Media | Articles

7 tips for cleaning car parts

Of all the unsexy projects and tasks that comprise the step-by-step of any project or restoration, cleaning the parts and pieces while everything is apart tops the list of most un-fun. It’s a necessary evil though and a little attention to detail at this point goes a very long way in the final product. There is no sense in “saving time” by leaving everything dirty and dealing with grease and grime working its way back into places it shouldn’t be and causing you to do the task twice.

Cleaning can be simple as wiping off some schmutz and as involved as soaking a bunch of little parts in a solution overnight before a thorough scrubbing. Regardless of how deep you need to clean, here are seven tips that will make sure your final product is one to be proud of.

Start soft

Start with the easiest and safest form of cleaning first. This often means a wipe with a clean towel or rag to see just how bad the situation really is. Sometimes just a clean rag is a enough to remove everything that needs to go and leave the surface in acceptable condition. Otherwise it will tell you just how bad it is and what the right course of action might be.

Glove up

This isn’t an article about safety, but it bears a mention here. So many chemicals used in automotive processes are quite hazardous or damaging to the human body–and it might not be immediately evident. For example, brake cleaner is very common to use to remove oily residue, but it is also very rapidly absorbed by the skin and carried in the bloodstream to the liver where it sits, and sits, and sits. Our organs cannot process chemicals like carb or brake cleaner and therefore it just accumulates and can cause long-term health issues. Disposable nitrile gloves keep fluids and chemicals from being absorbed and while they can be inconvenient at times, but then again so is having to show up to dialysis on a regular basis.

Use the right stuff

There is a huge array of chemicals on the shelves of your local parts store or grocery market that claim to remove the nasty grime with a spray and rinse process. Sometimes those work easily, other times it causes chaos. One such example is a product like Simple Green, which is very useful to cut grease, but can leave residue on aluminum surfaces and cause corrosion if not rinsed thoroughly.

Marketplace

Buy and sell classics with confidence

The same goes for rubber pieces. Warm water and a light detergent is often the best solution to prevent rubber from distorting, discoloring, or getting eaten up by aggressive solvents. On the other side oven cleaner can work miracles on cast iron pieces that have tons of baked-on grease and can only be chipped away with aggressive wire brushes before a water rinse. Match the product and process to your material for best results.

Be careful with your finish

A key thing to remember when cleaning is what the final surface finish will be. If you are painting or otherwise covering the part it might not be a big deal that there are some scrub marks or a less than perfect surface finish. If you are painting or polishing the piece though, suddenly you want to exercise a lot of caution while cleaning so that any marks that happen during cleaning don’t pop through or create more work to remove later.

A steel wire brush on soft aluminum is a prime example of something that can wreak havoc quickly. Plastic or brass bristles are much softer and will prevent scoring or damaging the finish and save you work in the end despite taking a little longer to actually remove grease and grime. Even a green Scotch-Brite pad can be too much for some rubber pieces, so be sure to check in an inconspicuous area to see if your plan will leave marks of damage before going to town scrubbing.

Hide the evidence

Dry or wet blasting are easier than ever with home kits available and cheap enough that its not out of the ordinary for someone doing enough restoration work to make the investment to having a cabinet. The key to remember if you are so lucky is to make sure to blow out or rinse out all the blasting media from the nooks and crannies of whatever gets cleaned up. Having that sand, walnut shell, aluminum oxide, or glass bead pop out while painting or assembling is frustrating at best and downright damaging at worst.

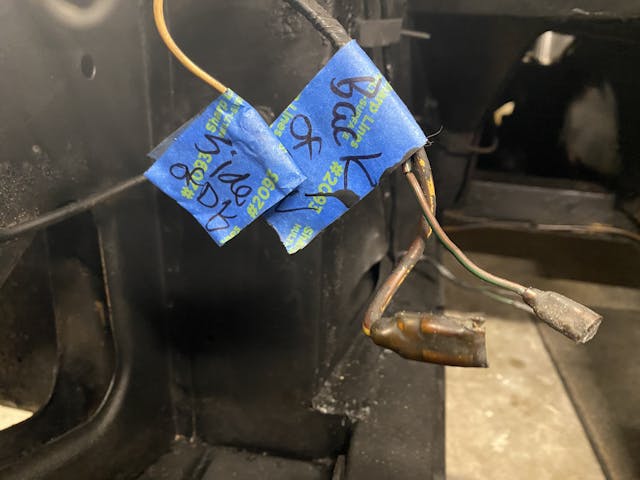

Careful with the tags

It’s important to not ruin the proper bagging and tagging of all the parts and pieces you did during disassembly when you go to clean everything up. If you have tags be sure they stay legible or be sure to transfer them after the cleaning is completed doing it piece by piece. If there are adjustments that you have to remove to fully get something clean–think carburetor adjustment screws or adjustable suspension components–be sure to document the adjustment so you can use it as a ballpark during reassembly.

Under pressure leads to failure

It’s really tempting to toss that working transmission or rear axle in the truck and take it to a car wash and use the high pressure nozzle to blast away the grease and grime quarter-by-quarter. Be careful though. Many of the gaskets are not made to withstand the high pressure pinpointed in one little area and can quickly fail and allow water and soap to flood inside and cause rust, corrosion, or leaks from the damaged gasket.

