Media | Articles

Heavy Breathing: The Z06’s LT6 is a love letter to internal combustion

General Motors is loud about its EV future, but that didn’t stop its powertrain division from designing an all-new monster V-8 for the Corvette Z06. We might one day look back at the 670-hp LT6 and recognize it as the pinnacle of the Chevy small-block, a swan song sung by engineers who wanted to demonstrate what they could do before everything in the GM stable runs on electrons rather than gas.

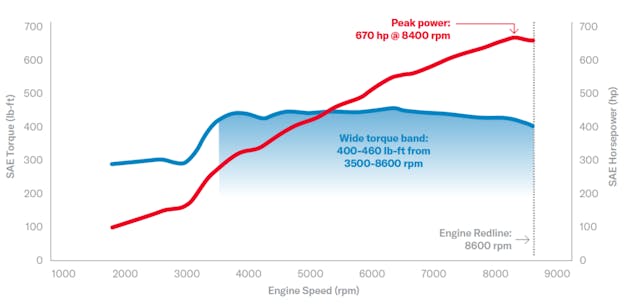

This race-bred engine matches the screamers from Porsche and Ferrari, with an 8600-rpm redline and outstanding power from 5.5 liters. It also marks a new spur for the small-block engine, a path that leans toward high rpm rather than boosting for power.

The previous Z06’s V-8 produced 650 horsepower with the assistance of a supercharger, a belt-driven pump that shoves in air. Engine horsepower is directly related to the amount of air that flows in and out, because the more air an engine breathes, the more fuel it can burn, and thus a more forceful boom drives the piston down the cylinder. A turbocharger is a pump like a supercharger, but the turbo is driven by exhaust gases. Engines with either pump—which are often called blowers—are known as boosted. Conversely, an engine without the pump is called a naturally aspirated engine.

As with every engineered product, there are pros and cons to each when it comes to power, fuel economy, cost, and the character or feel of the engine. Blowers are relatively easy-to-adopt bolt-on horsepower-makers, but they have a certain noise and the power delivery often surges, whereas naturally aspirated engines typically pull in a consistent way. As rpm increases, so does the power.

The LT6 began with the accountants, who greenlit a blank-sheet engine that would not be compromised by having to share parts with pickups. They were probably strong-armed by GM’s famously petrol-fueled president, Mark Reuss. In any case, you can hear the glee in the voices of the two main players for the LT6 engine: Jordan Lee, chief engineer for all small-block V-8s, and his colleague, assistant chief engineer Dustin Gardner.

Marketplace

Buy and sell classics with confidence

“We wanted the Z06 to scintillate all the senses,” says Gardner. “What you feel and hear from the engine is such a huge part of the experience. The mechanical and screaming cacophony of a naturally aspirated engine is the sweetest of music, and that’s what we aimed for.”

Though they biased the engine design for character, they also knew that the 2023 Z06 had to offer at least as much power as the previous model. That meant 650 or more horsepower without the aid of a blower. Furthermore, this new engine was going to be a derivative of the small-block V-8, an engine that debuted in 1955. Heritage matters to Corvette fans—and to Corvette engineers. “One of the things Corvette customers love about the small-block is low-end torque,” says Lee. “Even at low engine speeds, when you just dip on the throttle, it goes. We had to preserve that.”

High-rpm power and low-rpm torque are usually not bedfellows. Torque is a force applied in a circular motion, like a wrench turned on a nut. Horsepower is the rate at which torque is applied—how fast the nut was turned. Keep torque constant but increase the engine speed, and the horsepower rises. Conversely, maintain engine speed but increase torque, and horsepower increases. Small, light, and revvy engines, like those in a motorcycle, might boast high horsepower at 14,000 rpm but not enough torque to move a 3500-pound car from a stoplight. Tractors, on the other hand, can yank a stump from the earth with their slow, high-torque engines at idle.

