Media | Articles

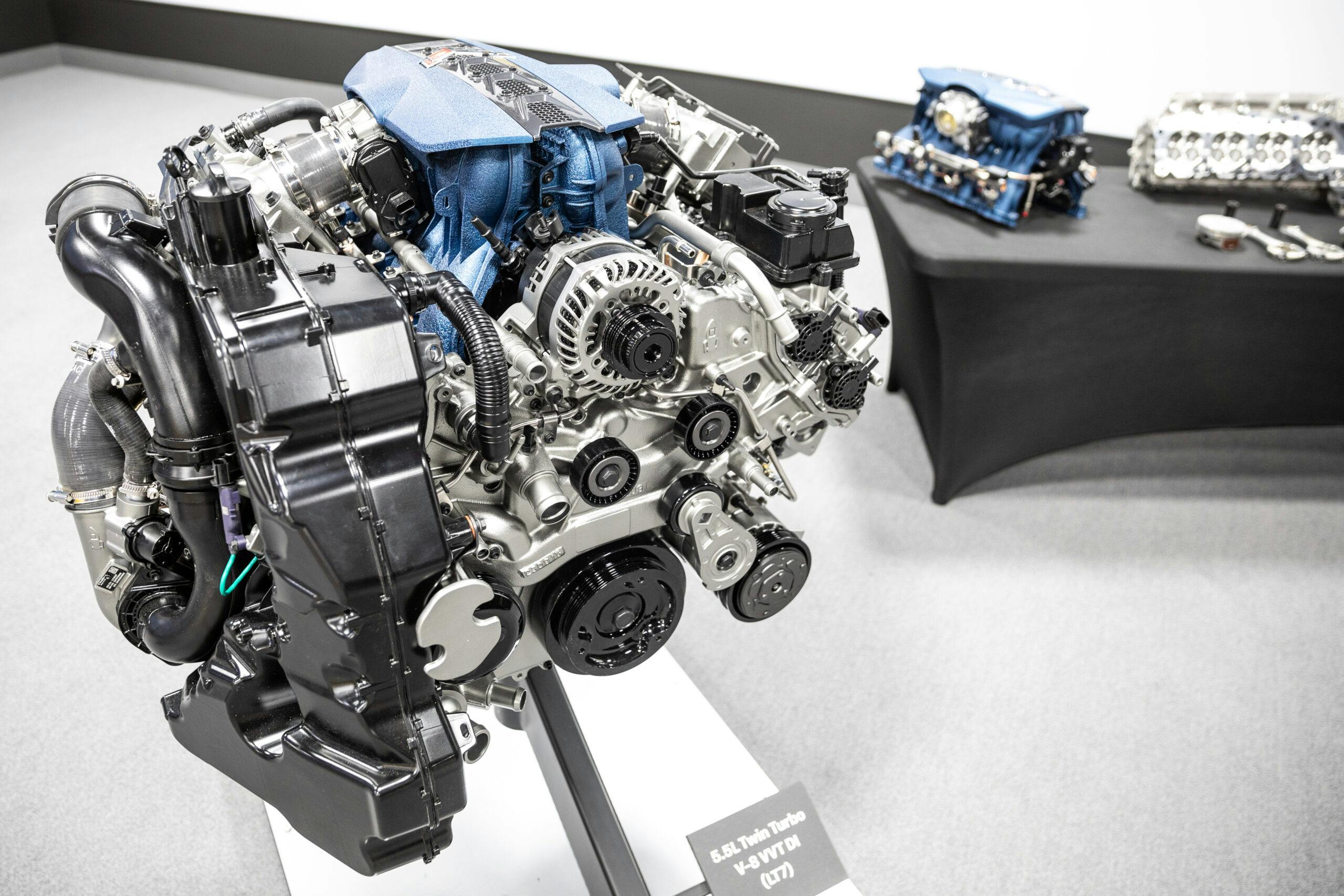

Epic Engine: How the ZR1’s LT7 Makes Its Magnificent 1064 HP

Bursting through the supercar ceiling to join the hypercar club is no mean feat. Next year, when ZR1 production begins, the Corvette Stingray will accomplish exactly that, with four-digit horsepower throbbing beneath its split rear window.

