Media | Articles

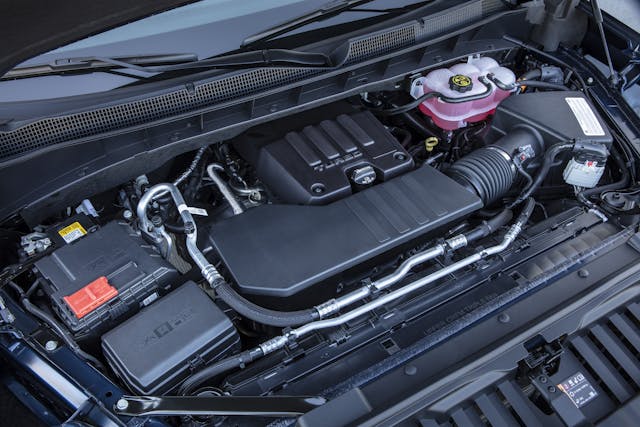

GM Engineer: L3B turbo-four is a true truck engine

The latest gasoline truck engine from General Motors, its 2.7-liter turbocharged L3B inline-four, is taking on a couple of important roles at Chevrolet and GMC. For 2019, the direct-injected four-cylinder replaced GM’s 4.3-liter V-6 as the base engine in the Silverado and Sierra, producing a respectable 310 hp at 5600 rpm and 348 lb-ft of torque at 1500 rpm. Not only did it improve on the naturally aspirated V-6’s 285 hp and 305 lb-ft of torque, the new engine, combined with the upgrades from the new-generation pickup that was wrapped around it, led to an improvement in fuel economy.

For 2022, the engine got an important upgrade. Thanks to improved hardware and a revised tune, the L3B now makes the same power but torque kicks in hard with 430 lb-ft at 3000 rpm—an increase of nearly 100 lb-ft—with a torque curve that retains its start low in the rev range.

GM, which sells more light-duty trucks in North America than any other OEM, is clearly confident in the L3B. The four-cylinder will be the sole powerplant for the upcoming third-generation Colorado and Canyon that were unveiled earlier this summer. In those mid-size applications, the engine will replace three outgoing mills: the 2.5-liter inline-four gasoline engine, 3.6-liter V-6 gasoline engine, and 2.8-liter turbodiesel four.

To become better acquainted with this new powerplant, we asked Kevin Luchansky, assistant chief engineer for the 2.7-liter, about its development and its recent upgrades. Mainly, how does it crank out such diesel-esque torque?

Although the L3B is also used in the Cadillac CT4-V sport sedan, Luchansky told us that the turbo-four was conceived from the beginning to be capable of hard work. “It’s a purpose-built, turbocharged truck engine. Every detail was designed as such.”

Marketplace

Buy and sell classics with confidence

Don’t feel too bad for Cadillac; GM’s pushrod V-8s were developed as truck engines as well, and that worked out quite well for the CTS-V.

Trucks need to go through the wringer and haul heavy loads, often pulling several times their curb weight up steep grades. Full-throttle performance for extended durations is non-negotiable, and they also must get those heavy loads moving from a dead stop. “Power is super important in a sports car,” Luchansky told us, “for a truck you really want low-end torque.”

The way the L3B’s turbo delivers low-end grunt is perfect for a truck. Luchansky explained that a specific dyno test, used in development to measure turbo response, holds the engine at 1500 rpm and measures the engine from no load to wide-open throttle. The dyno then records how long it takes before the truck to produce 90 percent of its max torque. For the L3B, it only takes 2.5 seconds. That’s the kind of response you especially appreciate when towing, but it helps every time you need to pass or dust somebody at a stoplight. In Cadillac tune, the engine produces an extra 15 horses (325 hp) thanks to premium fuel and more aggressive timing. Engineers prioritized a quick spool-up and low-end grunt, the downside of which is that the turbo runs out of steam in the upper revs.

