Media | Articles

9 old tools almost nobody uses anymore

The nuts and bolts that make up our beloved automobiles have not changed that much over the last 150 years. But the tools needed to maintain them? Those have changed a lot. Software has cemented itself as part of a service technician’s day-to-day regimen, relegating a handful of tools to the history books. (Or, perhaps, to niche shops or private garages that keep many aging cars alive and on the road.)

How many of these now-obsolete tools do you have in your garage? More to the point, which are you still regularly using?

Spark-plug gap tool

Though spark-plug gap tools can still be found in the “impulse buy” section of your favorite parts store, these have been all but eliminated from regular use by the growing popularity of iridium and platinum plugs. These rare-earth metals are extremely resistant to degradation but, when it comes time to set the proper gap between the ground strap and electrode, they are very delicate. That’s why the factory sets the gap when the plug is produced.

These modern plugs often work well in older engines, meaning that gapping plugs is left for luddites—those who like doing things the old way just because. Nothing wrong with that; but don’t be surprised if dedicated plug-gapping tools fade from common usage fairly quickly.

Verdict: Keep. Takes up no real space.

Marketplace

Buy and sell classics with confidence

Dwell meter

50 years ago, a tuneup of an engine centered on the ignition system. The breaker points are critical to a properly functioning ignition system, and timing how long those points are closed (the “dwell”) determines how much charge is built up in the ignition coil and thus discharged through the spark plug. Poorly timed ignition discharge is wasted energy, but points-based ignition systems disappeared from factory floors decades ago, and drop-in electronic ignition setups have never been more reliable (or polarizing—but we’ll leave that verdict up to you.)

Setting the point gap properly is usually enough to keep an engine running well, and modern multifunction timing lights can include a dwell meter for those who really need it. A dedicated dwell meter is an outdated tool for a modern mechanic, and thus most of the vintage ones are left to estate sales and online auction sites.

Verdict: Toss once it stops working. Modern versions are affordable and multifunctional.

Distributor wrench

When mechanics did a lot of regular timing adjustments and tuning, a purposely bent distributor wrench made their lives much easier. However, much like ignition points, distributors have all but disappeared. Thanks to coil-on-plug ignition systems and computer-controlled timing, the distributor is little more than a messenger: It simply tells the computer where the engine is at in its rotation.

Timing adjustments have become so uncommon that a job-specific tool is likely a waste of space. If you’ve got room in your tool chest, keep yours around; but know that a standard box-end wrench can usually get the job done and is only fractionally less convenient than the specialized version.

Verdict: Keep if you have them. No need to buy if you don’t.

Pre-OBDII diagnostic scan tools

Prior to the required standardization of on-board diagnostic computers by the U.S. in 1996, a single car could host a wild mix of analog and digital diagnostic methods. OBDII, which stands for On-Board Diagnostic II, wasn’t the first time that a small computer was used to pull information from the vehicle via an electronic connection; it merely standardized the language.

Throughout the 1980s and early 1990s each OEM had its own version of a scan tool. Now those tools can be reverse-engineered and functionally spoofed by a modern computer, allowing access to diagnostic info tools that, at the time, were only available to dealers. Since many pre-OBDII cars are now treated as classics or antiques and driven far less frequently, the need for period-correct diagnostic tools is dropping.

Verdict: Keep. These will only get harder to find with time, and working versions will be even rarer.

Distributor machine

A distributor is simple in concept. Trying to balance the performance and economy of the ignition system, with the distributor attached to a running engine, and achieving proper operation starts to get pretty complicated. That’s where a distributor machine comes in.

A distributor is attached to the apparatus and spun at engine speed by an electric motor. This allows you to literally see how the points are opening and closing. You can also evaluate the function of vacuum or mechanical advance systems. These machines are still great but the frequency that this service is needed these days is few and far between, especially when trying to justify keeping a large tool around and properly calibrated.

Verdict: Keep, if you are a specialty shop or tool collector.

Engine analyzer

Even a casual enthusiast can see there is a lot more information that can be gleaned from a running engine than whatever readouts might be on the dash. Enter the engine analyzer, a rolling cabinet of sensors and processors designed to fill in the data gaps between everything that is happening in a car and what its gauges report.

An engine analyzer is essentially a handful of additional instruments packaged into a small box hanging around the bottom of your tool drawers. It can also house a lot of sensors in a giant cabinet, which was likely wheeled into the corner of the shop in 1989 and left to gather dust. Now engine analyzers can be found listed online for as cheap as $200.

The funny thing is that many of the sensors in these engine analyzers are often the same systems that come built into modern dynamometer tuning systems. In a dyno, the sensors allow the operator to see more than max power; they also show how changes to an engine’s tune affect emissions. Maybe engine analyzers didn’t disappear so much as change clothes.

Verdict: Toss. The opportunity cost of the space these take up can be tough for most home garages. Sensors went out of calibration decades ago so the information you might get from one is dubious at best.

Most pneumatic tools (for home shops)

Air tools hold an odd place in the hearts of many gearheads. For many years the high-pitched zizzzz and chugging hammers of air-driven die grinders and impact drills were the marks of a pro. Or, at least, of someone who decided that plumbing high-pressure air lines around the shop was easier than installing outlets and maintaining corded tools. Air tools are fantastic for heavy use, as they are much easier to maintain and can be rebuilt and serviced.

Those tools can really suffer in lack of use, though, since pneumatic tools rely on seals and valves, neither of which deal well with dry storage. Battery tools have caught up to air tools for most DIY folk. No more air lines or compressors taking up space in the shop—and requiring additional maintenance—and, in return, a similarly sized yet more agile tool.

Verdict: Keep, if you already have the compressor. Don’t have one? Invest in battery tools.

Babbitt bearing molds/machining jigs

Every engine rebuild has to have bearings made for it in some fashion. Today’s cars use insert bearings that are mass-produced to surgical tolerances for a multitude of applications. If you wanted—or more accurately needed—new bearings in your Model T circa 1920, you needed to produce your own … in place … inside the engine. Welcome to Babbitt bearings.

The process is a true art form, from the setup of the jigs to the chemistry of pouring molten metal and machining the resulting orbs to actually fit the crankshaft and connecting rods. Now there are newly cast blocks for your T that replace the Babbitt with insert bearings. Since those antique Ford engines just don’t get abused the way they used to, and lead fairly pampered lives, they need rebuilding far less often than they did in-period. Modern oils also do a better job of protecting these delicate bearings. Since they are less and less in demand, the tooling and knowledge to make Babbitt bearings are difficult to find, and precious when you do.

Verdict: Keep. It’s literally critical to keeping a generation of cars alive.