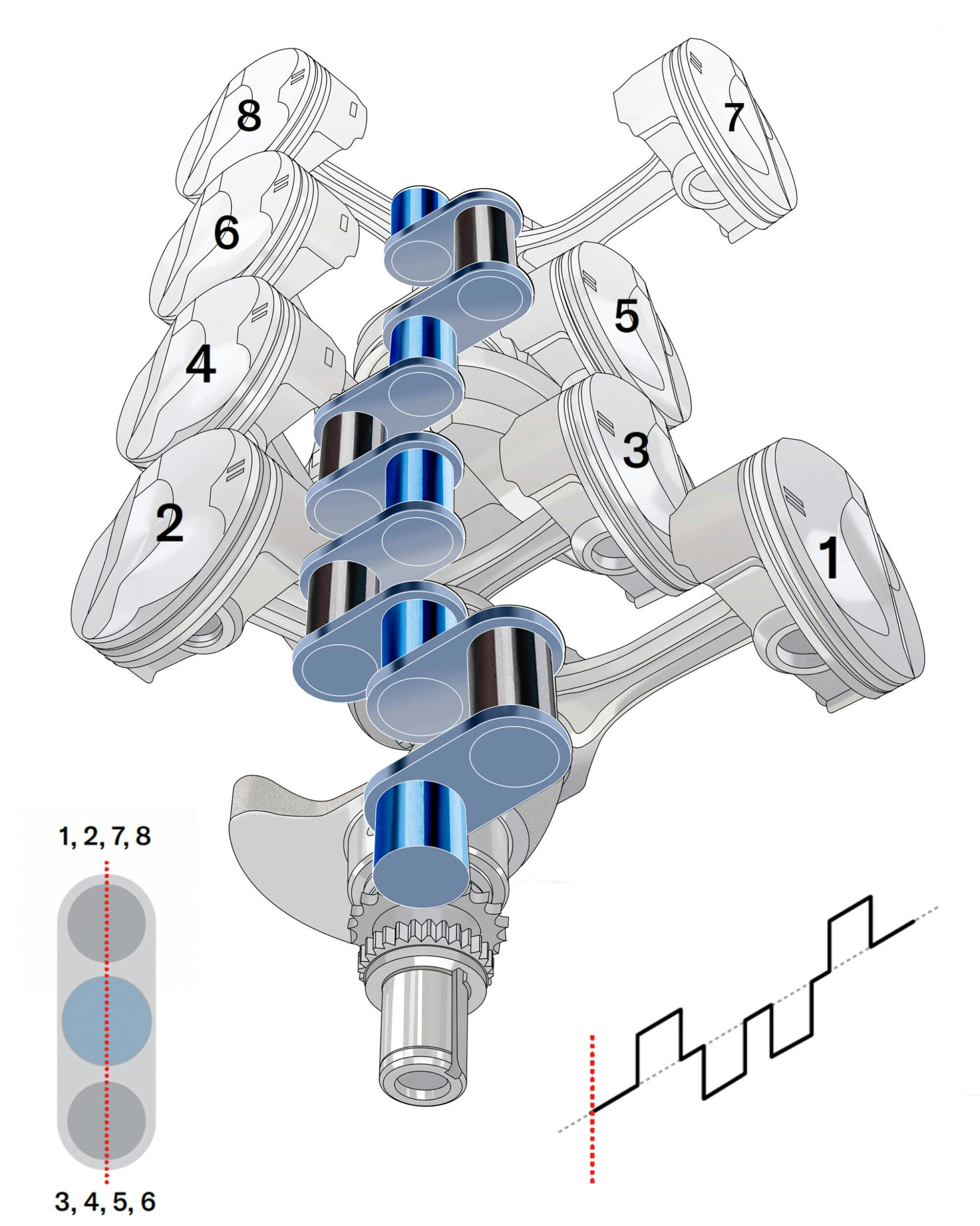

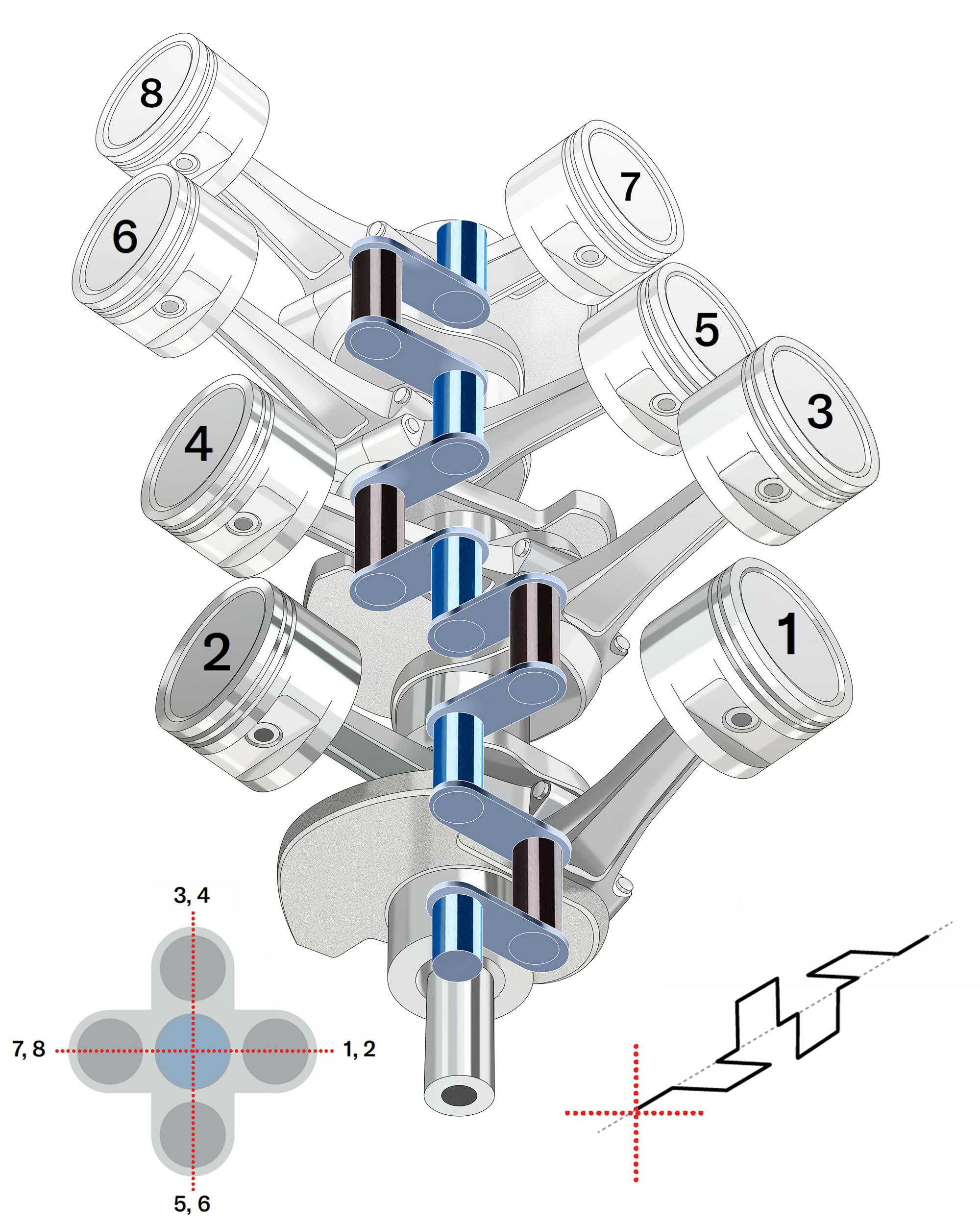

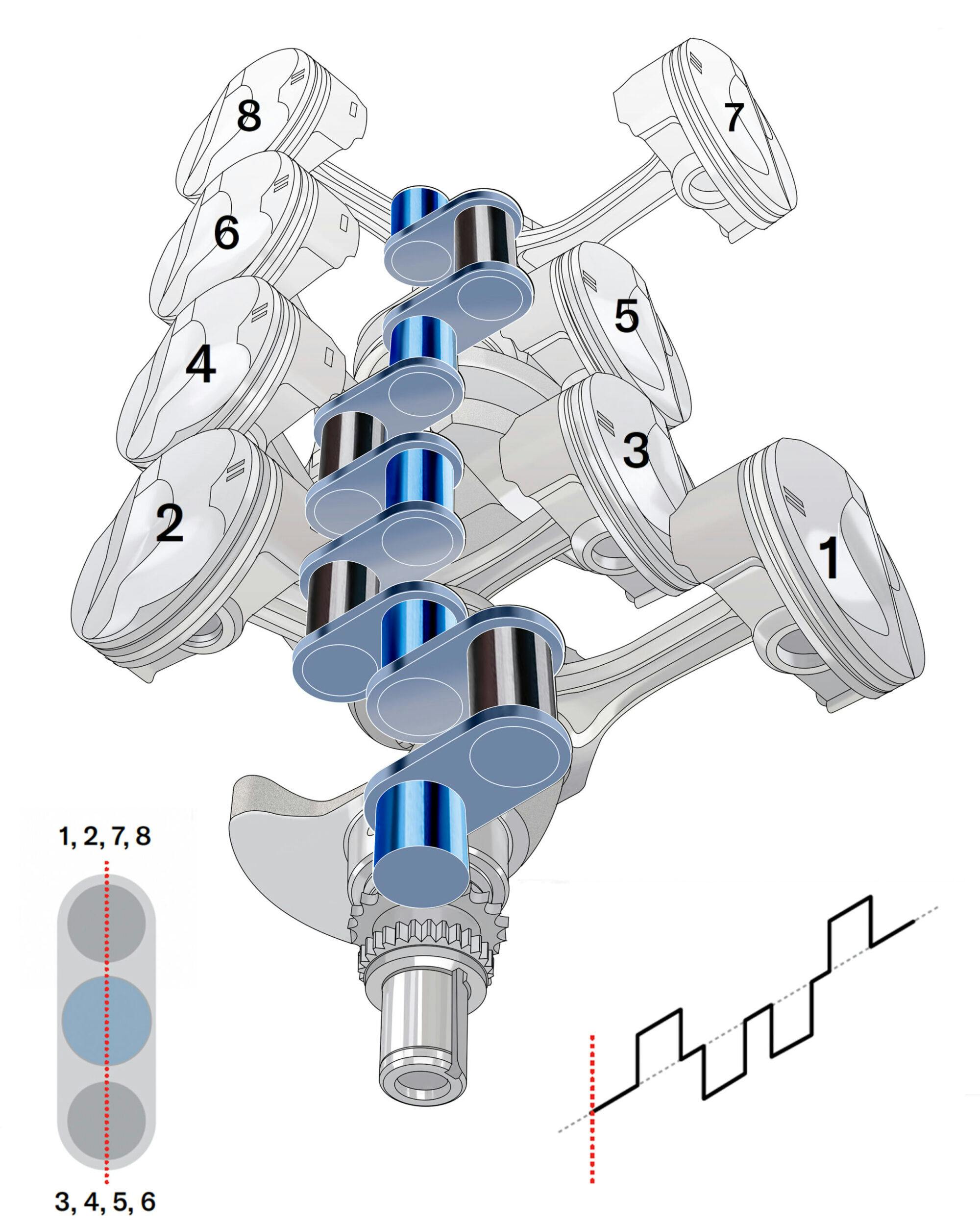

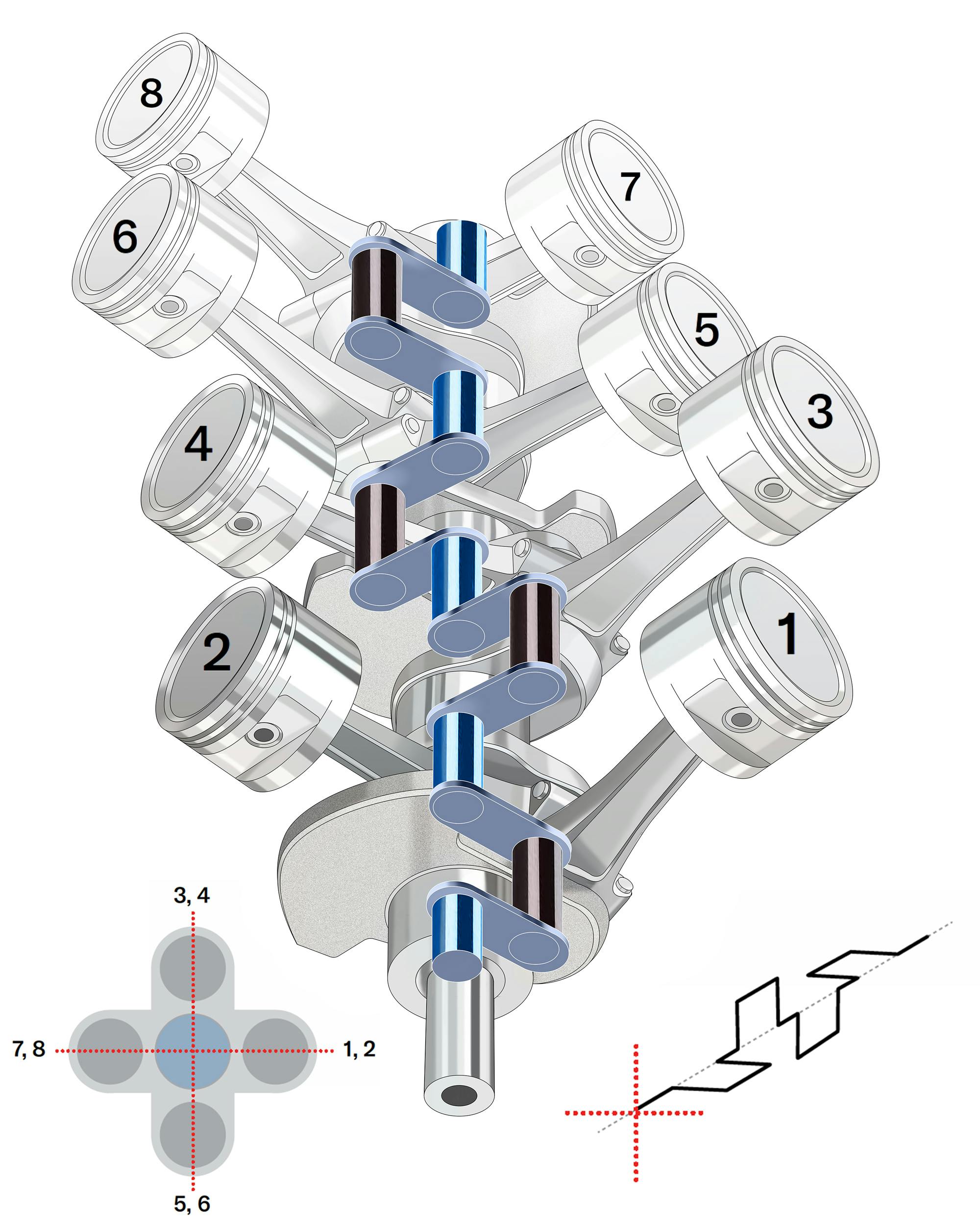

High rpm and high power dictated a flat-plane crankshaft. This maximizes scavenging—the effect where exhaust gas from one cylinder actually sucks spent gases out of an adjoining cylinder’s exhaust port, which increases airflow. With a flat-plane crank, the exhaust pulses of one cylinder directly aid the breathing of another cylinder on the same bank, in a way not possible with a conventional V-8 cross-plane crankshaft. Remember, the more air that flows in and out of the engine, the greater power it can produce. The firing order of flat-plane cranks also adds to a distinct, quite pleasing wail.

