Media | Articles

A beginner’s guide to 3D printing car parts

Oh no! After 40-plus years of baking in the sun, an unobtainium piece of your car’s interior has shattered to bits. So what now?

Unfortunately, used interior bits tend be expensive and hard to find. Not to mention there’s no guarantee they won’t meet a similar fate as the original piece that just broke. Wouldn’t it be nice to press a few buttons on a machine and that spits out an exact copy of your part, à la Star Trek Replicator?

Well, it turns out you can. Sort of.

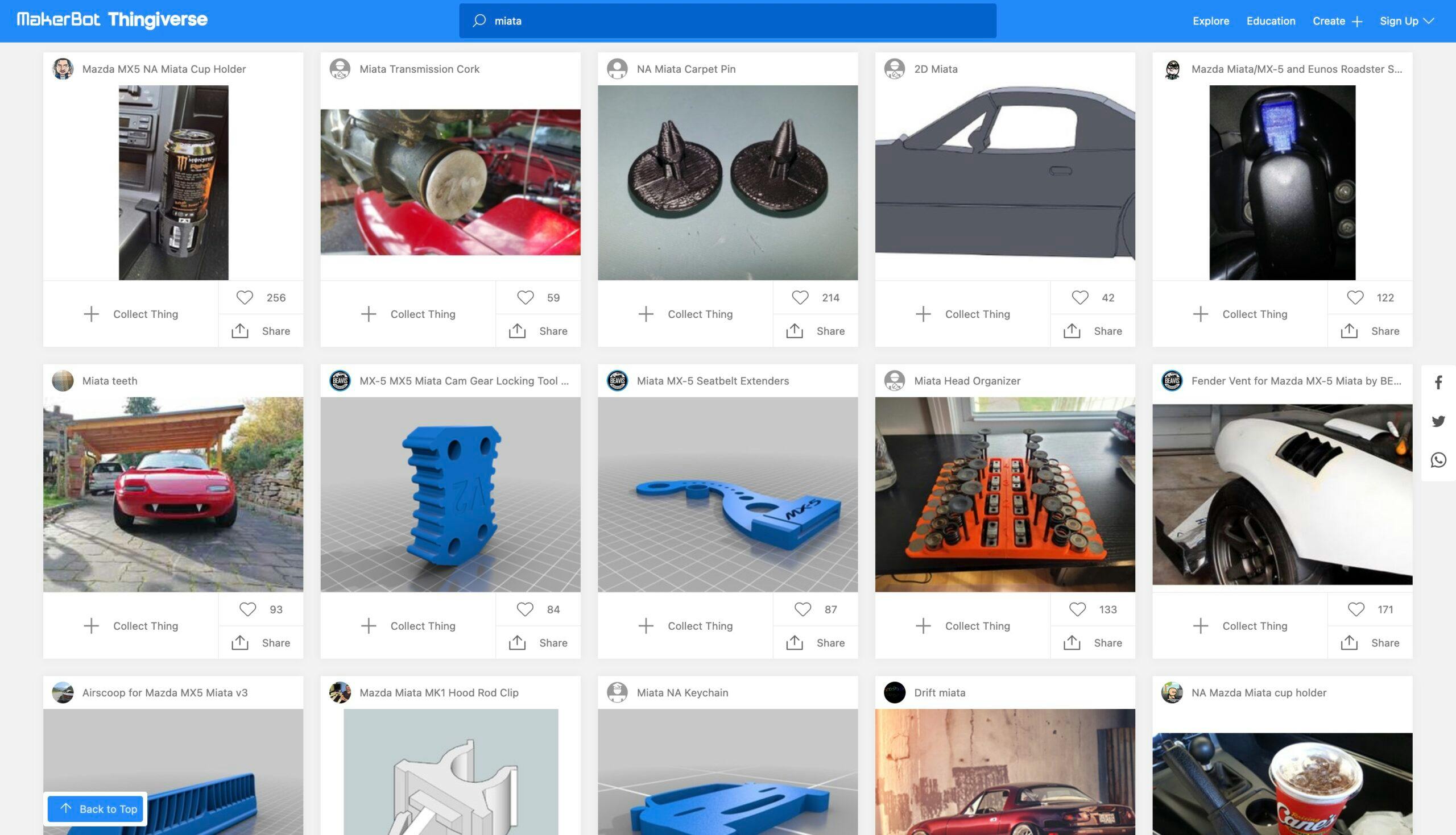

With a 3D printer and free, open-source blueprints from a database like Thingiverse, you can make some pretty amazing stuff for your car. How about cold-air intake, custom body parts, or tools for a tricky mechanical job? Heck, this guy even 3D-printed a full-scale hardtop for his Miata. The only limitations are your imagination and skills in the 3D modeling virtual world. We’ve even done it as part of our Redline Rebuild engine series.

Because consumer-grade 3D printers have been around for the better part of a decade, costs have amortized. A really solid 3D printer can now be had for under $300. The low cost of entry makes them an easy addition to your fabrication tool kit. In this guide, I’ll show you how to get started on your 3D-printing journey.

