Media | Articles

Are failed electronics no longer a vehicle’s death sentence?

We previously discussed the concept of modern cars aging as gracefully as older vehicles, with a light patina on the metal body and trim. But the comments from the Hagerty community, about the increasingly complex electronic systems in modern cars, inspired this article. Knowing that new electronics eventually become out of the question, and used parts can be a risky endeavor, reaction from commenters was swift and conclusive:

@Paul: You can refinish peeling paint. There’s nothing you can do when the computers start failing and all the wrecking yard parts dry up.

@Steve: Failed electronics will kill cars more quickly and often than patina or decomposing trim. It’s happened to me on a couple of ’90s vehicles. On the other hand, my ’60s cars are very likely to continue looking great and operating properly well into the future. Simple is good.

@smtguy: Completely agree with you, Steve. Automotive electronics are slapped together as inexpensively as possible. They then have to endure the harsh environment of a car with temperature swings that can be in excess of 100 degrees, to say nothing about vibration, and obsolescence.

@GP: Every car I have owned from the late ’90s on has had its computer either outright die or malfunction to the point the car was unusable. Used replacement computers are no help because all too often they are coded to the original VIN, and no one is going to pay $2000 and up to buy a new computer for a Pontiac Aztek or Ford Flex that already looks like trash.

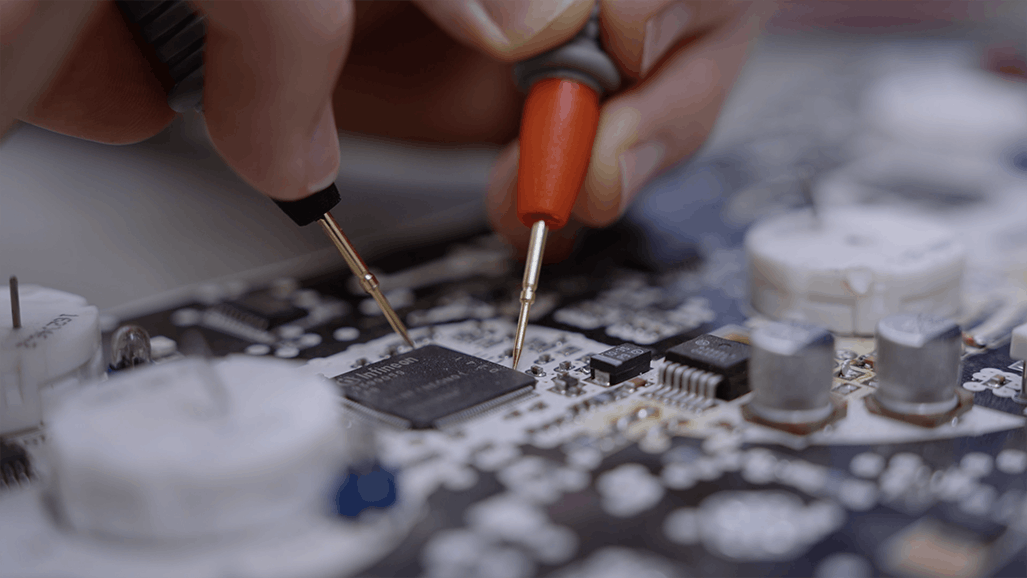

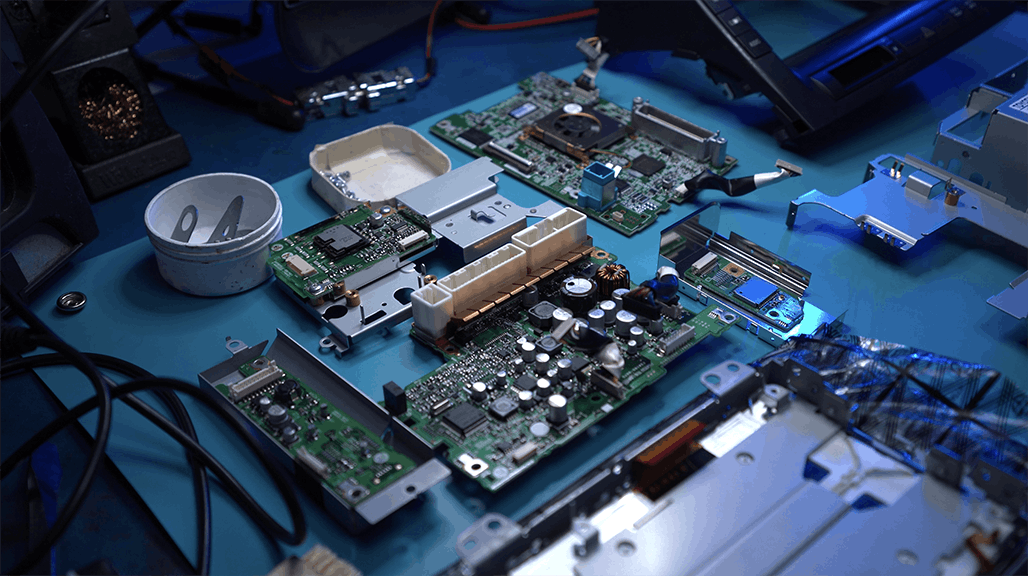

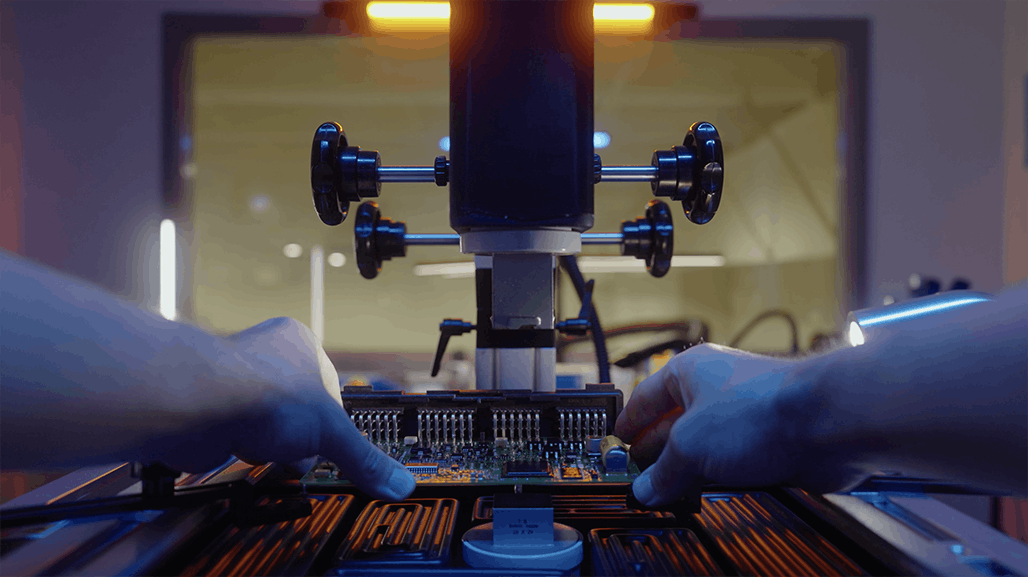

All valid points, but what’s being overlooked here is the fact that electronics can be rebuilt, be it with new internals, repaired circuits, or both. Rebuilding addresses the design flaws over time, often using OEM-grade (or better, in my experience) components for the circuit boards, and offering a warranty on the work.