Flat-plane cranks are standard in Italian supercars but rare in American engines because they cause more vibration. A century ago, Cadillac dropped 180-degree crankshafts for 90-degree units, and most V-8–makers quickly followed suit, sacrificing some power for smoothness.

Vibration can be mitigated by how the engine is mounted in the chassis, and there was more flexibility with the Corvette now that the engine resides in a roomy bay behind the driver. The best strategy, though, is to not just mitigate vibration but to generate less of it to begin with. “It’s really the stroke—the distance the piston travels in the cylinder—and the weight of the piston assembly that drive vibration with a flat-plane crank,” says Gardner. That meant lightweight—but expensive—materials such as titanium for the connecting rods and a shorter-than-usual stroke.

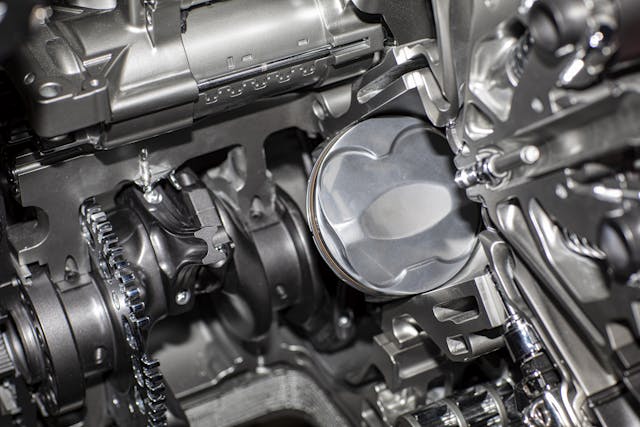

After numerous iterations and computer models, Lee and Gardner landed on an 80-millimeter (3.1-inch) stroke, nearly a half-inch shorter than the standard Corvette V-8—which is why the LT6 is called a short-stroke engine. The shorter stroke also kept the piston speeds in check, which is another concern for high-revving engines.

If you could see a piston in a running engine, it would be a blur, as if it’s traveling supersonically. But the peak speed is roughly 4500 feet per minute, or about 50 mph. The piston’s back-and-forth motion, however, is the killer. In a typical engine running at 6000 rpm, the piston zips from top speed to zero back to top speed in a microsecond. If we remember that acceleration is the change in speed over time, then we can see that increasing engine speed—or piston stroke—also ups the acceleration. Go too fast, though, and the piston fatigues, cracks, and then—boom.

Not to worry, Lee assures us. “With our 80-millimeter stroke, we didn’t come close to the limit for piston speed. We probably have some room to grow there.”

