Media | Articles

Faster Than Us: Dual-clutch transmissions

You’ve logged thousands of miles driving powerful automobiles with three pedals and a shifter. Banging gears has become second nature. You don’t think, “Disengage the clutch and then move the lever to the next gear position.” You just do it, near as rapidly as is a human being can. Your machine, if older, can perhaps even outperform a similar car with a torque-converter automatic gearbox. But what about a similar car with a dual-clutch transmission?

The conventional manual, with its direct-connection clutch and gear changes, had long been the best option for driver control, most forms of auto racing, and quick sprints to 60 mph and beyond. Its day on the performance podium, however, appears to be over. Now standard equipment in many performance cars and in some lesser automobiles as well, dual-clutch transmissions (DCT) enable both automatic and driver-initiated gear changes, and they shift faster—with less chance of error—than a traditional manual.

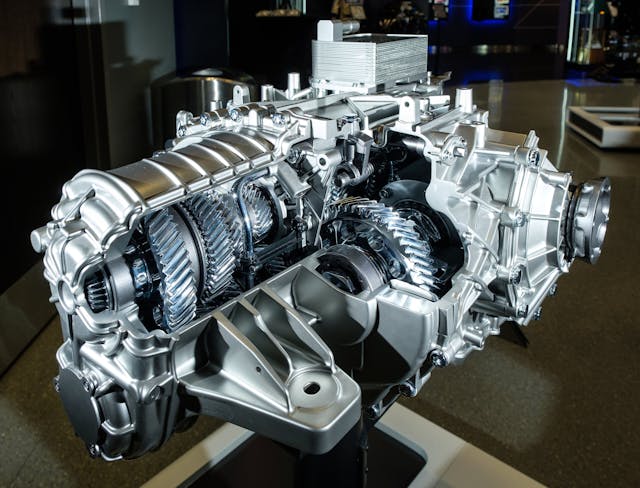

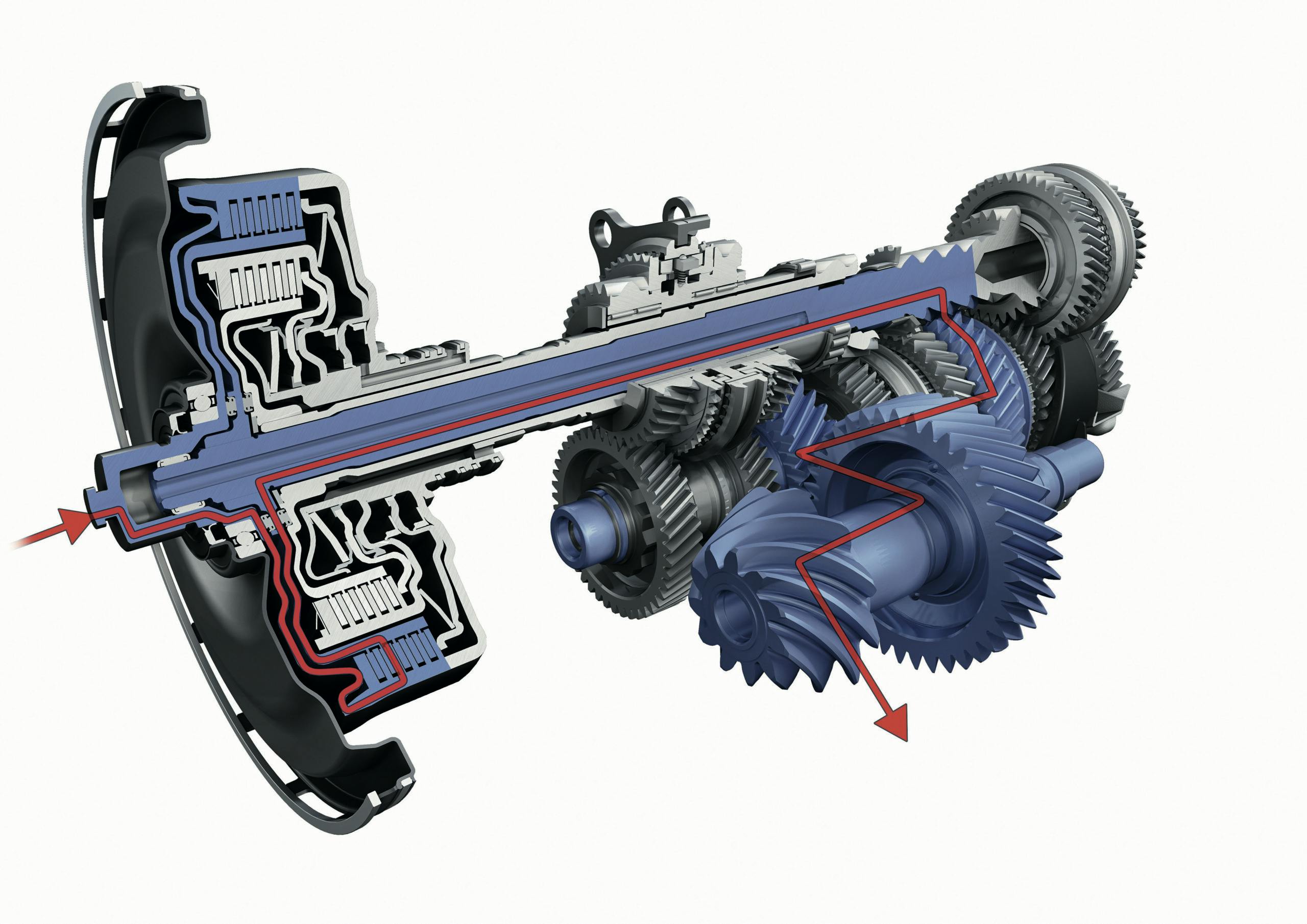

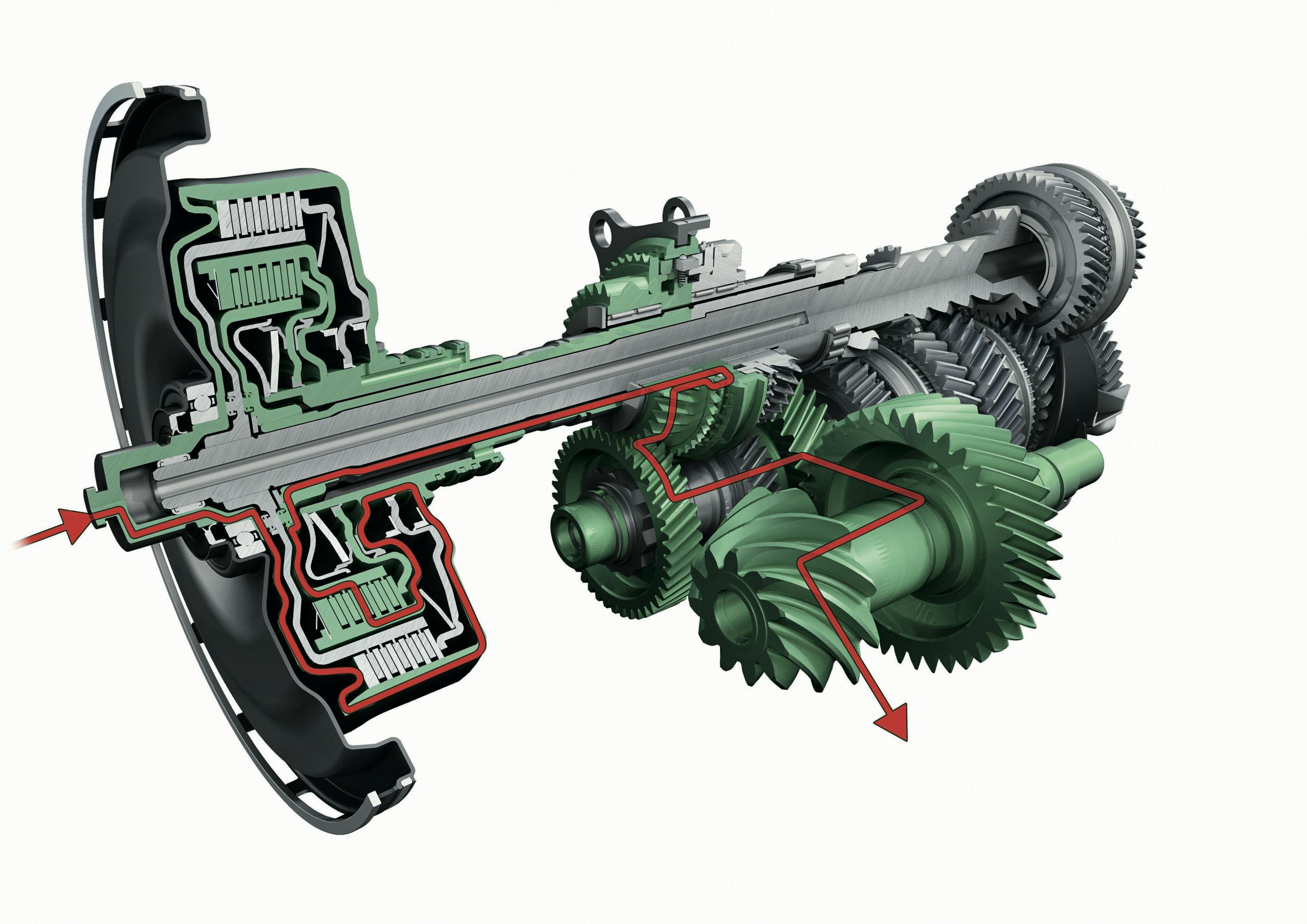

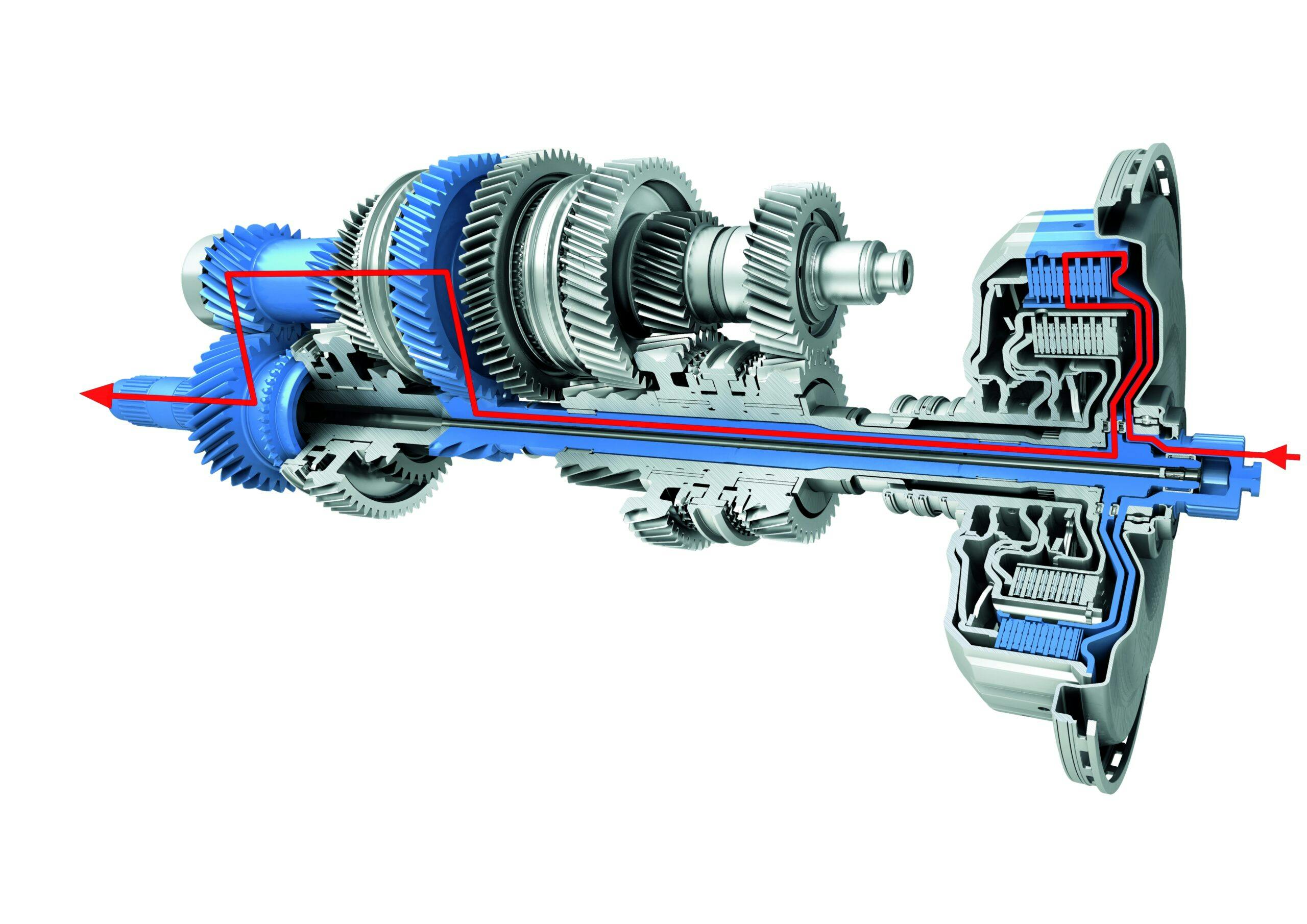

Because the DCT is coupled to the engine directly via clutches, there is no slippage and no loss of momentum. They can shift so quickly because the next gear has been selected before the shift occurs. A DCT is built with two main shafts, one with the odd-numbered gears and the other with the even-numbered gears. One shaft also includes a reverse gear and park mechanism, and each shaft is coupled to the engine with its own clutch. Hence the name “dual-clutch.”

When a DCT-equipped car powers out in first gear with the shaft-one clutch applied, second gear is already engaged on the other shaft. As the clutch on shaft one is released, the clutch on shaft two is applied. Electronic controls dictate the precise timing of clutch application, and hydraulics do the heavy lifting. How quickly and with how much force the second clutch applies depends on the control system calibration and, where applicable, in which mode the car is being driven. If the driver has selected an ultimate performance mode such as “track,” the result can be a shift time of less than 100 microseconds, or about 1/10,000 of a second.

