Media | Articles

Climbing Out of the Doldrums: What to Do with a Stalled Project

This article first appeared in Hagerty Drivers Club magazine. Join the club to receive our award-winning magazine and enjoy insider access to automotive events, discounts, roadside assistance, and more.

After more than a year of nursing my ‘48 Willys CJ-2A back from the edge of the scrap pile, I decided it was time to check the valves. Maybe look into finally addressing the worn steering gear. Both exercises require pulling the driver’s fender, which came away with no more than the usual handful of broken bolts. With the sheetmetal gone, I was treated to the first clear view of the little Jeep’s frame. More specifically, I could see the terrifying number of cracks around the front crossmember and the previous owner’s attempts to booger weld the thing back together. Determined to right these wrongs, I removed the bumper, which revealed one frame horn that sat 3 inches higher than the other. A smart man would have bolted everything back together and went on his way, enjoying the bright, warm Jeep months of spring and summer. I am not a smart man.

***

I bought a frame and tub—then two more when the first pair turned out to be more work than I bargained for—and tumbled headlong into my first frame-off rebuild. I say “rebuild” instead of “restoration” because I had neither the funds nor the inclination to wind up with a glossy, better than perfect re-creation of what I had. I wanted a truck that showed its bumps and bruises, that I wouldn’t mind firing at a fire road or the local off-road park. Something that could sit outside during a camping trip thunderstorm without giving me palpitations.

But soon enough, the old While You’re In There demon showed up. I wound up sandblasting and painting the frame, buying new springs, cleaning up the axles, and pulling the cylinder head. I rebuilt the transmission and bought an overdrive. Patched and painted the tub. After a few months, I looked up and found myself far from shore on a vehicle that once brought me nothing but joy. Every time I turned around, it asked for another couple hundred dollars worth of parts, none of which seemed to edge me any closer to bopping around downtown Knoxville or cruising under the hardwood canopy of the Nantahala National Forest.

Work on machines long enough and you’ll find yourself here: The Doldrums. Becalmed by your own decisions and the seemingly endless amount of work left before you can turn the key. The thought of sanding one more panel, turning one more bolt, or welding one more stitch is enough to make you scream. Your eyes wander. Your search history becomes full of other potential projects. Or worse, you grow to hate the thing. What was once a bright spot in your life becomes a pit of loathing. It transforms itself into a shelf in the garage, a convenient place for holiday decorations and your own despair.

Marketplace

Buy and sell classics with confidence

For ancient sailors abandoned by the winds that carried them along, the only solution was to wait for their sails to fill again, but that’s a gambit on a project. The longer you stay away from the wrenches, the larger the tasks facing you loom. The work seems to swell with each day. Soon enough, the project takes on a kind of menace. Days become weeks, weeks turn into years, and eventually your heirs sell your parts for pennies.

So what do you do about it? How do you find motivation when it has no interest in finding you? That’s a question that goes far beyond worn bearings and rusted fenders. So many of us find ourselves bent over a mechanical question because of the simplicity of the thing. There is a black-and-white answer to why a plug won’t fire or an engine won’t turn. In a world increasingly devoid of such luxurious simplicity, solving those riddles can be a balm, but motivation has nothing to do with metal. It’s anchored in the gray matter between your ears.

***

Writers aren’t strangers to this problem. Novelist Anne Lamott, in her excellent Bird by Bird: Some Instructions on Writing and Life, shares her tactics for squaring off against daunting tasks. For her, that’s writing a book, but putting a vehicle together isn’t so different. In it, she shares her father’s advice for a distraught child who put off a report on local birds until the night before it was due: Take it bird by bird. In other words, don’t look at the pile of parts before you as a whole. Break it out into smaller, more manageable tasks. Don’t fret about the body work. Focus on one fender. Cross it off the list and move on.

