Media | Articles

How to calibrate a vintage tire-pressure gauge

Tires are critically important things. Those four patches of rubber are the only mechanical connection we have to the roads and trails we drive. Maintaining and monitoring those humble, treaded rubber doughnuts is critical to keeping yourself and others safe on the road and vital to preventing premature wear on your vehicle’s steering components. That’s why we all have tire-pressure gauges hanging around. If you don’t, you should.

Not all gauges are created equal. Like any calibrated tool, a tire-pressure gauge has inner workings that can sometimes begin to wear or become damaged. In both scenarios, the accuracy suffers. New tire pressure gauges are pretty cheap, but recently I learned that it was possible to re-calibrate vintage ones. Naturally, this sent me down an eBay rabbit hole.

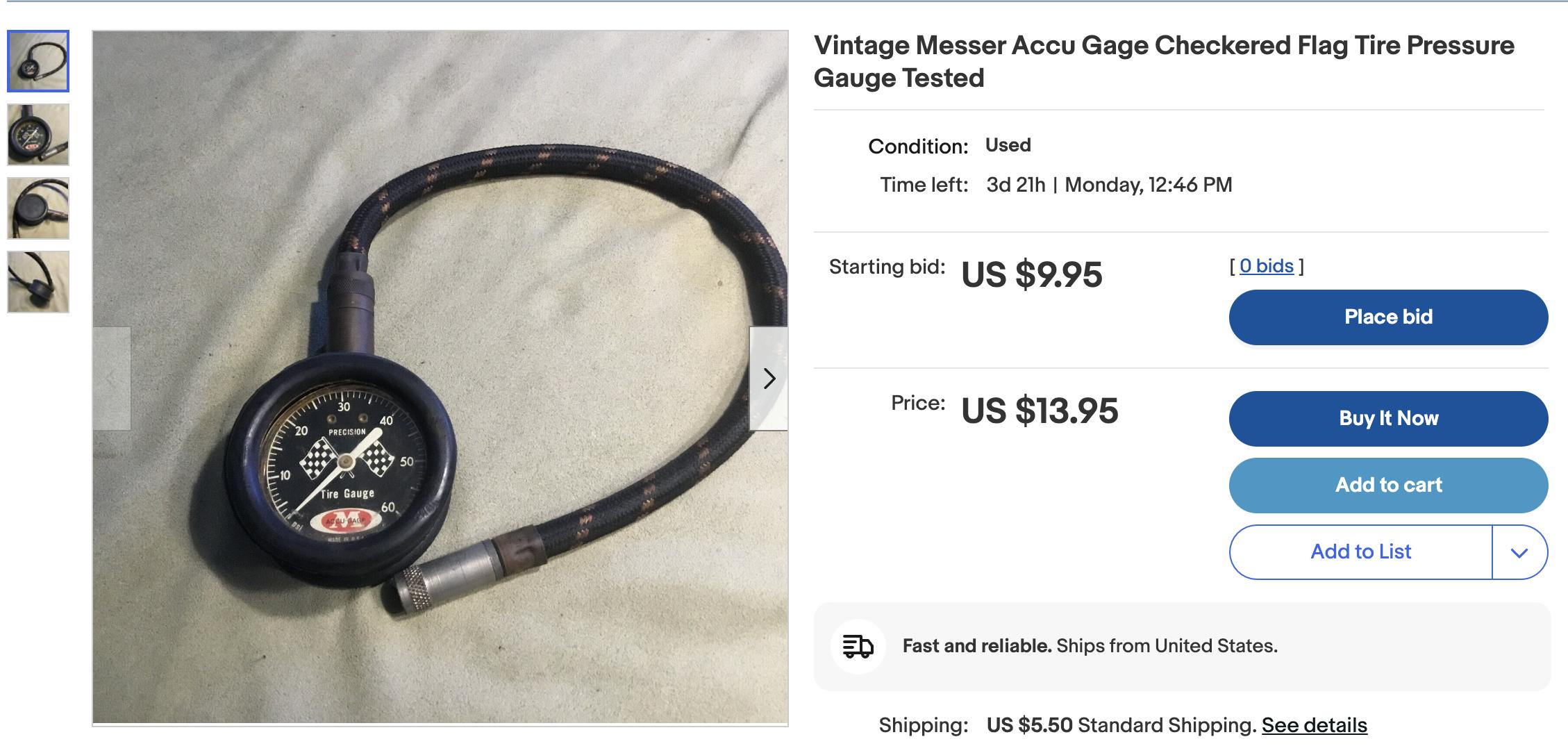

The journey ended by clicking Buy It Now on a $15 Messer Accu Gauge with a nice worn-in feel. Even better, it has a foot-long hose and a bleeder valve—two of my favorite features on the $90 Intercomp tire pressure gauge I use for track-day and motorcycle tires. I worry about damaging my nice Intercomp gauge, and that fear means that I fail to regularly check the tire pressures on the Corvair. This vintage Accu Gauge would solve that problem well: It has a max of 60psi, which would be perfect for the pressures I run in the modern radial tires.

With anything else of this age that I buy used, the gauge went straight from the shipping packaging to the workbench for cleaning and inspection. This gauge was quite grime-free, with the exception of the polycarbonate face, which had gotten hot and deformed. I’ll make a new one, not a big deal.