For those worried about turbocharger longevity, all of the engine’s systems are designed around it. As Luchansky said, “You keep a turbo alive by feeding it really clean oil, and keeping it cool. As long as you do that, the turbo should last a really, really long time.”

One of the most intriguing aspects of the L3B is that its bore centerline is offset from its crankshaft centerline. When viewed from the front, a line drawn through the bore centers would miss the crank centerline by about nine millimeters. In our case, in North America, the bores are offset to the driver’s side. It sounds a bit strange at first, but the offset allows the connecting rod to be closer to vertical when the piston is pushing down with its peak cylinder pressure. The configuration reduces side-loading on the bore, which means less friction on the piston skirts. It also helps the bore stay cylindrical.

Tough as it is to imagine, even something as sturdy as a chunk of cast metal can move around when subjected to the kinds of cylinder pressure generated inside a turbocharged engine. Luchansky put it into terms easy to understand, “It’s kind of like a bridge when you drive over it.” The metal can flex a bit, before springing back to its original position. “If you’re putting that much load into the block, it can make the bore oval.” A more cylindrical bore allows the rings to do their job and keep combustion gasses up top where they’re doing work, and out of the crankcase where they dirty the oil. This isn’t the first engine to employ this tactic; the first-gen Honda Insight did the same and Luchansky noted that Yamaha also built a motorcycle engine with similar geometry. GM’s 1.5-liter L3T and 2.0-liter LSY engines also feature offset bores.

Before the adoption of offset bores, engine developers might design an engine with longer rods in order to reduce piston side loading. However, for any given deck height there’s only so much room to work with, as the wrist pin bore can only move up so far before it interferes with the ring lands. For decades, truck engines have used increased deck height to get longer rods and allow for extra displacement when combined with a longer stroke, but efficient packaging in new vehicles is more critical than ever. GM’s engineers were able to keep the L3B compact while still delivering on performance. Just think of the offset bore as a substitute for a longer rod and the turbo as extra displacement.

The rotating assembly of the L3B was built with toughness in mind, as the aluminum pistons feature a cast iron insert to locate the top ring and improve cylinder sealing, while the connecting rods and crankshaft are steel forgings. The original iteration of the L3B featured cylinder bores with more material on the thrust side, to shore up the part of the block that takes the most abuse. Its cast-in-place cylinder liners are made from spiny lock centrifugal nodular cast iron. The liners are spun as they’re cast, forcing iron into the pores of the refractory material used to shape them. The process creates a texture that not only keeps the liners bonded to the aluminum block that’s cast around them but also provides an increased surface area for the iron to shed heat into the aluminum.

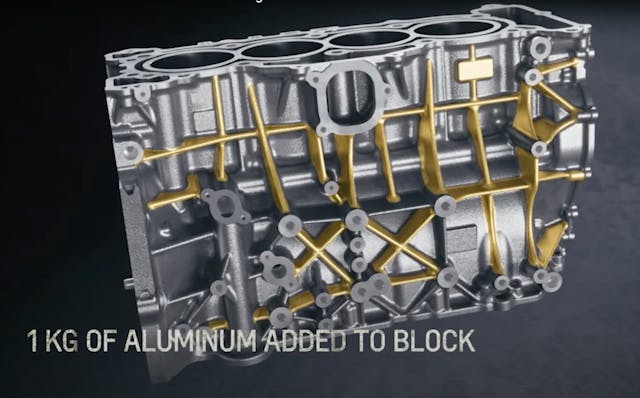

All of those attributes remain in the upgraded L3B that debuted in 2022 Silverados and Sierras, but to keep up with the increased cylinder pressure, the new engines feature an upgraded block casting, with an extra kilogram of aluminum webbing shoring up the outside of the block. The crankshaft was also retooled, as the new forging uses widened crank arms that improved stiffness in the front bay of the crankshaft by 30 percent. Not only did the improvements allow for the new tune that adds a heap of torque, but it reduced the NVH of the engine.

