Media | Articles

Can You Diagnose this Struggling Pro-Stock Chevy Small-Block?

Whodunits are fun. About a quarter of the top-ranking global podcasts are true-crime-themed. Working to understand every twist and turn to solve the mystery gives people a rush. That’s the feeling gearheads chase when something isn’t working and they want to track down the cause. The engines under our hoods are comprised of myriad parts and systems that, when all operating as designed, create a harmonious symphony of power, heat, and exhaust. When something is wrong, it can be a frustrating experience learning just how much more intricate an engine can be than simple “does it have fuel, air, and spark?”

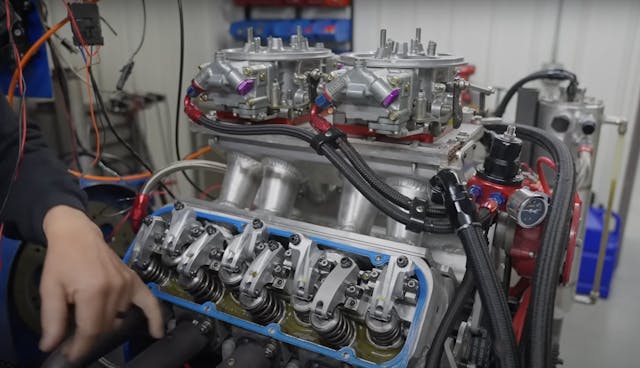

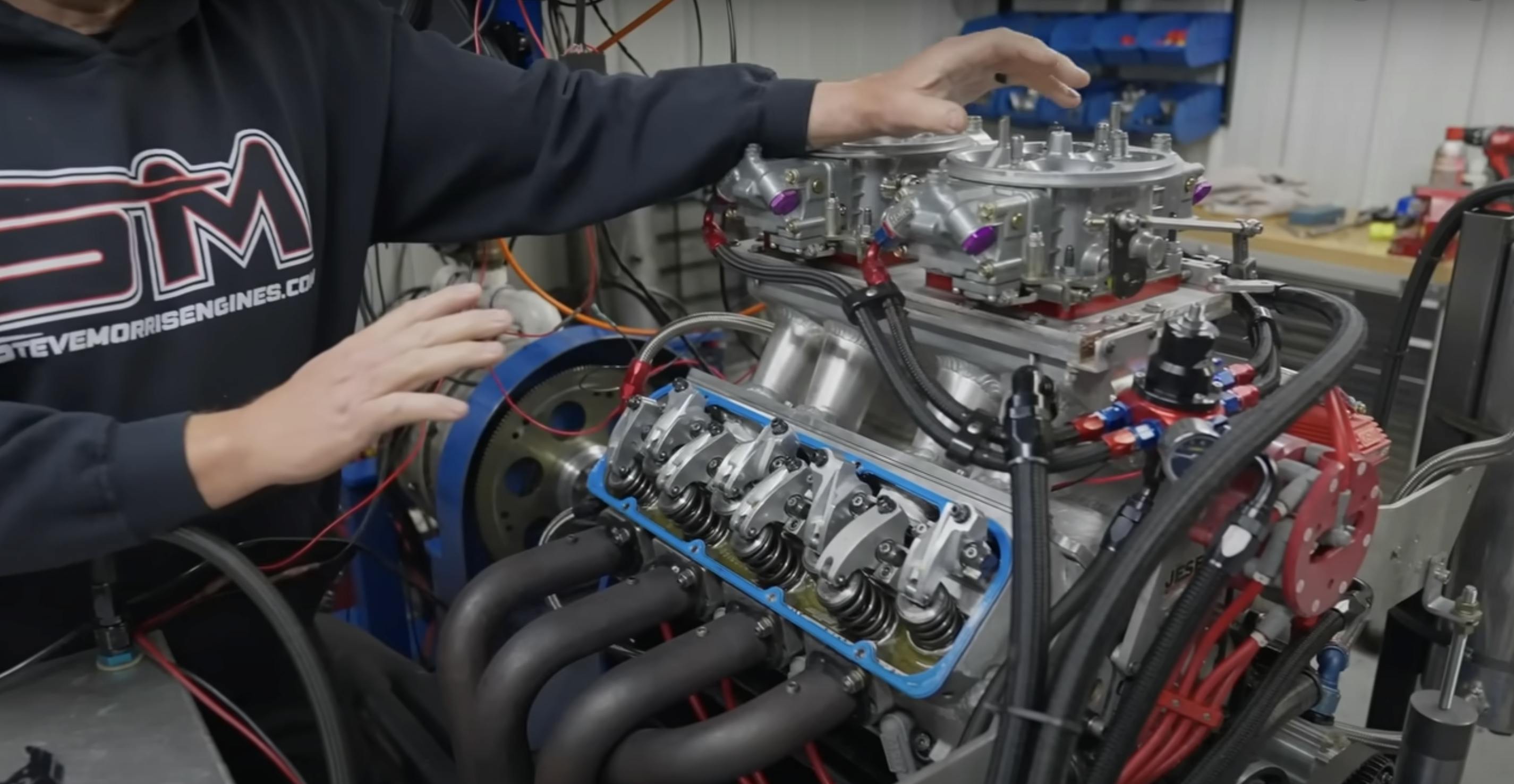

The latest diagnostics tale I’ve been following is that of high-performance engine builder Steve Morris and the small-block Chevrolet V-8 that got bolted up to his dynamometer. The engine is in its second life now; it first served as an NHRA Pro Stock Truck powerplant when the NHRA had such a class nearly 30 years ago. It wears heavily modified Chevrolet casting, which is unique compared with many high-horsepower applications these days that utilize aftermarket and improved castings or, simply, blank-slate billet engine blocks and cylinder heads.

That NHRA class, full of Chevrolet S10- and Ford Ranger-bodied vehicles, is long faded from it’s short-lived popularity. But that didn’t mean this engine was relegated to a shelf or scrap metal pile. Instead, it now lives inside a mini-mod pulling tractor that is designed to move a weighted sled as far and as fast as possible on dirt. It’s a very different use case for the engine, and that created problems. As we learn in Morris’ YouTube video, the first issue was recently solved, but another popped up and it’s a stumper. On the bright side, it’s an interesting reason to learn something.

The initial problem: The engine would destroy the thrust bearing on the crankshaft after only a few runs down the dirt track. Turns out, the amount of clutch usage and pressure plate force over the duration of a tractor pull run is significantly different compared with the rapid-fire hits of shifting down a drag strip. The solution was a roller-style thrust bearing, and to be sure the fix was going to work, Morris hung the engine on the dyno to give it final checks.

After the first loaded pull, the engine exhibited a slightly higher idle than before. After the second pull, the idle reset again to another couple hundred rpm higher. Even after the team dialed in the idle air screws and reset the idle on the carbs, the engine continued to high-idle after a dyno pull. It even coughed a bit of smoke on startup after sitting between pulls. No vacuum leaks could be found.

Marketplace

Buy and sell classics with confidence

Later in the video, Morris seems to have some ideas as to the cause of the high idle, but he doesn’t let on much. Can we at-home players suss out the problem?

My personal theory is that the problem is related to ignition timing. The short clip of a dyno pull at the start of the video shows that this engine is using the front-mounted distributor for arcing the plugs. While it’s extremely unlikely to be running a points plate, there could be some form of mechanical advance inside that is hanging up as the engine slows down after a dyno pull. Or the pick-up and sensor are moving due to vibration thus causing a slight timing change.