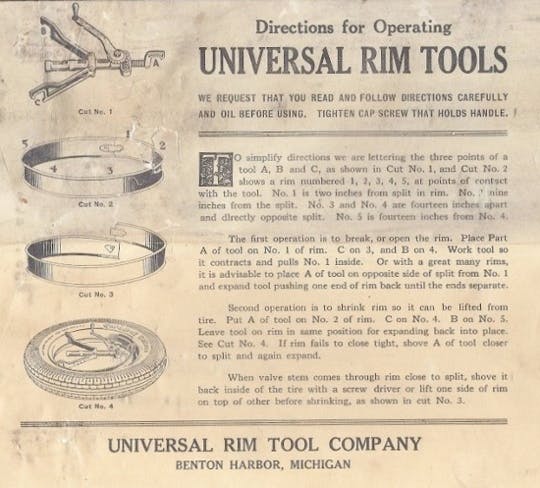

Split-rim tire tools

Among the realm of scary-looking tools that have earned their infamy, split-rim tools hold court. The concept is simple: The rim is sectioned, allowing it to contort into a slight spiral that can be “screwed” into a tire. (This is almost the reverse of a modern tire machine, which stretches the tire around a solid wheel rim.) When tires needed tubes, both tire and rim were relatively fragile, and the roads were rough, split rims were popular—and for good reason. Now the tooling for drop-center wheels is ubiquitous and shops often won’t take on split-rim work. Success is hard to guarantee, even if techs are familiar with split rims—and they rarely are.

Verdict: Keep. No substitute for the right tools with this job.

***

These tools might not make much sense in a dealership technician’s work bay, but that doesn’t mean they should disappear forever. Knowing how to service antiquated technology is as important as ever, whether using old tools or new ones. If you’ve got any of these items, consider it your responsibility to document what the tool does and how to safely use it. Keeping alive the knowledge of where our modern tools came from is powerful.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I am a sucker for nostalgia, I admit, and keeping old tools (especially ones that belonged to now-gone loved ones) is a weakness that I’ll not even attempt to shed. I use some when I can figure a use for them, and keep others just to display as bench or wall art. Space is never at so much or a premium that I can’t afford to dedicate some just to keep the memories alive. I’ve no idea what will become of my displays after I’m dust, but until I go – they’ll stay! 😋

I still own everyone of them and work on many old toys

I collect past generation Vehicles. I use all those tools. I still like a torque wrench on rims.

I still hang on to old tools. Battery tools are nice for many jobs and on new vehicles.

Me too. I always check the gap on plugs before installing them. I don’t have any cars I need a dwell meter on anymore as I’ve switched over all the point cars to Pertronix. And it’s ALWAYS good to use a torque wrench on the lugs. Check them after having your tires rotated as most shops use those torque bars & after 50 million wheels changed, who knows how accurate they are. I had a car come back with lugs so tight I had to use a breaker bar to reset them, & others on the same car finger tight. Needless to say, after that I rotated my tires myself

Greg, with the emergence of platinum and iridium plugs, and their super fragile center electrodes, it’s really not advised to touch them with anything. This is why the plugs come with sleeves on the threaded ends; to prevent the ground electrode from getting disturbed. Most platinum and iridium plugs come pre-gapped for maximum performance from the manufacturer.

I have all of those and many more. Only one I haven’t used recently is my old Marquette engin analyzer with the 8″ green screen oscilloscope. Manuals in it are for last 50’s- early 60’s. When someone needs service on an old car they’ll pay what you charge since nobody else has the equipment or desire. Hobbyist owners are different, they enjoy doing their own work.

I saw this right away cause it’s stuck out like a sore thumb, when I was a kid I worked in a gas station that had a contract for milk trucks. DIVCO was the name of the truck and they all had split rims. as much as you clean the groove and you clean the ring, we still would set it face down and sit on the tire while inflating it. At the time I was probably about 240 pounds and that thing could easily pick me up more than 2 feet off the floor when the ring blew off

That’s a different kind of split rim than the type the tool here is used for. I’ve owned vehicles with both. For the potentially deadly type you mention, many tire shops had cages to put the wheels in when being inflated, and used remote inflators so you weren’t right next to the tire if it blew.

Army still uses a cage for many tire/wheel Sam lies.

OSHA requires a tire cage be used on all tires IIRC.

I had a friend get his arm broke airing up a tire change

He’s lucky. Some have died when these explode

Yes! I’m not that old, but when I was a teenager, I worked at a tire shop that had one of those cages, and actually learned how to work on those “widowmaker” split rims, where the wheel actually splits in half down the middle. The lips that hold the halves together would corrode and weaken, causing them to blow apart. A guy I worked with there had one blow apart while it was still on the truck and he was checking the pressure of the inner dual. It shattered his wrist.

DIVCO: Detroit Industrial Vehicle Company

I never knew THAT’s what it was an acronym for, and I grew up in Detroit!

Thank you.

My dad ran a milk route, they were meant to be driven while standing up, the driver jumping out many times in a few feet. The shifter was a pedal that protruded thru the lower dash, it was parallel to the floor. Pushing down on it shifted it and I think it had a hand throttle…four cylinder, bullet proof vehicles ….

I remember those DIVCO milk trucks vividly. I was always amazed at how the driver could control the vehicle standing up but it seemed to work very well. Today’s regulations would never allow a vehicle like that to be on the road.

Those trucks would be ideal for today’s rural U.S mail delivery vehicles, but again with today’s safety mandates would prevent any employee to be subjected to extreme 5 to 15 mph stop & go danger.

The Divcos we serviced had a swivel seat. It could throw you out the door going around a corner.

Same here! And the Twin Pines driver lived just down the street.

You could stand up and drive them. The brake and clutch in same peddle.

your boss should have been shot for having you sit on the tire while inflating it! I was taught in no uncertain terms to chain the rim and tire to retain the pieces if it let go. I was also shown the patch in the ceiling where one went through before chaining was the only way to do it, and yes, a remote fill control to keep your hands clear.

Boy, ain’t that the truth! When I worked in a Chevron sta in the 70s in SOCAL, we would put the tire on the tire machine & put the de beader part up on top of the wheel. Then you air the tire up partially to seat the lock ring, then tap the ring with a hammer lightly to make sure it’s evenly seated, then inflate it to what you want. ALWAYS with a remote fill attachment! Never had a problem

I worked at a Goodyear tires tore in the 80’s. The day I started, I was shown a large circle on the outside of the back wall, about 16.5″ in diameter. Yup, a split rim had exploded and sent the ring into the block wall. Luckily, we had a tire guy to do the split rims. Oh, and a cage, too.

My father worked for Sealtest Dairies in the late ’50s in Ft. Pierce FL. I can still see clearly the small fleet of Divcos hooked up to electrical outlets to keep the contents refrigerated. Happily rode “jump-seat” often as he made his stops.

You are lucky too be alive, we raised the hoist put the wheel under the drive on hoist, lowered it and put the snap on chuck on and stood back. Never had a problem around 1963

We would put them under the vehicle lift to keep them from blowing off. Split rims can be dangerous if you are not careful.

When I was in the Army we had split ring wheels. We too used the upside down method. In my three years I never had a blow off but I ALWAYS used precaution.

I suspect many here are like us in this manner .

I find good quality special tools cheaply in yard/tag/swa meet sales and thrift/pawn shops too .

-nate

And here, I thought I’d be the ‘odd man out’ !

Good on ya Dale!

I still use many of these. For my 50s and 60s cars , they work fine.

“(the “dwell”) determines how much charge is built up in the ignition coil” I can tell a Millennial must have written this because it’s incorrect. The charge is built-up in the condenser and when the points open it is released into the coil and amplified many thousands of times.