Marketplace

Buy and sell classics with confidence

The printer

For the purposes of this guide, and because it’s what I have on hand, the focus will be on Fused Deposition Modeling (FDM) printers. They are the best entry-level printers for making car parts, and it’s what beginners use.

FDM printers work by feeding plastic filaments through a heated chamber. This process melts the plastic in a heated chamber and pushes it through a metal nozzle onto a flat surface, known as the bed. The heated chamber and nozzle exist in a single unit, which deposits melted plastic along a path dictated by your part’s 3D file. From the bed up, the printer builds your design layer by layer until it is finished.

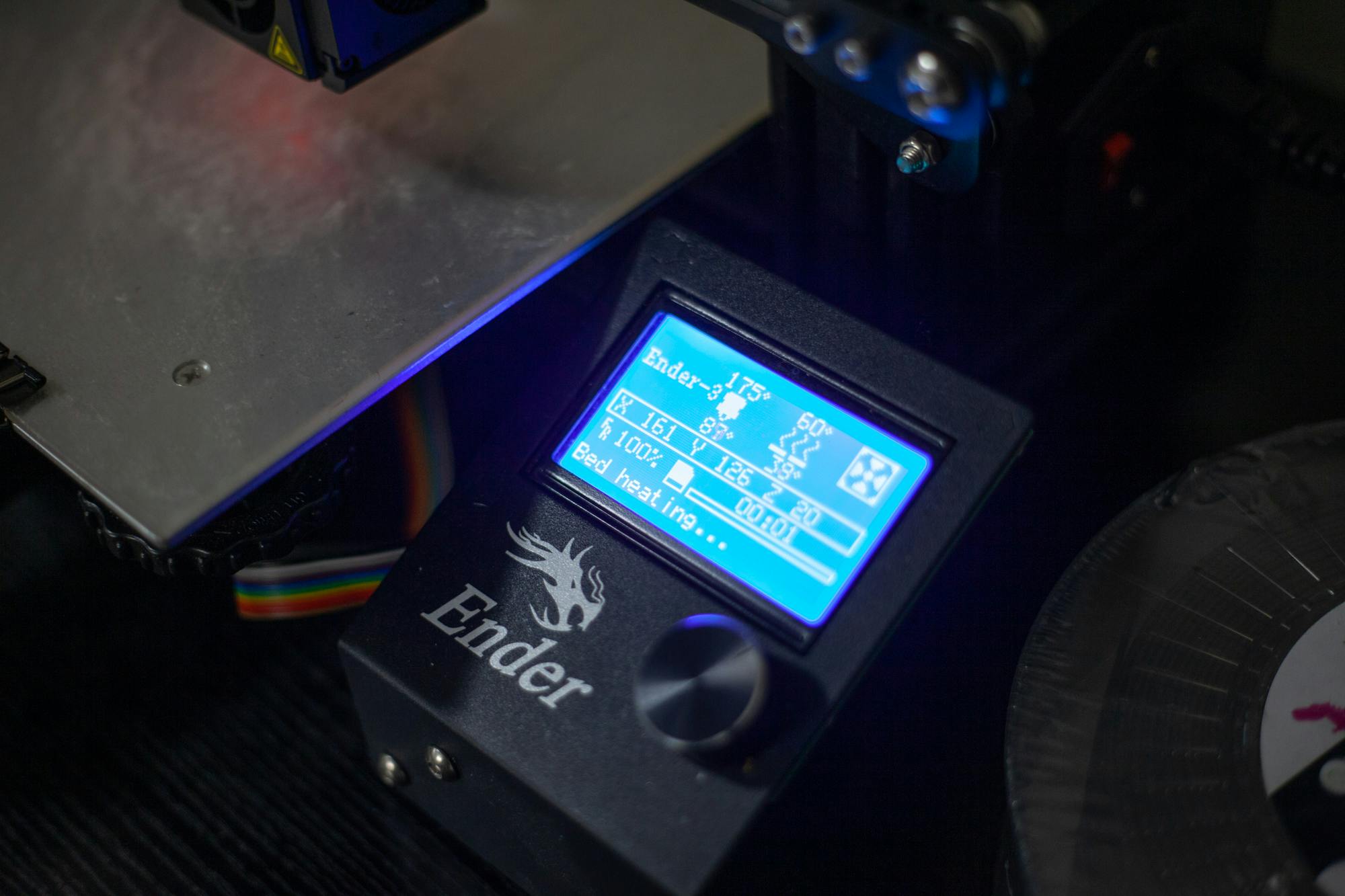

Within the FDM world, there are many printer brands and models from which to choose. I use the Creality Ender-3—a popular choice due to its low price of around $200 and supportive user community. Assembly of the Ender-3 is a bit fiddly, as there are a lot of components and the included directions aren’t especially clear. That’s where the user community comes in, offering robust assembly and troubleshooting guides as well as recommendations for aftermarket upgrades. These third-party mods are plentiful for the Ender-3: a glass print surface should you want more consistent print quality, or a sensor that reduces the amount of time you spend twisting knobs to level the bed.

