Media | Articles

9 old tools almost nobody uses anymore

The nuts and bolts that make up our beloved automobiles have not changed that much over the last 150 years. But the tools needed to maintain them? Those have changed a lot. Software has cemented itself as part of a service technician’s day-to-day regimen, relegating a handful of tools to the history books. (Or, perhaps, to niche shops or private garages that keep many aging cars alive and on the road.)

How many of these now-obsolete tools do you have in your garage? More to the point, which are you still regularly using?

Spark-plug gap tool

Though spark-plug gap tools can still be found in the “impulse buy” section of your favorite parts store, these have been all but eliminated from regular use by the growing popularity of iridium and platinum plugs. These rare-earth metals are extremely resistant to degradation but, when it comes time to set the proper gap between the ground strap and electrode, they are very delicate. That’s why the factory sets the gap when the plug is produced.

These modern plugs often work well in older engines, meaning that gapping plugs is left for luddites—those who like doing things the old way just because. Nothing wrong with that; but don’t be surprised if dedicated plug-gapping tools fade from common usage fairly quickly.

Verdict: Keep. Takes up no real space.

Marketplace

Buy and sell classics with confidence

Dwell meter

50 years ago, a tuneup of an engine centered on the ignition system. The breaker points are critical to a properly functioning ignition system, and timing how long those points are closed (the “dwell”) determines how much charge is built up in the ignition coil and thus discharged through the spark plug. Poorly timed ignition discharge is wasted energy, but points-based ignition systems disappeared from factory floors decades ago, and drop-in electronic ignition setups have never been more reliable (or polarizing—but we’ll leave that verdict up to you.)

Setting the point gap properly is usually enough to keep an engine running well, and modern multifunction timing lights can include a dwell meter for those who really need it. A dedicated dwell meter is an outdated tool for a modern mechanic, and thus most of the vintage ones are left to estate sales and online auction sites.

Verdict: Toss once it stops working. Modern versions are affordable and multifunctional.

Distributor wrench

When mechanics did a lot of regular timing adjustments and tuning, a purposely bent distributor wrench made their lives much easier. However, much like ignition points, distributors have all but disappeared. Thanks to coil-on-plug ignition systems and computer-controlled timing, the distributor is little more than a messenger: It simply tells the computer where the engine is at in its rotation.

Timing adjustments have become so uncommon that a job-specific tool is likely a waste of space. If you’ve got room in your tool chest, keep yours around; but know that a standard box-end wrench can usually get the job done and is only fractionally less convenient than the specialized version.

Verdict: Keep if you have them. No need to buy if you don’t.

Pre-OBDII diagnostic scan tools

Prior to the required standardization of on-board diagnostic computers by the U.S. in 1996, a single car could host a wild mix of analog and digital diagnostic methods. OBDII, which stands for On-Board Diagnostic II, wasn’t the first time that a small computer was used to pull information from the vehicle via an electronic connection; it merely standardized the language.

Throughout the 1980s and early 1990s each OEM had its own version of a scan tool. Now those tools can be reverse-engineered and functionally spoofed by a modern computer, allowing access to diagnostic info tools that, at the time, were only available to dealers. Since many pre-OBDII cars are now treated as classics or antiques and driven far less frequently, the need for period-correct diagnostic tools is dropping.

Verdict: Keep. These will only get harder to find with time, and working versions will be even rarer.

Distributor machine

A distributor is simple in concept. Trying to balance the performance and economy of the ignition system, with the distributor attached to a running engine, and achieving proper operation starts to get pretty complicated. That’s where a distributor machine comes in.

A distributor is attached to the apparatus and spun at engine speed by an electric motor. This allows you to literally see how the points are opening and closing. You can also evaluate the function of vacuum or mechanical advance systems. These machines are still great but the frequency that this service is needed these days is few and far between, especially when trying to justify keeping a large tool around and properly calibrated.

Verdict: Keep, if you are a specialty shop or tool collector.

Engine analyzer

Even a casual enthusiast can see there is a lot more information that can be gleaned from a running engine than whatever readouts might be on the dash. Enter the engine analyzer, a rolling cabinet of sensors and processors designed to fill in the data gaps between everything that is happening in a car and what its gauges report.