The condenser is more to smooth out the spike of current when the points open to prevent arcing which would burn out the points quickly. How long a current is applied to the primary windings of a coil does equate to how hot the spark will be on the secondary when the field collapses. The current isn’t amplified, but the voltage is increased due to the disparity in the number of windings on the primary and secondary coils within the ignition coil.

I know little of electronics. I think the meter measures (in degrees) how long the points dwell in the closed position. It can change the timing slightly so you need a timing light (another old tool) to coordinate the two.

Right!. The article missed the timing light. Haven’t seen on one in years.

I have a home made tool box I made decades ago for my timing light, dwell meter and now I have been able to squeeze in my OBDII scanner. Compression gauge fits in there too

I still have points in my 67.5 SPL311 so I still use my timing light and dwell meter. Also work on a lot of magnetos where point gap and dwell is critical.

Good catch, Eric! I still have two timing lights that belonged to my grandfather and my dad, both master mechanics. I just can’t bring myself to the point of tossing them.

I still have and use the timing lite, distributer wrench, plug gaping tool etc, when tuning up my 70 AMX. Also use vacuum gauges. The only duty my air compressor gets any more is blowing off the lawn tractor and inflating tires.

Don’t forget after blowing off your lawn tractor you also do the same with your boots and pants for the same reason like I do. But all my automotive tools are still air powered from impact guns air ratchets to cutoff wheels and paint guns etc… 🙂

That was my first thought, along with the gap tool.

I’ve got one somewhere in the garage.

Good comments. Yes changing dwell (time points are closed/open) changes timing, but changing timing DOES NOT change the dwell. Even with “electronic modules” ignition to replace points, a dwell meter AND timing light come in handy when working on 60’s cars. And yes few seem to understand automotive ignitions, OR electrics. I do and get a lot of calls from local club members.

The timing light is used to correctly phase the firing of the spark plugs with the pistons reaching the peak of the compression stroke.

The dwell meter measures the period in crank degrees that the points are closed and charging the primary winding of the coil. Dwell is inversely proportional to point gap.

The dwell meter measures the period in distributor degrees that the points are closed and charging the primary winding of the coil.

I still use my timing light and dwell meter when tuning my 1967 SPL311

Right on the money, Paul. Thanks for correcting the previous misinformation.

I think you are the most correct about the cap’s job.

DO NOT WORK ON SPLIT RIMS! My neighbor lost his life mounting mounting a tire on a split rim. He had done that for work,so he was no amateur. Still want to do them? Ask his widow and family…

Right! If you have an older Ford truck with split rims, throw them by the wayside and get newer wheels like from 80s-90s Fords. Wheels from pickups and vans are 16” and will interchange with them and they are abundant.Besides there is a much wider range of tires available. 16.5 tires not much anymore.

Use a cage if you must!

The split ring, and split wheels are super easy to deal with.

Clean, clean, clean, paint, install new clean tires and bead flaps coated in baby powder, set regulator, and air up slowly, in a cage. Wait a few mins with full pressure, install, and drive. The main reason folks had so much trouble was dirty, rusty rims and rings with putting old or dry tires not properly lubed and aired up slowly to allow everything to set. I’m running a set now. 0 issues

Split rims are not the same as what 90% of people are talking about. 2 piece “lock ring wheels” are usually still around. I run 4 on my truck. Not a big deal if you know what your doing. Telling people not to work on split rims is like saying dont ever change coil springs on a modern car because they can explode and take your face off. Anything can kill you. Keep wrenching.

Paul, quite correct. This is also the Achilles heel in conventional ignition systems at higher revs. At high revs, the time in which the magnetic field is built up becomes shorter and shorter. If the dwell time is too short, the engine will skip earlier at high revs due to a too weak spark.

Too many years ago I used a Mallory dual point distributor on a crate LT1 corvette small block. Dealer who put the engine in a 65 Chevy imp credited $110 for the stock corvette mechanical tach drive transistor distributor. The Mallory had to be set up in a distributor machine most easily but the maker/breaker points lasted 10X as long as stock breaker points and were good to 8K engine rpm. Ask me how I know that😂

How do you know that?

Hate to be pedantic but protecting the points is a secondary function of the condensor. By preventing arcing it speeds up field collapse, which (as Faraday discovered) enhances coil voltage. Voltage is further increased by the way that the condensor then self-discharges (in the opposite direction).

That is correct. Points closed, the coil current builds up. When the points open, the coil primary voltage jumps up to a few hundred volts and the secondary winding increases that to the voltage required to jump the plug gap. The capacitor smooths out the change in voltage across the point to minimize point arcing

Nope, incorrect. The coil does store the energy that is releases to the plug when the points open. Think of it as magnetic charge. With the points closed just before the spark, the condenser is shorted by the points and has zero volts across it and therefore no stored energy. The condenser provides a short term current path for the primary circuit to allow the poinnts open without arcing

No, the energy to fire the plug comes from the magnetic field created in the coil during the dwell period, then when the points break the field rapidly collapses, inducing a very high voltage in the coil secondary winding and firing the plug. The capacitor is there only to suppress the voltage that kicks back across the points. Proof? Remove the capacitor (“condenser”), the engine will still run. Remove the coil, not so much.

Exactly. Remove the can capacitor and the car will still run, as the secondary field will collapse and the spark plug will fire, but there will also be a a bit of a spark spark on the “points” side of the ignition coil windings when the field collapses upon breaking point contact. And the charge is not “amplified many times”; in fact the amperage (current) is much less, negligible; it’s the voltage which is much higher to achieve a proper spark, able to reliably jump the plug gap. Since the dizzy opens and closes the points to allow ALL cylinders (in firing order) to fire with every rotation, the dwell setting sets the time that the contacts are closed, and to a small degree this affects the engine timing too.

*distributor

Ah yes, my favorite statement that almost always draws a blank stare “Dwell affects Timing”

I still remember that to this day. My auto shop teacher taught us: Dwell effects timing. Timing does not affect dwell.

“remove the capacitor and the car will still run” is not true for a ’72 Buick Skylark. I had the capacitor fail the day after a tune up in ’83 and had a no start condition. That was a “fun” exercise in troubleshooting I recall to this day.

Agreed. Had a dual point distributor in a 69 Dodge. The condensor wire parted at the condensor body and the engine stopped while driving at highway speed.

Another good use of the condenser and get a good laugh, was to charge it (after replacing it) by momentarily connecting it to a battery, then placing it on the seat of the forklift. Watch the operator jump when he sat on it! 😂

In high school 1969 we charged up a condenser and left it on our nasty English teacher’s desk, our shop teacher figured it was us 3 guys the next day hearing about it and said don’t do that again with a smile.

Correct. The kick back is caused by discharging the secondary coil over the spark plug electrodes which will also cause a change in the magnetic field that will therefore also generate a voltage in the primary coil of a few hundred volts. This voltage energy will be captured by the capacitor. On an ocilloscope the pendulum movement can be seen very well

Good description. I think that we have to remember what an ignition coil is and that it is a transformer. There is a primary coil and a secondary coil. This ignition coil (transformer) is stepping up 12 volts to over 20,000+ volts to jump a spark gap to ignite the fuel mixture. When DC is applied to the coil and the points are closed completing the circuit it builds up a steady state maximum voltage of 12 volts DC in the primary coil. When the ignition points are opened by the cam inside the distributor the primary coil voltage is interrupted and the collapsing magnetic field cuts across the secondary coil stepping the voltage up to the 20,000+ volts needed to jump the gap at the spark plug and firing that cylinder. That secondary voltage that fires off the plug is also creating a counter electromagnetic force (voltage) on the primary coil that is much higher than the 12 volts that was originally applied and the capacitor (condenser) absorbs that voltage spike to prevent arcing and burning of the points.