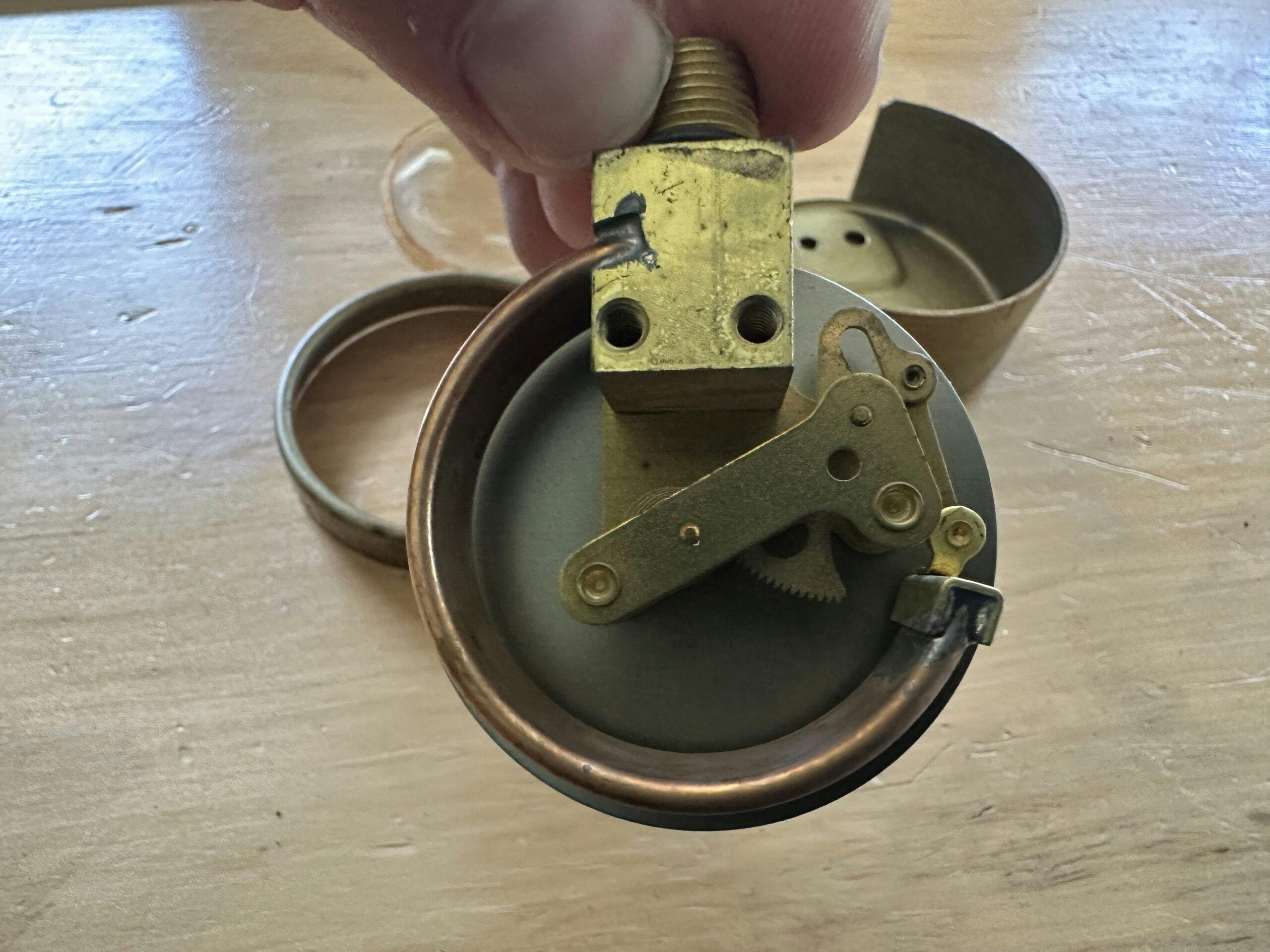

Further inside lay the good stuff.

This is what’s called a Bourdon tube gauge. The design gets its name from Eugène Bourdon, a Frenchman who penned the design all the way back in 1849. The copper, C-shaped tubing is formed so that, when pressurized, it deforms. The rate of that deformation is linear, so Bourdon used it to drive a needle, which indicates pressure on a scale drawn on the gauge’s face. The copper tube deforms consistently and reliably, at least until it hardens or cracks. With such small movements day to day, such breakage will take a long time, but a fluctuating environment or heavy use can cause the copper tube to deform in different ways that also produce inaccuracy. In that case, the gauge must be recalibrated.

That is where the linkage comes in. This is the piece that translates the movement of the Bourdon tube to the gearset that moves the needle. That linkage often looks as if it is trying to take the longest path to connect two points; it’s not a straight and simple piece. However, the goofiness of the design allows for fine-tuning and calibration by opening or closing the gap, thus lengthening or shortening the linkage. This changes the ratio between the movement of the Bourdon tube and movement of the needle.

Now comes the fun part. By comparing the reading of the Messer gauge to that of the Intercomp, a modern one I know and trust, I can alter that linkage in small increments and retest until the vintage unit reads correctly and consistently in the range I will use most: For the Corvair, 20 to 32 psi. In a perfect world