Now that we know many of these items are not black boxes with mysterious components, the next issue to resolve is to find the person or company who can rebuild the component you need. Sometimes there’s a vendor on your favorite forum that has a good reputation with owners of your vehicle. (The same applies to Facebook Groups for your cars, and vendors on eBay.) Often doing a Google Near Me search gets you the service provider of your dreams, especially when you widen your search parameters to businesses outside of driving range.

History is littered with cases of consolidation of industries, and I’ve always wondered if someone was going to do the same for the automotive electronics space. Someone needs to scale up in order to carry the array of parts and also feature a deep roster of technicians to meet the demands of the ever-increasing needs of depreciated automobiles.

@JW: I think the biggest issue we will see in present cars as they age is the breakdown of their snazzy screens and infotainment systems. Their complexity almost guarantees they won’t be functional in 30–40 years. And it won’t be a matter of just replacing or rebuilding your broken speedo or tach.

Maybe there will be companies that can rebuild them, but will the proper chips and other electronics be available?

Not maybe, definitely. Even the buggy Cadillac CUE system can be repaired for under $300 with free round-trip shipping and a one- or two-day turnaround. Just remove the screen (or pay a mechanic), ship it to an electronics repair vendor, and you’ll be back in business in about a week.

That’s where a company called UpFix comes into play. The folks there have been repairing and reprogramming computer modules since 2006. In those early days, they focused on resetting airbag modules that freeze up after a collision, and their customer base of collision centers proved the business model had merit. But UpFix’s management noticed more and more electrical gremlins in the automotive landscape, so the model adapted to the market’s need, encompassing solutions to more diverse problems: What started out as resetting software on airbag modules became actual hardware repairs.