There are other highly rated printers on the market which will totally work, but they tend to cost a bit more than the Ender. Models like the Prusa Mini Plus and the Flashforge Finder 3 offer a more plug-and-play experience.

The material

After you have acquired a printer, you’ll need some filament. Online retailers have a dizzying array of color and material choices available. The three most common types of plastic filament that an entry-level machine can easily print: PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PET-G (Polyethylene Terephthalate-glycol-modified). Each type is has its advantages and disadvantages.

PLA is great for creating mock-ups and prototypes. It’s cheap—around $20 for a standard, 1-kg roll—and you can find it almost anywhere. (Once, I bought a roll from Jo-Ann Fabrics.) However, PLA has poor heat and UV resistance, which makes it unsuitable for under-hood or exterior applications.

Then there is ABS filament, which has very strong and high heat and wear resistance—good for most automotive uses. It also doesn’t cost much more than PLA. The downside is that it can be tricky to print; the material has a tendency to shrink and warp when it cools.

PET-G is a great middle ground. It is both easier to print than ABS and stronger and more durable than PLA. Naturally, it costs more. You get what you pay for.

Parts to print

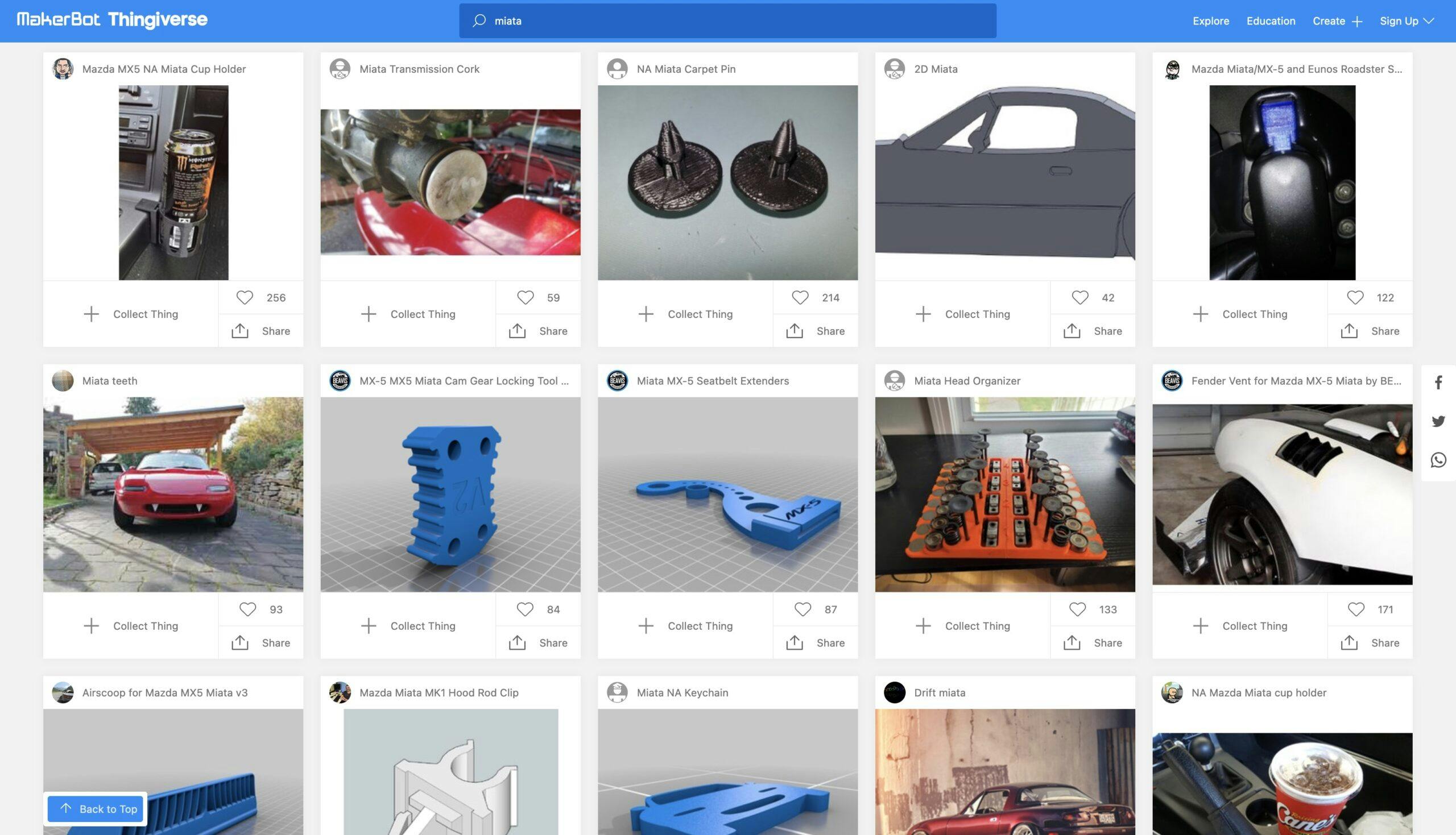

Now that you have the hardware, you need stuff to print. Thingiverse, that online repository of free-to-download parts, should be your first stop. Other options include GrabCAD or Thangs. If you have a popular car like a Miata or a BMW 3 series, there are plenty of uh, thangs, to download. Think door panel repair kits, brake cooling ducts, pedal spacers, cupholders, shifter boot trim, and so on.