I would calibrate this gauge with a known quantity of some type, like a manometer or regulated air pressure. I have neither at home, so this method will do. The Corvair doesn’t require pinpoint accuracy. Once reassembled, the old gauge is ready for use.

This Messer gauge looks perfect in the glove box or front seat of my Corvair and also allows me to keep my more delicate, valuable Intercomp at home or in the race toolbox, where it belongs. Practical, vintage flair for $15? Seems like a no-brainer.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Neat find! I love the looks of the gauge. And good advice on how to retune an old item so it can double as both “art” and useful tool. 👍

Used to repair pressure gages (and other mechanical instruments 50 years ago. Now a days, you order electronic pressure gage from AliExpress for 3$. Do not mess with gages.

Why buy some piece of throwaway junk for $3 when its possible to keep something working and usable? Worst case scenario is someone tries and damages a gauge that was just a display piece before and after it got messed up… its still a display piece. There is literally no risk.

rehash article from the Garage Journal. Hmm.

I get that you like to fix older things rather than buy new. Couldn’t agree more.

Some people are just uncomfortable reading unless it’s on a screen. The rest of us think screens are for video, gauges are best on dials.

I have a question on the calibration. Do you pinch the linkage if pressure reads high and spread the linkage if pressure reads low? or the other way around or are you only supposed to pinch the linkage?