While our prediction that the ZR1 would arrive as the first turbocharged small-block V-8 in the Vette’s 70-year history was accurate, our 850-horsepower forecast was 20 percent low. Commenting on the error of our ways, the small block V-8’s chief engineer Jordan Lee notes, “850 was, in fact, our team’s initial goal. However, a decade of engineering effort yielded a more satisfying final answer: 1064 horsepower at 7000 rpm.”

How exactly will the 2025 ZR1 run with Ferraris, Lamborghinis, and McLarens at a fraction of the price? The answers lie deep inside the nuts and bolts explored here.

5.5-Liter V-8 Block

The LT7 is the second and likely final sibling of the Gemini V-8 family. A 4.4-in (111.8-mm) bore-to-bore spacing qualifies it as a legit member of GM’s longstanding small-block V-8 line.

Like the LT6 engine powering the Corvette Z06, the LT7’s cylinder block is a two-piece A319-aluminum casting. Heat treating that aluminum relieves internal stresses that arise during the cooling process after casting. The upper portion of the block houses cast-in iron liners, providing a piston-to-cylinder wear surface far tougher than aluminum. The lower block contributes structural stiffness and secures the crankshaft via four bolts at each main bearing. Due to differences in accessory equipment mounting pads, the LT6 and LT7 blocks do not share the same part number.

Marketplace

Buy and sell classics with confidence

The LT7’s dry-sump lubrication system has seven scavenge pumps drawing the synthetic oil out of crankcase cavities for delivery to a remote reservoir. This eight-quart system avoids frothing and power losses caused by the crankshaft and connecting rods whirring through wet mist. Block passages route lube to the main and connecting rod bearings, as well as the four overhead camshafts. Jets squirt the underside of the pistons to cool them. Spraying the scavenged oil into the storage tank at its outer edge produces a centrifuge effect that helps separate vapor bubbles from the liquid oil.

Pistons are forged aluminum while rods are forged titanium. A large bore and short stroke are essential in any high-performance engine to reduce piston velocity, acceleration, and inertia loading at any given rpm. A short stroke also minimizes the connecting rod’s monkey motion.

LT7 designers selected the largest possible bore—4.104-in (104.24-mm)—that could be stuffed within the classic small block’s 4.4-inch bore spacing. The iron bore liners are so tightly spaced—in what’s called a Siamese arrangement—that there’s minimal coolant flow between them (Small notches machined where the block and head meet do facilitate some lateral flow). The large bore also maximizes the space available in the combustion chambers for the large valves essential for the engine to breathe freely at high rpm.

The 3.150-in (80 mm) stroke dimension was selected to yield 5.5 liters (333 cubic inches) of piston displacement; it’s no coincidence that this is the size limit for production sports cars competing in international endurance races such as the 24 Hours of LeMans.

32-Valve Dual-Overhead-Cam Heads

Like the LT6 V-8 in the Corvette Z06, the LT7 engine is topped by cylinder heads equipped with two chain-driven camshafts operating dual intake and exhaust valves (a total of four per cylinder). More valve area maximizes the air-fuel mix admitted during the piston’s downward stroke and eases exhaust flow out of the cylinder following combustion. The titanium intake valves are 1.77 in (45 mm) in diameter, and the sodium-filled Nimonic exhaust valves are 1.37 in (35 mm) in size. Titanium is used because it’s lighter than steel, avoiding float at high rpm. Nimonic is a trademarked alloy commonly used in gas turbines due to its ability to maintain its strength at high temperatures. The cylinder heads are made of A356 aluminum which is heat-treated after casting to toughen surfaces exposed to combustion pressure and valve loads.

Variable drive camshaft sprockets called “phasers” allow computer-controlled intake and exhaust timing changes to improve idle quality, running smoothness, and power throughout the rev range. A finger follower lever is positioned between each cam lobe and the top of the valve it operates. Each valve is closed by two coil springs. A computerized tool used during head assembly selects the thickness of the shim fitted to control the lash between each valve stem and its cap. Since wear is negligible, these shims remain in place for the life of the engine.