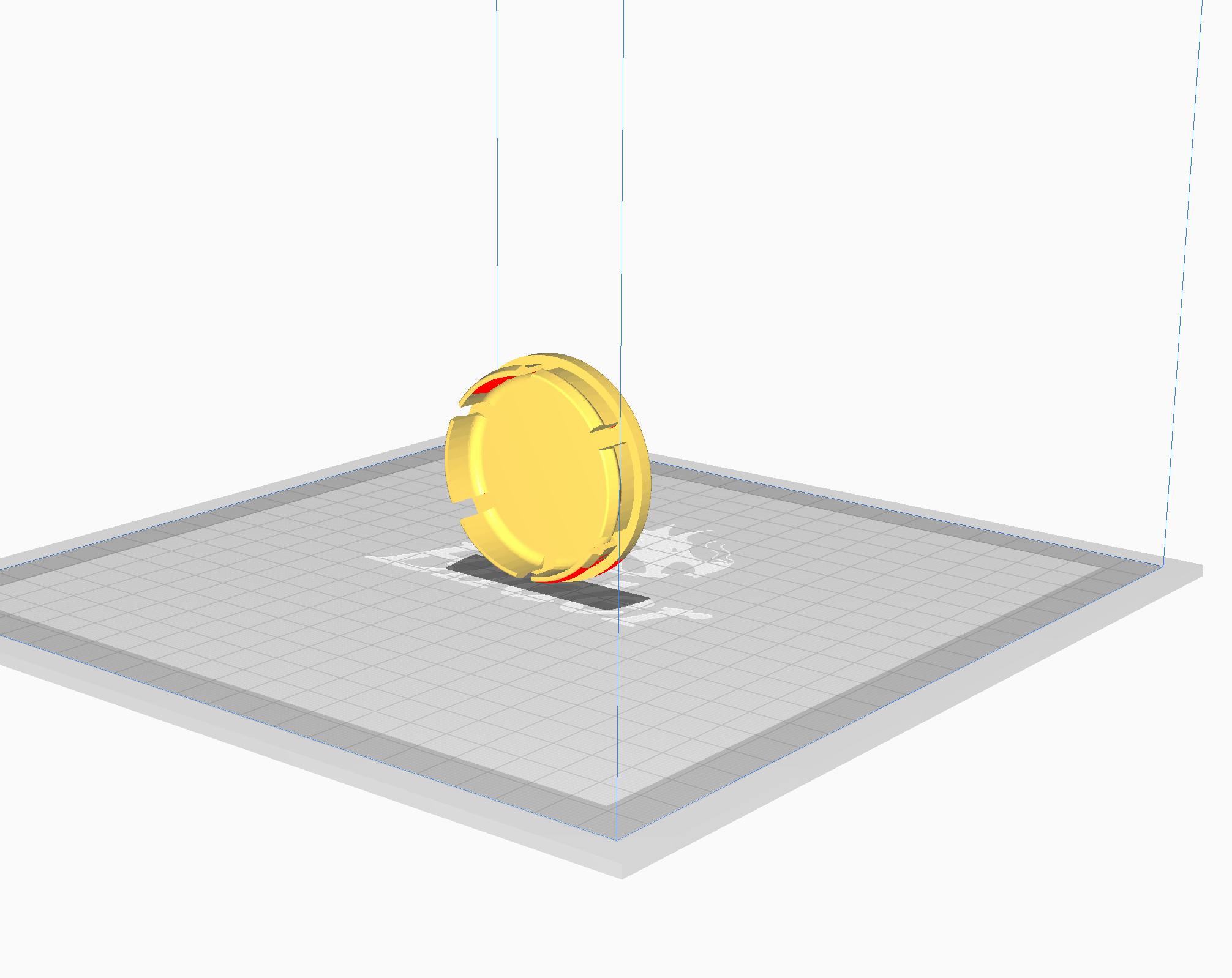

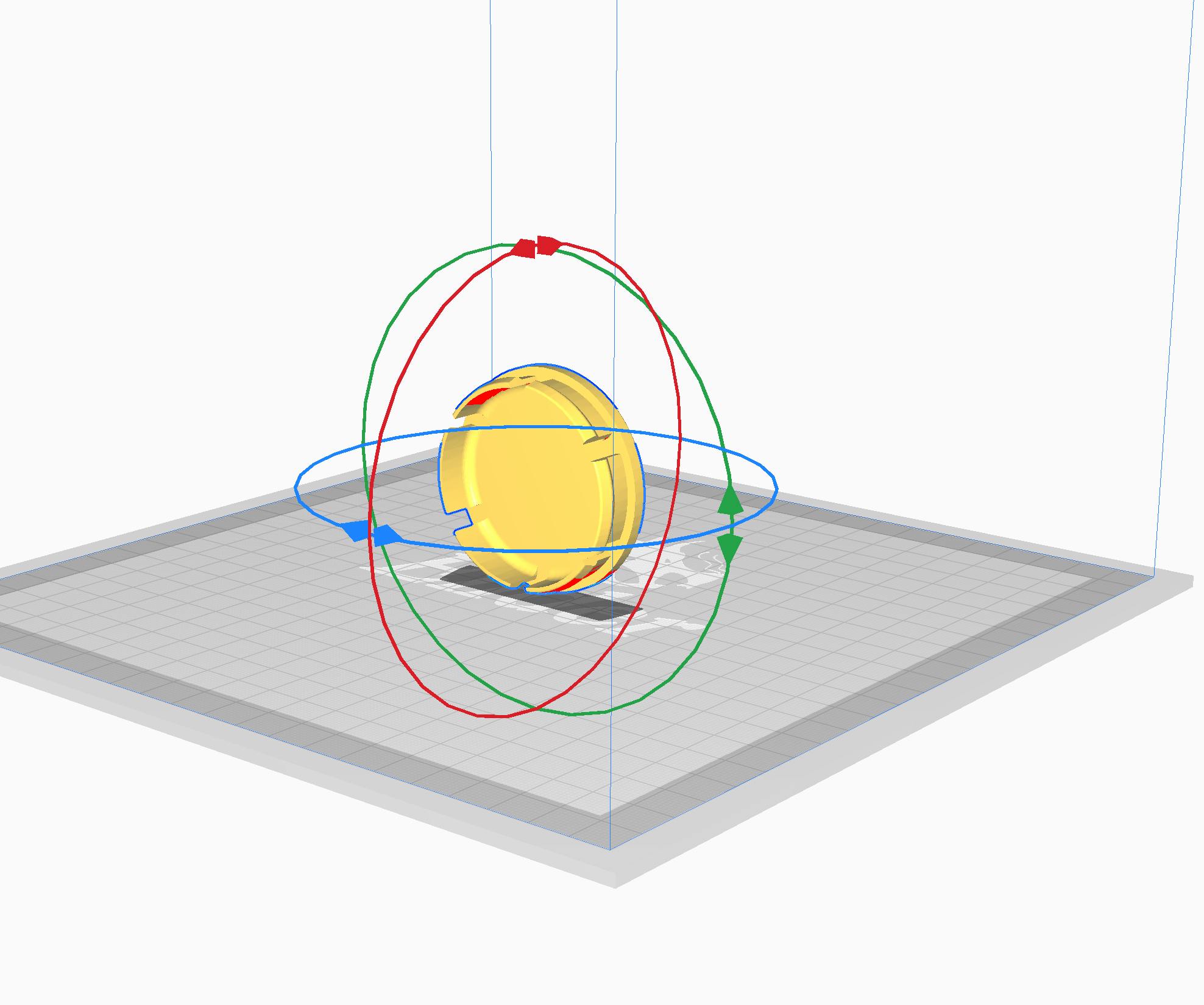

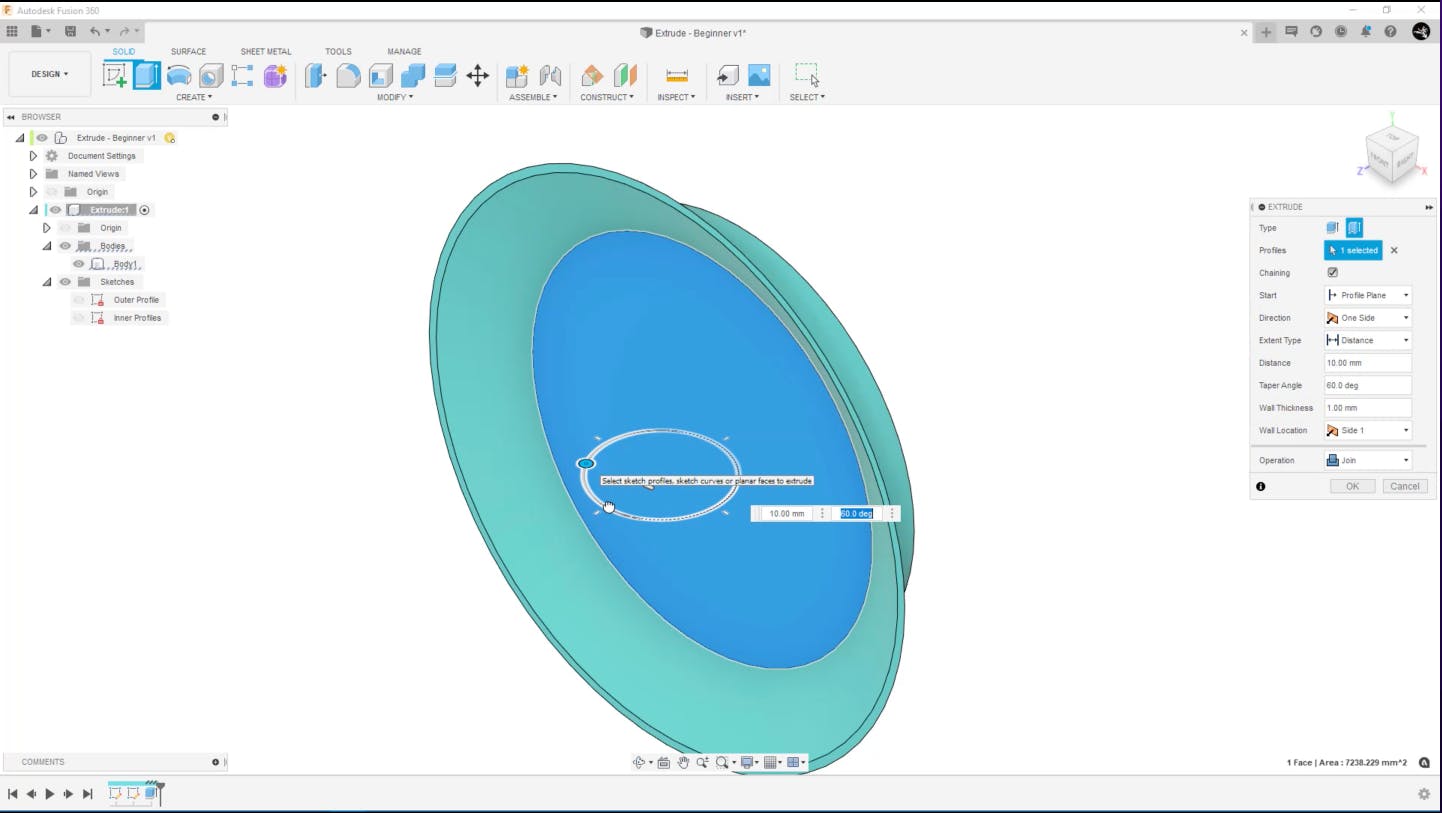

If you can’t find pre-made blueprints for your specific car or application, you’ll have to 3D model the part yourself. There are free programs and tutorials online if you are unfamiliar with 3D modeling. I recommend Fusion 360, which is free for personal (non-commercial) use. Learning to design your own parts will be beneficial in the long-term, as you will not be limited to what others have created.