Transformers work on the principle of magnetic induction and alternating current (AC) is constantly changing polarity and voltage this works great for sending power across the country and our neighborhoods stepping voltage up and down but for automobiles we have DC systems because power can be stored in a battery which we need to get the car started. We need the distributor point system to provide this transformer action on our DC ignition system. I know this is a long reply but I did not fully understand the automobile ignition system until I studied transformers.

Primary voltage is typically limited to 6 volts by voltage division across the ballast resistor. The ballast resistor limits primary current to also help improve longevity of the ignition points, along with the snubbing action of the condenser.

Ballast resistor cut out during starting, at least on Chrysler 60s products I owned. Chevys too maybe. Bad open BR resulted in engine firing during starting (S1 terminal hot) but dying when key released (s2 terminal hot). Made for interesting diagnosis if you weren’t aware….

In layman terms I use the term (shock absorber ) to describe the function of the condenser. Because that’s basically what it does.

” Remove the capacitor (“condenser”), the engine will still run.” Then why have I had experience with two cars ( 1974 Honda Civic and 1966 Ford Mustang) each of which had a no spark condition which was corrected by replacing a bad Condenser?

Because the bad condenser is shorting the points to ground.

Condensers can short out resulting in no spark.

You sir, are correct!

After having my car intermittently stall due to lack of spark and then poop out altogether, I found– much to my surprise–that dead condenser = dead engine. That after 60 years of messing with point and distributor ignitions and never having had that happen. Lesson learned: carry a spare condenser in addition to points, cap and rotor.

Finally, somebody came up with a great explanation of how the coil works. It’s the field collapse that creates the secondary high voltage. as far as diagnostic tools when a friend of mine passed on his shop was opened to auction for all parts and tools. I made offers on two sun diagnostic machines the good ones that check all the plug wires, the dwell the cadence of the spark through eight wires(identifies a worn distributor cam or bad bearings which throws off the timing to each cylinder) I was bidding hundreds a guy came in and offered 10,000 for both machines. I said sell it to him. The family needed the money and I didn’t need the machines 10,000 worth.

My father was an instrument repairman for the military in the 40s thu 60s. He taught me how to set the dwell using a degree wheel and a pointer attached to the distributor shaft. Attach a light bulb and battery across the points, you can rotate the distributor shaft and watch the pointer. If the dwell is supposed to be 20 degrees, you adjust the point gap till you achieve the proper dwell on the degree wheel. Points close, light goes on, points open, light goes out. This method never needs calibration and is dead on, whereas the dwell meter may or may not be all that accurate. As for the condenser, he said look at your points contacts, if you have no or very little build up, no need to change it, it is a good match. If you have big spikes, change it. You don’t need any electric doodads to set points accurately, and most likely, more accurately.

Dale, this is partially correct. The method you described works fine if there is no wear on the shaft or bearings. A dwell test device measures dynamically, which compensates for any slack. Of course, the clearance must be within the tolerances, otherwise the distributor must be overhauled or replaced.

That is a horse of another color. Dwell angle is what we are setting, nothing more. If your distributor is worn out, fix that first.

Dear Dale,

I don’t know if this comment is still read, but due to personal circumstances I’ve been out of the running for a while. My response to the distributor machine was incomplete and does not do the device justice. It is not always easy to see whether an axle or the cams are worn. What added value does the machine have? The opening moments of the contact points can be seen exactly, so if one or more cams deviate slightly, the ignition moment for the relevant cylinders will shift. A dwell meter indicates the average opening angle. The machine every single opening angle. In addition to whether the vacuum and/or centrifugal advance achieves the required values, it is also clearly visible whether this is smooth or jerky. Sorry for my English, I have to blame google translate fot that:-)

I loved the lights that indicated all 8 or number of cylinders during around the ring on the distributor machine. The lights needed to be evenly spaced on 8s…uneven meant worn points cam or something else to chase down.

I disagree with Robert. The charge in the coil happens when the points are closed. When the points open, the current in the coil is stopped and causes a magnetic field in the coil which causes high tension and the spark in the plug. The condenser is there to swallow part of the spark between the points and make their life longer. The condenser has nothing to do with the charge of the coil.

I agree. When you apply a negative pulse to the coil is when it fires. I still have and use on occasion use most of these tools. unless you have coil over plugs, a timing light can be a very easy tool to ensure you have spark going to each plug

I use my timing light to find a bad plug or wire.

Thank You

The condenser is used to stop arcing between the points thus extending the life of the points.

That is totally incorrect. The condensor is there to control arcing across the points. When the points are closed there is no charge in the condensor as both ends are at ground potential.

The charge is built up in the primary windings of the coil, and when the points open the magnetic field in the primary windings collapses, inducing a current in the secondary windi gs producing the high voltage for the spark. The purpose of the condenser is to prevent arcing across the points when they open.

Hey, Robert, I believe you are referring to a capacitive-discharge type of ignition, which was not used on the older cars (it’s a high-performance, aftermarket option for ignition systems).

In the older, factory-style, ignition systems, the points close and current flows into the primary windings of the coil causing the build-up of a magnetic field. When the points open, the rapid collapse of the magnetic field cuts across the windings of the secondary coil and induces a high voltage in the secondary windings. Give this voltage a path to ground (through the spark plug) and current will flow, jump the gap in the spark plug, and create a spark.

The condenser is there to “absorb” electrons that would otherwise try to jump the gap in the points as they open. A vehicle can run without the condenser, but not for long because the points would burn up quickly.

Not quite. The ignition coil is a transformer and it does amplify the voltage of the primary winding. The condenser is simply protection for the points to prevent them from burning prematurely with the arc formed as they open, and the magnetic liked collapses in the coil. It is at that point the peak voltage is reached in the secondary winding of the coil, and the rotor aligns with one of the cap contacts to fire a spark plug.

Correction: magnetic field collapses…

Sorry dude, age aside you’ve been mislead. The condenser’s use is to “absorb” the charge that would otherwise try to jump the air gap created when the points open. Without it, the resulting arc burns & pits the points.

Hi,

actually that condenser is only there to dampen the spike to prevent arcing as Paul H mentioned. the coil ratio determines output voltage but dwell does affect how long the coil has to establish its primary magnetic field, which in turn produces the current in the secondary winding at a higher voltage, WHEN it collapses (which is when the points OPEN. thus the need for the condenser to dampen the ARCH of current through the points and thereby lengthen the life of the points considerably!) BUT you can tell a millenial idiot wrote this and Hagerty should be ASHAMED because they are WHAT???? A COLLECTOR’S CAR INSURANCE company!!! and COLLECTORS have MOSTLY cars that were BEFORE electronic ignitions… notice that the author NEVER mentions that you MIGHT own a pre-electronic ignition car!!! SAD and once again Hagerty should be ASHAMED to put out such a tone-deaf article!! But at least now you know the straight dope on points! (FYI: I have extensive auto repair training and a degree in electronics as my qualifications for knowing about points/coil ignition systems).

