Media | Articles

Driving AEM’s Tesla-powered Mustang

Electric motor swaps are gaining mainstream popularity, and that’s only going to increase with both Ford’s Eluminator and GM’s eCrate offerings to come. We even got the chance to drive Ford’s Mustang Mach-E-powered F-100 pickup, and our story piqued some interest over at AEM Performance Electronics. Would we be interested in giving its Tesla-swapped S197 Mustang a go, AEM asked?

We said yes, naturally, and soon headed to AEM’s headquarters in Hawthorne, California. First up, Lawson Mollica, AEM’s Director of Marketing & Public Relations gave us some of the technical basics. There’s a lot to unpack here—some of which we will get into—but we’ve opted to keep you engineering nerds in suspense with a more holistic nitty-gritty deep-dive article to come, in which we will explain exactly how an EV swap differs from your average engine swap. For now, what follows is our experience behind the wheel of AEM’s electric-propulsion pony car.

The basics for this build, which AEM is calling the “Testang”: it started as a 2007 Mustang GT, the model’s final solid-axle generation. AEM purchased the car from an enthusiast that had already made the Tesla conversion, and from the outside, you can hardly tell the car’s been converted. Replacing the solid axle is Tesla’s base drive unit that you can see through a Plexiglas window in the trunk floor. The Mustang’s chassis was modified to accept the unitized package of Tesla hardware that includes the motor/regen system along with the Tesla control arms and brakes. Replacing the Tesla shocks are QA1 coilovers. Teslas are quite wide, and the backspacing required to fit under the Mustang quarterpanels was very close to matching Corvette wheel specs, so that’s what the Testang wears.