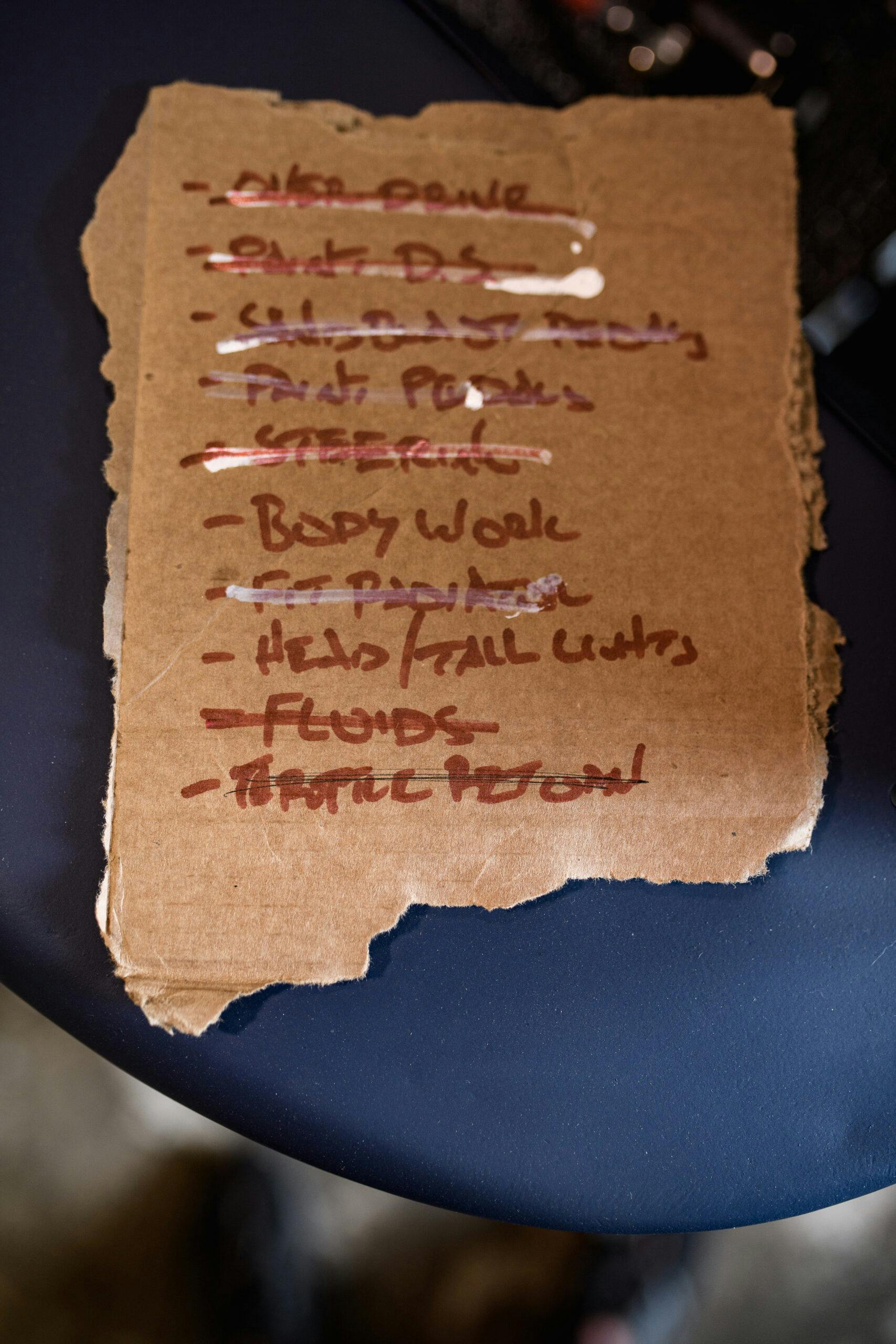

But whatever you do, keep moving. There’s a reason we call it working on cars. It’s work, and work isn’t always a holiday. As I’ve dragged myself through the various stages of grief, I’ve come to rely on the almighty List to help me cover ground. It’s no good trying to keep it all straight in my head. I’m likely to start on a wheel bearing and wind up trying to solve that pesky radiator mount with the front hub still disassembled. I have to write the thing out, usually on a scrap of cardboard. I sketch out 10 manageable tasks and go from there. I’m not alone. Billionaire Warren Buffet famously gets through his day by making two lists. The first contains 25 goals. He reportedly circles five of the most important and scraps the remaining 20. Those five items become his actual to-do list, and he avoids the leftovers like the plague. I’m not sure if that sort of dogged prioritization will get me closer to becoming a billionaire, but it has helped me work on an old Willys.