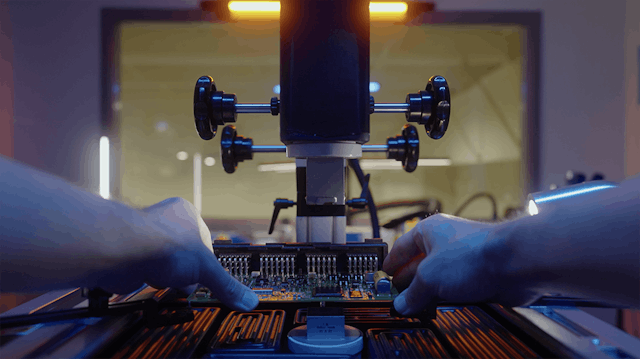

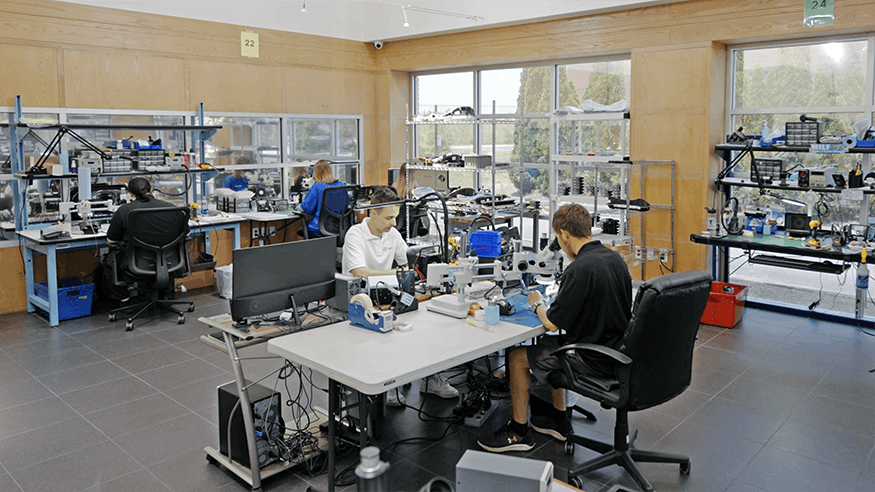

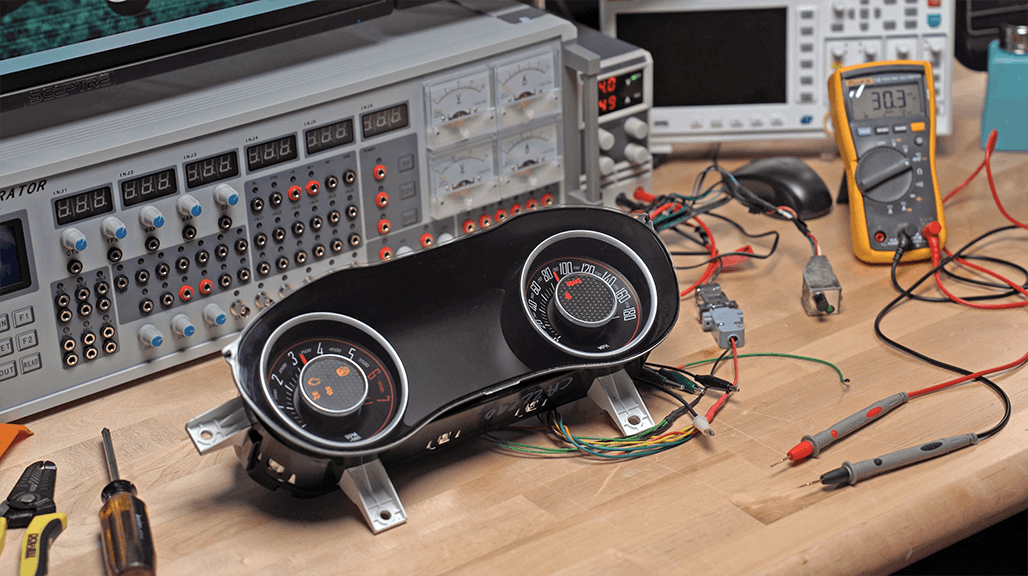

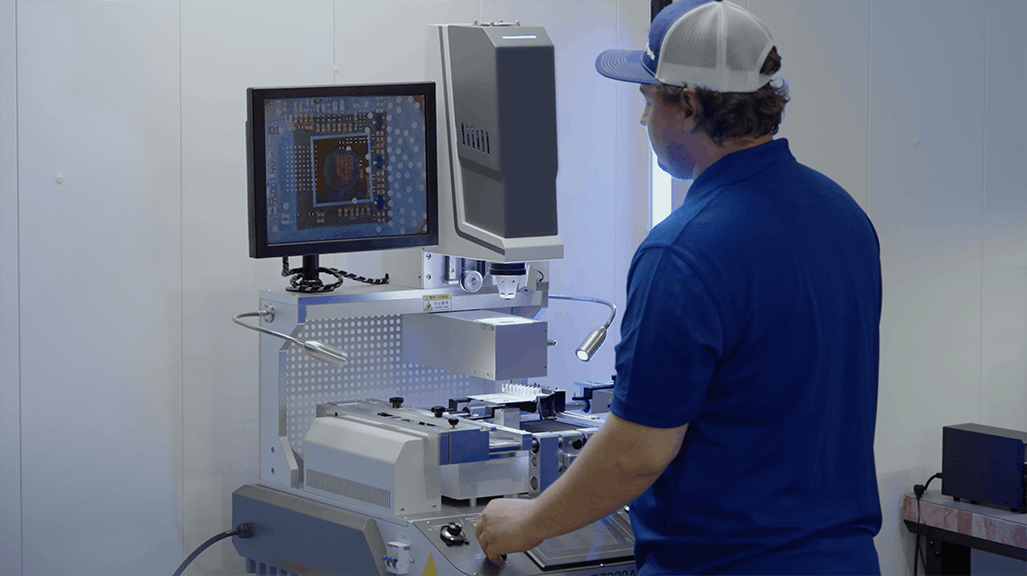

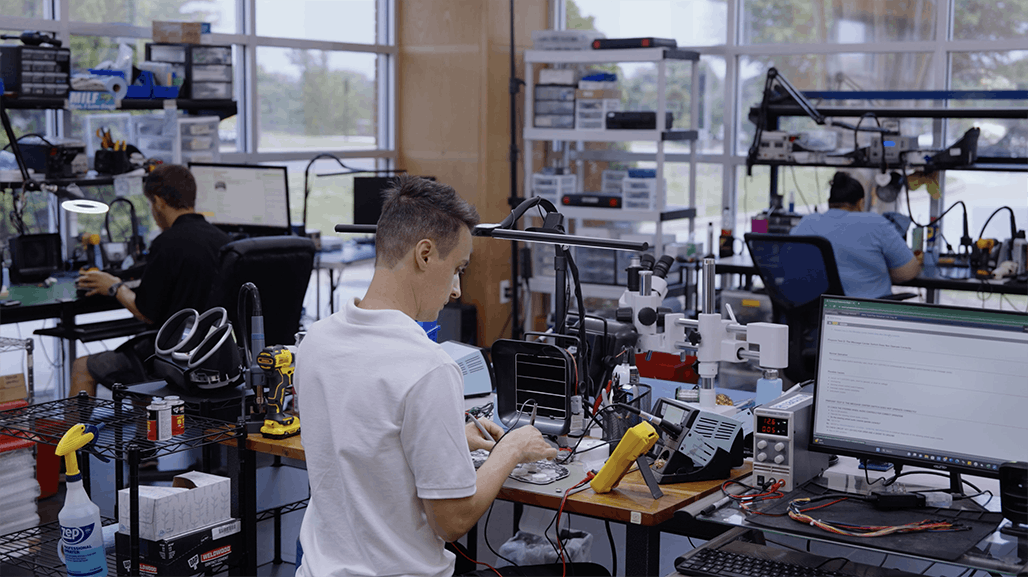

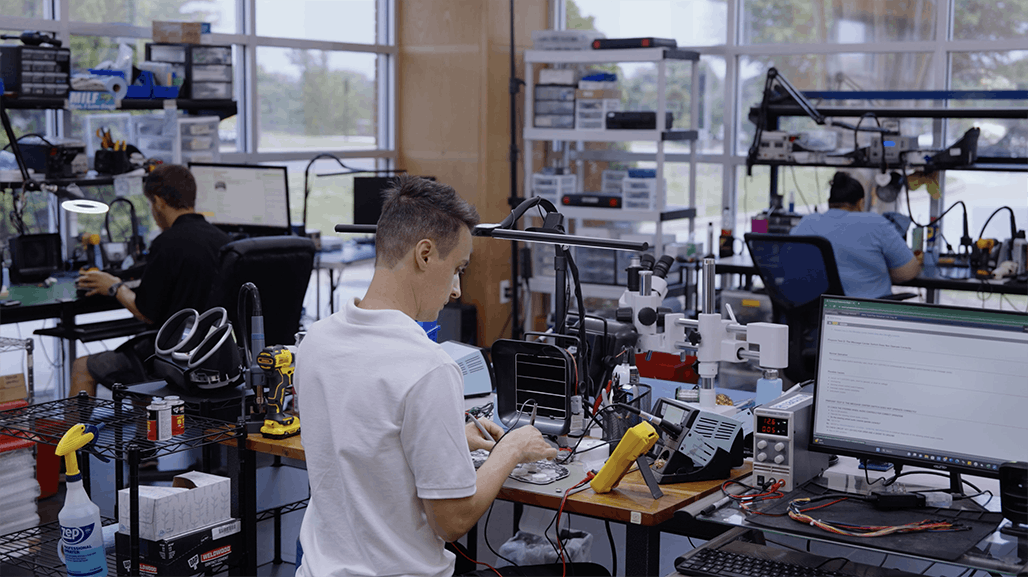

I spoke with Ernest Martynyuk, UpFix’s auto electronics division leader, about his company’s unique value proposition. If you’re like me, you’ve had components rebuilt by local Mom & Pop shops in the past, and they operate in less-than-ideal workspaces with limited staff and salty customer service. They get the job done, but some are merely a necessary evil to keep your car on the road. Martynyuk thinks his company does things differently, and UpFix’s facility suggests he’s operating with the professionalism of an OEM parts provider.

