Media | Articles

Are failed electronics no longer a vehicle’s death sentence?

We previously discussed the concept of modern cars aging as gracefully as older vehicles, with a light patina on the metal body and trim. But the comments from the Hagerty community, about the increasingly complex electronic systems in modern cars, inspired this article. Knowing that new electronics eventually become out of the question, and used parts can be a risky endeavor, reaction from commenters was swift and conclusive:

@Paul: You can refinish peeling paint. There’s nothing you can do when the computers start failing and all the wrecking yard parts dry up.

@Steve: Failed electronics will kill cars more quickly and often than patina or decomposing trim. It’s happened to me on a couple of ’90s vehicles. On the other hand, my ’60s cars are very likely to continue looking great and operating properly well into the future. Simple is good.

@smtguy: Completely agree with you, Steve. Automotive electronics are slapped together as inexpensively as possible. They then have to endure the harsh environment of a car with temperature swings that can be in excess of 100 degrees, to say nothing about vibration, and obsolescence.

@GP: Every car I have owned from the late ’90s on has had its computer either outright die or malfunction to the point the car was unusable. Used replacement computers are no help because all too often they are coded to the original VIN, and no one is going to pay $2000 and up to buy a new computer for a Pontiac Aztek or Ford Flex that already looks like trash.

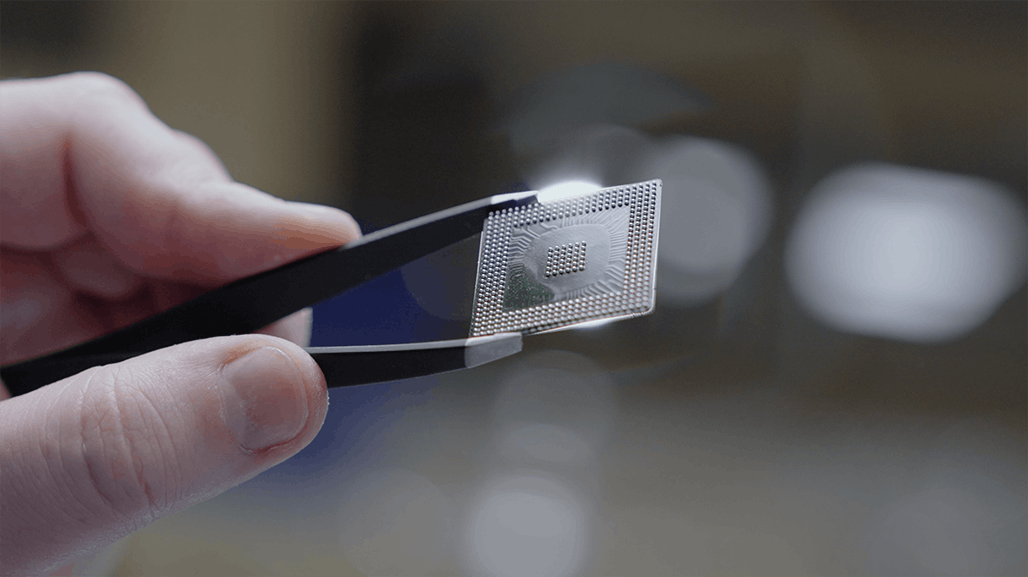

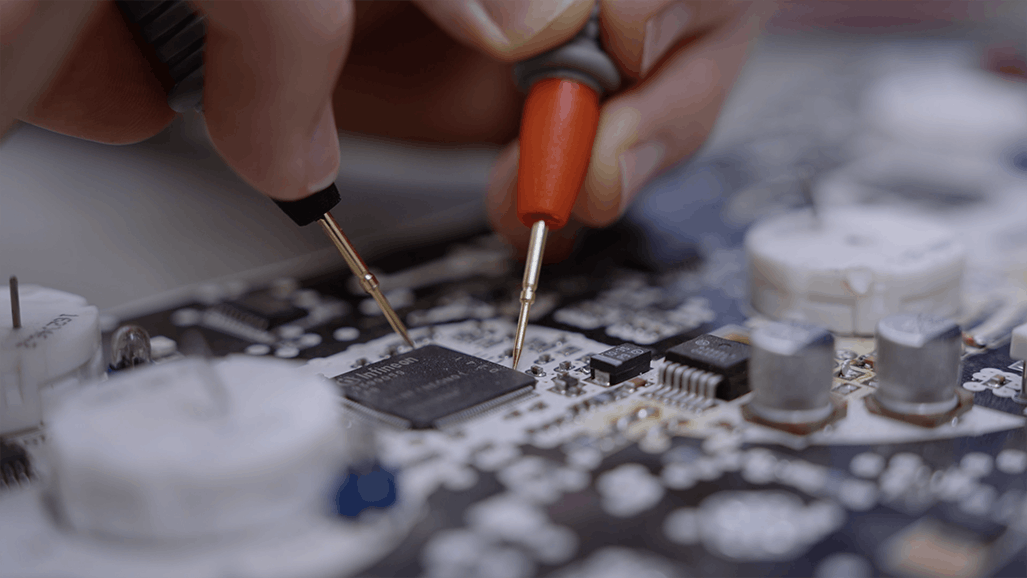

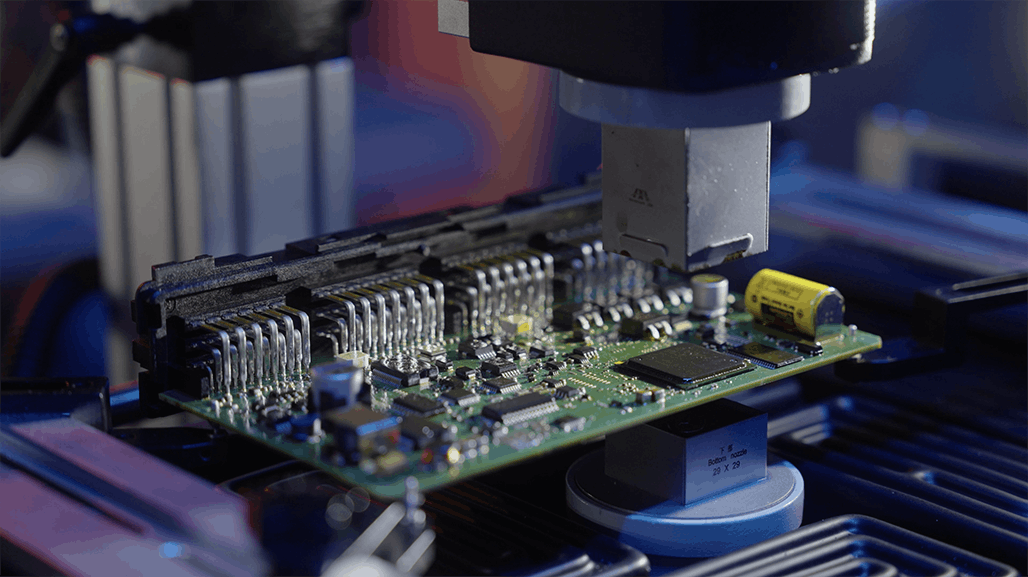

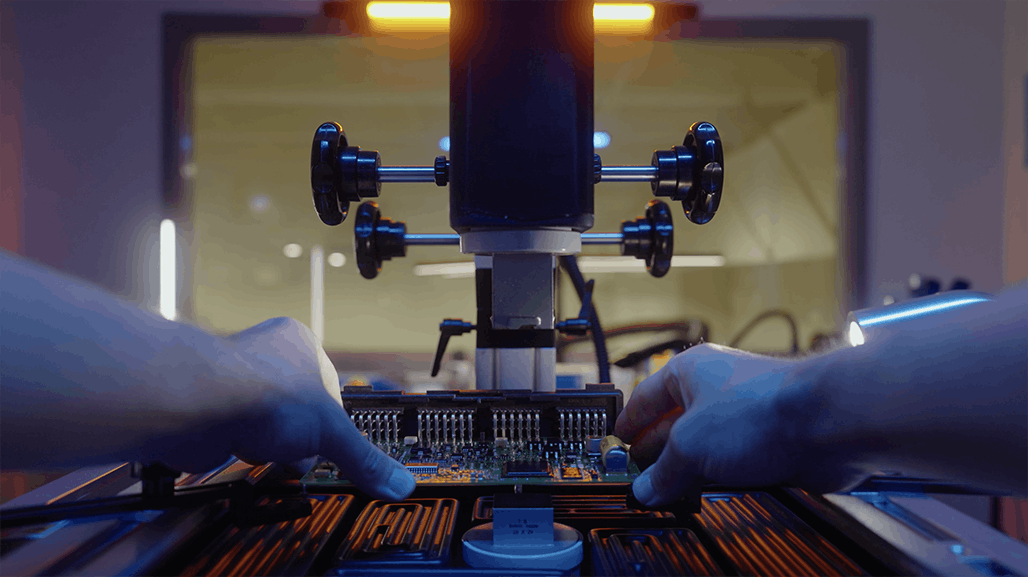

All valid points, but what’s being overlooked here is the fact that electronics can be rebuilt, be it with new internals, repaired circuits, or both. Rebuilding addresses the design flaws over time, often using OEM-grade (or better, in my experience) components for the circuit boards, and offering a warranty on the work.

Now that we know many of these items are not black boxes with mysterious components, the next issue to resolve is to find the person or company who can rebuild the component you need. Sometimes there’s a vendor on your favorite forum that has a good reputation with owners of your vehicle. (The same applies to Facebook Groups for your cars, and vendors on eBay.) Often doing a Google Near Me search gets you the service provider of your dreams, especially when you widen your search parameters to businesses outside of driving range.

History is littered with cases of consolidation of industries, and I’ve always wondered if someone was going to do the same for the automotive electronics space. Someone needs to scale up in order to carry the array of parts and also feature a deep roster of technicians to meet the demands of the ever-increasing needs of depreciated automobiles.