There are ways to make the effort a little sweeter. Stuck waiting for other parts, I ordered new gauges for the 2A to replace the cobbled-together mess that came with the Jeep originally. There weren’t even axles under the frame at the time, and most of the transmission was still spread out over the workbench. But I installed the gauges as soon as they arrived anyhow. Seeing those gleaming faces against the fresh matte blue paint gave me a nudge to go ahead and finish the wiring. For the first time in months, I could see why I started down this path. I could imagine bopping along a mountain stream, the air slick with the smell of trout, the gauges reflecting the forest above. Just like that, the tub was ready to go onto the new frame. Over the next week, I finished the transmission and wrestled the axles in place. Then I bought some beer, called a couple of buddies, and we married the two halves of the old Willys.

That’s not to say I’m done. I’m slogging through the last of the body work now, filling holes and cutting out rust. The internet’s full of freshly stamped metal, but the budget ran dry back in July, and I’ve come to appreciate the dings this machine wears. This vehicle is nearing 100 years old, and by the time I’m done, it will be ready for another 100. It’s earned the right to wear its scars.

It’s been a grind—and not at all why my wife, Beth, and I brought the 2A home all those months ago. But it is satisfying seeing the Willys sitting in the shop, wearing its fenders and a grille. I can feel that spark of excitement again, same as the day I put Beth in the passenger seat for the first time. We went sailing down a country lane with only the faintest suggestion of brakes, the Go Devil four-cylinder happily churning along ahead of us. The world sang by with a backup track of our laughs and the whine of straight-cut gears.

For some of us, the work is the point, but for me, those moments are why I spend my spare seconds up to my elbows in the bowels of one machine or another. They make the split knuckles and barren checking account worth it. That was hard to remember when I spent my summer sandblasting and welding, sanding and painting, rebuilding and assembling. But seeing that upright grille in place makes it clear again. Of all the joys this world offers, none are equal to those of an old machine.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Wonderful piece! Vehicle-project-doers all over the world can relate to this story (well, probably furniture-builders, quilters, painters, and many other folks too). We’ve nearly all covered something up with “holiday decorations” or some such stuff and tried to forget the painful process of slogging through the minutiae. Camden paints a great word picture of the highs and lows and hopefully highs of a build.

It definitely can be difficult to maintain momentum and even harder to get it back once it goes away.

I agree with the list, whether on paper or in the mind, but I’d emphasize that it is good to have a mix of things from quick and easy to harder more involved projects.

The act of crossing something off the list can be very motivating and of course maintain some momentum. So yeah hopping the gauge project even though it is far from driveable can get it to the driving state that much faster from the momentum and motivation gained by crossing something off the list.

On the other hand you do need to know when you need to take a (short) break either to prevent burn out, or just let things soak.

I’m going to finish up the steering box project on my F-250 today*. It is something I’ve been putting off for a while since it still drove, just wandered around more than it should. But to gain/keep momentum I started out by giving the exterior a long overdue through wash. Then I did an initial pass of cleaning out the interior and did some initial checks on why the auto hubs weren’t working in auto mode the last time I needed 4wd.

*assuming nothing crazy comes up as it should be a fairly straight forward process to bolt the new box back in, fill and bleed the system.

That project also showed that breaks can help. When trying to free the drag link from the steering arm I had whacked the pitman arm as hard as I could several times and finally said, enough is enough. Sprayed some WD-40 not expecting much actual help from it, cracked the mounting bolts loose and took a leisurely lunch. Once lunch was done I crawled back under and gave it 2 or 3 good whacks and was rewarded with the stud dropping down out of the taper. The fact that the mounting bolts were already broke free made it quick to get it the rest of the way out and head to my buddy’s who has the big ass impact and large sockets to swap the pitman arm and borrow his smoke machine so I can check for leaks on the vacuum hubs.

Hopefully all of this gives me the momentum to head out to the wrecking yard and grab the stuff to add remote power door locks.

I have a stalled project. The issue for me is I cannot figure out the overheating issue on a new motor, No oil in the water, No water in the oil. Highly pressurized radiator when it overheats. So I assume somehow combustion gas is getting into cooling system. But when I pressurize the the cooling system there is no leak down. I know the answer, pull the motor and tear it down, but the brain just won’t allow me to put it into that gear, the syncros are broken and that gate is closed. Thanks for the article, I will try take some much needed advice from it.