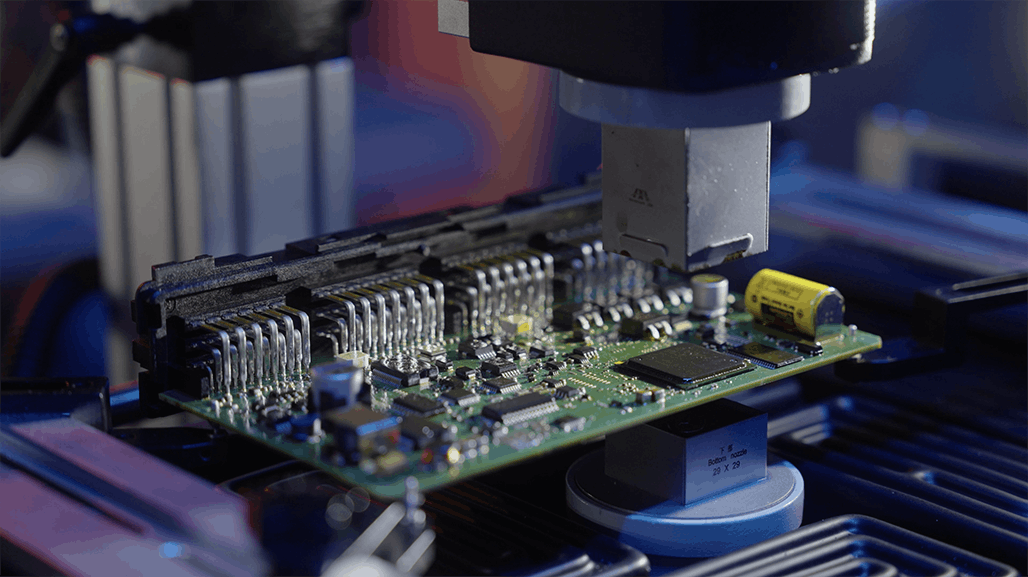

UpFix puts more more time into testing parts, Martynyuk says, than its smaller-scale competition. Further, it has an enviable stash of individual repair components, can reprogram a variety of applications, and possesses more specialty tools. But humans fix electronics, and UpFix also has more staff than a typical Mom & Pop. Even better, someone on the team frequently updates the website to ensure would-be customers understand what items they can fix, without needing to call or send an awkward email. (Many smaller operations still use websites that are more at home on a GeoCities domain.)

The more you poke around UpFix’s website, the more you realize they might be likely/willing to repair old parts from the 1990s OBD-II era, and even from older OBD-I vehicles. Martynyuk encourages this, as Upfix is willing and has a track record of repairing older modules from modern classics. Like other shops, they’ve repaired the usual pixelated problems from BMW displays of the 1990s, but have also mastered the more obscure. Consider the dashboard power supply of the Z31-generation Nissan 300ZX, and the failing gauge clusters of the oft-overlooked Suzuki XL-7. If you don’t find your vehicle in the website’s pull-down menus, Martynyuk encourages you to submit a repair request form.