Intake and exhaust ports, along with the combustion chambers, are machined using CNC (computer numerical control) equipment to assure consistency and maximum flow in and out of the cylinders. A 60-cc combustion chamber and dished-top pistons provide a 9.8:1 compression ratio (versus the LT6’s 12.5:1) to avoid detonation with up to 24 psi of boost provided by the turbochargers.

Flat-Plane Crankshaft

Ninety-degree—aka cross-plane—crankshafts have been standard V-8 practice for a century because this arrangement avoids the second-order shaking (at a frequency double that of engine rpm) common to four-cylinder engines and V-8s with flat, or 180-degree crankshafts. While that’s fine for most applications, the pursuit of maximum rpm and power is a distinctly different matter. Here, a flat-plane crank featuring four rod journals (each of which is attached to the big ends of two connecting rods) spaced 180 degrees apart improves volumetric efficiency (flow of fluids in and out of the cylinders) for maximum power.

In addition, a flat-plane crank schedules combustion events more advantageously. While a 90-degree crank fires two cylinders in the same cylinder bank in sequence, a 180-degree crank does not; instead, the firing order is always left bank, right bank, left bank, etc. The most noticeable change is to the engine’s exhaust music, which eschews the familiar V-8 burble for a shriek common to exotic engines. More importantly, though, with 180 instead of 90, 180, and 270 degrees between same-bank firing events, flow into the exhaust manifolds is more efficient. With proper manifold design, one spurt of exhaust helps suck the flow out of another cylinder in the same bank.

Second-order shaking is a lower priority when there’s power to be made. Using light materials such as titanium for the connecting rods and selecting a short stroke helps manage this issue. Furthermore, the mass of the LT7 V-8 and its eight-speed dual-clutch automatic transmission are supported by intelligently tuned rubber mounts, so vibration and harmonics in the passenger compartment aren’t a concern.

Intake and Exhaust Systems

While supercharging was the preferred form of boost for the hottest models when the Corvette’s V-8 resided up front, the mid-engine C8 presents alternate opportunities. Now, adding forced induction to the engine’s flanks doesn’t interfere with steering equipment, and heat radiated by the turbos can be readily flushed out the rear. Despite being behind the driver, engine height was a concern—stacking a blower atop this mid-mounted V-8 would interfere with folding convertible top equipment.