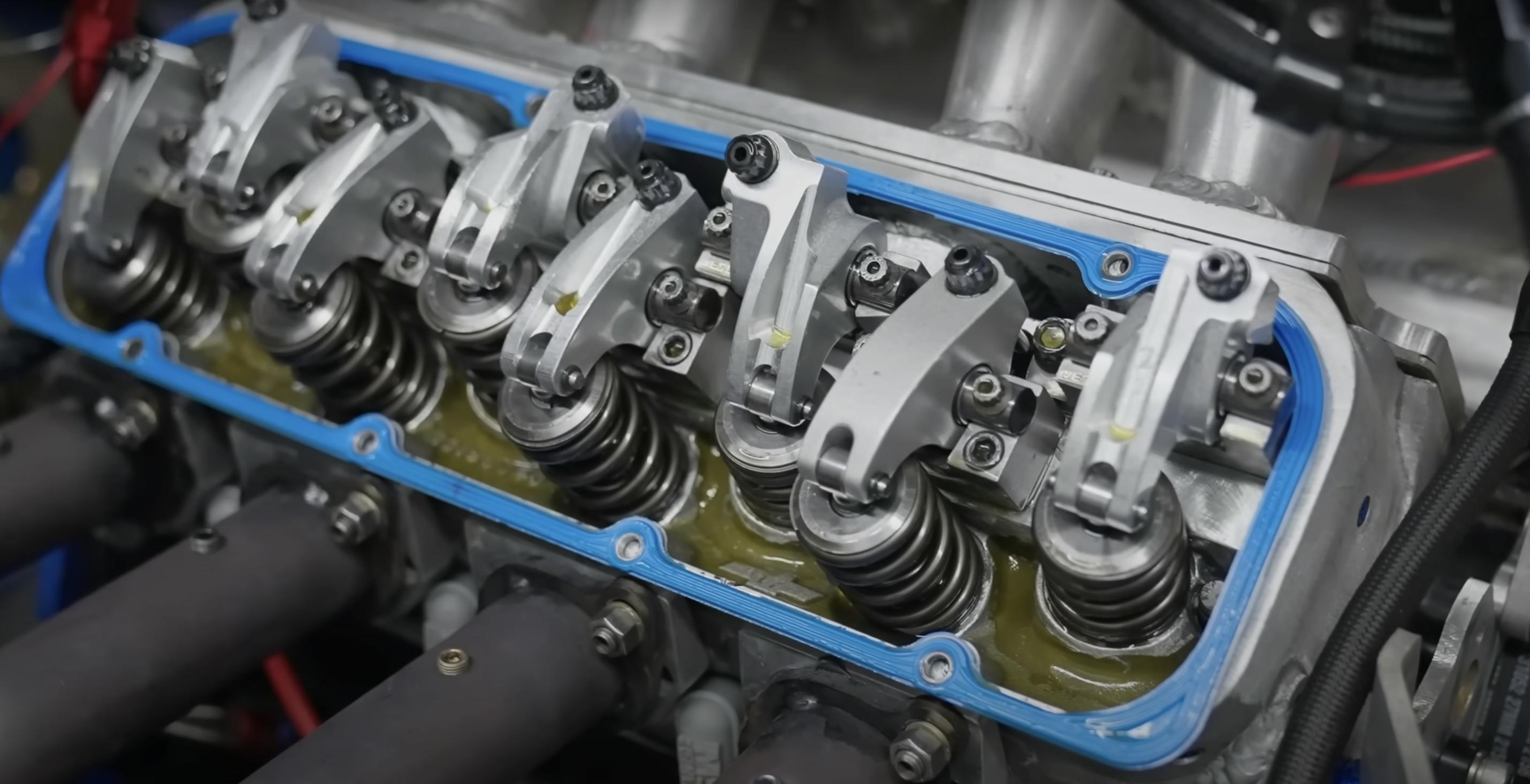

I am also totally aware that my theories could be 100 percent wrong. Is the fact that Morris has the valve cover off in the video a tell or a well-placed red herring?

Morris closes the video with a promise that he will post a video within a couple of days, revealing the answer. These kinds of diagnostic discussions are just plain fun for some gearheads. If you have a solid guess, leave a comment below. I promise not to edit the story when you prove how wrong I am!

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

#1–should-ah left the engine as it was intended–a stock workhorse V-8. Would never have had any problems! And–it would-ah lasted for “centuries”. I laugh when guys groan about how their souped engines misbehave. Mine engine is stock and never fails to start and run–well! Yuh gets what yuh puts into it!

What’s the point of keeping the engine “stock?” That would only keep the power at, say 400HP, while the other competitors are competing with 900+ HP. BTW, there are heck of a lot of cars out there with stock engines and many have some issues with their “stock” engines. Some more serious than others.

Without looking at any other answers:

Most internal combustion engines are a simple system — give them more air and fuel and they run faster. That suggests an air leak. If you could check the air-fuel combustion ration, that may show a mixture change at idle 1 vs. idle 2, 3, or 4. If it is leaning out, there is an air leak.

OR

At idle there is a balance between power available and drag in the entire assembly. Is there a change in oil temperature making a difference? Or a change in piston/ring fit in a cylinder or two?

I would be looking at valve guides and seals first. Possible crack in a head on the intake side. Oil in a cylinder will give a puff of smoke on startup, and will provide fuel to affect idle speed. Worsening crack will be the vacuum leak that requires more fuel from carbs to prevent lean mixture.

small leak around the cylinder head or intake causing a timing problem, reset the timing re adjust carbs check fuel pump, clean filters .

Thinking it has more to do with the flywheel / end of crankshaft mating area due to the enormous load from this application, resulting in ignition timing fluctuations.

Cracked intake port or crack in head near intake port, or possibly valve seals and worn valve guides.

The second roller rocker in is different than the others, does that mean the spring is different also?

The odd ball rocker arm, might be expanding enough to hold the valve open just enough to keep it open to create a vacuum leak

Inadequate crankcase ventilation.

based on personal experience, it’s extremely likely an artesian moved into this engine 30 years ago. now, with the engine being resurrected, the artesian has been woken up and is not happy. he’s now making havoc as is an artesian’s nature. my best to steve in getting him evicted

Assuming solid lifters and roller rockers you have improperly adjusted valves do to the increased heat.

or, could be a expansion contraction issue and not properly gasketed between the intake and heads (air leak).

or, fuel pump issue. we were not told what temperature was achieved after each push and is it running much hotter each run.

Possible ignition timing issue, although he said he checked it but was it re-checked after the 1st and 2nd run.

Loose throttle plate? . . . . .

Weak valve springs due sustained “overloading” of engine. The intakes are closing soon enough so on the compression stroke a small amount of air is escaping acting as a vacuum leak therefore increasing the idle. Same scenario on the exhaust valves. Their not closing soon enough is allowing a small amount of fuel to escape out the exhaust. I’m guessing the smoke was white. Either I’m right or I’m blowing smoke out my…

Probably has a cracked block from the crank banging against it. Air intruding from the crankcase breather. Would have liked to see the carbs covered to see what that did to the idle. Venturi plates closed means big air from somewhere.

Maybe a stretched timing chain ?

Looking at the picture this engine uses a belt drive camshaft and doesn’t have a normal distributor, housing contains only a rotor to distribute spark. Ignition is all electronic, probably a crank trigger.