Media | Articles

Climbing Out of the Doldrums: What to Do with a Stalled Project

This article first appeared in Hagerty Drivers Club magazine. Join the club to receive our award-winning magazine and enjoy insider access to automotive events, discounts, roadside assistance, and more.

After more than a year of nursing my ‘48 Willys CJ-2A back from the edge of the scrap pile, I decided it was time to check the valves. Maybe look into finally addressing the worn steering gear. Both exercises require pulling the driver’s fender, which came away with no more than the usual handful of broken bolts. With the sheetmetal gone, I was treated to the first clear view of the little Jeep’s frame. More specifically, I could see the terrifying number of cracks around the front crossmember and the previous owner’s attempts to booger weld the thing back together. Determined to right these wrongs, I removed the bumper, which revealed one frame horn that sat 3 inches higher than the other. A smart man would have bolted everything back together and went on his way, enjoying the bright, warm Jeep months of spring and summer. I am not a smart man.

***

I bought a frame and tub—then two more when the first pair turned out to be more work than I bargained for—and tumbled headlong into my first frame-off rebuild. I say “rebuild” instead of “restoration” because I had neither the funds nor the inclination to wind up with a glossy, better than perfect re-creation of what I had. I wanted a truck that showed its bumps and bruises, that I wouldn’t mind firing at a fire road or the local off-road park. Something that could sit outside during a camping trip thunderstorm without giving me palpitations.

But soon enough, the old While You’re In There demon showed up. I wound up sandblasting and painting the frame, buying new springs, cleaning up the axles, and pulling the cylinder head. I rebuilt the transmission and bought an overdrive. Patched and painted the tub. After a few months, I looked up and found myself far from shore on a vehicle that once brought me nothing but joy. Every time I turned around, it asked for another couple hundred dollars worth of parts, none of which seemed to edge me any closer to bopping around downtown Knoxville or cruising under the hardwood canopy of the Nantahala National Forest.

Work on machines long enough and you’ll find yourself here: The Doldrums. Becalmed by your own decisions and the seemingly endless amount of work left before you can turn the key. The thought of sanding one more panel, turning one more bolt, or welding one more stitch is enough to make you scream. Your eyes wander. Your search history becomes full of other potential projects. Or worse, you grow to hate the thing. What was once a bright spot in your life becomes a pit of loathing. It transforms itself into a shelf in the garage, a convenient place for holiday decorations and your own despair.

Marketplace

Buy and sell classics with confidence

For ancient sailors abandoned by the winds that carried them along, the only solution was to wait for their sails to fill again, but that’s a gambit on a project. The longer you stay away from the wrenches, the larger the tasks facing you loom. The work seems to swell with each day. Soon enough, the project takes on a kind of menace. Days become weeks, weeks turn into years, and eventually your heirs sell your parts for pennies.

So what do you do about it? How do you find motivation when it has no interest in finding you? That’s a question that goes far beyond worn bearings and rusted fenders. So many of us find ourselves bent over a mechanical question because of the simplicity of the thing. There is a black-and-white answer to why a plug won’t fire or an engine won’t turn. In a world increasingly devoid of such luxurious simplicity, solving those riddles can be a balm, but motivation has nothing to do with metal. It’s anchored in the gray matter between your ears.

***

Writers aren’t strangers to this problem. Novelist Anne Lamott, in her excellent Bird by Bird: Some Instructions on Writing and Life, shares her tactics for squaring off against daunting tasks. For her, that’s writing a book, but putting a vehicle together isn’t so different. In it, she shares her father’s advice for a distraught child who put off a report on local birds until the night before it was due: Take it bird by bird. In other words, don’t look at the pile of parts before you as a whole. Break it out into smaller, more manageable tasks. Don’t fret about the body work. Focus on one fender. Cross it off the list and move on.