Among the first to explore the dual-clutch concept was the French engineer Adolphe Kégresse. He experimented with the approach to transmissions in the 1930s, but World War II got in the way and Kégresse died before peace resumed. If not for war putting the DCT on the back burner, your dad’s ’67 Sting Ray might have been a quick-shifting beast. Well, probably not, but fortunately, the concept didn’t die with Kégresse.

Marketplace

Buy and sell classics with confidence

At the end of the 1960s, Imre Szodfridt, a Porsche engineer, pitched a DCT development project to Ferdinand Piëch, then head of development for the Stuttgart automaker. Szodfridt went so far as to develop prototypes, but they languished in storage until Porsche engineers dug them out and dusted them off in the early ’80s. Hoping to gain an advantage for Porsche race cars, the engineers went to work building a modern version of the Szodfridt transmission.

“It was a huge challenge for a small department such as ours,” said Rainer Wüst, the technical manager assigned to Porsche’s DCT project at the time. “Maybe it was naiveté that helped us, but certainly our pragmatism in dealing with the challenges did, as well as our passion for the subject.”

The team succeeded in building a workable transmission called Porsche Doppelkupplung, or PDK, and tested it in a 944 Turbo. A single gear lever in the center console was marked with plus and minus signs to signify upshifts and downshifts. Given the simple operation of a DCT, that’s all that was necessary.

That experiment was deemed a success, so the capability of the PDK was tested more rigorously in the 1983 Porsche 956 race car. With the test drivers free of clutch work, they could brake with the left foot and stay on the throttle with the right, keeping turbo boost high. Reaching for a gearshift lever in the middle of a corner was no longer required. Missed shifts were a thing of the past, and late braking was possible given the PDK’s rapid downshifts. Near-instant gear changes reduced lap times significantly, but the jolting application of torque resulted in mechanical carnage. The team went back to work and introduced a refined version of the PDK in the 962 race car, successor to the 956. This time, Porsche turned it loose on the rest of the racing world to great success.

The quick-shifting PDK transmission would eventually become a key component of Porsche road-going automobiles, but there was some resistance to overcome. Porsche’s 1967 attempt to market the Sportomatic automatic transmission had been met with well-deserved disdain, since a 911 so equipped was two seconds slower to 60 mph. The bad taste that lingered from that effort had made the lack of a clutch pedal a non-starter for Porsche cognoscenti.