Hi Keith. Thanks for reading and taking the time to respond with a comment. Personally I fail to see what my age has to do with the article above. I (like you) have dedicated my life to cars and the knowledge and culture that surrounds them. I’ve been building up my toolbox over the years based on the tools I need to keep my 1930 Ford Model A, 1965 Chevrolet Corvair Corsa, and dozens of various motorcycles over the last few years running, and even doing multiple restorations and race motorcycle builds as well. Over half my life (17 years) has been spent deeply embedded in the automotive world, including obtaining a Batchelor’s of Science in Automotive Restoration from McPherson College–the only 4-year automotive restoration degree in the U.S.

As I responded to another comment with similar thoughts, this article is not calling on people to sell their tools or change the way they do things, but merely a fun way of pointing out that time marches on and technology has advanced a significant amount from when the automobile first transitioned to mass ownership and usage. How we maintain and modify our cars is just as personal as the results and that includes tool choice. Properly used there is no reason not to use these tools if a person wanted to, and I never said there was.

Kyle,

Good article, informative and brings back memories of the tools I have used many times in the past and a few that I continue to use today to keep my classic running smooth. Thank You! As Erik Wagner pointed out, you missed the timing light, I have two, one which is very old, I use for a fast check of timing and a new version for timing, advance timing, checking RPM and a tachometer. The timing light is a valuable tool for me and I use it often.

There will always be someone with a negative opinion and their response is to be rude instead of offering constructive criticism.

Thank you for writing the article.

I won’t be as nice as the author here. Your response makes me believe that your reading ended at the headlines and you never continued past that.

The author conceded that there is a case to be made for these items but that they are not must haves. And I also disagree with you on the commonality of points in even in classics. The advent of drop in electronic ignition systems have made points obsolete unless you are a stickler for correct parts nobody will ever see in their car and actually makes it run more efficiently…

Your rude comments about the authors age and assumed qualifications (or lack thereof) due to his age are unnecessary and honestly detracts from how seriously your opinion is to be taken.

Kieth,

I really wonder what your point is? From one Boomer, I would like to say to you, relax…… Boomerboomer

Harshing up the Mellow…

Haven’t heard that one since most of these tools were new.

Recall the condenser being the culprit many times. I still have my dwell meter and do use it.

Yep

@Robert – The coil is a type of transformer, and the field collapsing in the coil, and the time it is charging is what determines most of the high voltage spark. The condenser helps, and it also reduces arcing on the points. You can get a spark without the condenser, but not as good. Without a coil, you get no more than a 12v spark from the condenser.

Pneumatic tools obsolete? Anyone invested in serious compressor hardware looks at the cost of the lithium batteries and the size of the electric tools compared to the pneumatic equivalents and just shakes their head. The rebuild cost for an air tool is a fraction of the cost of a single Li battery. Having recently purchased Astro Pneumatic’s Big Nasty and Thor, the battery equivalents would be far more expensive, especially down the road. Concerning the older analyzers, they still have some value in measuring aspects of the modern engines if you are creative, as well as still servicing older vehicles.

You make fair points about the serviceability and size of air tools, but as pointed out in the article air tools only makes sense if you are invested in a compressor. A good compressor is a lot of money and space, and can require a decent amount of maintenance. Those Astro tools you called out are really heavy use stuff. Arguably total overkill for at-home DIY maintenance and upkeep. Personally have an electric impact that has 650 ft/lbs breakaway and have yet to find something it can’t undo in over five years of usage. That’s a $250 tool that I can take with me to events, junkyards, or friend’s garages to help.

A decent air compressor is at least $1000. As a long-term investment, maybe. Lot’s of folks don’t have the space or permanence (I’ve had to move my garage and everything in it at least twice until I got lucky enough to become a homeowner with a medium-sized garage.) I’d hate to have to move a 60-gallon two-stage compressor every couple years and hope that the next garage or storage space has appropriate power to run it.

Completely agree. I’ve been working on cars for 40 years, and am restoring a 61 scout currently. I’ve always longed for a compressor, yet, I’ve been doing just fine for 40 years, and the electric impacts and other tools I have from harbor have served me well, been mobile, and kept me in the hobby!

I agree. My not-quite-big-enough compressor struggled to keep up with my impact. My cordless Makita impact has been a game changer. I don’t miss the compressor racket nor the hose limitations.

Overkill till that one time you need it.

Well, that one time I need it, I’ll get a 10′ piece of pipe as a breaker bar and do the job.

I got a pretty goo compressor at Lowes maybe 10 years ago. Its got a 60 gal tank and I installed in the corner of my garage. When I bought it, I think the price was $600 but I went in for something small at the end of the year, maybe the 30th of Dec, and it was marked down to $400 and there was some sort of mix up on the tag and it said $100 off the sticker /tag price. I had to get the manager but I got it for $300 so not too bad a deal. Fortunately I am OK with basic wiring so I was able to wire a 240 line into the garage to power it. Not the world’s best but not bad for most jobs including the spray painting I do.

Great piece, Mr. Smith! I can’t remember how long I’ve had my Sears twinky compressor, but it worked with my C-P budda-budda wrench for tire changes after my $nap-On electric failed. And it came in handy when I had to build a shear wall in Mondo Condo (don’t ask). Now I not only have a nail gun, a brad gun, and a pin gun, but a kind of inside-out gun that punches nails back out of reclaimed lumber!

Oh, and yes, I am fully addicted to battery-operated tools. Hint: CHOOSE ONE BRAND. You can buy additional tools without the expensive battery. But whenever I see the rally guys of the WRC using an electric impact gun on their tires, I remember what they wanted for a new $nap-On battery when mine failed.

I agree I have a 1950 car and these are very handy to have.

Agree with you. My late uncle, who knew a thing or two about cars, died three years ago. My brother and I have his old tools. They are a joy to use and will always have a place in my toolbox and heart.

I agree 100%! I am rewarded with memories of someone everytime I walk into my garage!

have many of these tools and more special sockets for removing thermo vacuum switches ‘ie’ 1975 -1990 veh.

I still have a timing gun. Anyone want to buy it?

Never fails, the day I toss it, the next day I need it…I keep them all.

Spot on, well said, me too.

Re Distributor wrenches: Although I rarely use one for adjusting a distributor any more, those little bent wrenches have proved extremely useful for getting at nuts or bolts in difficult to reach places, and because they have boxed ends, they are much better than crows-feet. Keep them!

I hardly know a bumper from a windshield wiper. I have to pay or beg a buddy to work on my cars. But let me tell you of my one proud moment! In 1967 me an old army buddy went to Jamica together. We rented a Simca car, six cylinder. We were on a empty country road and the car started running rough. My buddy was a banker and knew less about a car then I did. I told him to pull over to the side of the road. Let me look at the engine and see if I can find something wrong. There it was a broken spark plug wire! I looked on the ground and there was a piece of string and twigs. I used a short string to brace the wire and splited the twig to the wire. Wow! It ran great then! When we turned the car back in I told them they needed a new sparkplug wire. The guy said, “I will take two days rental off of your bill for that! Thank You!

