modification of the Wankel with clean power that seems unbelievable. How about an article about it?

I don’t see ANY inherent advantages of this configuration. First of all, it is horribly balanced. You need FOUR cylinders like a flat four boxer engine, so the reciprocating motion of two pistons counterbalances the other two pistons. Without this, that motor will shake like a corn sheller. Second, like all internal combustion engines, thermal efficiency is horrible compared compared to an electric motor.most ICE engines waste up to 2/3rd of the energy produced by burning any kind of fuel (gasoline, diesel, biodiesel, E85, even hydrogen).

Check out the top photo. It has four cylinders.

As a huge fan of Citroen 2cvs, I really hope this makes it to market (and isn’t quite as wide as it appears to be). A tin snail would fly with one of these.

What about heat removal

The square four configuration might help reduce vibration but would still be significantly dynamically unbalanced.

Why even write about a “New” fossil fuel engine–Man kind Has to get away from Burning things–I know that I’m going to get Grown men throwing tantrums & Insulting me but Facts are Facts-

All of this reminds me in my history centric brain of a period about 110-120 years ago when electricity was new and amazing and the automotive world struggled with the decision to go with IC, electric or steam. IC won out because of it’s simplicity and affordability. Steam was too complicated and even dangerous in some ways. Electrics were fine for simplicity but where was all that electricity to come from? And how long would an operator be willing to wait to refuel? Really, not much has changed early in this century. Any “age” such as the suggested here. EV age cannot be and is not real if it is government mandated. That would be governments populated by politicians that are heavily invested in electrical generation whether it be the damming of streams or nuclear. It pleases me to see people such as these who pursue creative and logical approaches over virtue signaling or political pressure. I like the world I have lived in for the last 60 years. The one envisioned for the profits of power brokers today would appear to be full of miles of high tension cables, Hectares of flooded valleys and mountains of nuclear waste along with third world kids and their parents digging with garden trowels for minerals to build storage for electricity to power little bubble shaped transports that drive themselves. Not to mention even more coffee shops to sell tall lattes for you to drink while you sit in parking lots attached to extension cords regenerating the batteries in your egg shaped SUV.

I’m always glad to see entrepreneurs take the initiative to advance the state of the art in combustion engines. I know from experience that it can be very hard for an individual to get the attention of those that are in a position to fund and produce such a project; they usually won’t look at anything unless it has extensive test results, and that costs money.

The engine can be made to run more smoothly by converting it to a direct injection 2 stroke, which would even out the firing pulses. This will also cut the peak load on the cam bearing in half. I will follow the progress of the Waissi engine with interest.

I have some experience in trying to help engine inventors bring their designs to market, One of them was a direct injection diesel engine developed by the late Max G. Fiedler, whom I met 50 years ago, and who was nominated for the Nobel Prize in chemistry for his work on diesel and ramjet combustion. He manufactured two stroke marine engines in Germany post WW1, and he made an interesting compression-ignition 2 stroke engine that had a 12:1 compression ratio with a 2:1 supercharging piston (the effective 24:1 ratio was very high for the day). It also had a non-atomizing carburetor, and combustion was smooth! This was probably the first-ever HCCI engine, and this principle can be seen in the so-called diesel model airplane engines, which operate on compression ratios above 30:1 without knock or soot.

He came to this country from Germany in 1928 (his father was conductor of the Boston Symphony Orchestra) and worked at the REO Motor Car Company. One of his projects was to design an automotive diesel for them, so he made a prototype based on the one he designed back in Germany. Thinking he was losing some efficiency with the carburetor, he installed a state-of-the-art fuel injection system purchased from a supplier. When the engine started, it knocked so badly that the pistons melted and came out the exhaust. He knew something was not right because he already had achieved good combustion with the carburetor. This started him on a nearly 8-year quest to solve the problem of diesel knock, which he did by 1939. He reported his findings at a talk given at the Franklin Institute in Philadelphia, and they were published in the Journal of the Franklin Institute in January and February 1942 under “A New Theory of Combustion in Diesel Engines”. What he found was that the prevailing theory of diesel engines is inherently incorrect. It is not possible to inject fuel at high pressure into a cylinder at TDC without causing damage to the chemical bonds that hold the hydrocarbon together. The fuel will enter the cylinder as a cohesive stream, which will not mix well, and the fuel will be heated to a high temperature before it can form a proper combustible mixture with the air, which breaks the chemical bonds in the molecule. Free hydrogen and carbon atoms will then be released; the hydrogen will burn explosively, which we know as diesel knock, and the carbon will resist burning at all, which results in soot in the exhaust.

During WWII Mr. Fiedler worked with Charles Lawrence, inventor of the Wright Whirlwind engine, to develop a radial aircraft diesel, which produced 1500 HP by the end of the war. After the war he continued to refine his engine design to what we today would call a direct injection HCCI engine, a lightweight ported 2 stroke that could turn up to 8000 RPM with compression ratios as high as 34:1. He formed a company, raised capital, and intended to put the engine into production, but ultimately was unsuccessful. If anyone would like to read his papers I have put them up online at https://aerocamengines.com/hcci-research.

The rest of the aerocamengines.com website covers the other bootstrap-funded engine I worked on. Ten years ago, I was introduced to Jim O’Neill by a co-worker at Bose. Jim had been working for ten years developing proof-of-concept radial piston cam engines, designed to eliminate the tail rotor on helicopters, the vulnerability of which he observed first hand as a first lieutenant in the Vietnam War. Dubbed the “NorEaster”, these demonstration units feature built-in coaxial counter-rotation and integral ratio reduction without using gears. Jim received patents US 10,473,027, US 10,598,090, and US 11,261,946 for high-torque, low velocity internal combustion engines and gearless counter-rotating transmissions. The NorEaster has been the subject of student research projects at Worcester Polytechnic Institute under the direction of Professor Robert Norton, who is currently the Milton P. Higgins II Distinguished Professor Emeritus at WPI and who literally wrote the book on cam design, and Jim received a 2012 Invention of the Year Award from Popular Science Magazine for “A Simple Helicopter Engine”. Jim asked me to enlarge and convert one of his engines to four-stroke operation for the purposes of a DARPA grant application, and that engine is currently on a test stand. It is both mass and force balanced. Here is a video of one of the early two cycle engines being tested: https://vimeo.com/135461528

Beside inherent light weight and simplicity, cam drive engines have an efficiency advantage over crank engines. Part of this comes from the piston acting on the cam at a much greater radius than a piston can act on a crankshaft, and the other part comes from being able to apply peak leverage much earlier in the down stroke.

The obvious next step will be to combine Fiedler’s high efficiency cylinders with the unitized power unit concept of the cam engine, and that work is underway as time and funds allow. Such is the life of the inventor.

I have to laugh. These two men have spent countless hours and lots of money studying, designing,and working on their engine to try to get it to work, and you guys all sit in your armchair and tell them what to do or why it won’t work. High opinions of yourselves?

What is the difference between this engine and the usual engines? You just removed the connecting rod, it added a whole lot of complexity, it is not justified at all, and in my opinion, it is not considered an invention. You just changed the shape of the crankshaft, and it is useless.

ICE is dead. It’s amazing it ever lasted as long as it has after you consider the complexity, relatively short lived engines, pollution, maintenance, and all the support required to supply the fuel.

This is another version of the Bourke cycle engine, which my father and I made a running prototype in about 1976. We ran out of money to develop it any further, but ours was even simpler based, on a two-stroke design.