@JW: I think the biggest issue we will see in present cars as they age is the breakdown of their snazzy screens and infotainment systems. Their complexity almost guarantees they won’t be functional in 30–40 years. And it won’t be a matter of just replacing or rebuilding your broken speedo or tach.

Maybe there will be companies that can rebuild them, but will the proper chips and other electronics be available?

Not maybe, definitely. Even the buggy Cadillac CUE system can be repaired for under $300 with free round-trip shipping and a one- or two-day turnaround. Just remove the screen (or pay a mechanic), ship it to an electronics repair vendor, and you’ll be back in business in about a week.

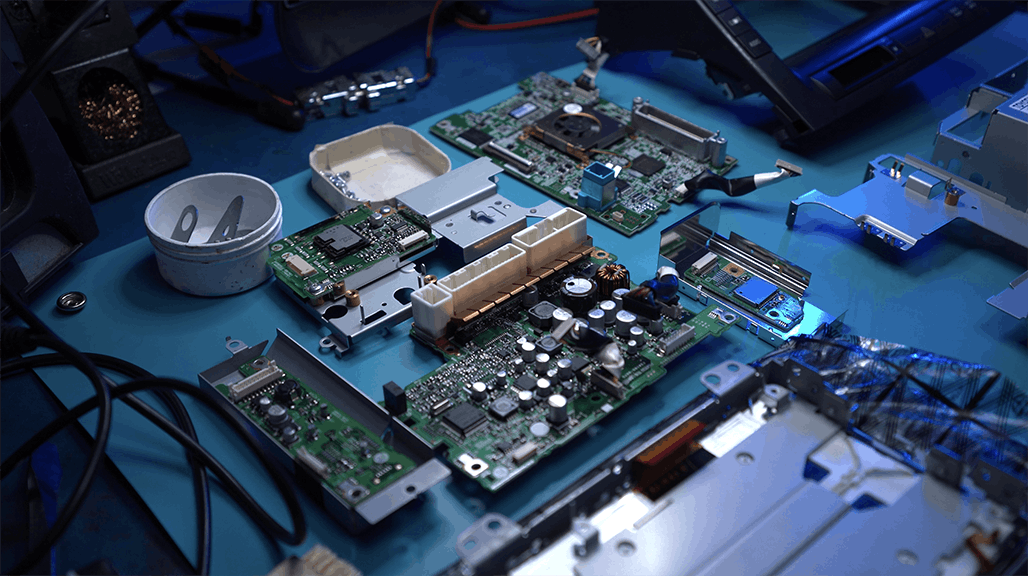

That’s where a company called UpFix comes into play. The folks there have been repairing and reprogramming computer modules since 2006. In those early days, they focused on resetting airbag modules that freeze up after a collision, and their customer base of collision centers proved the business model had merit. But UpFix’s management noticed more and more electrical gremlins in the automotive landscape, so the model adapted to the market’s need, encompassing solutions to more diverse problems: What started out as resetting software on airbag modules became actual hardware repairs.