Next came the bore size, which is the diameter of the piston. There are numerous factors at play, including how close the cylinders are to each other, which is defined by the distance from the center of one cylinder to another—the bore center. Here, history played a role. “Yeah, there’s a huge following of small-block lovers who appreciate the engine’s history,” says Lee. “Even though the LT6 is all new, we kept one dimension that is the DNA of the small-block: the 4.4-inch bore center.”

The 104.25-millimeter (4.1-inch) cylinders are packed in shoulder to shoulder. The 104.25-millimeter bore and 80-millimeter stroke yielded 5.5 liters, the combined total volume of all the cylinders and a good compromise between an engine that can rev and one with decent low-end torque. It also happens to be the maximum engine displacement for production-based cars in the 24 Hours of Le Mans, where Corvettes won their class eight times.

Once Lee and Gardner defined the LT6’s foundational elements, their attention shifted to maximizing horsepower and making sure that the power gets to the tires by reducing parasitic friction. Friction rises exponentially with engine speed. Double the engine speed and frictional losses triple or more. A major contributor is the engine oil, which the crankshaft usually bathes in. “If you move your arm or your hand through water, there’s resistance,” explains Lee. “That’s a crankshaft trying to move through oil. You want to remove the oil from around the crankshaft.” Achieving that goal is one reason the LT6 has an all-new aluminum block with a shallow oil pan.

The LT6 is a so-called dry-sump engine because the bottom of the pan is not a reservoir for oil, as is typical in many engines. Instead, there’s a separate tank that holds 8 quarts. Typical engines have only one oil pump, but the LT6 has seven. Four evacuate oil from around the crankshaft. Two vacuum oil from the cylinder heads, and one pumps the oil back in. About half a quart of oil circulates through the engine, and small nozzles squirt oil on the bottom of the pistons to cool them. The rest of the oil spins in the tank like a centrifuge, which removes any trapped air.