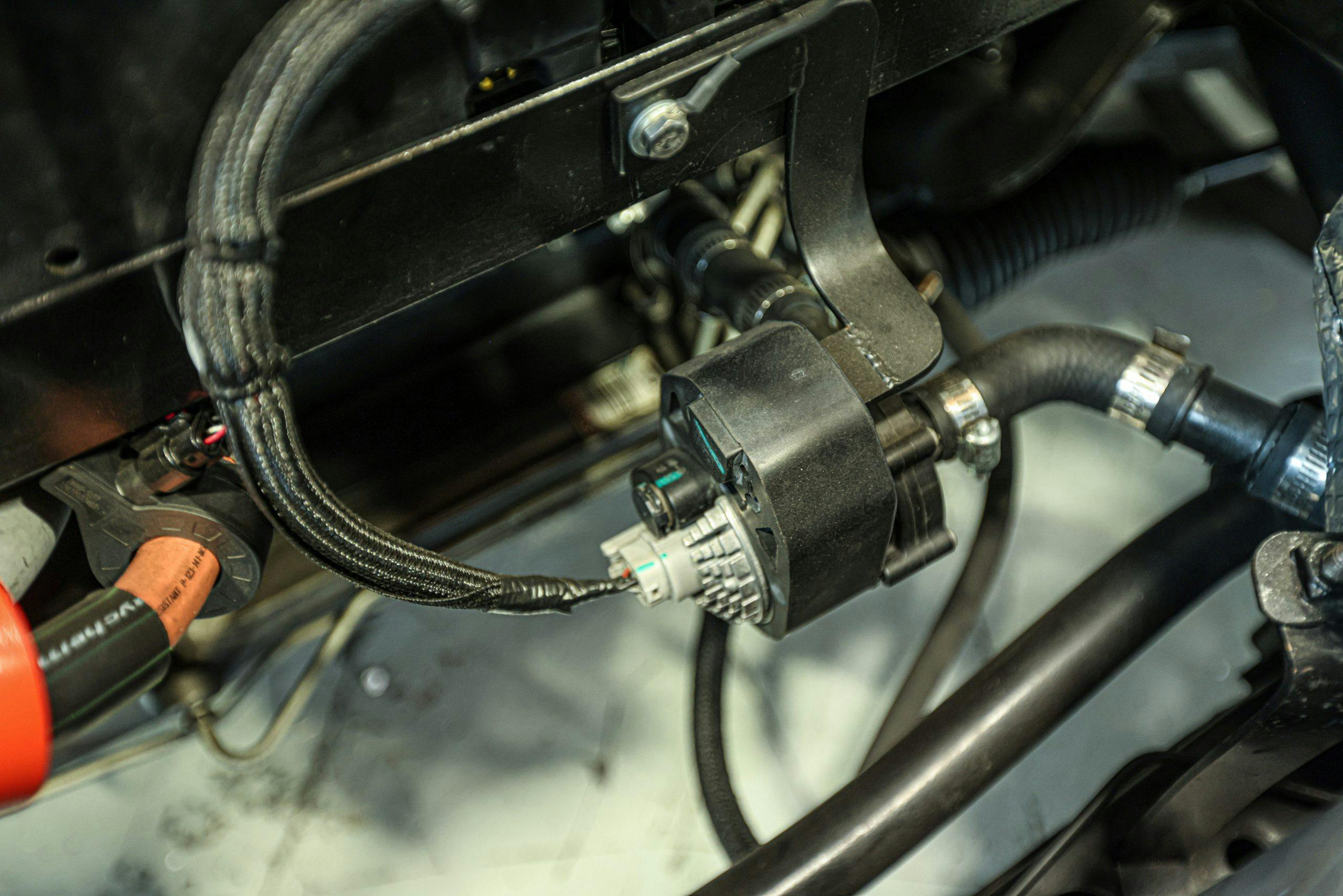

AEM is an electronics company, and those components are what the Testang is meant to highlight. AEM developed its own Inverter Control Board which replaces Tesla’s inverter controller, allowing the company to build its own torque maps and change the driving characteristics and get more power out of the Tesla motors. That controller is mounted to a circuit board that attaches to the Tesla’s inverter. AEM’s Vehicle Control Unit (VCU) is what orchestrates current demand in relation to pedal input to turn a wild project car into a relatively civilized machine.

Under the hood—replacing the three-valve, 310-hp, 4.6-liter V-8—is an array of six hybrid car batteries, with six more located under the car where you’d normally find the fuel tank. AEM went with batteries from hybrid cars because they’re optimized for short bursts of high-energy draw, like getting a vehicle up to highway speeds, allowing the gas engine can take over when cruising. We mentioned that the car is equipped with Tesla’s base drive unit, but the original builder equipped it with the more powerful sport drive unit. But this setup is no wimp; AEM’s controller, in conjunction with these hybrid batteries, is able to get 330 lb-ft of torque and 300 kW from the motor, which translates to 400+ horsepower. That’s more power out of the Tesla base drive unit than Tesla gets from its larger, sport drive unit.

Marketplace

Buy and sell classics with confidence

Drive control for the Testang is operated with a console-mounted panel that includes the shifter, an on/off switch, and a button whimsically labeled with a turtle and a rabbit that allows for the selection of pre-set power levels. The turtle mode, unlike the one found on your riding lawnmower, will still power the Testang to highway speeds. It is, however, adjustable, so you could add a valet mode that truly limits buffoonery. We started our test will full power and tapped the D button to shift to Drive. Hawthorne is located in Los Angeles’ South Bay, so we used Highways 105, 710, and 405 to get a feel for the Testang in real-world conditions. Merging into freeway traffic, we demanded full-throttle acceleration and got all 400 hp in a smooth, controlled manner, without any wheel slip thanks to AEM EV’s extensive torque mapping development time. The Testang easily climbs in speed, a feat that’s particularly salient during 60-80 mph passing maneuvers that feel like they’re over in half a second.

As with a factory electric vehicle application, AEM enables the motor to act as a generator, although the regen function was dialed way back when we were driving to allow for a much more familiar coasting feel when releasing the throttle. That’s also adjustable, of course.

The Testang’s 12-volt system was left intact to power the aftermarket stereo in the dash worked, as well as the auto-up power windows.

There’s only one real aspect in which the Testang is lacking: HVAC. With no engine constantly running to drive it, electric vehicles rely on a separate motor to power the AC compressor and the previous owner removed much of the factory Mustang’s AC system. AEM will have that resolved soon, as their VCU has been used to run AC as well as battery cooling and heating loops in other electric vehicles. The company is already working on Testang V2 to satisfy increasing demand to get this car into the hands of eager enthusiasts. AEM’s engineers still need a development mule that can be torn down and modified at a moment’s notice, and AC in the Testang will be a must during the summer.

AEM’s Testang handles a lot like a modern Mustang, in part because the batteries are positioned in such a way that they replace weight where it would be found in a normal Mustang—up front and under the hood. The additional batteries and the drive unit do put more weight over the rear, effectively balancing the car a bit more, but it doesn’t feel like a heavy modern EV. As for the electric power delivery, it is 100-percent smooth and dialed in just as you’d expect from a factory EV. That’s a hugely impressive accomplishment, and somehow the Testang still feels like a Mustang aside from the powertrain.

There are some compromises. The battery capacity of the Testang provides it less than 100 miles of range, and that range is quickly used up by aggressive track driving. AEM has been hitting the autocross with the Testang, which is why it the computer (which calculates based on recent usage) showed just 37 miles of estimated range with the batteries more than half charged. On the other hand, with the modest battery packs, the vehicle’s weight isn’t as high as you might expect. AEM reports a 3600-pound curb weight, which is right at the high end of a well-equipped 2007 Mustang GT. As battery tech gets better and there are more and more options for power-dense batteries become available, enthusiasts building their own EV conversions will hopefully face fewer compromises. As it stands, it’s already viable for an enthusiast to build a car like the Testang and the process should only get easier as companies like AEM lay the groundwork.

AEM sees EV conversions as a critical avenue for future enthusiasts and hopes to be the supplier for the hardware needed to simplify the process. Considering that even some of our most carburetor-obsessed gearhead friends have warmed to the benefits of an electric cruiser, let alone one that can hit the autocross like the Testang, we think that AEM is onto something.