There are only two options to this: Either the cooling system isn’t circulating, or it is insufficient. If it isn’t circulating, it is most likely the thermostat, but I’m sure you have checked that. So it may be that the engine creates too much heat for the cooling system. You might be able to fix that with a fan, or need a bigger radiator.

get a block tester. it’s the one with the blue chemical solution. it’s simple to use. can’t imagine they’ve gotten over $50.

and doc’s comments got me thinking. so i ask, what brand/model engine? for example, small block chevy water pumps changed rotation, i believe when it went to a serpentine belt (experts, let us know!). so, as a friend years ago dealt with a similar issue, he finally found out about the rotation change. simply correcting the rotation resolved the issue. cooling systems are simple, so don’t do as i do and make it complicated. go over everything w/o engine teardown i.e., correct t-stat position, etc. my best to you and your discovery.

Timing is 100% good? Saw a early 70s Cadillac get its whole cooling system redone with no change in overheating but the timing diaphragm was locked up, ran great after swapping out that cheap part.

I would also take out the thermostat to confirm that the new one isn’t bad.

Not mentioning what engine it is hinders diagnosis .

The venerable Chevy small block V8 is always popular but when you up date an older one to serpentine belt, the water pump changes because it rotates the opposite direction…..

Guess how a whole bunch of us old guys learned this .

-Nate

Loved this piece when I saw it in the magazine. Wonderful writing and photos!

I bought a 65 Impala out of a storage unit knowing that the drivetrain was toast. Plan: stuff another SBC and trans in it and ride. One other issue the car had was about a 6″ hole in the windshield and a corresponding dent in the dash… which evidently came from a tree in my yard where the car apparently previously resided… long story there. Any rate, I remove the windshield and discovered that the entire lower frame area of the windshield was gone… wires in the dash visible gone. While working through that issue, folks on the interwebs told me (logically) if you have that problem, you have no floor pans left. Lifted up the carpet and discovered it was held up by a mesh of duct tape. Throw on some frame damage, no trunk seal gutter left, and two rear quarters, and this project has ended up being a heap more body work than I ever anticipated.

This project has stalled multiple times… but big deal

The one thing I keep going back to is I bought it for a reason. I finished up my last project and didn’t have anything to tinker on anymore. I have 5 other cars, so there is no real dire need to get this one going on any kind of a timeline. It’s not eating anything, and at least for the present nothing is eating it.

The problem with my stalled project is that humidity is rusting and decaying everything faster than I have been fixing it.

My best advice is plan stages of a restoration and keep it road worthy. The joy your vehicle brings to you will keep the fire lit, Plan stages, that will keep it on the road when you want to enjoy it.

One of my vehicles is a 1984 VW Westfalia camper.

First year was sorting the engine, and getting it safe to use.

Winter season I rebuilt the transmission and CV joints,

The following season I installed a 12v fridge and sorted the electrical system.

key thing is to keep it on the road for summer holidays.

Very wise!

Something to keep in mind . . . In this hobby there are builders and there are drivers.

For some of us, the primary motivation is to build something beautiful. We are craftspeople; it’s our art form. For the rest of us, we are primarily motivated by the desire (or need) to drive the thing.

Determine first which you are. Or at least eventually. That is a secret to finding and enjoying the right project.

Just my 2 cents.

The article on doldrums – excellent!

Artist or builder or driver. I’m a bit of all three. I love designing and fabricating pieces. I love being on the road with my car/truck – whether to the parts house of the national park two states away.

Sell it. Find a more enjoyable hobby

Yup. Sell. Buy something you’re prepared for.

(Not addressed to Zach specifically. Just anyone . . .)

Here is my advice. I’ve been collecting cars for over 50 years. I have 25 beautiful vehicles sitting in 2 buildings with concrete floors. When it comes to buying your dream car be smart. Buy with your head and not your emotions. A car has 3 areas. Body, interior and mechanics. If 2 of the 3 areas need extensive work don’t buy the car. You’ll never get done. Besides you’ll have more time and money into the car than it will be worth. Parts are becoming so expensive and harder and harder to find. Know what you are looking at. Be patient. You’ll find the right car at the right price. You’ll spend your time driving it instead of fixing it.

I agree completely with this. Myself – I can fix about anything mechanically but I am not a body and paint man or upholsterer so when looking for a project car I look for one in great shape body and upholstery wise.