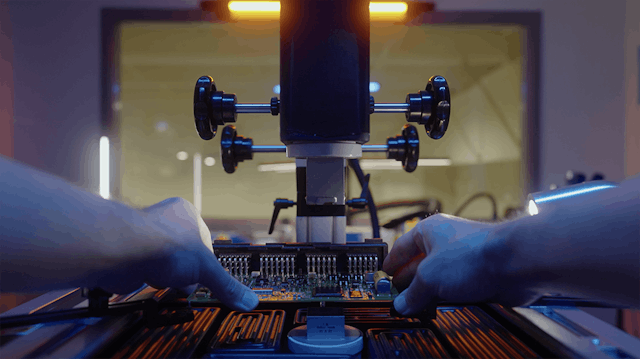

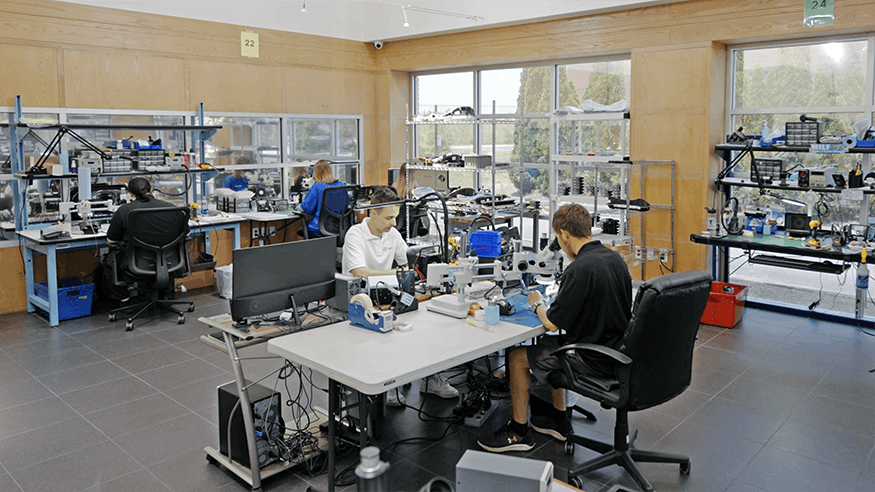

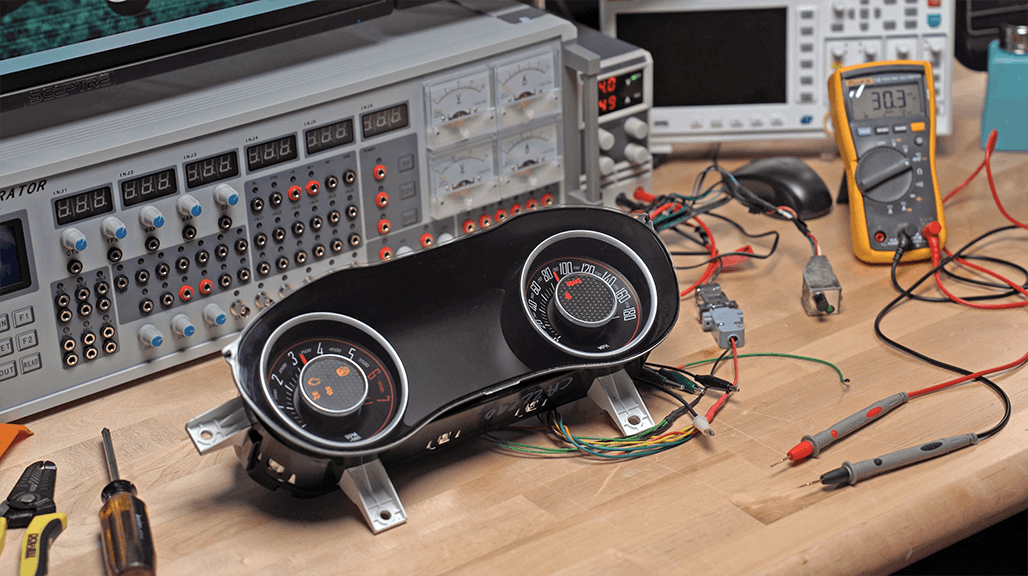

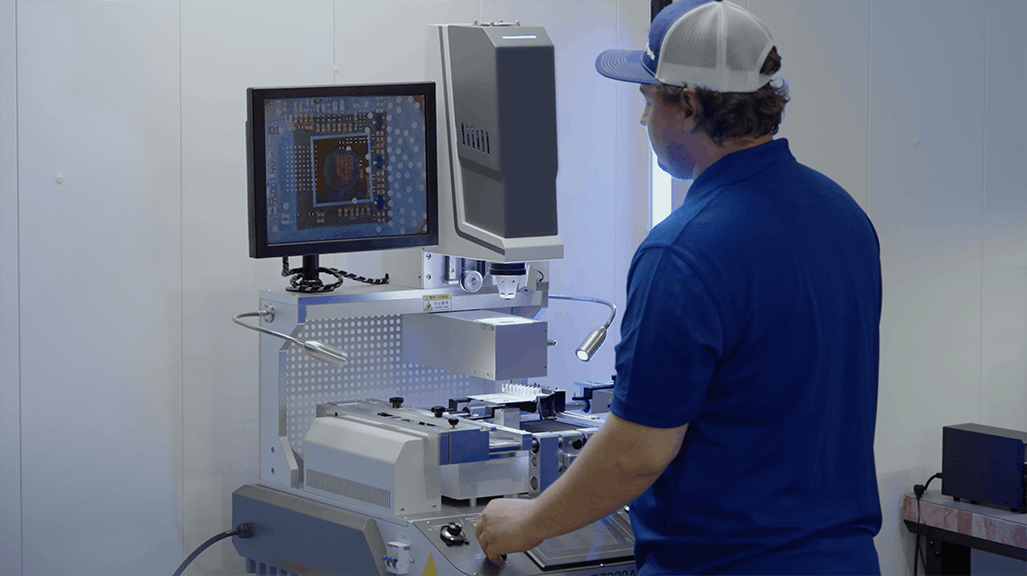

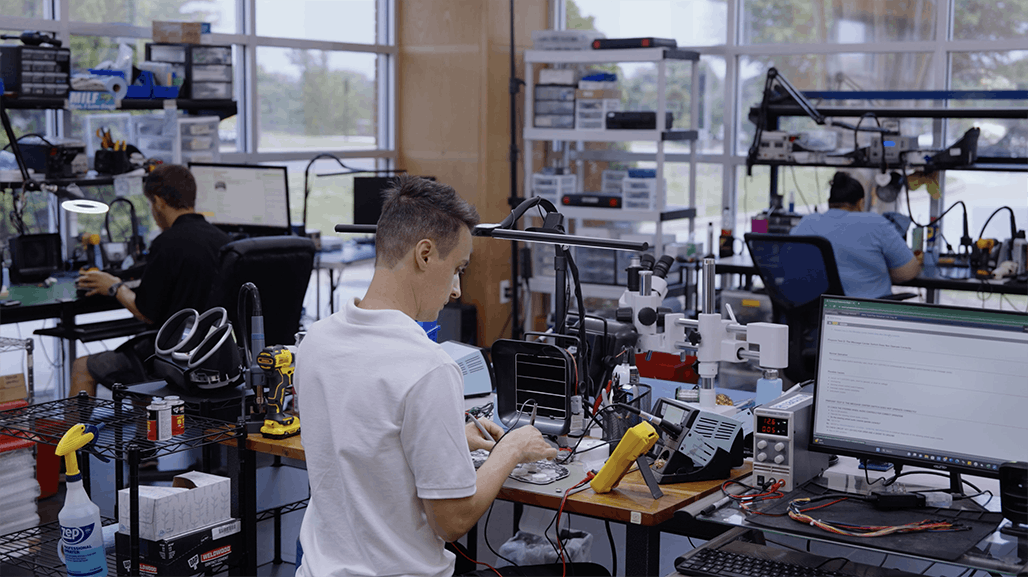

I spoke with Ernest Martynyuk, UpFix’s auto electronics division leader, about his company’s unique value proposition. If you’re like me, you’ve had components rebuilt by local Mom & Pop shops in the past, and they operate in less-than-ideal workspaces with limited staff and salty customer service. They get the job done, but some are merely a necessary evil to keep your car on the road. Martynyuk thinks his company does things differently, and UpFix’s facility suggests he’s operating with the professionalism of an OEM parts provider.