In 1969 I bought a new ’69 SS 396 Chevelle. I could hardly get the car to back up. I took it back to the dealer and told them and said maybe the brakes needed fixing. They checked the brakes and said they were okay and never followed up what was wrong with the car. I was mad and took it to a gas station down the road and thought, I will have them check the differencial. They put it on the hoist and said not a drop of anything it never had any in it! I took it back to the dealer and chewed out the service manager. Why, didn’t you follow through your inspection and check the differencial? Its dry! The gas station guy said only the car dealers had the oil for the differencials. Back then the car had a five year 50,000 mile warranty.

👍

On the contrary many of us here still use these tools as we still work on cars with distributors and OBD2.

As for the gap tool we all still should check as not all plugs are gapped correctly even capped.

I couldn’t count the number of new plat and iri plugs that we have to correct the gap on.

I’ve bought spark plugs that have been dropped or just not gapped properly. As long as cars use plugs, you’ll need this.

I agree about at least checking the gap. I have to say, though, that when I use Denso Iridium Power (my first choice for all modern engines), I have not had to change it to the .044″ it’s supposed to be; they seem to be dead-on. However, when I use NGK Iridium IX, or just about any other brand, I do need to tweak the gap a bit to be to spec.

While the picture in the story was of what is now called “sparkplug gap adjuster” I was taught for checking and setting spark plug gap you used ONLY a wire gauge. I still have my Craftsman tool that gets used regularly on my yard equipment. Came with two different size grooved tools for bending the ground electrode as well. I’ve double checked plugs where friends have used a tool similar to the one shown and found their measurements to be off as much as on.

Except Mopars. Mopars won’t run right on Iridium’s except for the minivans and one or two others. At the dealership, we have replaced thousands of sets of Bosch platinums with the correct Champion Copper core to cure driveability problems that started after a “recent tune up”. NGK is also a OE manufacturer on certain engines in the Mopar family. Modern Hemi’s used to run 16 Champion copper cores at least to 2012, maybe they still do, (when I last was in the business.) These are replaced at 30k miles

Yes

I think the title of this article should have been:

9 old tools almost nobody uses anymore, except for most of Hagerty’s customers that own classic cars.

Good one Tom. Totally agree!

Yeah, I found it odd that most of these tools are still used by what I assume to be the very core of Hagerty’s business. “Coil on plug”, “post OBD-II” ? Really? None of the ’50’s & ’60’s cars I know of (and own) have these – Does Kyle Smith actually know anything about classic cars? I’d love to watch him try to adjust timing on my ’60’s GM cars without a distributor wrench 🙂

Hi Tommy. You didn’t include your address for me to drop by and tune up your cars but luckily I recorded this DIY video for Hagerty about adjusting the timing on a small-block Chevy back in 2018 ( https://youtu.be/sATO6kfi_VY ) You might notice my lack of a distributor wrench in that video. I’ve been building up my toolbox over the years based on the tools I need to keep my 1930 Ford Model A, 1965 Chevrolet Corvair Corsa, and dozens of various motorcycles over the last few years running, and even doing multiple restorations and race motorcycle builds as well. Still haven’t found the need to purchase a set of distributor wrenches even after 17 years being involved in the restoration and automotive enthusiast community.

This article is not calling on people to sell their tools or change the way they do things, but merely a fun way of pointing out that time marches on and technology has advanced a significant amount from when the automobile first transitioned to mass ownership and usage. How we maintain and modify our cars is just as personal as the results and that includes tool choice. Properly used there is no reason not to use these tools if a person wanted to, and I never said there was.

That’s one heck of an armchair you’ve got there TommyAZ!

Mikki my exact thoughts why get rid of tools if we all have old cars ?!

This is why we subscribe to haggerty’s……

Spot On

Thank You

I totally agree with Tom. I have saved all my old tools from the 70’s when I started as a mechanic. Assorted Distributers wrenches (10) to fit different engines including HEI GM. These old tools even when broke can be repurposed when in a bind. The only old tool I never liked were the brake pliers. I use all my old tools on my Classic today including my SUN Engine Analyzer. I dedicated Vintage tool box. You can’t replace these tools today!

Except for the split rim tire tools, I own the rest. I still run a points distributor in my 509 cubic inch BBC flat bottom drag boat. Stock points distributor also in my 55 Chevy (482 CID bored and stroked 409 W engine). I’m old school, just the way it is.

I agree Tom!

I agree with Tom. I have all of the above tools except the split rim tool (don’t use them) and the distributor machine (can’t afford one). Of the 5 “fun” cars I own, 4 of them use the rest of the tools except the OBD-II diagnostic tool (no computer in those 4 cars), although I also have that tool. The article reads like we don’t need these tools, but the fact is, I can’t maintain my cars without them. Perhaps, the article should have read “Old tools that are used to maintain our aging fleets.”

How many of you have a bearing scraper in your tool box for poured babbit bearings? I inherited my dad’s tool box which he had been building up since he started in the business pre WW2. When I cleaned out his garage I found a couple of boxes of custom made tools that I probably will never know what they are for but I will never get rid of them.

There is simply no good reason to assume that any new “pre-set” plug has been perfectly gap set AND that the gap has not been affected by shipping and handling. How many brand new 12 volt batteries come defective? I have never and would never install a spark plug in ANY car without checking the gap with the tool that I paid about $5 for 44 years ago. The tool still works and will be fine long after we are all gone.

Not mentioned is that a spark plug gap measuring tool, either the wire kind or the band kind are needed to also set the valve lash.

Don’t forget the tappet wrench to go with it. I have two or three lying around I inherited from my grandfather.

Yup, although I prefer my wire gages to the silly toy in the photo.

and I prefer my feeler gauges.

I have a 1995 z28 that is OBD 1, but has an Obd2 port. I am still trying to figure out what scan tool to buy…

Tech2

I have a pre-OBD scan tool… the problem is that I don’t have the right cartridge for either of my pre-OBD cars – which was the general problem with pre-OBD

I have watched a lot of friends graduate to cordless electric shop tools… and I have watched them play the battery game where the batteries die for the 14V tools and are no longer available, so now they have to go out and get the 18V or whatever the current flavor is, and end up throwing away a lot of perfectly good tools. I am still running on the same air tools I had since I was a professional mechanic, and that has been a while

Distributors are pretty basic devices where I can’t see why you would have to remove them from the car to do any testing

The distributor machine was and is primarily used to set the desired ignition advance curve, including both vacuum and mechanical advance systems. No need to guess as to when maximum advance was occuring because the machine will show you. Especially nice to have when a hotter cam, a bigger carburetor and headers were installed. There’s more to a distributor than what a timing light shows you!

I guess I’m never too old to learn something new about an old tool

Plugs need gap checked. Yeah they are factory set and that’s cute and all but doesn’t account for the banging around they endure before actually getting in your hand! ALWAYS check gap

Absolutely agree with you. This is just common sense, which isn’t actually common.

The key here is that depends on the type of plug. Multiple types of modern spark plugs come pre-gapped and the manufacturer specifically states to not change the gap as it damages the plug.

You are correct, but check all 8. I’ve never had them all be correct. Close, but i prefer exact.