It’s clear from our conversation that Martynyuk has a genuine curiosity and willingness to help owners of modern classics, and he’s in a position to ensure UpFix can work on oddball stuff for the likes of the Hagerty community. Although some of his smaller-scale competitors can say the same, they often focus on a single vehicle or a particular marque.

A company like UpFix is precisely what we classic car enthusiasts need, because it is indeed getting harder and harder to find someone to work on these old circuit boards, much less do it in a facility this impressive. The days of a majority of vehicles being made by three Detroit automakers are long gone; our reality is one of disparate global automakers using unique parts in a unique fashion. Even worse, all that technology was deemed antiquated by their parent companies decades ago.

UpFix is still growing into its large facility, hiring more technicians, stocking more components, and adding more workstations. Perhaps with this extra capacity comes an added willingness to repair a more diverse grouping of electronic modules. Martynyuk seems willing to take a shot at anything, so perhaps we have an alternative to overpriced service departments at new car dealerships. And maybe we finally have a safer bet than a junkyard or eBay listing for a used electronic component of questionable condition. That alone might be cause for celebration.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

When my 2011 Mini Cooper R56 died, the OBDII said the fuel wasn’t getting to the engine. I replaced the fuel pump and still no start. Replaced the fuel filter..still no start. Now the web says the fuel pump relay is likely the problem. It is built into the fuse box in the footwell. I must now remove the fuse box and send it off to be repaired. What ever happened to “plug and play” relays? Fortunately, I found some guy’s online who do this work for $180. The new fuse box is $400+. These guy’s are so appreciated, versus the manufacturers who make things so difficult. Built in obsolescence!!

I am amazed by the cottage repair industry that support E39 5 series BMW electronics – repairing dash pixel displays and ABS modules cooked by the exhaust.

Also very happy to discover an LCD polarizer rebuild kit for my 94 Corvette Speedo. Now I just need a 3D scanner and printer to reverse engineer and manufacture all the ABS plastic bits that are turning to dust…

Nice to add this info to my Vendors tab. I did have the ECM on my 2004 SRT10 go bad. It was the driver for the #1 ignition coil. Thought the end of the world was coming but I found a place in Illinois (prob a mom and pop) who were able to diagnose and fix the ECM for under 150.00 including shipping.

I have a 2006 Gmc serria 2500 the tmc has been a problem for some time. The parts houses dont carry replacment parts, do you know of any company that can rebuild tcm for six speed tow models thank you for any help you can offer

Ross

Sorry Sajeev, I don’t buy the rosy outlook. As someone with 30 years career experience in electronics, processors, ASICs and SoCs, scrounging parts and board repairs are hit and miss. My own experience with these firms was disastrous.

We could categorically solve the problem, simply by mandating that vehicle manufacturers must release their source code and interface specifications, only whenver they CHOOSE to end parts support for a vehicle. Simple cause and effect. This would enable 3rd parties to build replacement electronics using state of the art processors, memory, etc. versus the original obsolete components. However don’t hold your breath waiting, because this federal administration could not think of a better way to remove older ICE vehicles from the highways than by rendering them useless via failed electronics.

You bring up a great point, this will always be a hit or miss. The open sourcing of code is actually a great idea, it’s so good I assume it will never come to fruition. That said, the intent of this article wasn’t necessarily to say everything will be perfect going forward, it was more to suggest that there is an avenue for restoration that many have not considered.

The Suzuki XL-7 is my favorite example, as the chances are much better if you share knowledge/components with a big company like GM. Not a catch all for everyone, but hope for many more modern classic enthusiasts.

This is a good article. It’s too bad from the late 80’s forward the cars will be trash In the next few years. With our throw away culture and salvage yards drying up. Plus the aftermarket parts are getting junkier. The big powers want all the old reliable cars off the road. Look at what ethanol fuel has done to so many carbs and fuel systems. Soy based wire insulation is breakfast, lunch, and supper for rodents. No shop will touch an 82 anything “no money to be made” then add salt damage. Then abs components. The List goes on. I always like how some people think a 1996 impala will be worth more in another 20 years. ALL these cars are bad investments! Once all the boomers are gone and the children want to sell, sell, sell. You’ll fetch them for Pennies.

I’ve been there and done that, in September the ABS module in our 2003 Buick LeSabre threw a 1214 code, as they often do and the module is NLA. Fortunately a company called Module Master in Idaho specializes in rebuilding all sorts of modules and clusters, and I had my ABS brain out of the car in 30 minutes, and the failed solder joints reflowed for $150 plus shipping and a week later I had working ABS and traction control again.