UpFix puts more more time into testing parts, Martynyuk says, than its smaller-scale competition. Further, it has an enviable stash of individual repair components, can reprogram a variety of applications, and possesses more specialty tools. But humans fix electronics, and UpFix also has more staff than a typical Mom & Pop. Even better, someone on the team frequently updates the website to ensure would-be customers understand what items they can fix, without needing to call or send an awkward email. (Many smaller operations still use websites that are more at home on a GeoCities domain.)

The more you poke around UpFix’s website, the more you realize they might be likely/willing to repair old parts from the 1990s OBD-II era, and even from older OBD-I vehicles. Martynyuk encourages this, as Upfix is willing and has a track record of repairing older modules from modern classics. Like other shops, they’ve repaired the usual pixelated problems from BMW displays of the 1990s, but have also mastered the more obscure. Consider the dashboard power supply of the Z31-generation Nissan 300ZX, and the failing gauge clusters of the oft-overlooked Suzuki XL-7. If you don’t find your vehicle in the website’s pull-down menus, Martynyuk encourages you to submit a repair request form.

It’s clear from our conversation that Martynyuk has a genuine curiosity and willingness to help owners of modern classics, and he’s in a position to ensure UpFix can work on oddball stuff for the likes of the Hagerty community. Although some of his smaller-scale competitors can say the same, they often focus on a single vehicle or a particular marque.

A company like UpFix is precisely what we classic car enthusiasts need, because it is indeed getting harder and harder to find someone to work on these old circuit boards, much less do it in a facility this impressive. The days of a majority of vehicles being made by three Detroit automakers are long gone; our reality is one of disparate global automakers using unique parts in a unique fashion. Even worse, all that technology was deemed antiquated by their parent companies decades ago.

UpFix is still growing into its large facility, hiring more technicians, stocking more components, and adding more workstations. Perhaps with this extra capacity comes an added willingness to repair a more diverse grouping of electronic modules. Martynyuk seems willing to take a shot at anything, so perhaps we have an alternative to overpriced service departments at new car dealerships. And maybe we finally have a safer bet than a junkyard or eBay listing for a used electronic component of questionable condition. That alone might be cause for celebration.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

There have been a cottage industry of repair going on for some cars and some parts. C5 Corvettes can have stability control computer issues. The early Bosch units can not be repaired or replaced but 01 and later delco units can be repaired. There is a company that can take these and repair them and the HVAC controls.

The issue often is cracked solder joints on chips. This company can make a fix for around $200 that could be $1300 if you have to buy a used unit.

The problem is some models are just going to still end up difficult or near impossible to repair.

When it becomes more to repair vs the cars value or the lack of parts that could be needed or used. Some creativity could help in some cases but some others are just going to be an issue.

This is the benefit of working with some models in great number or popularity. They will always try to find a way to serve these models as that is where the numbers and money is.

The real problem is going to be plastic. The interior bits get destroyed with age, sun and time. If there is not a call for a part you are stuck with swap meets, E bay or junk yards if you can still find one with old cars.

Cars like the Fiero T top has no real replacement for the rubber gaskets or tops. Drop a roof you are screwed or need a gasket you are hurting. The last NOS gasket was sold years ago and went for $1500.

Rarely do these NOS parts come out many are sitting on in case they need them. I have two glass tops just for insurance should one break. Not good to have a car with no roof or a scratched up glass.

Proficiency in fixing tech-laden electronics should only increase in the future. I predict a healthy cottage industry based on keeping the various modules, screens, and sensors operating as intended. Finding someone to competently tune your Webers or rebuild your Spica fuel injection will be more difficult.

I’ve been looking at which automakers are doing a good job of supporting their heritage products these days and I think it will be crucial to own cars from these automakers going forward. The parts may not be inexpensive, but at least they’ll be available.