Apparently you do not know that different cars use the same spark plug but require different gap settings for a particular electric system in each vehicle. In 50 years i have come across the R45ts gapped at 35, 45, and 60 thousandths. And now plugs are made in china. The people there have absolutely no idea what measurement systems are used in the states. I feel sorry for anyone who is too lazy to check a plug gap when it is taken out of the box

IF you have the proper tool you will not damage the plug.DO NOT pry on it

I totally agree. How easy to modify, change, and precisely set your distributor, re-install, and rock and roll. Fun!!!

Also needed to set up a dual point distributor. Very hard to set one up without this machine.

Wayne, I couldn’t agree more. It is also possible to check not only the pre- or post-ignition but also whether this is regularly without shocks, which would mean that the centrifugal weights are worn out or are too tight on their shafts due to contamination or thickened fat.

Wayne A Gilmore, which is also important: Dynamically you can see if one or more cams have more wear than the rest. Adjusting timing well to cylinder one does not guarantee that all other cylinders will also get ignition in time. Dynamically, that’s becomes perfectly visible.

Not to mention dist. shaft bearings also.

I agree about the battery run tools.

Yes!!! Air is air. Tool manufacturers want to sell you new tools so they change the battery configurations.

Except for Ryobi, their batteries are backwards compatible to well over 20 years ago.

There are plenty of places like Batteries Plus, that will remake or rebuild a 14 volt battery pack. It isn’t very tough, but it is expensive. It’s probably still easier and less expensive to get new 18V or 20V tools.

Likely never “re-curved” a dizzy.

Then you probably did not Drag race , where you were always rejetting carbs or new intake manifolds looking for hundreds or tenths of a second back in the day.

*distributor

I own a company that repairs tools, both electric and air. I can tell you from experience that when a battery tool needs repaired, no one pays for the repair. The manufacturer builds the tool, and sells the parts, in such a way that it’s not cost effective to repair them.

Pneumatic tools on the other hand are super serviceable. We rebuild anything from a Snap On 1/4″ ratchet to a Chicago Pneumatic 90 pound rock drill.

Toolserviceco.com

True. Thank You

Can’t ignore the cost to buy a compressor, power it, and it’s maintenance.

For anyone who is not a pro mechanic etc working in a shop, electric is the way to go. I have Ryobi stuff that’s 10-15+ years old and gets used a lot more than most others- and is doing just fine. Plus without having a compressor banging away, with it’s maintenance,dryers, etc. Been there,done that.

For the price of a decent 80-120 gallon air compressor, you can get completely tooled up with electrics including wood working tools, chainsaw, car polishers,weed wacker etc etc a few times over.

Dave … How do you air-up tires ? …

I can’t speak for Dave, but for me personally I have been reaching for my Rigid 18v battery inflator more often than firing up my pancake compressor. Quieter, just as quick, and no hose to drag around. Also transports much easier.

Here is a link, though most brands have their own version: https://www.ridgid.com/us/en/18v-digital-inflator-r87044

There wasn’t any battery powered impact wrenches back 30 plus years ago except for small drills, so your option was doing everything by hand or bite the bullet for an air compressor and work efficiently like a professional. And there are many hear like me that worked as a mechanic for a living years ago and were required to own air powered tools, so when we left the trade or retired it was a no brain-er to get there own compressor for their home shop garage.

Now for today’s weekend warrior starting out yeah’ I agree go with battery tools if that fits their needs whether it’s what they grew up with and know and are comfortable with, and then all they’ll need is a small 3 gallon $100.00 pancake compressor for various needs like clearing clogged passage ways whether it be dissembled brake parts – lines airing tires pool toys to blowing sawdust off your pants etc.

I also own and operate a tool and motor repair shop and I will disagree a tad some electric & cordless tools the good expensive ones are cost effective to repair. The inexpensive are not because allot of companies only sell assemblies of items instead of individual parts. they want to sell new tools. Air powered tools such as the ones from harbor freight or any China made are throw aways

I once had a Y-block Ford with dual point distributor – couldn’t get it to run right. It either ran good at low rpm and bad at high or just the opposite not matter what I did with the points. Took distributor to shop with machine – found out shaft bushings were wore out. Couldn’t have found that out without the machine. I was young at the time with little experience (knowledge).

Was a great tool for re-calibrating ignition advance “weights”.

Absolutely, All my air tools work when I need them. Some are nearly 50 years old. They have never died in the drawer. I do use electric tools. I have 6, 4 1/2 angle grinders each having a different tool attached. I cut off all the cords to 6″ long and re-attached the plug. Since I usually had to use an extension cord when I used them anyway, I no longer have the snakes nest of cords to deal with, just one extension cord. I have a couple battery powered tools and just when you need it, the battery starts dying. I like them for many jobs but you have to put up with the battery issues, dying, no longer available, and the cost.

for a while Milwaukee was selling electric power tools with a built in socket you plugged the cord into, so they were easy to store like pnuematic tools. seemed like a good idea that never caught on. I had a sawzall from that era.

Milwaukee made millions of those. Drills and sawzalls and I stock those cords in my repair shop.

The old OBD 1 tools are the ones that use cartridges and had all different kinds of connections. OBD 2 was made out of necessity to make all connections the same. So the Ford would be the same as the Chev etc. You can still buy OBD 1 cartridges. Cheers

Early Ford flatheads most 8/9n tractors had the distributor down in front of the engine. It was easier to remove it for points and other services than try to service it in place. I always thought that was one of the main reasons why shops had the distributor machines back in the early days. I do remember dyno shops in the 60-70s having them for setting up distributors

I agree with TG on the battery tool issue. I have stopped buying them for that exact reason. I bought a 3/8″ battery powered drill with 2 batteries & a charger for $95. a couple of years back. Great tool, but the batteries lasted less than 2 years before they wouldn’t take a charge anymore. The cost of a single replacement battery for the 2-year old drill, when I found one, was $159. I currently use both corded electric and air-powered drills in my shop now.

I use to do propane conversions on school buses. When doing the conversions we had to replace the springs on the weights of the distributor because the the advance curve between gasoline and propane is different. When doing a couple conversions a day having the distributor machine was invaluable.

Hub puller; pickle fork; timing light; etc.

Still have them all! No old car at the moment, but work on my old motorcycle and older boat.

Does anyone still use brake pliers on drum brakes? Used to have a tire iron and we changed tires in the driveway. Used a car to run over the sidewall near the rim to pop the bead on each side, then irons to remove the tire. We’d go to the local gas station ……remember when air was free?

I used to pop the bead on tires with the bumper jack that came with cars from the 60s and 70s. Remember the base of the jack was used to tie the spare tire down in the trunk?

Yes. I do rrmrmber that along with the hook you had to sttach to the bumper.

A buddy of mine and I were many miles off-road and got two flats. We used the spare on the first, but then had no way to fix the second flat. Another camper just so happened to have the correct size tube and a tire lever, but we couldn’t seem to break the bead.

An Apache Indian Ranger helped us out with his bumper jack. He did just as you described, he put the plate on the tire and started jacking. The bead popped off the rim quickly. He saved our butts. Thank you White Mountain Apache Ranger!

Those old bumper jacks were special. I wonder how many times one slipped?

If you look at the base of many bumper jacks, you may notice that one size has a concave radius instead of being straight across. It is specifically made this way so that you can use it to pop the bead loose on a tire. My newest vehicle is an old 2000 Dodge van and the original jack base still has this feature. I suspect that many current USA made SUV’s and light trucks still do as well. I wonder how many people even notice the shape of a bumper jack base, and know why it is made this way? I doubt very many.