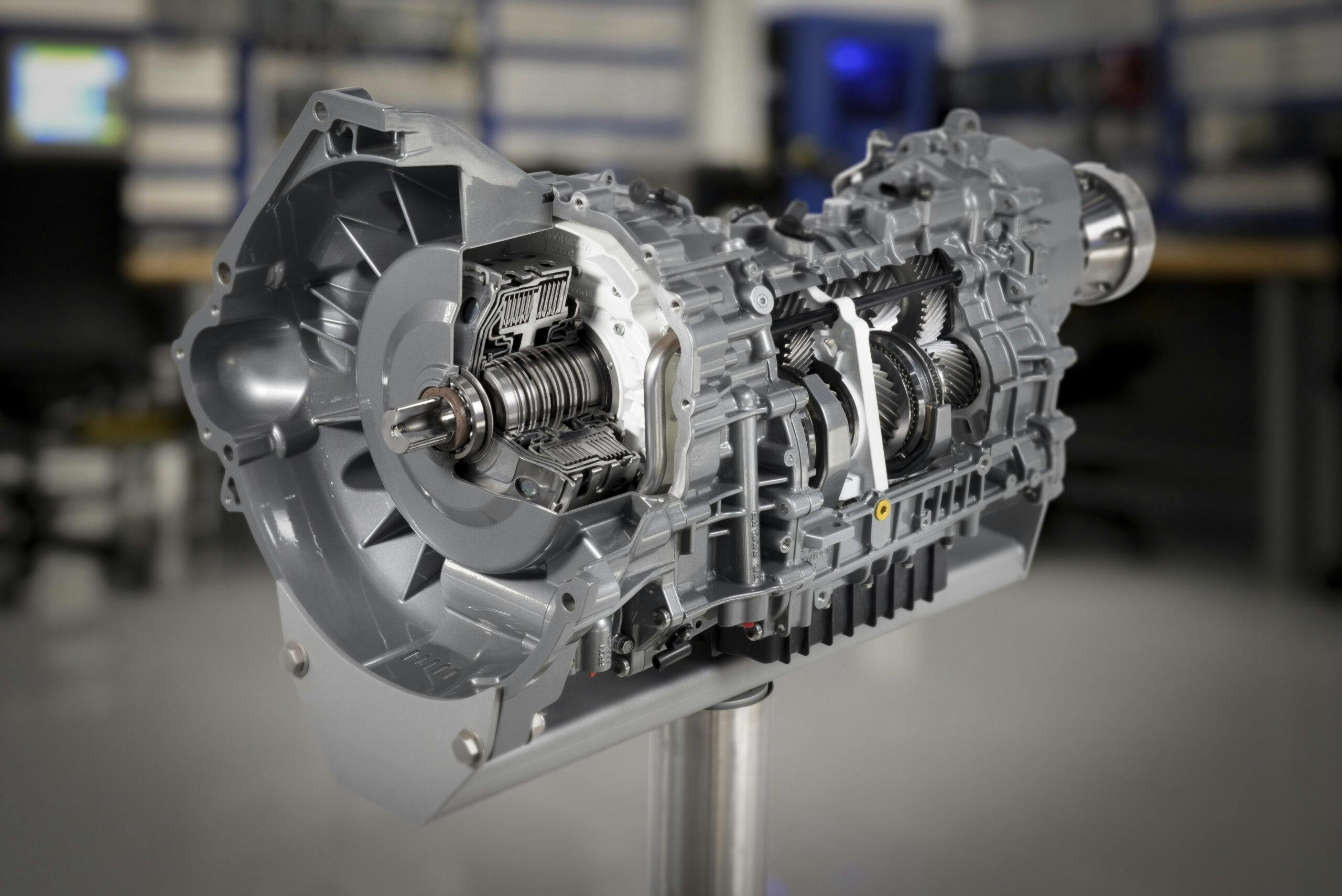

Porsche engineers were not deterred. After refining the dual-clutch PDK in the race cars, in 2008 Porsche adapted it to the 911 Carrera and Carrera S. It made the Carrera nearly half-a-second quicker to 60 than it was with the six-speed manual, and the system enjoyed moderate success. A year later, Porsche made the dual-clutch box standard equipment on some Panamera models. In 2016, the eight-speed PDK II dual-clutch became the only transmission available in the Panamera. Today, more than 75 percent of all 718 and 911 models are equipped with a ZF-manufactured eight-speed dual-clutch PDK transmission that can outperform any conventional manual on the planet.

In the years that have passed since Porsche pioneered the DCT, the technology has migrated to other nameplates. Audi used a DCT early on in endurance racing, and Volkswagen pioneered it on the street in 2003. Both have long partnered with Porsche, which along with Audi is part of the Volkswagen Group. Beyond those marques, a variety of automakers have shifted with a DCT, including Mercedes-Benz, Hyundai, Ford, Dodge, Acura, Nissan, McLaren, Lamborghini, BMW, and Chevrolet in the Corvette.

Adapting DCT technology to an automobile that will be used in a variety of ways presents a challenge. When a car is driven aggressively, the transmission should follow suit. When it’s driven leisurely, the transmission software must recognize that and regulate shifts accordingly. A well-executed mapping of transmission operating parameters will prevent jarring shifts when cruising and optimize full-throttle shifts. A DCT’s electronic control unit can also be programmed to take advantage of the acceleration boost that is generated between shifts when engine torque remains constant. In today’s advanced DCTs, the control units are sophisticated microprocessors, and the solenoids that regulate shifting and clutch application aren’t mere on/off switches. They’re complex devices that can gradually apply a clutch or hammer it home almost instantaneously. Making it all work seamlessly is dependent on exacting calibration.

Ford worked extensively with Tremec to calibrate the seven-speed DCT in the Mustang Shelby GT500. George MacDonald, Ford Performance powertrain supervisor, in speaking of the vehicle’s development, said, “We had full integration of the Tremec calibration teams. When we went to tracks, they were right there with us. Our pro drivers know what customers will want, so we integrated them with the Tremec people.”

MacDonald explained that the transmission’s electronic control unit can determine when to downshift and upshift on a racetrack, even when the car is driven as an automatic in track mode:

“A really good race car driver will know exactly when to upshift and downshift when shifting manually, so working with Tremec calibrators we were able to implement upshift and downshift times that are accurate in automatic operation. When to downshift is determined by where you are in throttle and brake. If, for example, you’re in track mode at 35 mph and 25 percent throttle, as you brake the software will determine when you get a downshift. In track mode, upshift and downshift points are much different than in normal or even sport mode.”

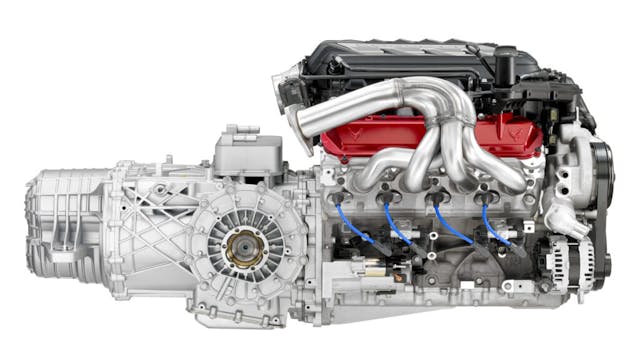

The mid-engine C8 Corvette must compete with the world’s best performance cars, so a DCT was the obvious choice; a conventional manual isn’t even offered. The complex shift linkage required by the rear-mounted transmission also entered into Chevrolet’s decision to forgo a third pedal.