An engine analyzer is essentially a handful of additional instruments packaged into a small box hanging around the bottom of your tool drawers. It can also house a lot of sensors in a giant cabinet, which was likely wheeled into the corner of the shop in 1989 and left to gather dust. Now engine analyzers can be found listed online for as cheap as $200.

The funny thing is that many of the sensors in these engine analyzers are often the same systems that come built into modern dynamometer tuning systems. In a dyno, the sensors allow the operator to see more than max power; they also show how changes to an engine’s tune affect emissions. Maybe engine analyzers didn’t disappear so much as change clothes.

Verdict: Toss. The opportunity cost of the space these take up can be tough for most home garages. Sensors went out of calibration decades ago so the information you might get from one is dubious at best.

Most pneumatic tools (for home shops)

Air tools hold an odd place in the hearts of many gearheads. For many years the high-pitched zizzzz and chugging hammers of air-driven die grinders and impact drills were the marks of a pro. Or, at least, of someone who decided that plumbing high-pressure air lines around the shop was easier than installing outlets and maintaining corded tools. Air tools are fantastic for heavy use, as they are much easier to maintain and can be rebuilt and serviced.

Those tools can really suffer in lack of use, though, since pneumatic tools rely on seals and valves, neither of which deal well with dry storage. Battery tools have caught up to air tools for most DIY folk. No more air lines or compressors taking up space in the shop—and requiring additional maintenance—and, in return, a similarly sized yet more agile tool.

Verdict: Keep, if you already have the compressor. Don’t have one? Invest in battery tools.

Babbitt bearing molds/machining jigs

Every engine rebuild has to have bearings made for it in some fashion. Today’s cars use insert bearings that are mass-produced to surgical tolerances for a multitude of applications. If you wanted—or more accurately needed—new bearings in your Model T circa 1920, you needed to produce your own … in place … inside the engine. Welcome to Babbitt bearings.

The process is a true art form, from the setup of the jigs to the chemistry of pouring molten metal and machining the resulting orbs to actually fit the crankshaft and connecting rods. Now there are newly cast blocks for your T that replace the Babbitt with insert bearings. Since those antique Ford engines just don’t get abused the way they used to, and lead fairly pampered lives, they need rebuilding far less often than they did in-period. Modern oils also do a better job of protecting these delicate bearings. Since they are less and less in demand, the tooling and knowledge to make Babbitt bearings are difficult to find, and precious when you do.

Verdict: Keep. It’s literally critical to keeping a generation of cars alive.

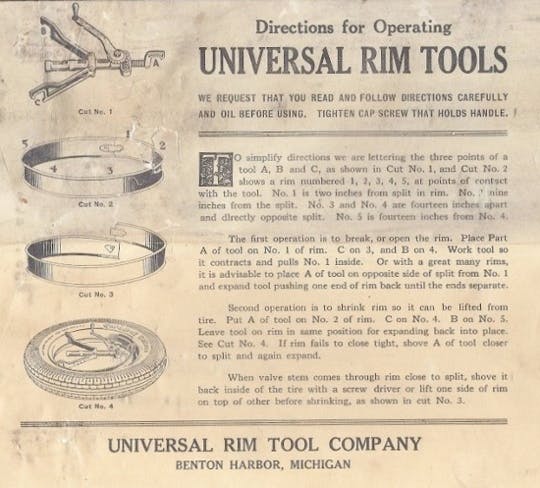

Split-rim tire tools

Among the realm of scary-looking tools that have earned their infamy, split-rim tools hold court. The concept is simple: The rim is sectioned, allowing it to contort into a slight spiral that can be “screwed” into a tire. (This is almost the reverse of a modern tire machine, which stretches the tire around a solid wheel rim.) When tires needed tubes, both tire and rim were relatively fragile, and the roads were rough, split rims were popular—and for good reason. Now the tooling for drop-center wheels is ubiquitous and shops often won’t take on split-rim work. Success is hard to guarantee, even if techs are familiar with split rims—and they rarely are.

Verdict: Keep. No substitute for the right tools with this job.