Luchansky knows that there’s a lot riding on the L3B, and he also knows that its diesel-like output may have its skeptics. He addredssed the question we know many of you are asking: How can this engine make that kind of output and live long term? “It’s details like [the block casting and the crankshaft], and 50 others like it.”

Luchansky was especially excited about the chain tensioners used on the new L3B. There is a chain at the back of the engine running the balance shaft and oil pump, and a chain at the front of the engine drives the camshafts. “This engine had to be reliable, no questions.” Luchansy said. As such, the engineering team sought out the best, most reliable suppliers for parts. For example, the pressure relief valves on the chain tensioners. When there’s a higher engine load, the oil pump responds with additional oil pressure to keep the bearing surfaces supplied with clean oil. The timing chain doesn’t need the extra help, so the pressure relief valve bleeds off just a bit of oil pressure to maintain proper load without additional wear on the tensioner.

We’ve only spent a brief amount of time with the recently upgraded L3B—in a crew-cab Silverado, which left us rather impressed. What we’re really looking forward to is what it can do in the Colorado and Canyon, which should be gearing up for production shortly. Mid-size shoppers will likely savor a Colorado and Canyon with low-end grunt of the L3B rather than the 3.6-liter V-6’s higher revs. Perhaps this engine, which is an improvement in nearly every metric over the three powerplants it replaces, proves to be the jack-of-all-trades GM hopes.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark us.

Ford did better than this several years ago with their turbo 4 and 2 sizes of v-6….Gov. Motors catching up?

Can the 2.7 H.O up grade calibration be installed on a 2022 silverado 1500 crew LTD early 2022 edition,not the refresh addition.

I have order 2023 Chevy crew cab Colorado and it comes with a 2.7L twin turbo 4 cylinder rated at 310 hp with 391 tourch and eight speed transmission. I expecting a 4.3 V6 and looks like time has changed. I have read reviews on the 2.7L from both outside sources and the engineers that design the engine. I am wonder if I am making the right decision. I want reliability, longevity for many years to come. I am 63 and my high performance and racing days are over. I will never forget owning a 85 mustang Gt and broke my speedometer at 135mph at 2:00 am drunk heading from the bar to home. And making a 24 minute ride in 9 minutes. I want longevity out of my truck, because it is the last vehicle I am going to buy. We don’t drive many miles. So I am thinking bring it in the dealership every six months for a complete serve and a preventative maintenance check up. The truck is on order and hopefully I will get in July.

If you want a truck that will last you the rest of your life then buy a Toyota.

I prefer to buy American so I’d get the Colorado with the high output 2.7T. It’s a nice truck, I had the last generation Colorado with the 3.6L V6 and my only complaint was the engine. If I needed power then I had to wring the engine out to full rpm at which point the engine would shake like a paint shaker. Astonishingly unbalanced for a V6, especially since I’ve driven Japanese V6 engines that were silky smooth.

The 2.7T I drove was actually well balanced and I barely felt any vibration. Torque was delivered on demand with no waiting and no drama. It’s one of the best mass market GM powertrains I’ve driven. Too early to know long term reliability but it’s American so you know it won’t be great.

If your primary requirement is a truck that will last the rest of your life then buy a Toyota or Honda. My friend bought a used Toyota truck many years ago and uses it for winter driving and summer hauling, so it sits for long periods and is occasionally worked hard. Never any major repairs and it’s still running strong at 260,000 miles.

Last Fall I traded my 2018 RAM truck for a new 2023 Colorado LT, it is now at 7,000+ miles on the odometer and I like it for the simple reason that I do not have to fill the gas tank up every week like the RAM, and yet it has plenty of power when I need it. One main concern is the temperature gages that are on display for the coolant, motor oil, and transmission oil, the concern is that they run hot. With no load at 80 degrees F. outside temperature the engine runs at 213 – 215 degrees F. and the transmission runs at 205 – 208 degrees F., coolant is at 195+ degrees F. To me this is too hot but I’m told by the dealer that this is normal… I just wish that GM would tell me that.