A 2000 Dodge van still used a number jack?! I have not seen a bumper jack in a vehicle since the late 1970’s.

Always thought drum brakes are a pain, but I still use my drum brake pliers when drums need serviced. They make it so much easier.

I agree the pliers make the task a bit easier but back when I used to buy $2 of gas at a time, pliers and a screw driver got the job done.

I’ve never owned brake pliers. Vise-grips, needle nose pliers and flat tip screwdriver is how I do drum breaks.

Back when, I had a pal who was doing his brakes with a vice grip on the spring. He was close up, so to speak and when the vice grips slipped off the spring, he managed to take out 2 front teeth.

Craftsman brake spring pliers were the first specialty tool I ever purchased. Still have them today.

*brakes

Yes u people don’t know crappy bout cars these days if something breaks not computer controlled u b screwed now! Ever heard e m pluse, old cars still b running on 10 mins

If we are hit by EM pulses, getting into a car to run for a trip to the store or corner bar will be a waste of time, there will be nothing there any more.

Jetfire … Hope you don’t mind if I get in my old Dodge and have a look for myself …

Good old days. When everyone knew how to change a tire, let alone break a bead and mount a tire. Now it’s just a call to roadside assistance and wait.

Air Free? The Granola Jet Set dont know what “Air” is . They need “Nitrogen” cause the

dealer says so. It is here in Vancouver a cool $ 400.00 to have Nitrogen in your new enviro

friendly 3 ton EV. You must keep in mind that one does NOT wants to be seen at Starbucks,

without the Nitrogen sticker and green valve stem cap, the horror.

For the life of me, I can’t figure out what the advantage of nitrogen is. Air is already 78% nitrogen already. Another 21% is oxygen. An O2 molecule is actually larger than an N2 molecule so the “slower loss of pressure” claims seem dubious. Nitrogen filled tires are still only about 93-95% nitrogen. If you are worried about the small amount of water vapor in air (which has never been shown to really cause a problem), it would be a lot simpler to fill you tires with air from a compressor with a drier than a nitrogen tank.

According to Goodyear, tires filled with nitrogen stay properly inflated longer. This makes them last longer and produces better gas mileage. Racers use them because nitrogen-filled tires give them steady performance during a race. For street driving, you can get just as good results by checking your tire pressure frequently and making sure they’re properly inflated.

What is Starbucks?

Never discard ANY tool. It’s insulting to the creativity that invented it regardless of its age ‼️

I used to help my Dad change tires in our stand alone garage. I can remember the tire irons very well. Pieces of flat iron used to leverage off/on tires. It seems that a lot of people today, refer to their lug nut wrench as a tire iron. I have found that a lot of old terms have morphed into modern use as referring to something else.

You think people aren’t gapping plugs? Pretty much anyone that has a turbo car with the boost turned up substantially had to close the plug gap to prevent spark blow out…

I think they mean as maintenance to close the gap on used plugs.

You don’t need a turbo to have the need to gap plugs.

I’ve been in the industry for over 25yrs. As the GM I occasionally get bored. At those times I’ll therow my shop uniform in and go help my techs. The first time i was helping one install the pre-gapped irridium plugs that I had ordered, i went to toss them in. I knew they were correct because i had been the one to write up the quote and I always check specs. I told him this and he tossed me his gap tool. Two out of eight were correct. The rest were close, but we weren’t satisfied with close.

I just posted my distributor cap wrench on FB.

As Sears was slowly dying, they had a GM distributor wrench on sale for 97 cents.

A ” bargain” that I couldn’t pass up.

(I don’t have any GM vehicles!)

Here’s one for you

Hope I spell this right

A Growler

Helps when rebuilding a generator

As i remember a growler was used to check the armature of a starter-brings me way back

A growler is now a container that you fill up with beer. We used to have our beer in cans or bottles after we used the growler to check and had rebuilt our generators or starters

Strictly FYI, having been in electronic warfare with the Marines way back in the mid-to-late 1970’s, the latest (?) EW platform is the EA-18G Growler.

How about a tripod?

Three pieces of 10’-12’ pipe with a long bolt holding them together and a pulley (for those who didn’t have a suitable tree branch)

or a pair of A-frames.

Funny, I own and occasionally use my Allen Engine Analyzer, Sun Distributor tester, distributor wrenches,and spark plug gauge to set up my vintage cars, and people can’t believe how well they run. The only modern device I use is a AFM gauge driven by a Bosch sensor that is designed to be installed in an exhaust bung on a restomod. Instead I’ve MacGyver’d it to be portable and used in setting up the carbs on all my vintage cars. My friends come over and ask my help setting up their cars. So I guess my tools aren’t so obsolete. Try finding good ones, they come for sale rarely. And, you also forgot my electrical load tester.

I’ve still got several items mentioned from the late 80s. A fancy spark plug gap tool made like a feeler gauge, a dwell meter, a timinglight, a pickle fork, which I still use on newer cars, some old VW service tools and and inductive tachometer made by Stihl around 1990.

I still have my Lincoln 225A AC Transformer Welder purchased in 1978. Very handy, versatile and it still works!

Vjay, I too have a vintage AC 220 stick welder I bought at (wait for it) MONTGOMERY WARD! In about 1976 I think. Still going strong after all these years. I’ve welded more stuff with this machine than both my MIG & TIG combined. Even some sheet metal stuff like lawn mower decks.

Those things mever die!

Dwell meters actually can measure the duration of the spark in time and shape due to the L R C time constant inherent in the ignition coil, condenser, and resistance of the plug itself, (resonance) allowing optimum spark duration relative to piston travel thru TDC…

Why wouldn’t you keep these items if your interest is classic cars? They will always be necessary (hand tools) when working on “old iron”.

I have NEVER bought a spark plug that has been gapped correctly. I use my gap tool all the time. I never trust the manufacturer to do anything right. Always double check

I don’t trust the parts guy to not drop the box of plugs on the floor before they get to me.

Hope you align the electrodes too.

All these tools will be back in use as the old ICE cars will be on the road for many years to come.

EV are over priced and have no range in cold weather or extreme heat.

There is a Tesla station in the same lot as my local gas station.

When I pull up to fill up my Jeep CJ 6 ( I have a 25 gallon tank fitted) I get on my PA and announce I am filling up and I am going to have enough gas for 300 miles, after about 5 minutes I get back on PA and let them know I am on my way with 300 miles of gas in my tank,

They just look at me with dumb founded faces.

Piss off Tree Huggers we want the open road and the FREEDOM of the ICE

BUY OLD CARS NOW !!! stock up on parts.

When the charging station quits working they are going to call a diesel mechanic to fix the diesel powered generator that’s powering the charging station.🤣

I’m with you Leroy. Keep your old cars and stock up on the parts.

Hahaha I love that the verdict on pretty much every tool is “keep”

Kyle is an automotive hoarder like the rest of us! The week after you throw something out is exactly when you will need it!

Guilty as charged. Culling some of the parts from the shelves in my garage has been on my to-do list for…..3 years. I moved houses in that timeframe and still didn’t get rid of anything.