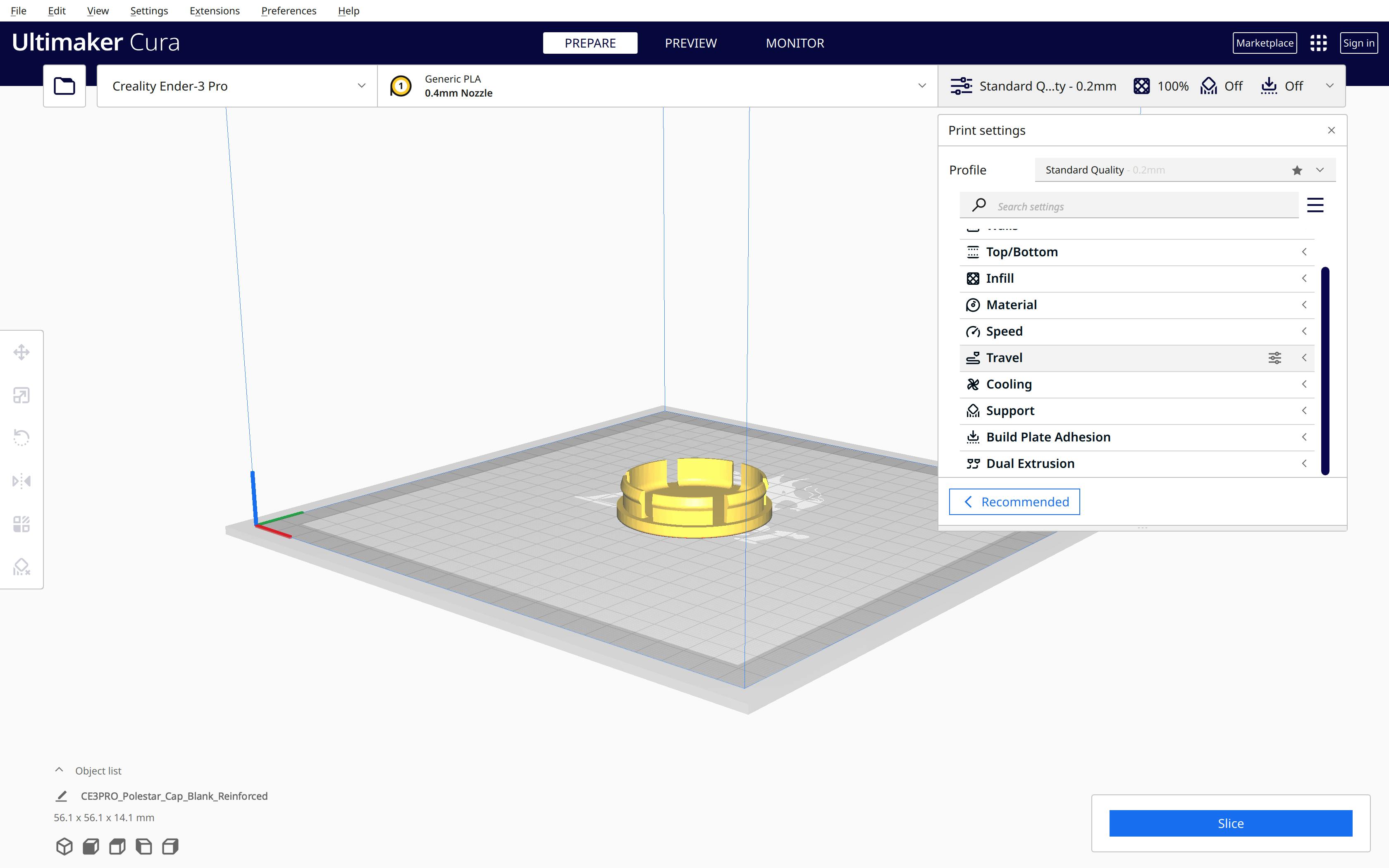

Printing parts

Before you fire up your printer, you need to translate your 3D model into a language the printer can understand, called GCODE. Your friend here is what’s called a slicer program. It’s software on your computer, to which you upload your design file. From there, you can specify your filament material and tweak other parameters to customize the quality and speed of your print. Once that’s finalized, the slicer then automatically converts the design file to printer-friendly GCODE language. Export the translated file to the printer using either an SD card or USB cable, and boom—time to watch your part come to life. If all goes well, you can bask in the glory of your first 3D print.

I’ve been away from 3D printing for the better part of a year, due to a broken printer. In putting together this article, I fixed my machine and fell back in love with the process. Seeing a part you designed in a computer materialize in real life is deeply satisfying. Especially when the alternatives are more expensive and potentially more of a hassle.

Good luck, ye modelers!

If you want to get into the hobby of 3D printing, building your printer and adding upgrades, the Creality printers are fine. If you want to make parts right out of the box, I’d suggest getting a Prusa. If you want to make parts fast right out of the box, I’d suggest geting a Bambu corexy machine.

Also, for design work, FreeCAD is a fairly powerful parametric CAD program and as the name indicates, it’s free.

It’s not printing. Printing is applying ink to a substrate. It’s fabricating. The terminology drives me nuts.

Kind of like all those references to an E-type as an “XKE.”

The toothpaste is already out of the tube.

The funny thing is that when people ask me how a FDM printer works, I tell them it’s like squirting toothpaste in a pattern over and over.

Not sure if I agree with the Jaguar comparison… Doesn’t that depend on where you live? In one place, it’s an E-Type. In another it’s an XK-E.

Now… what I WOULD compare it to is when someone says “I got that on film!” when they are using a digital camera.