Like Ford’s DCT, the Corvette transmission is made by Tremec, but it’s calibrated by Chevrolet engineers. Its hardware support includes accelerometers, throttle-position sensors, and steering angle sensors to provide the data that enables the control unit to determine how the car is being driven. Shifts and other operating parameters are regulated accordingly. Paddle shifters are wired directly to the transmission control module to minimize the time it takes the transmission to respond to paddle action. A modified version for the potent Z06 Vette has a stouter final-drive gear ratio and some fortified components.

Glenn Hoefflin, GM’s assistant chief engineer for DCTs, said the engineering effort that resulted in today’s Corvette DCT began 10 years ago. Asked about the biggest challenge the engineering team faced, Hoefflin said, “With the elimination of conventional automatic and manual transmission options, creating a driving experience that appeals to the automatic customer while providing an equally engaging and responsive experience for the manual customer … required considerable effort from the development team.”

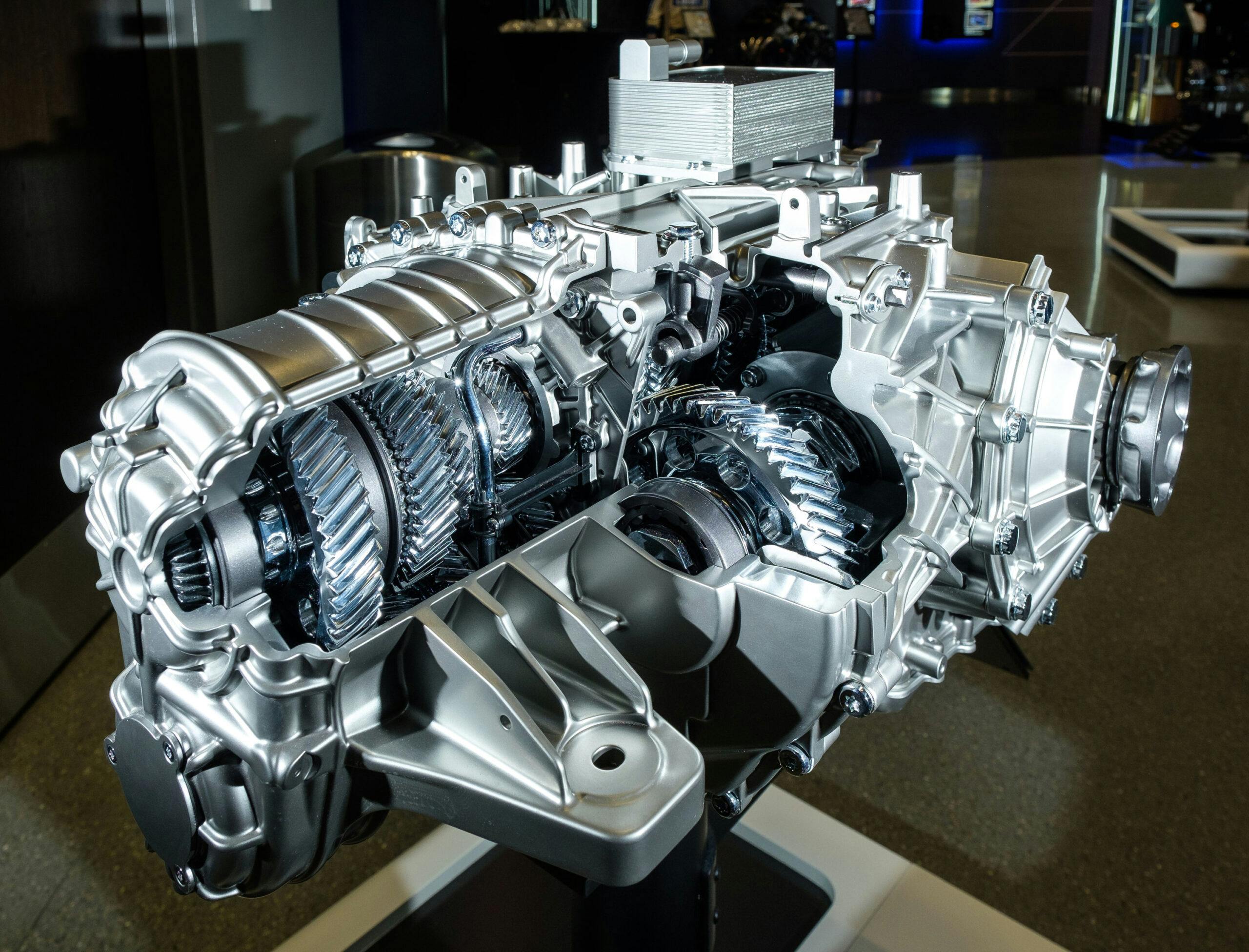

Although most automakers have dipped a toe in dual-clutch technology, Hyundai has gone all-in by developing DCTs for a range of internal-combustion and hybrid Hyundai and Kia vehicles. The gearboxes are manufactured by Hyundai Transys, and all calibration work was performed by Hyundai engineers. The transmission control units are supplied by Vitesco, a partner company to Hyundai.