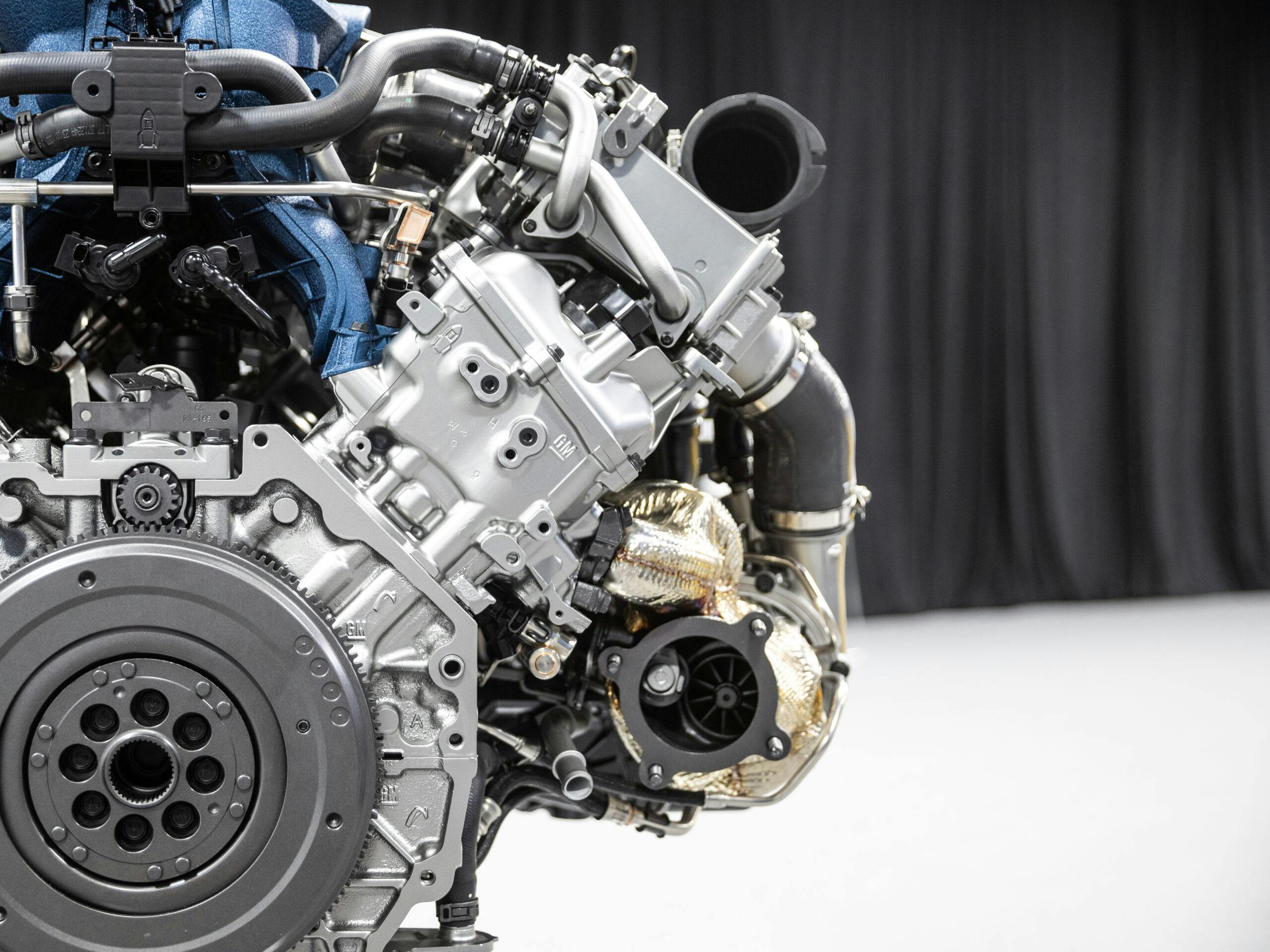

So, each of the LT7’s insulated exhaust manifolds feeds a turbocharger. A ball bearing shaft within these energy recyclers carries a 76-mm turbine wheel fed by a single-scroll housing and a 67-mm compressor wheel. The turbine is made of a nickel-based “super alloy” called Mar-M, which offers maximum durability at high temperatures. Electronically controlled wastegates limit boost to 20 psi most of the time, with 24 psi briefly available during certain conditions. Each turbo spins up to 135,000 rpm.