***

These tools might not make much sense in a dealership technician’s work bay, but that doesn’t mean they should disappear forever. Knowing how to service antiquated technology is as important as ever, whether using old tools or new ones. If you’ve got any of these items, consider it your responsibility to document what the tool does and how to safely use it. Keeping alive the knowledge of where our modern tools came from is powerful.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Battery tools are at a disadvantage for tools like cutting wheels, grinders, sanders, or paint guns because the battery drains quickly. I have a battery angle grinder I almost never use, because the 20v battery doesn’t last very long…but its air-powered counterpart will go until I melt the wheel. Same with the impact gun — I have a battery gun in my race kit so I don’t have to carry a compressor, but for regular, repeated use in the shop, I keep an air gun. A 50-ft hose takes it anywhere I need it.

Never and I mean never toss out a tool you just never know if someday you will need it again. Put them in a box and stick them under your workbench , this way when your dead and gone your kids will open it up and say what the heck is this ? They might even learn something from it.

I have an old Ferrari and need almost all of these. Pretty surprising article from a magazine dedicated to collector cars????

When I was a kid, I saved up to buy a Montgomery Wards engine dwell meter for my dad. He was a shade tree mechanic in his spare time to save money on our family cars. He loved it and I can still see him opening the gift wrap on Christmas morning. I was so proud of that thing. After he passed in 2019, I found it in his toolbox still in great shape. Dad always taught me to take good care of your tools and to put them back up after use. Although you are absolutely correct, I will probably never use it, it has a safe and cherished spot in my toolbox!

It’s surprising to me that this article didn’t mention oscilloscopes. True, it showed an engine analyzer but any decent shop in its time would also have had a scope. I sold more Snap-On scopes (and AVRt testers) than any dealer in my branch. They weren’t as capable or impressive as some of the machines from Sun, Marquette, etc, but worked well if you knew how to use one. The reason I sold so many scopes was because I would train the purchaser how to use it. A good technician could see worn timing chains, and distributors, bad plug wires, cross-firing caps, low compression on a cylinder – the list goes on and on. I still use a cylinder-shorting dwell tach to tune my ‘65 235hp Dart. It’s great for setting the idle mixture, or seeing which cylinders are working well or poorly. Maybe a there is code reader can see some of these things, but I haven’t seen one that can do all of them.

still have special thermo vacuum switch sockets

Spark plug cleaning machines have virtually disappeared, even before the advent of plugs that use exotic rare earth metals, like iridium and platinum. When I was in high school in the mid 1970’s, there were already falling out of favor, as Champion Spark Plugs could be bought for between $1.00 and $1.25 each, so there wasn’t much point in trying to clean plugs when new ones were so cheap, even if they only lasted about 12,000 miles. Now, with unleaded gasoline, electronic fuel injection and electronic ignition, plugs last for 100k miles, and now that all of the other tune up parts (points, condenser, distributor cap, rotor and plug wires) have been consigned to oblivion, the need to clean, re-gap and re-use spark plugs has essentially disappeared.

Here’s one from the memory hole for you two wheel devotees. Does anyone remember the Carb Stix? Four (4) mercury manometers mounted side-by-side on a common scale, you used it to synchronize the four (4) carburetors on your Honda CB750/550/350 Four. You adjusted the vacuum on each carburetor until all four mercury columns hit the same mark. They used to advertise in Cycle World magazine. I don’t remember if they made a six-column version for a Benelli 750 Sei, though. Modern fuel injection has rendered carb synchronization a lost art, unless you’re working on old Italian or British iron (MG, Triumph, Ferrari, etc.) with their multi-carb Weber or SU carb setups.

yup; I had a set for my Honda CB750C and my VF750F. Real mercury and all the supposed hazards. No need any more

I wish shops had the old suction cup/headlight aiming devices. I’ll never get my 1969 Road runner’s aimed correctly.

Check the Factory Plug Gaps. I changed the plugs in my 1985 Ferrari and it was miss firing. The plug wires were very old and expensive so I changed them thinking my pulling on the wires to get them dislodged from the spark plugs must have damaged one. A couple of months of working on it, including compression check, intake valve cleaning and injector cleaning left me stumped. I finally pulled the plugs again and one of the factory set plugs was over 70 thousands’ of an inch. It came that way in the protective cardboard tube over the electrode. Now I use my plug gap tool to to be sure. About one in each set is off.

Not sure that I can fully agree that battery powered tools are a good choice. Those batteries have been known to start fires that do great damage. Perhaps there are best practices that will mitigate this danger and that could be the focus of a future article.