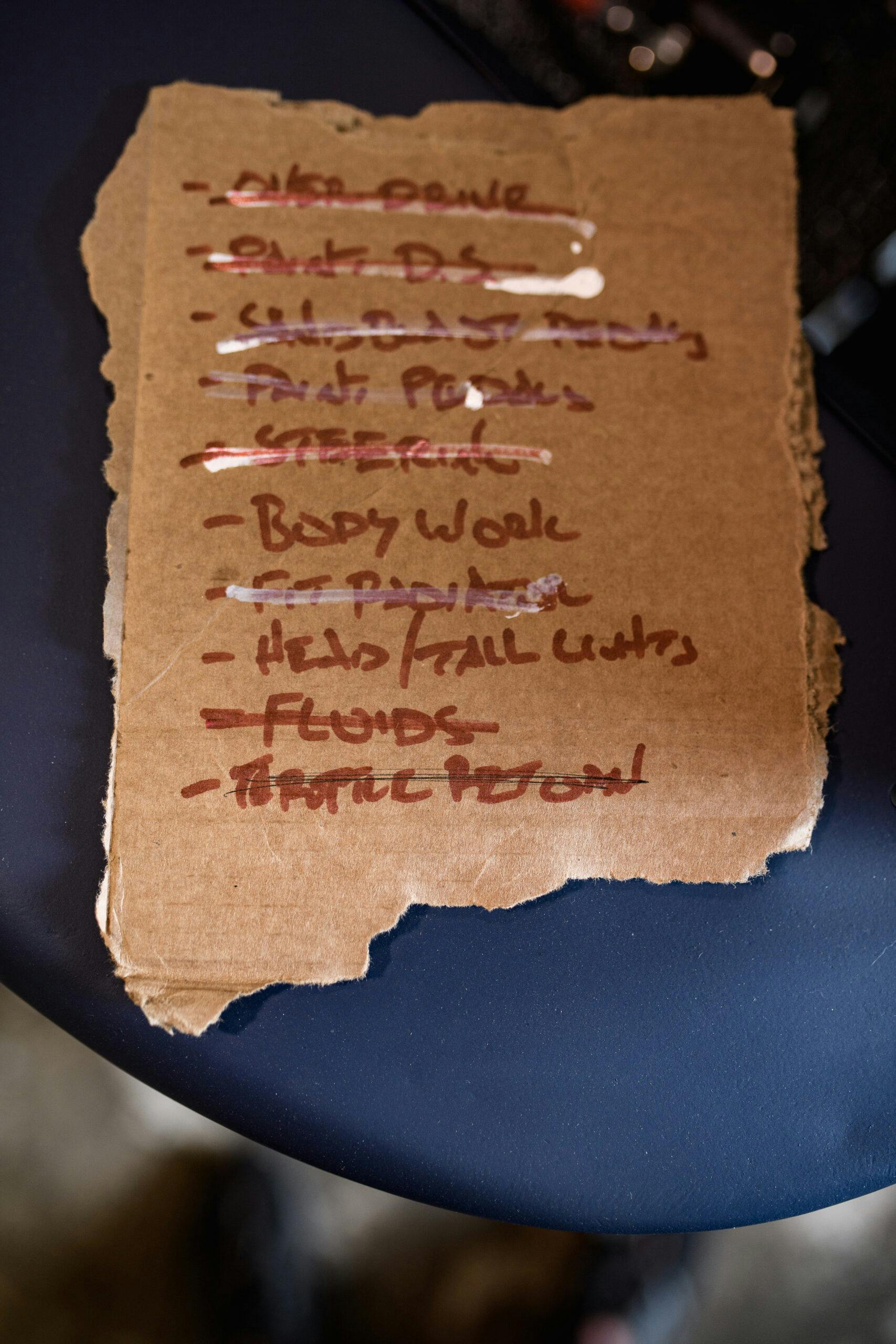

But whatever you do, keep moving. There’s a reason we call it working on cars. It’s work, and work isn’t always a holiday. As I’ve dragged myself through the various stages of grief, I’ve come to rely on the almighty List to help me cover ground. It’s no good trying to keep it all straight in my head. I’m likely to start on a wheel bearing and wind up trying to solve that pesky radiator mount with the front hub still disassembled. I have to write the thing out, usually on a scrap of cardboard. I sketch out 10 manageable tasks and go from there. I’m not alone. Billionaire Warren Buffet famously gets through his day by making two lists. The first contains 25 goals. He reportedly circles five of the most important and scraps the remaining 20. Those five items become his actual to-do list, and he avoids the leftovers like the plague. I’m not sure if that sort of dogged prioritization will get me closer to becoming a billionaire, but it has helped me work on an old Willys.

There are ways to make the effort a little sweeter. Stuck waiting for other parts, I ordered new gauges for the 2A to replace the cobbled-together mess that came with the Jeep originally. There weren’t even axles under the frame at the time, and most of the transmission was still spread out over the workbench. But I installed the gauges as soon as they arrived anyhow. Seeing those gleaming faces against the fresh matte blue paint gave me a nudge to go ahead and finish the wiring. For the first time in months, I could see why I started down this path. I could imagine bopping along a mountain stream, the air slick with the smell of trout, the gauges reflecting the forest above. Just like that, the tub was ready to go onto the new frame. Over the next week, I finished the transmission and wrestled the axles in place. Then I bought some beer, called a couple of buddies, and we married the two halves of the old Willys.

That’s not to say I’m done. I’m slogging through the last of the body work now, filling holes and cutting out rust. The internet’s full of freshly stamped metal, but the budget ran dry back in July, and I’ve come to appreciate the dings this machine wears. This vehicle is nearing 100 years old, and by the time I’m done, it will be ready for another 100. It’s earned the right to wear its scars.