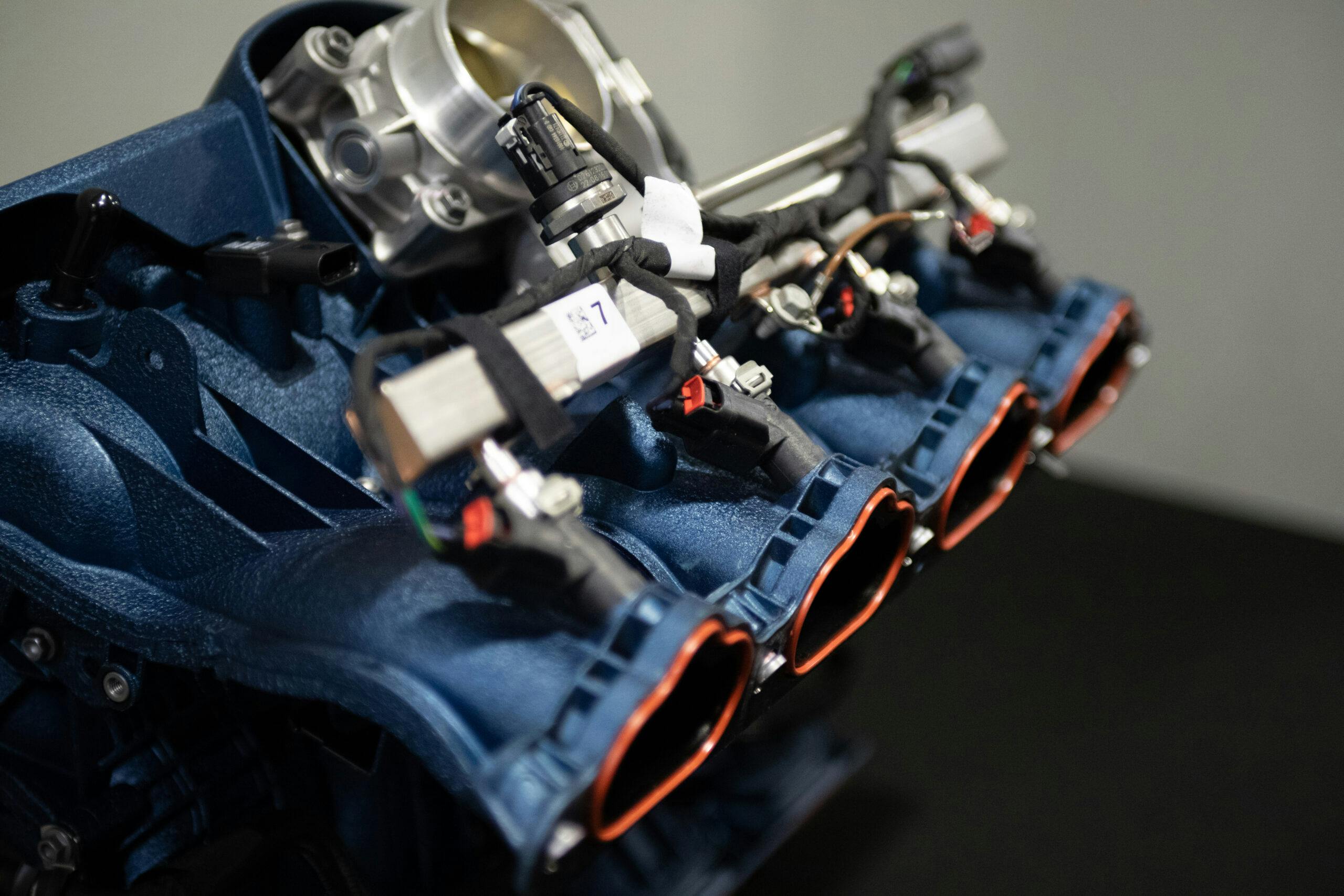

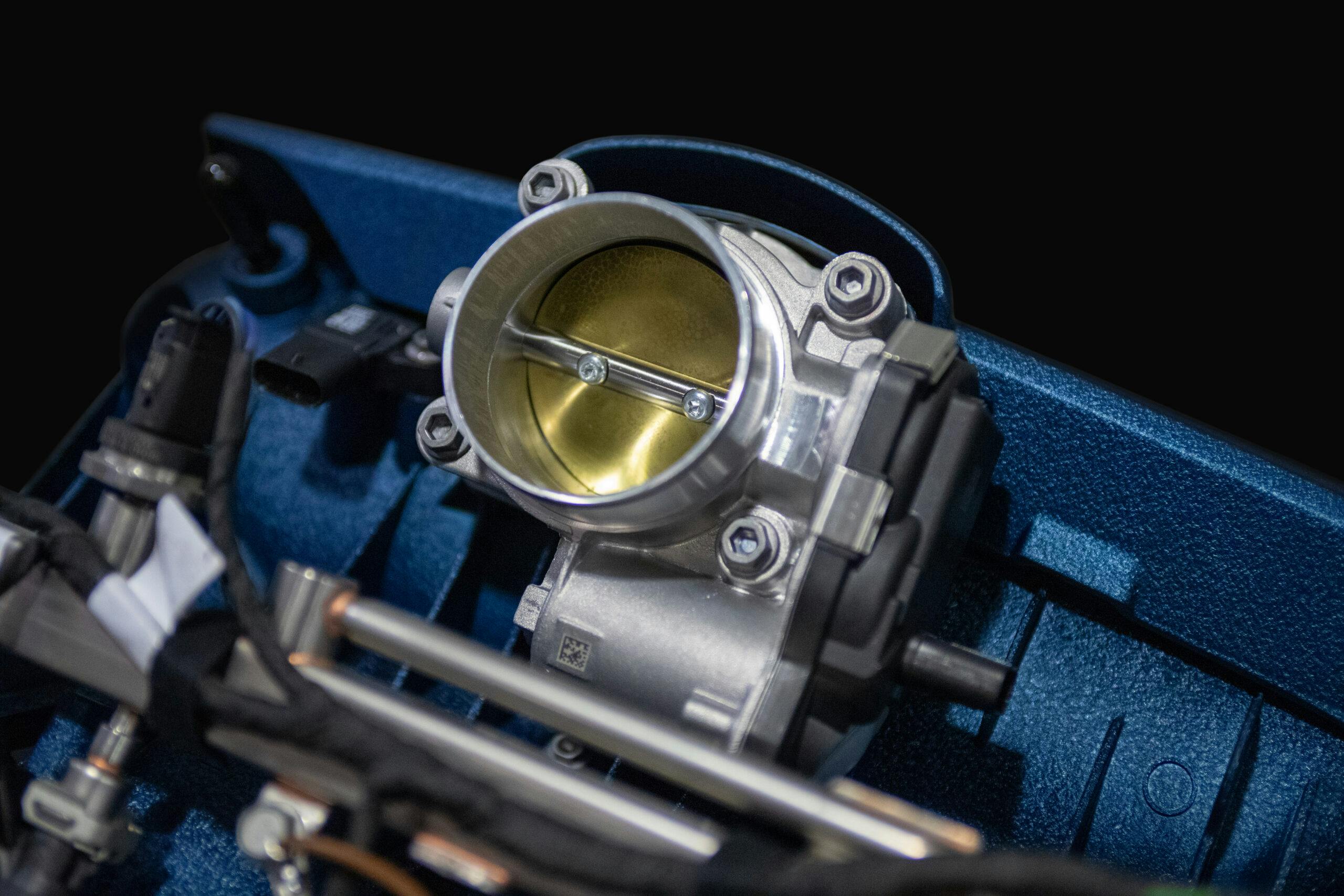

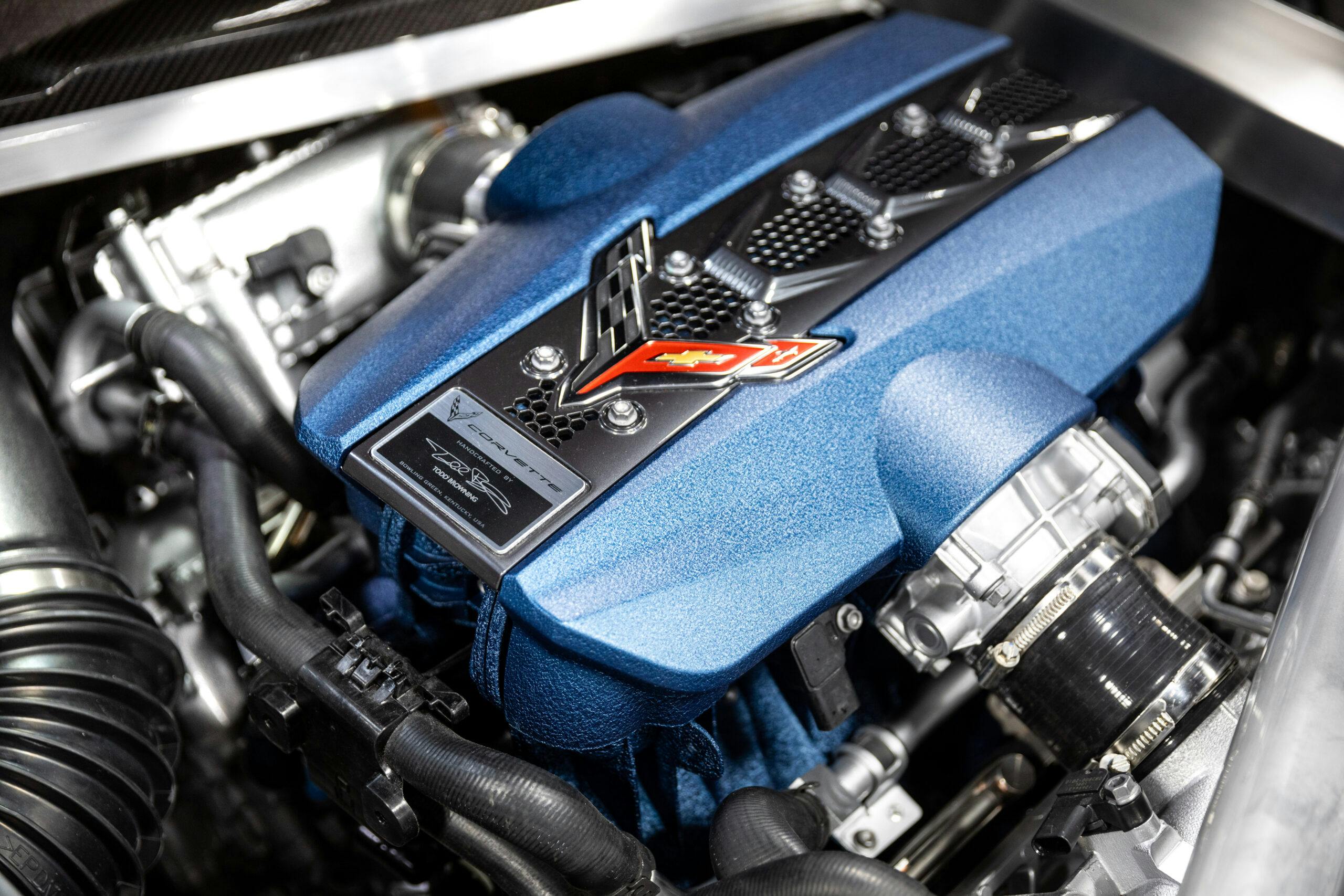

Compressed induction air is cooled by a heat exchanger mounted atop each head. Coolant flows between these intercoolers and a radiator mounted at the front of the car. (Adios frunk!) One electronically controlled 2.6-in (65-mm) throttle body is positioned between each intercooler and the blue-painted intake manifold.

Fuel is delivered by no less than 16 electronically controlled injectors. One per intake port handles idle fuel delivery. Eight more squirt directly into the cylinders. Full-tilt flow tops two gallons of premium-unleaded fuel per minute. At peak power, the tailpipes spurt 37 pounds of jet thrust.