Nice to see my comment mentioned but I don’t think it was addressed really. Sure companies now can fix infotainment and engine management systems from the past ~20 years of really chip heavy systems but I was talking 30-50 years out. If the chip (or chips with a lot of modern cars) fails, there’s not going to be a chip fab making them in 2063. Intel doesn’t still pop out 8086 chips from 1983. Chip foundries cost in the billions to build so it’s not like making new machine tools to repop GTO fenders.

Sure some basic electrical components (resistors, capacitors, sensors, etc) will probably always have some sort of compatible modern replacement, but the core chips won’t. It’ll be like trying to find a vacuum tube for your vintage 60s Zenith stereo. And god knows how expensive it would be to get 40-50 year old engine computer code to work with a year 2073 processor chip.

Look at the McLaren F1 for example. To maintain and fix it requires a computer to interface with the system. But they can only use specific 25+ year old Compaq laptops. IIRC correctly McLaren and some tech shops just started buying up as many of this model they could still find and rehabbing them but they’ll eventually all die and then what do you do with your $25M super car that needs a decades old laptop with less power than an Apple Watch?

Of course this whole argument may be moot because cars are getting so expensive, complex, and disposable at the same time we’ll probably just be car sharing anyway.

Hi JW, thank you for re-asking that concern. I have a feeling that the attrition rate of these vehicles for other issues pertaining to age and complexity will ensure there will be more supply and demand. Maybe I am an optimist and have had good luck finding NOS parts, but it seems like mass produced components always wind up on someone’s shelves instead of a land fill because they have a future value greater than zero.

All legitimate concerns. But progress happens. An 8086 can be virtualized, as can a 20 year-old Compaq laptop. There just needs to be demand. I suspect that the McLaren F1 pockets will always be deep enough to see that their cars keep running! They’ll drive technological solutions that may well trickle down to us mere mortals.

There’s also the “make it better than it was” route. The one I see more and more recently is outdated or broken infotainment systems, which are a great opportunity for upgrades. In the Porsche 996 realm for example folks are putting an iPad Mini in the dash and bluetoothing it to the existing audio system. Takes the radio, CD player, and so on completely out of the picture, and updates the interface. Fun stuff. I’m optimistic.

Possibly excepting Mclaren, Car companies aren’t making / using custom silicon. They are buying modules from Bosch, Delphi, Denso, etc. Even if you have a car that only sold 1000 units, the electronics were used in hundreds of thousands or millions of other cars. The fix 50 years from now will be to get a NOS module or used one from one of those millions of another cars, and then find the guy that can program it for your car. I have zero concern electronics will prevent my cars from the 90s and today from working 50 years from now (and I own a 90 year old car). I’ve had plenty of experience with 90s and early 2000s German cars with fixing / reprogramming used modules – it’s been inexpensive and easy – if you know “the guy.” The electronics from my 90s and 2000s Japanese cars, however, have been absolutely bullet-proof

One thing I have learned from an industry moving from analog controls to digital is that no one, not even the OEM, knows what all of those black boxes inside the black boxes are doing.

It’s good that there are outfits out there who can fix the common problems and the occasional popped solder joints, but take an older low-production car with an uncommon problem and good luck. I have been tinkering with arduinos, and I suspect that arduinos will serve a role in keeping my older computer controlled cars going down the road. As old as my collection is in terms of average age, over half are fuel injected

The average hobbyist will be the in zone that we are presently with A/C.

-There are ways to get factory looking AC in many vehicles that came with it.

-You can retrofit non-factory AC into just about anything.

-100% accurate factory AC isn’t even legal to recharge where I live, but some have ancient systems still holding together.

3D printing will solve the plastic components issues for many things.

But, people will be paying a premium for all original or even as-close-to-original-as-legal versus the typical mildly updated to keep it going vehicle the majority will have. There will be a lot of custom dashboards/gauge clusters I am thinking.

Engine management and such will be full replacement looms, just an evolution of the “Ron Francis Wireworks” or “Painless” approach hot rodders have used for the last 30 years.

HA – I waited a whole week to read this story, because the mention of the word “electronics” was scary enough all by itself, let alone on Halloween. So far, I think snailish has done the best job of comforting me. But of course, discussions of A/C in classics is way above my head, as my (non-electronic) solution is wing-windows…

4-60 air

When software became a thing for vehicles, I questioned what was going to happen when the satellite that fed the network had been de-orbited and crashed into the ocean.