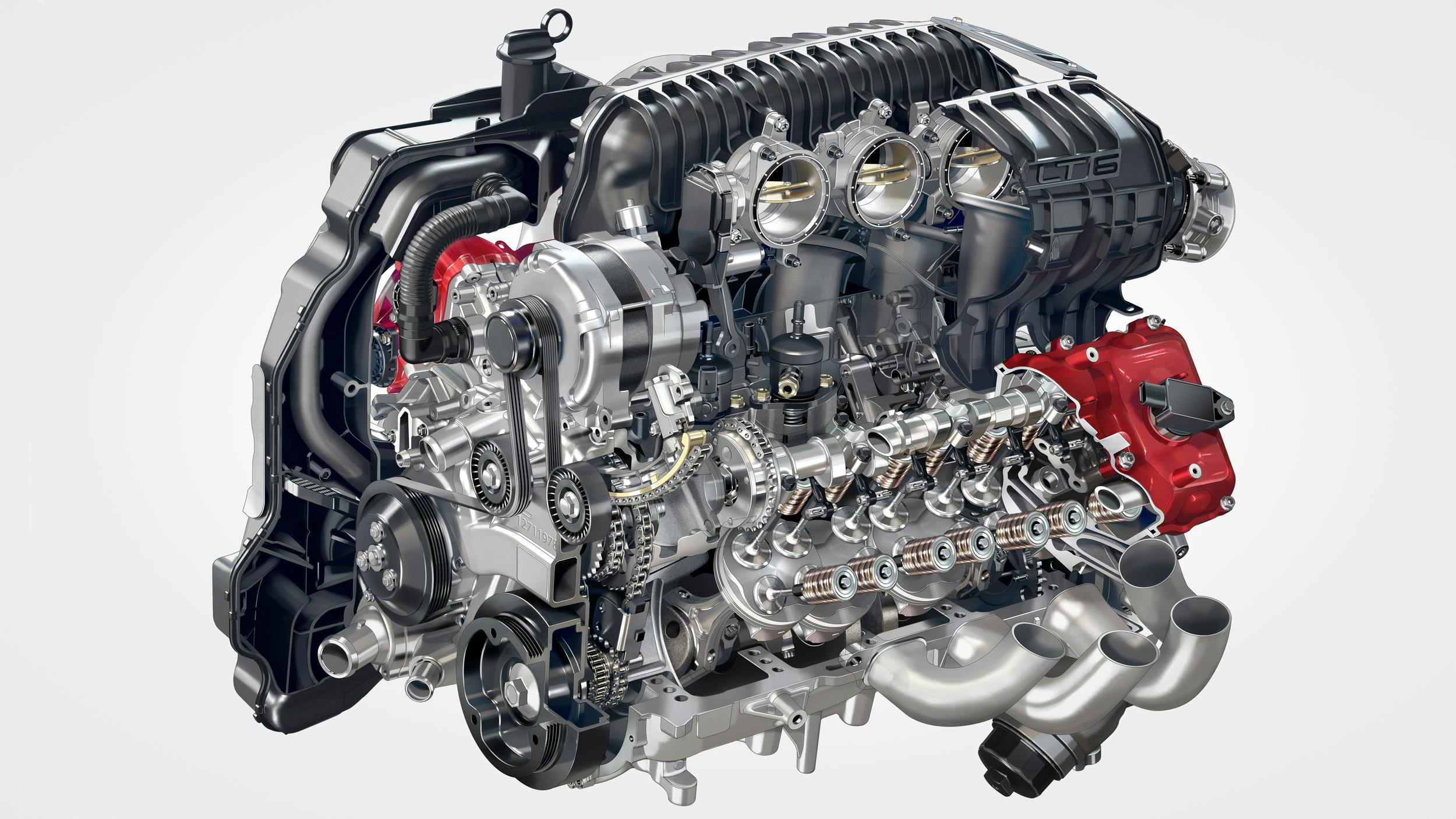

5 key areas of engineering significance

- Big Lungs: Two 1.5-gallon intake plenums are connected via three computer-controlled butterfly valves and optimize air-pressure pulses to feed more air into the cylinders.

- Exhaust Help: In the LT6, there’s a Y-shaped manifold for every two cylinders. The design takes advantage of the flat-plane crank to improve exhaust scavenging, or when the exhaust flow from one cylinder actually sucks exhaust from another, thereby improving the engine’s breathing.

- Four Cams on Top: NASCAR engines aside, shooting for 8600 rpm means going overhead cam. The valvetrain has to be as light as possible, with as many valves per cylinder as possible. And meeting torque and emissions targets requires independent control of both the intake and exhaust valve timing.

- Short Stroke & Light Weight: The Italians have been making short-stroke screamers for decades. Now the Corvette has one, with half an inch cut from the base Corvette’s stroke for a 3.1-inch stroke, which means shorter and lighter rods, a more compact crankshaft, and faster spin-up.

- Dry-Sump Oil System: Rather than a bottom oil pan, the LT6 has a side-mounted reservoir and dry-sump system for better lubrication at high revs and during high-g cornering, when a sloshing wet sump might lead to starvation. Seven pumps extract not just oil from the bottom but also oil mist in the crankcase, reducing air drag on the crank as it spins.

“That crank,” says Lee, “can spin with a vengeance, with very little restriction.” It also spins with a fury thanks to a massive breathing system. Since the Corvette engine is behind the passengers, no longer in position to block the driver’s view, engineers were not as constrained as they were with previous small-blocks. That meant the space- and cost-saving pushrod valve actuation, which is most often paired with two valves per cylinder, was ditched for four camshafts that sit on top of the valves. That arrangement enabled four valves per cylinder and the largest air paths they could machine into the heads.

Which brings us to the LT6’s pair of massive, lung-like 5.5-liter (1.5-gallon) intake plenums, which are canister-like chambers that feed air to the cylinders. Tubes inside the plenums direct air to the intake valves, and the plenums are connected by three butterfly valves. This is where things get interesting and complicated.

The air moving inside the plenums and traveling to the valves is constantly accelerated by the downward-drawing piston and then it abruptly stops. “These columns of air,” says Lee, “compress and decompress, like springs.” Those air columns and pressure waves help the LT6 cram even more air into the cylinders. If the intake valves, for example, open at the optimum moment when a column of air is already expanding, then more air goes into the cylinder.

Defined by dozens of characteristics such as the size and shape of those plenums, the runners inside them, and the exhaust system, the optimum moment when an air column is expanding typically occurs over a narrow rpm range. The butterfly valves that connect the intake plenums help widen that range. The LT6’s breathing capability emerges from the whole system, including the intake parts, the variable valve timing, and the exhaust, which is itself defined by the flat-plane crank.

“When things are really on the boil,” says Lee, “10 percent more air is getting crammed in the cylinder than it displaces normally.” A naturally aspirated engine usually strives to inhale the full volume of the cylinders, its displacement, so in a perfect scenario, where losses don’t exist, an engine builder might hope to get the LT6 to ingest 5.5 liters. Its trick intake and exhaust systems, however, take advantage of the physics of airflow and actually inhale 10 percent more. This is like having a boosted engine without the blower.