In the long term at least some modules may be replaceable with FPGA chips and interface boards but anything that relies on a factory system could be at risk like Saab key fob programming that required authorization by a computer in Trollhattan which went offline after the bankruptcy.

Between the doom & gloomers and the eternal optimists, the truth usually lies somewhere in between, right? Older electronics will likely be available in the future for the most part for most cars that use them. Cost and availability of specific types of ECUs and the like may well vary depending on make, model, model year, etc, but I’m pretty sure we’ll be able, for the most part, to repair or replace these components on some level going forward. In any case, as the owner of a ’95 Porsche 911 and a ’00 Ferrari 550, I’m not losing any sleep over it.

While I do agree that these electronics repair vendors will be able to continue breathing new life into failed modules, I do not believe that it will have a significant effect on the longevity of those vehicles when looking at the ‘classic car’ lifespan as opposed to a normal service life.

You must consider that a majority of the repairs they do are not difficult, nor are they returning the module to “like new” condition when repaired – I have significant experience with this. They are simply getting it functional again. Solder joint failure is common due to the nightmare known as “lead free solder”. Power transistor failure is common due to high current+high temperature+some external failure which caused a damaging/catastrophic event. Etc. When a part has failed, and is available, they replace that part – They do not “rebuild” the entire module. Even if they wanted to, there is a major roadblock for such an endeavor – Parts availability.

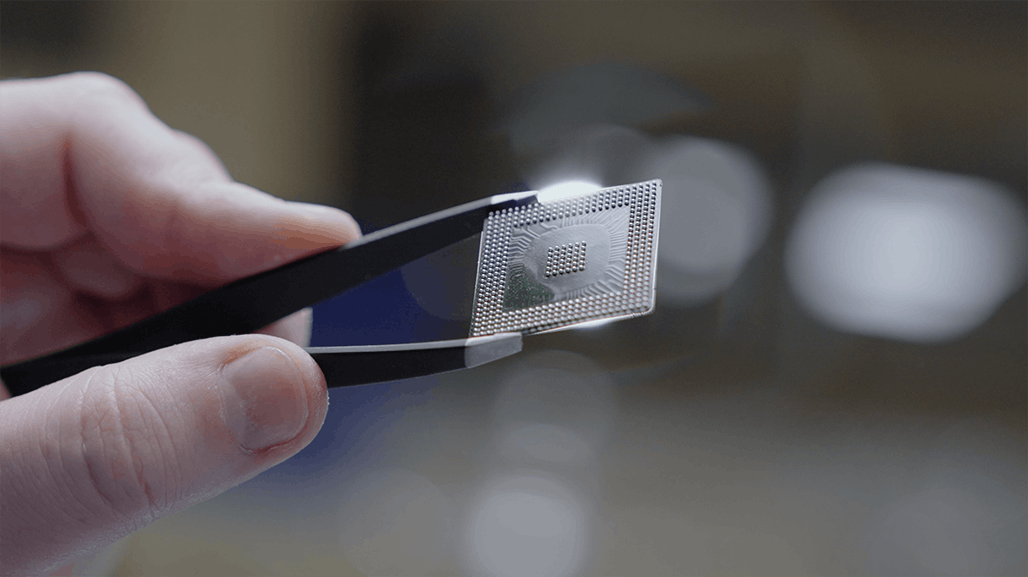

Parts availability isn’t just about “is that part still made, or can I find it NOS somewhere in china” – It is much worse than that. Automotive electronics from the 80’s and 90’s used a decent amount of electrical components which could be considered “off the shelf”, some of which are still made today. Custom electronics (bare silicon dies mounted on heat sinking substrates, custom chips known as ASICs for “Application-Specific IC”, etc) were limited to certain modules where no off the shelf solution fit into the available space, or fit into the cost constraints for the project.

Moving into the 2000’s, we started to see ever-increasing ASIC and other custom electronics content. There was a massive push to fit more and more functionality into the same size computer/HVAC control box/etc and an ever-increasing electronic feature set of the car. By the late 2000’s, a majority of modules in the car used at least one custom component, some chip that was made for and sold to only the automotive OEM, never to be seen for sale to the general public (or any other company) ever.

The greatly increased electronic complexity, and custom parts content of the late 2000’s now intersects with the early 2010’s, when we not only started using a large percentage of custom parts in every module (industry became VERY cost sensitive after the late 2000’s crash), but we also started using copper bond wires in chips instead of gold ones (due to cost). Up to this point, we still had gold-bonded chips, transistors, you name it, which were still functioning mostly within specification 3+ decades later. Failure rates obviously skyrocket as these gold bonded chips get to that age, but there are still enough from lightly used equipment which still function to find used parts you can harvest off of old boards to service old equipment.

