Media | Articles

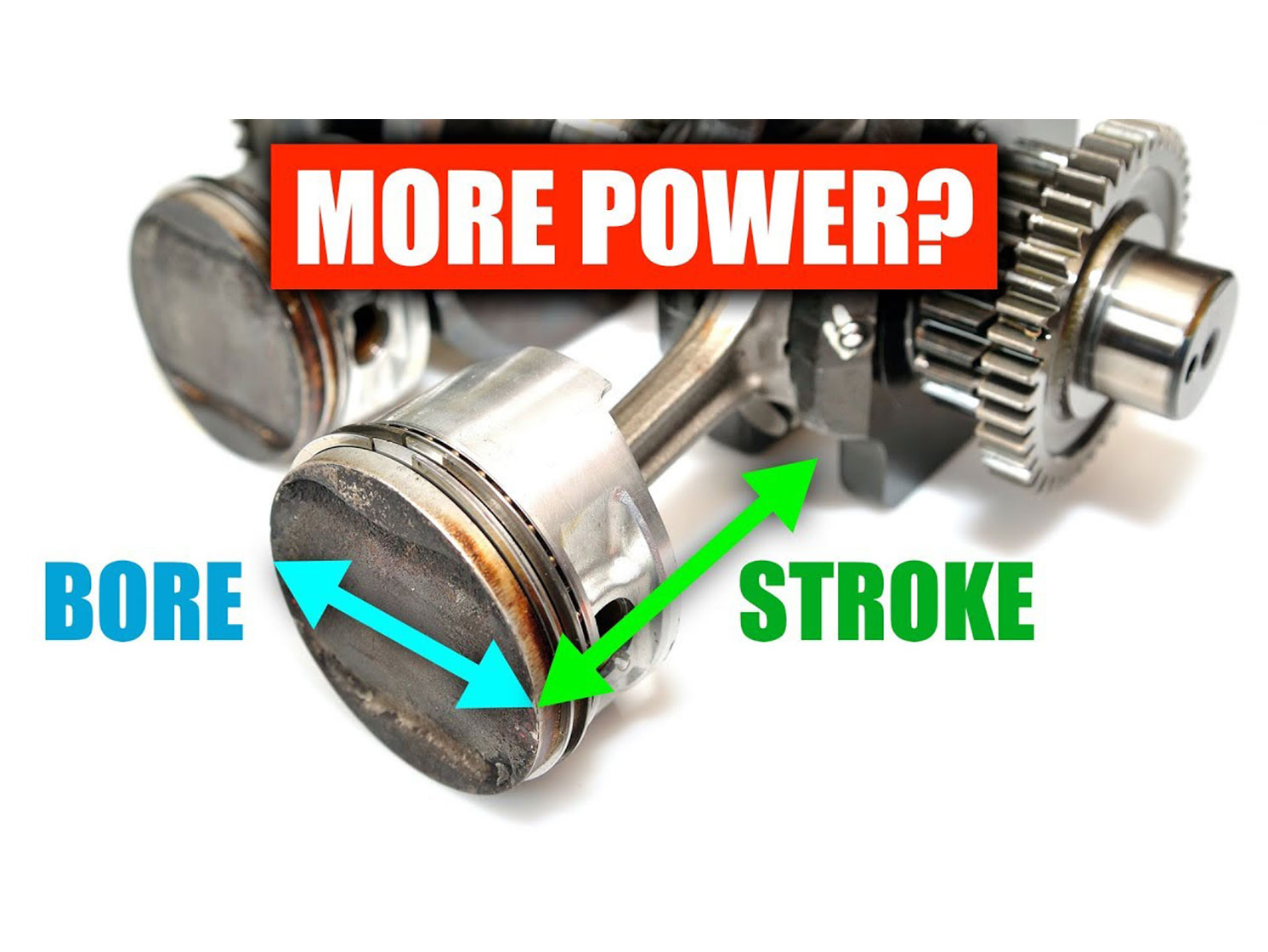

How bore vs. stroke can affect horsepower

What’s the best bore-to-stroke ratio for an engine that’s trying to make a lot of power? How about one where the goal is maximum efficiency? Jason Fenske from Engineering Explained takes a look at how piston engines move air and burn fuel to answer those questions in his latest video.

Fenske details how the bore-to-stroke ratio affect an engine ability to make power using three hypothetical cylinders of the same displacement, one with a huge bore and short stroke (oversquare) like an F1 engine, one that’s perfectly square like a lot of production four- and six-cylinders, and one with a tiny bore that’s about as undersquare (small bore relative to a long stroke) as a cargo ship’s marine diesel.

The oversquare engine, with its short stroke, is able to rev very high without extreme piston speed, which shortens the life of piston rings. Given a maximum piston speed of 25 meters per second, the hypothetical oversquare engine could rev to 16,000 rpm, the square engine could rev to 8700 rpm, and the undersquare engine would max out at just 4700 rpm.

What does this prove? As power is a product of torque and engine speed, high-revving, large-bore engines excel at producing a lot of power for their size, which shouldn’t be any surprise: sanctioning bodies often limit bore size as a means to level the playing field. On the other hand, long-stroke engines—often thought of as being superior torque producers—are just bad at producing lots of power. If your maximum engine speed is below 5252 rpm, torque output in foot-pounds is always going to exceed your horsepower.

Marketplace

Buy and sell classics with confidence

Another key component to an engine’s ability to make power is airflow through the cylinder head. An engine is just an air pump, and the more air that can be moved through, the more power can be produced. A larger bore will offer more real estate to fit larger intake and exhaust valves that flow more air. Comparing the valve curtain area, the space air has to get past the valve at maximum lift, shows that the area can increase by 35 percent from the undersquare example to the square example, and by another 35 percent when looking at the oversquare engine. Even if small-bore engines could overcome their high piston speeds, they’d lack the airflow capability to make significant power.

Power is fun to talk about, but some engines aren’t concerned as much about power density as they are about turning every last drop of fuel into motion. That’s where the efficiency of a long-stroke engine comes into play, and we were surprised by why the undersquare engine excels there compared to the widely-adopted square bore and stroke. It comes down to the shape of the combustion chamber when the fuel is ignited and cylinder pressure is at its peak.

There’s a lot of good information in this 15-minute lesson—it’s worth a close watch.

I appreciate your article! I’m trying to engineer the/an engine for my 1994 Chevy K2500 with a 454 in it. I’m thinking about dropping it back to a 427. Maybe even a 402, 454 with 4” stroke and a 396 with 4.094” bore? My goal is 500-600 ft.lbs, torque at 1800-2000 rpm so I get decent fuel mileage while pulling my fifth wheel trailer.

I would like the best of both worlds,?AFord FE is a tall deck and has relitively thin bores. I m thinking of a 4.125 bore and 4.125 stroke with long rods modular iron crank lightened and treated in a top drawer manner and the whole assembly as light as possible to reduce bearing speed and reduce weight. This is to get good cubic inches, and balance, get the best power via room for large intake valves and cubic inches with a reasonable piston speed. Narrow rings for low friction.