It’s been a grind—and not at all why my wife, Beth, and I brought the 2A home all those months ago. But it is satisfying seeing the Willys sitting in the shop, wearing its fenders and a grille. I can feel that spark of excitement again, same as the day I put Beth in the passenger seat for the first time. We went sailing down a country lane with only the faintest suggestion of brakes, the Go Devil four-cylinder happily churning along ahead of us. The world sang by with a backup track of our laughs and the whine of straight-cut gears.

For some of us, the work is the point, but for me, those moments are why I spend my spare seconds up to my elbows in the bowels of one machine or another. They make the split knuckles and barren checking account worth it. That was hard to remember when I spent my summer sandblasting and welding, sanding and painting, rebuilding and assembling. But seeing that upright grille in place makes it clear again. Of all the joys this world offers, none are equal to those of an old machine.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

A closing comment. I have had my 3WD Deuce for 70 years. Been through four engines and three transmissions. Stock/tube/dropped axles at different times. Custom Jag suspension at both ends. I’ve done probably 20% of the work – paint, replacing wood, fabricating dash, wiring, well you get the idea. As life got in the way, it has sat as many years as it has been on the road. This article really speaks to me. I’m making a Warren list tonight!

How do you eat an Elephant?

One bite at a time!

Thank you for the article

-from a guy with a stalled project. Or three.

Oh, do I need THIS article ! My ’62 Beetle has been sitting dormant for over TWO MONTHS, due to:

A Woodruff Key issue in the generator shaft-pulley — persistent oil leak (VW’s don’t leak, they mark their territory !) — directionals non-functional — dim brake lights — and the effing horn doesn’t work ! All these happened within ONE WEEK, and it’s driven me absolutely nuckin’ futz.

I have just enough confused, mixed auto knowledge to be dangerous — that coupled with REALLY oppressive heat, and being a not too young 77… has me just not inclined, interested or anxious in even trying to fix anything on the car.

(…SIGH…) Guess I’ll just have to push in my human clutch, and GET MY ASS IN GEAR !!

Glenn ;

I’m a long retired VW Mechanic who never learned his lesson so I bought one last Beetle, a raggedy, rusty and bent ’59 .

I’ve gone through all the 6 volt issues, all they take is time, not much $ to fix .

I’m on Reddit at /R Beetle if you have questions .

-Nate

My ‘79 super beetle sat for about a decade while I drove another car, retired and spent another year finding a suitable house in another state. But she’s back in the road after I spent three or four cold months going through it inch by inch.

It really felt good the first time the engine coughed!

Some of the jobs I did on it weren’t ones I wanted to tackle, but I wanted it back on the road. Draining the gas tank multiple times, I eventually didn’t dread the faceful of gas I was pretty sure I was going to get.

I know now that it’s not that I want to do the work as much as I want the work to be done, and I’m usually too cheap to hire it out. Just make some progress every time you work on it, even if it’s just learning or figuring out what should be done next.

First and foremost : It’s nice seeing a young person who “Kens” the original Jeep CJ-2A / MB for what it is .

? Is that a rubber apron ? sweet . I have a canvas one that’s old but still works okay .

I agree that the “Might As Wells” have stalled and killed many a project but following through will make your old battered Jeep drive even better making your enjoyment better .

My method is “Baby Steps” ~ keep at them and before you know it you’ll be reassembling the parts to a rust free (if not perfect) body tub and re igniting the flame that caused you to do a foolish thing like buy a clapped out whatever and take it to bits .

Once the rust is halted and the cracks welded up painting is not that difficult unless you want a super shiny paint job ~ I like your shade of blue .

Sadly you stopped writing about the time I got really interested, I hope you’ll post up a progress report .

-Nate

So nice to see good writing in a car magazine, and effective humor, too. Just one thing: that to-do list might be a valid technique, but it’s not Warren Buffett’s. He never said it.

i have been building land cruisers, mostly from ground up, for 40 years and every build, i hit a wall. sometimes it takes a couple months to get motivated again. sometimes years. on my own projects i have a 2 week dead line. if it takes longer then there is a great chance i will loose interest. it will sit. so far i have not found a cure for the wall, how to prevent it from happening. maybe it is because i reach a point where what i need to do is mundane, no real challenge. the last couple months of the build is usually when it hits. once the custom parts are designed, machined, painted or powder coated and just need installation, the lost interest. i love the initial chatting with the customer designing to his needs. i love the designing of the custom parts. i love the turning over of the keys. it is that one small (huge) step of assembly. i am glad i am not the only one with that issue.