But you’re ignoring the folks who get enjoyment out of actually spending time out in the shop, working on the car. Listening to some good music. Solving some problems. Learning some new skills. Celebrating small and large wins. Whatever. Yes, we all want to drive our projects. But for some, building is as much a part of the enjoyment as driving. For those who don’t fit in that group, it’s simple – buy, don’t build.

Agree wholeheartedly. Different stroke for different folks.

Sometimes you can’t win the battle. My Pop bought a 43 Willy’s. It been a hunt club jeep- a real POS.He procured a new tub which didn’t fit. We sent the busted motor out for a block weld job and rebuilt the motor ;transmission as well. it was in the store part of the restoration, he came across a friend that had a similar 43 in running condition. I told him buy that Jeep. it ran good. Had a nice patina and a bunch of non-stock parts over the next few years we replaced most of the nonstock parts under the hood and I had to do some brake work. He had a lot of enjoyment with that jeep over the next 10 years until he passed in 2015 I bundled up all the old parts for the first jeep and sold off the junk. And put together a great bunch of spares, including the rebuilt welded motor the whole kit and caboodle went to my sister. for the first jeep and sold off the junk. And put together a great bunch of spares, including the rebuilt welded motor. The whole kit and caboodle went to my sister in exchange for his 68 Camaro; good trade. bro, the story is get it roadworthy…ASAP

My reason (AKA excuse) for not working on a project is finding more extensive rust issues than I initially knew about and lacking the equipment, skills and space to do something about it. The car is a 1970 Fiat (Fix It Again Tony) 850 racer. There were only 1500 of these made and it really is a nice looking car. I decided, in about 1975, to take it off the road and do something about the rust before it completely ruined the car. There she sits, in pieces. The rust work I did do on the top failed and took the wind out of my sails. So that’s going on 50 years of procrastination. I may win the “coveted” procrastination award for this one.

Sometimes you get into a project because you’re caught up in the fantasy of how cool it will be when you get done. A bunch of things can happen on the way to nirvana: 1. You wake up in the middle of the night and realize it was actually a dumb idea, 2. You find that working on the project is supremely B-O-R-I-N-G, 3. You discover that you need expensive professional help to complete parts of the project, and/or 4. You get it sort of finished and find that it is a vastly inferior to the grocery-getter you drive every day. It’s often better to buy a completed car, make sure it’s “turn-key” (instead of “turkey”), and enjoy! When you tire of it, at least you’ll have something someone else will actually want to take off your hands.

Long term projects can be the worst to maintain enthusiasm so goals along the way will help.

After a substantial electrical fire, my project sat for close to 8 years (a 1962 AC Ace tribute built on an MGB Chassis). I honestly lost track of how long it had been sitting in the corner collecting dust…. new wiring in a box sitting for 7+years along with other parts, interior gutted, dash out of the car….

In 2023, my neighbor (and now friend) drove his car in a local vintage race, driving his 1956 Austin Healy 100M. We had a blast! Once I discovered my car could qualify for one of the classes, that was it!! Plans started forming over beers to get mine back on the road with a target date of the next race – October 2024. THAT was the motivation… a hard deadline! To make sure I didn’t blow it off, I paid my entry fee on the date applications opened up!

Here it is several months later and I am a master cylinder install and brake bleed away from having the car back on the road, which should occur in the next 48 hrs!! Of course, I’m sure there will be the requisite tweaks & fixes after the shakedown, but the motor is running & tuned, new interior installed, new mechanicals, new transmission, new suspension & rebuilt steering, new brakes, and on and on. Oh, and a new American-made wiring harness!

Short story – having a meaningful, hard deadline is what did it for me.

Yes, I’m replying to my own post. After I made my first comment, I thought – What the hell am I doing on the computer? I promptly went out to the garage, installed the m.c., called my neighbor, bled the brakes and DROVE THE CAR FOR THE FIRST TIME IN EIGHT YEARS!!! WOO WOO!!!

Congrats.

Funny how the right sort of ‘thinking about it’ so often gets me up and out into the yard for work marathons =8-) .

-Nate

I enjoyed the article enormously .I have been working on a Glen PRAY CORD FOR MORE YEARS THAN I wish to admit. Still can’t find a top ,which is beyond my fabrication abilities . I am going to rethink the priorities and start with a small task .Perhaps they will set the momentum up

Start small!

Perseverance.

If you don’t have it, don’t take apart cars.

Find a different hobby.

I see ads all the time of people selling dismantled project cars.