or using the “ATM – Machine”

By that standard, a laser printer isn’t printing since it doesn’t use a liquid ink but rather powdered plastic that is fused to the paper. Technically speaking, a FDM printer is extruding.

Our local public library has a 3D printer (sorry Ron West, it annoys me too but it’s too widespread for us to reverse the tide) available for free use by card holders. I haven’t taken advantage of it yet though I’m itching for an excuse. I suggest checking your local ‘brary for an even cheaper initiation.

As one whom recently dipped her feet into this realm, I’ll add my two cents. IMO, don’t cheap out when buying your first printer. If you’re serious about printing good quality parts, buy a unit that can grow with your skills. (I purchased a Qidi X-Plus because it is fully enclosed and includes a high temp extruder that can handle nylon and carbon fiber infused filaments.) If you’re going to print ABS, be aware this filament off gases some pretty noxious fumes. Take ventilation into account when figuring out where to install your unit. I also recommend doing lots of research into filament types and their pros and cons when determining where your parts will be used (UV exposure, outdoors, etc.) Finally, being able to design and produce your own parts and tools is fantastic! I started using OnShape, a free design software. Just last night, I designed a clutch centering tool and downloaded it into my slicer software. One and a half hours to produce and didn’t have to wait over a week to get one from the dealer! Priceless!

Have you ever upgraded to another 3D printer, yet?

3D printing with metal is the next (expensive) level. Either way it is very cool.

Someone, maybe BASF, recently introduced a metal filament that will work with standard printers (with hardened steel nozzles). You send the printed part to them for sintering and post production. It’s not cheap, though.

Are items fabricated by metal printing

as strong as the same items manufactured by forging or casting.

This is something I don’t understand about “printing” metal.