Torque and Horsepower

Lee and his astute team of 100 design and development engineers patiently tuned the LT7 to produce impressive power and torque. The torque “curve” is essentially flat between 3000 and 6500 rpm with a peak of 828 lb-ft (1123 Nm) at 6000 rpm. Power rises in a steep, straight line from 3000 to 8000 rpm, at which point output reaches an entertaining 1064 horsepower (873 kW).

During ZR1 press rides, journos were treated to neck-torquing acceleration and 200+ mph speeds. The Corvette engineering team is claiming quarter-mile ETs below ten seconds with trap speeds topping 150 mph. Now that the hottest Corvette’s exterior has been revealed, the car’s development will continue for several more months without camouflage flapping in the wind. Top speed tests at a track in Papenburg, Germany are scheduled for later this year and will surely add more luster to the ZR1’s portfolio.

Prices haven’t been announced, but you can expect creative dealers to charge $200,000 or more for an early, fully optioned example of this Ferrari-beater.

The pictures of the intake and exhaust ports need to be reversed..

Let’s not forget the 12 mpg city/highway rating.

Reminds me of the film; ‘Treasure of the Sierra Madre’.

Protagonist (skeptically): If you’re a halo car, let’s see your MPG’s.

Antagonist (smirking): MPG’s? Halo car don’t need no steenking MPG’s.

Brilliant response. A triumph for modern technology.

When you say “creative dealers” you actually mean shitbag car salesmen, right?