I had an actual experience with a vehicle at my dealership. The “update” bricked the car, nothing worked. After several days of phone calls, a tech instructor showed at the service department with a 286 model desktop in pieces. On its hard drive was the last known copy of the recovery software for this model car. It got the car running and out of the shop. I recommended that a copy of the software be made, I’m not sure if it was.

Very good information to keep in my back pocket for future reference! Appreciate Hagerty!

Thankfully, there are several technicians who specialize in rebuilding and/or upgrading the notoriously failure-prone instrument cluster on third-generation (FD) Mazda RX-7s.

Great to add this company to the list of cpu, etc. repair sites.

There is no way to replace an application specific integrated circuit when they are cooked for whatever reason. ASIC chips are a one off design that is protected under patent.

I had an 81 Lincoln I thought would be a good restoration project appearance wise. However, the electrical system gave me nothing but problems. I took it to a shop that actually had the equipment sitting around to check it out. They gave me some very bad news; the main computer was no good. At the time I worked for an auto parts distributor. They had a source for rebuilt computers, unfortunately they could not do an 81 as it was the first years. The shop I was working with was able to adapt a carb so it ran a while longer until the timing chain went and took a couple of valves.

That’s the thing… up until (in some cases) the early 2000s, you could always cheat and go with the carb. It’s distributorless engines that pose the bigger challenge

I purchased new a 2013 Ford Fusion for the wife. As a DIYer I handled all the automotive repairs and wanted to leave her something new and hopefully trouble free when I’m gone. Small miracle I’m still around after 10 tumultuous health years. We’ve kept the car out of the nasty NE Ohio winters and currently there’s only 18k on the clock. The free service trips to the dealership as a result of numerous manufacturing screw-ups has christened the car the “Recall Queen”. There’s plenty other deficiencies discovered over ten years in a car that is essentially new. Lately, electrical gremlins have reared their ugly head. There are infinite postings on the net about failure of the APIM module. This is what Ford calls their body control module. The horror tales are astounding in frequency, cost, lack of parts, lack of trained techs and outright “You’re SOL” stories. This is across all product lines and I can’t believe this continues unabated. One example of the wife’s car is the failure of backlighting on all the dozens of buttons throughout the car (console, doors, overhead, steering wheel, etc.) Makes driving at night a real challenge. I know the backlighting works because it’s there when opening the door but soon times out after start. Last week after dark the lighting decided to work but I noticed the steering wheel only had third of the icons lit. The other third dead and remaining third flickering. Thanks to Youtube, I decided to tackle this myself. I successfully removed the IED (air bag) and then the wheel trim which holds these switches as two independent units. I can replace the pair with Motorcraft parts from Rockauto. My curiosity led me to disassemble one of the switches to see whats inside. A circuit board that handles the switching similar to TV remote utilizing a rubber membrane interface. Lighting is handled by LEDs (no surprise). However, the LEDs and other associated components are SMT (surface mount technology) and are of such micro size I don’t see any “repair” even if you could get replacement parts. When I trained in industrial electronics decades ago, at least we could see the damn components. And I really need not say I’ll never buy another Ford product or any of the hi-tech junk on the market.

Nice to know that someone out there can fix car electronics. Too bad that neither I nor my mechanic knew about it before we gave away our 5-speed Plymouth Voyager minivan that was completely rebuilt mechanically and ran perfectly until its engine computer would no longer allow it to pass emissions. Let’s enjoy our classics as long as we can because all cars are made to wear out in a decade or so and manufacturers have no interest in supporting them

Great comments. In my retirement I still write software for off the shelf microprocessors and build boxes for projects. The key phrase is “OFF THE SHELF”. Decades ago in aerospace I watched the change from using basic hardware chips to the use of custom designed chips to perform functions. Eventually this happened with consumer products. An example is many older T.V.’s where the custom chips are NOT available now. If someone had access to the firmware/software they might be able to emulate the “custom” chip function, but would it be affordable? Sure folks will make replacement “black boxes” for Corvettes, but what about the less desirable collectible cars, or the budget collectible cars?? Time will tell.