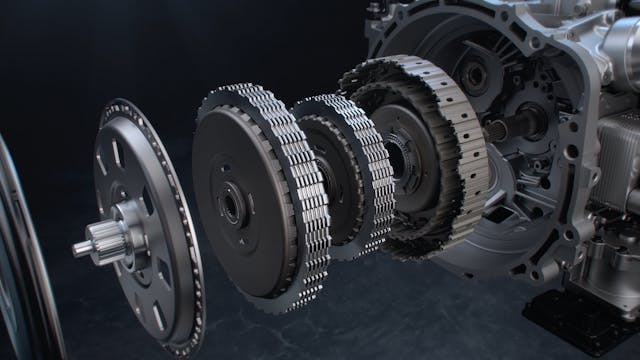

Hyundai dual-clutch applications range from modestly powered small cars to more potent midsize machines, so the automaker has developed both wet-clutch and dry-clutch DCTs to meet the different requirements of its products. The oil of a wet-clutch DCT cools the clutch pack and enables higher torque loads, but it comes with an efficiency penalty, as the oil exerts drag on rotating clutches. When efficiency is the primary goal and torque loads are not a major concern, a dry clutch is advantageous.

Hyundai’s most robust DCT, the eight-speed “8DCT,” uses a wet clutch and is offered on the manufacturer’s “N” models, both of which use a 2.0-liter turbo four-cylinder of 276 horsepower. The six- and seven-speed DCTs used in models where high torque loads are non-existent are dry-clutch units.

Though excellent drivability is of some importance in supercar applications, it’s essential in vehicles where reliable, comfortable daily transportation is the goal. Jason Valentini, the Hyundai manager for transmissions at the Hyundai America Technical Center, said the automaker devoted plenty of development and calibration time to achieve excellent low-speed shifting. “The result,” he continued, “is smooth, crisp shift response.”

Supercar engineers speak of shift times of approximately 100 milliseconds (a tenth of a second), which is the speed of the proverbial “blink of an eye.” The Hyundai 8DCT at wide open throttle in performance driving mode achieves what might appear to be a leisurely shift time of 300 milliseconds—still only three-tenths of a second.

Still faster than me or you? Definitely. More fun than the three-pedal shuffle? Highly debatable.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Check your milli/micro math…

Part of me says “rather drive to 60 in 5 seconds than ride there in 3.”

The other part says that advancements in transmission tech don’t seem to have gotten nearly enough coverage in enthusiast corners of the press. Maybe I’m in an echo chamber, but a lot of the focus on “tuning” seems to fall around making more power. Ironic, given that a transmission swap would probably do more to change the overall drivability of a classic car than power adders.

100% spot on. When you look at improving any car’s lap times, there is a reason you start with tires, suspension, and brakes (and a better clutch if a manual): because they cost little (relatively) compared to power adds and they will return relatively large gains for the times, while paving the way for power adds later that the stock setup couldn’t handle. Similarly, and as you said, swapping in a better transmission, be it a manual with more gears, or a modern automatic to replace the 60s/70s slushbox, will provide gains in both drivability and lap times without adding power, and pave the way for that future added power.

There is no doubt that in a drag race a dual clutch automatic is faster than a manual, but I debate whether that is true on a course. You’re driving your dual clutch equipped automatic and you’ve been riding the brake going into a curve, you hit the apex, and go to accelerate. What happens? The transmission says, “What? You were braking! Now you want to go fast again!?! Make up your mind! Here let me try a gear, how about this one? No, you don’t like that one? Let me try a different one. Is that one better? Okay! Here we go.” What happens when I drive my manual transmission into a curve? I’m riding the brake with the clutch in and I’ve already got the correct gear selected, when I hit the apex I simultaneously let the clutch out and hit the gas. Faster than the double clutch!