Be aware that an FDM leaves a rough finish. This comes from the fact that the filament doesn’t completely melt, and is heated only enough for it to stick to the previously layed down layer. It can be wet sanded to smooth it out, but I would rather go with powdered media 3-D printing. Far better finished surface. And you don’t have to own a machine. Shapeways can take your CAD file and make your part in pretty much any kind of material, including metal. In any event, realize that most people who buy a cheap 3-in-one computer printer are sorry later with the poor quality of print and reliability problems. If you are going to do hours and hours of work, check out the tech publications for some insight into the best machines.

This right here is what prevents me from doing anything. I had a friend print a part for my car. It’s not smooth at all. But it’s also not visible, so I’m not concerned about it. But a visible piece? It’s a must that it has the correct finish.

So any of these 3D metal printing able to reproduce a gas tank for an old car?

Even if it’s not metal, but even a very sturdy plastic.

I realize fuel tanks have baffles inside, but trying to source even something from a junkyard is almost impossible anymore.

Other than just trying to fabricate a gas tank from scratch in your garage; I would really like to know if this is possible yet to “print” a new fuel tank on an old classic car.

I suppose the printer would have to be large, or you create in sections, then essentially fuse/glue them together/assemble it. Something like a 10-11 gallon tank.

One can hope 🙂

It’s pretty common among the Ford Fiesta ST crowd to 3D print a pedal spacer that raises the height of the throttle pedal for easier heel-toe shifts. I loved mine and kept it when I sold the car. Kind of crazy it cost about a buck for my friend to print.

How do you print something that doesn’t have a file on thingiverse?

I can’t emphasize enough the value of learning to use 3D modeling software such as Fusion 360, FreeCAD, or any of the others. Yes, there is a learning curve, but if you lack that skill then you are limited to printing parts that someone else has designed and made available on the internet. You may stumble across some interesting parts that you never thought of, but you won’t be able to create parts that YOU thought of to fulfill YOUR specific needs.

As for printers, I still use an old Creality CR-10 that is older and even simpler than the author’s Ender 3. It prints just as nicely as much more expensive printers, as long as you stick to appropriate materials (no carbon fiber nylon, for example). The real secret to high quality prints lies in tuning your settings in the slicer program. If the part is highly visible and requires a nice smooth finish, you just have to spend some time sanding and painting, just like you would if you had fabricated the part any other way.

As the author noted, some materials are better than others for automotive applications. I’ve found that PLA isn’t appropriate for any part of the car, not even the interior, because it warps in summer heat. ABS has much better heat resistance, but as noted it tends to warp during the printing process (unless your printer has an enclosed heated print chamber). It is also not UV resistant so it will break down over time if exposed to sunlight. The best all-around automotive material is ASA (Acrylonitrile Styrene Acrylate). It has mechanical and heat resistance properties similar to ABS, but warps less during printing and is highly UV resistant.

Another useful material is TPU (Thermoplastic Urethane), which is rubbery and can be used to make functional gaskets and parts that need to flex or cushion. It can be a little fiddly to print, but I’ve had a lot of success with it.

PETG is also good for automotive applications, especially if you need transparency for parts such as lamp lenses. It’s fairly heat resistant, and it prints almost as easily as PLA.

Over the years I’ve designed and printed dozens of one-off custom parts for my car, everything from simple mounting brackets to a combination CHMSL/backup camera and everything between. It’s now hard for me to imagine building a custom car without a 3D printer.

There are some great examples of 3D printed car parts on this YouTube channel: https://www.youtube.com/@GrindhousePE

Are there services that will print stuff for you?

Yes, there are service bureaus that will do 3D printing for you. A Google search should turn up many options. The problem, however, is that developing a part is inherently an iterative process if you want to achieve optimum fit, finish, and functionality. Paying a third party to do the printing for you will quickly accumulate time and expense.

Some parts are quite complex and may be difficult to model, especially for someone new to 3D modelling. I believe I have read about scanners that can create a 3D model for use in a 3D printer. Any info on those? Modelling is the stumbling block for many and existing models are not likely available for the millions of different parts used on cars over the past 100+ years.

Great topic for an article, and also great discussion in the comments. I’ve been looking for a nudge to get started on 3D printing, this should do the trick. I need that Enkei centre cap!

a few years ago i remember seeing an app for the ipad that supposedly could 3D scan an existing item – think broken old part you still have and want to make a shiny new copy – i wonder if anyone has used a program like this and how effective /accurate it is

There are apps that convert your phone or tablet into a 3D scanner, and my understanding is that they can work fairly well (haven’t tried them personally). Of course there are also dedicated 3D scanners that do a better job for a price. Check out this YouTube channel for for examples of 3D printed car parts modeled from scratch in a CAD program and also by starting with a 3D scan:

https://www.youtube.com/@MakingforMotorsport

thanks for info!

just take a hammer to it.

Can a 3 d printer fabricate a folding arm to pull up the top of a MBZ cbk 450. The top will not go up because the “hinge” is busted.