Copper bond wires, lead free solder used in the lead frames, and other cost cutting measures, from a perspective of decades IMO reduce the lifespan of all of these components to near zero. The number varies with chip maker but typically they were designed with a 7-10 year projected lifespan, and by the 2010’s we had become very good at actually predicting the lifespan of these components (The decades-long lifespan of older components was simple coincidence – Not intended – Unless we are talking about military-specific chips which we know little about except the fact that they still use gold bond wires, and still use leaded solder).

The roads are now full of 2010’s and 2020’s vehicles with modules full of custom chips which will never be sold, many of which are already starting to go out of production, and due to the absolute complexity of the automotive systems of the 2000’s and beyond (encryption; immobilizer security ring between modules; etc) this is not a situation where someone can just say “Well, I’ll have to take some modern electronics and design a circuit board that does the same thing” – This endeavor would be hundreds to thousands of hours of work by a skilled automotive engineering team.

My prediction: Nearly every vehicle made after the 2000’s will disappear off the road, and the 2010’s vehicles will actually disappear before quite a few 2000’s models. We are already seeing it – Inexplicable module failures caused by failed memory cells in FLASH with reprogramming a costly option even if you can get a replacement module; Custom multi-output driver chip failure (the ones that drive the injectors, coils, other high current devices) failure with no replacement available ever, and no space inside the computer to “dead bug” an old-world discrete transistor solution into the housing even if you were able to reverse engineer the digital communication bus which controls the chip, etc. I have been repairing modules for more than a decade now, and when I run into one that I simply can not solve for reasons mentioned above, I have reached out to one of the well known module repair houses for assistance. In every case, they have informed me that the module was not repairable, and that replacement with a reprogrammed junkyard unit was the only option. We all know what happens when there are no junkyard parts available and no possibility to repair the affected part.

Lastly, I will just mention a few other things which limit the repair of newer vehicles:

Screens – Someone above mentioned repair of clusters and other modules with LCD displays. LCD displays decay over time – You have probably seen it on an older calculator or computer monitor. No one will be making a custom replacement LCD display. This is even more problematic if you look at the 2000’s vehicles and beyond as they use custom LCD panels, most with digital communication which is also customized, and even if you were able to find a bare LCD panel which fits the space, the communication interface would not be compatible.

Wiring harnesses – Sure, we’ve seen this on the 90’s and previous cars, but their harnesses were simple and building a new wiring harness from scratch usually wasn’t *that* much of a hassle. Fast forward to the 2000’s when we have massively complicated harnesses with insulation literally flaking off of the wires in the engine bay where they have been cooked for decades; Even just figuring out which wire has cracked insulation and corroded inside is becoming a nightmare because you end up finding that it’s not one wire, it’s a dozen wires, and the massively complicated wiring harness is no longer sold.

Lighting – Filament bulbs are all but gone. They were half gone in the 2000’s when we moved to projector style HID lights. HID lights use inverter modules which usually are not rebuildable either due to decades of cooking themselves or a high voltage failure causing unrepairable damage. Now fast forward to LED lighting – Nearly all of which in automotive use 100% custom parts, including the LED’s, and secure digital communication (security to prevent theft). You can’t just swap a headlight from a junkyard car anymore – It would need to be reprogrammed, if the OEM will even allow it. No worries, though, the amount of heat generated in the LED lighting assemblies, combined with copper bond wires, lead free solder, and mostly plastic always renders them unrepairable after 7 years or so. Best go buy a new one while they are still available, at a cost of thousands of dollars (instead of tens of dollars for the old filament housings and bulb). I am already seeing a significant quantity of LED headlight/tail light failures, they flock in after the first cold weather, or first hot weather – Both temperature extremes bring out the failures.

This is my “rant” about the serviceability of newer cars. I am driving pre-2006 cars almost exclusively as the models which I’ve selected I know can be kept running at least for another 10 years or so. I do have one “nearly new” car, and at 3 years old it has already experienced its first module failure, and ironically, it’s first headlight failure – The LED driver in the headlight overheated and failed before the thing was 4 years old.

I foresee a very dark future for the repairability of newer cars. Best buy the older ones while you can unless you want to be driving one of these toxic, volatile, environment-destroying bombs (with the most cost-reduced and complex electronics to date!) known as “electric vehicles”.