Lee, Gardner, and the development team spent eight years designing and experimenting to land on the answers we’ve simplified here. Their work didn’t just match the outgoing Z06’s 650 horsepower but surpassed it and delivered a high-rpm wail that gives any gearhead jelly legs. The LT6 sets a new record for naturally aspirated V-8 engines, eclipsing the 622 horsepower achieved by Mercedes-Benz with its 6.2-liter, V-8–powered AMG Black Series coupes of 2013–2015. Energized by this new V-8, Z06 C8s are expected to click off the 0–60-mph run in just 2.6 seconds.

The party is not over, however, as the LT6 will likely someday be boosted by a pair of turbos and installed in the upcoming Corvette ZR1. Assume 800 or more horsepower in a car available at the Chevy dealer. Sure, EVs are coming—General Motors talks about little else these days—but the 2023 Z06 is proof that we remain in a golden age for internal-combustion engines.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it.

Excellent analysis–and the bolt example is the best analogy for HP and torque I’ve heard. Highly doubtful you will ever see this amount of analysis–or interest–in EV powertrains. I’m guessing you will be able to buy a disposable EV powertrain at Harbor Freight in a few years..

Thank you! I love my internal combustion engines, but there are hot rodders tuning batteries and electric motors too.

https://www.caranddriver.com/features/a39493798/ev-motors-explained/

This engine is a masterpiece and I love the new Z. My only issue is the car’s weight. If they could use more CF and make a lightweight stripped down version, this car would be sports perfection (for me, anyway).

As much as I dig EVs – this is massively impressive. 670hp from a naturally-aspirated 5.5 litres is comfortably into Ferrari/Lamborghini territory; and probably beyond some of their offerings. Waiting for someone now to make an aftermarket carbon fiber or brushed aluminum intake manifold…tasty.

Welcome, General Motors, to the Twentieth Century.

Really well written article on a beautiful engine. If only the car it is installed in was as beautiful.

Seven oil pumps, what could go wrong there? Hmmm. If one or more gets plugged or inoperative, is it kaboom time?

If you’re running basically a dry sump system, why do you need an eight quart reservoir?

Cooling! Remember that oil still does over 50% of engine cooling. Oil pumps are very reliable, if one gets plugged it’s because the owner didn’t maintain their expensive car properly. It ain’t a chevy astrovan!

Probably to ensure a large, ready supply of cool oil; such large capacities are not uncommon in all-out performance engines, from what I have read.

In the ’80s I served as a military advisor in the Middle East and Sub-Saharan Africa, had an apartment in Riyadh, KSA. A friend owned a Ferrari 400i, a V12 sort of gentleman’s express coupe with a GM TH400. The engine, as I recall, required 22 qts of oil (good oil, ala Shell Helix or Mobil 1) and carried 2 full sized oil filters in the engine’s V. It also had a Chevy Vega radiator sized oil cooler. In the blistering Saudi summer heat, a/c full blast and travelling +/-140mph Riyadh-Jedda-Riyadh the somewhat blah white 400i never came close to max temp, much less overheat. We were in our 20s, and used it hard, never a cooling problem. Sweet car, I wish I had bought it and brought it home. Lovely sound when prodded.

Only one of those pumps is critical for engine survival and I’d gamble it’s the highest pressure, most durable one in the assembly.

Cooling, as the commenter below mentions and the oil tank also removes the air from the oil.

Certainly one of the best descriptive and informative articles I’ve ever read about engines.

Fantastic!

I would love to put the air-asperated in my C-5 can I buy one? And what type of rear end would I need, My corvette just has 350 horses under the hood.

I’d love to see that but I’m not sure you could see over this engine. It’s a whole bunch taller than the pushrod engine. I have not heard if GM plans to sell this as a crate engine, but I’d wager it’s a strong possibility.

Thanks for the article, it helped me understand the difference between natural and boosted.

Anybody seen Z06 motor fail in 52 miles on YouTube ? Would like to hear what happened

I love he meme showing a full coal train.

“Oh look, another load of electric car fuel!”

An amazing engine. I do have some concerns about GM reliability with this motor though. Time will tell.

Excellent Commentary regarding internal components and their interaction with each other regarding “boosting” very informative, wish these design options had been available in 1978! What a disservice to vettes during the 70’s, anemic regarding HP comes to mind!

Engineering (and metallurgy) have made HUGE strides since 1978.

Great article about an incredible piece of engineering. Is that a single row timing chain? Yikes. Is your chevy tech up for the challenge if this motor? Will the dealer invest in the training of their techs?

Dealer techs won’t be doing any serious work on these engines, failures will be replaced and the cores returned for post mortem.

So is there now finally a “replacement for displacement”?