What you describe may have been true with some of the first-generation DCTs, but I can assure you from ownership experience that is not even remotely the case with current DCTs in performance-oriented cars. My car has the same Tremec 8-speed as is used in the current Corvette. If I engage a sport or track mode, even when driven in automatic (rather than manual) mode, the transmission will hold the gear upon deceleration, as it is fully expecting more power will be coming soon. So, even in automatic mode, I’ve already got the correct gear, and your manual operation will never match. In manual mode, I can made gear decisions the same as you, only I’m never at a loss of power while switching gears. You’ll lose on upshifts, downshifts, acceleration in the straights…basically, every time you need to shift a gear, you’ll fall further and further behind. A manual is for the fun of rowing the right arm, but it’s no longer the performance option.

I had the same question when reading the article. One sentence reads: “When a DCT-equipped car powers out in first gear with the shaft-one clutch applied, second gear is already engaged on the other shaft”. I can see how that would be an advantage when you are in first, since second is the only place to go next. But what about when you are in fourth? How does it know whether the next gear to pre-select should be third for a downshift or fifth for an upshift?

The DCT technology has also moved into the motorcycle world. I’ve owned and ridden over 40 bikes over the last 52 years. I currently own a 2021 Honda Goldwing with the automatic DCT trans. I do not miss the manual shifting. I often tell people the DCT can shift as good or better than I can. The article gave me a better understanding of how those trans work.

These folks you mentioned here basically took apart what ZF developed and copied it without infringing on patented elements.

I enjoy a DCT transmission. On a track I found myself much quicker with one. On street I do find that my enthusiasm varies depending on the DCT in question as some lurch or are just not happy at part throttle or stop and go traffic.

The Corvette transmission has zero dealer available repairs. Even leaks require removal and replacement with an exchange unit. Please be sure you buy an extended warranty.

You might be surprised to learn that Eaton Corporation in the 70s and 80s also developed dual clutch transmissions for medium duty trucks. This is a great technology but it only became practical with the advent of the CAN Bus, which allowed the engine and transmission to communicate electronically.

Like many street guys, I spend maybe 10% of my time driving on a race track. I spend 90% of my time in commuter traffic at low speed with inept other drivers and predatory police, in the same car. The notable extra weight of a PDK-type tranny negatively affects my fuel mileage and the extra complexity negatively affects my service bill. Tell me again how a PDK is $$$ better in my not-unique situation? Manuals Forever!

I’m old school. I like using my left foot on the clutch pedal and my right hand on a Hurst shifter, it’s my exercise

Interesting article. Empirical evidence shows that a DCT is undoubtedly quicker in all-out driving, i.e. on a track or an illicit street race. However, I am not a regular track rat and decline race challenges on the street so I will stick with my perhaps hidebound view that my pedal-pushing, stick-stirring manual is a more engaging (pun intended) way to drive on the street. And likely just as fast in the real world. So my attitude towards a DCT/paddle shift trans is still like that of a four-year old presented with a plate of asparagus – I haven’t tried it but I don’t like it.

“So my attitude towards a DCT/paddle shift trans is still like that of a four-year old presented with a plate of asparagus – I haven’t tried it but I don’t like it.”

This gave me a good chuckle. Points for self-awareness AND for poking fun at yourself. Thanks for reading and commenting, come back soon!

FOR A STREET CAR a softer, smooth shift is better. For the driver and the car. No need for all that neck snapping and mechanical damage. Most importantly, your girl friend will be embarrassed to ride in the car and will ask what’s wrong with your transmission?

Use by Honda in some motorcycle models also.

The problem is—they just don’t last.

No mention of the extra weight of a DCT, and how it affects handling. Also, in the field these things tend to grenade between 100-125K. So, the DCT movement would seem to be part of the disposable car philosophy, to which many afficionados do not subscribe.

Technically, unanswered is how the gearbox knows if one is upshifting or downshifting when preselecting gears. So, if in 3rd gear, is 2nd or 4th preselected? No doubt they get this right, but how?

I had a Power Commander on my Honda CBR600RR track bike that allowed full-throttle up shifts. It paused ignition for 65ms, and was actuated when I pressed the shift lever. It improved my lap times 1 to 2 seconds, depending on the track. So, no doubt in my mind a DCT could make me faster on the track in a car, versus MT. Oh, it was more fun, too, than the conventional motorcycle up shift while racing my buddies.

For unimportant logistical reasons, I own two 2012 BMW 335’s, one with DCT and the other with MT. They are both fun and rewarding cars to drive. I love the “brap” noise during up shifts with the DCT, but manually shifting up and matching revs during the down shift with a clutch pedal are very gratifying. No doubt the DCT would be quicker on the track. I feel fortunate to be able to bounce between the two.

I have to say I love the comment “ The size and weight of a dual-clutch gearbox make it more suitable for street performance rather than high-level racing”. Utterly hilarious, yup, them F1 cars ain’t high level like NASCAR! A manual is about as leading edge as an iron block. If you love the romance of manual shifting that is your opinion and you are welcome to it but the idea that manuals will even be in production in the near future is pretty funny. Like ICE engines, stock up now if you want them later.