If a soap-and-water wash is required often times the best course of action is to use nothing more than household hose water pressure. That pressure is low enough that it is safe for gaskets and seals while still getting things clean. It does mean you will spend more time scrubbing, but would you rather scrub or replace gaskets due to damage?

While tedious and oft annoying, cleaning your project will make for a much more satisfying assembly. Take the time to make every project something worth showing off and being proud of and it will elevate your DIY confidence far more than you might realize. Have a tip not on this list? Leave it in a comment below.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it.

I’m always looking for something that is a couple of notches up from what I have on hand for tough cleaning (such as suspension parts, third-members, and other under-car parts with decades of buildup on them). In the “old days”, one could buy solvents that, to my knowledge, just aren’t available today. Guess it’s an environmental thing.

One thing that didn’t use to be much considered – but is important to think of nowadays – is disposal of cleaning agents, especially those that contain other contaminants that you have cleaned off of parts. I don’t need help with selecting Dawn dish detergent for some tasks, but I’d like to see some guidelines on what chemicals are out there today for REALLY tough cleaning, and proper disposal suggestions for those products!

Have you tried simple green products?

Simple green will attack aluminum unless you use the right one. Personally I think it’s crap. Try using dawn dish soap, I know it cleans my hands when they are greasy.

My ‘87 Trans Am has the factory polished rims. There is no clear coat or sealer on them. I spray them one at a time with Simple Green , scrub it then rinse thoroughly with water and dry. I immediately put a heavy coat of paste wax on and then do the next tire. After all are waxed I then wipe the wax off. The water marks disappear completely. Works well for me every time. I clean them once every year like this.

I often use my Ultrasonic cleaner and have had great success with a 50/50 mix of Simple Green and Distilled Water, then a hot water rinse afterwards.

But after reading the above “Sometimes those work easily, other times it causes chaos. One such example is a product like Simple Green, which is very useful to cut grease, but can leave residue on aluminum surfaces and cause corrosion if not rinsed thoroughly”

Now I’m wondering what else I could use in my ultrasonic cleaner instead of Simple Green? Any suggestions?

In your ultrasonic cleaner, fill the tank with plain water and put your part you want cleaned in a heavy-duty plastic bag, add some gasoline to the bag and seal it. Run your ultrasonic cleaner as normal.

I use a mix of Oil Eater and water in an ultrasonic parts cleaner with success. https://oileater.com/industrial/cleaners-degreasers/original-formula/

The Oil Eater is fairly aggressive, perhaps more so than Simple Green, works better at grease removal. In my experience it has not damaged aluminum parts. I run them in the ultrasonic cleaner for 15-20 minutes, remove immediately and rinse with tap water.

Simple Green Extreme Aircraft and Precision Cleaner is what you need. Safe for aluminum, rubber and plastics.

Purple Power. No special disposal required. Works great. Cheap.

The purple power itself is not toxic, but the dissolved oils and grease are extremely harmful. Need to dispose properly at your municipal household hazardous waste depot. Not for rednecks.

Super Clean is by far the best APC I have ever used and very inexpensive. Normally a 5×1 mixture will clean

most parts, carpets, wheels you name it

The absolute best overall and at the same time safe cleaner on the market is called S100 Motorcycle cleaner.

I have used it since 1983. Just spray it on, let it sit while getting a water hose ready. Spray it off with a sharp stream of tepid water. Some times a little scrubbing on heavy deposits may make the job easier but this product makes cleaning a pleasure.

The cleaner by itself might not be hazardous / toxic, but the dissolved oil and grease and grime is 100% hydrocarbon.

Interesting point. I actually hadn’t thought about that previously.

Tractor Supply Company sells solvent for the parts washer. Crown PSC 1000 Parts Cleaner,5 gal. PSC1000MOS. $44.99 plus tax. This stuff works great, the water base degreaser is garbage.Don’t forget Gloves and safety glasses.

Steel wool comes in many grades that vary in abrasion level so choose wisely before starting. Using multiple levels of abrasion can be useful in some applications.

Good point. The ultra fine (0000) grade is great for chrome. But anything coarser will scratch it pretty badly.

Even 4- 0000 steel wool will scratch chrome so be very careful. I always use a mild metal polish and use the steel wool if you are so inclined, the polish will cut down on the damage that steel wool caused .

I have my bumpers etc rechromed to show chrome which is a wonderful result but it’s also somehow softer. The owner of chrome shop uses Sprayway or Windex to show how nice his work is or if there is dust on it with a microfiber towel. The next time you are at a car show look at the chrome closely and you will find someone with show chrome used steel wool or something else to clean , it will always leave scratches .

Use cotton. Towels to polish chrome, not microfiber towels. Re-Tire by Pacfic Products to clean grease, Tires, carpets, metal parts, leather upholstery and more. There are no chemicals in this product, all natural mixtures. I have used it on all these thi gs with the best of results.

Bronze wool, available at marine supply stores, is softer and less damaging than steel wool.

Also available on Amazon. A great alternative to steel wool for anything which could be scratched by steel wool.

“New” chrome IS not as durable as the “old” stuff. The old stuff was hexavalent chrome. No longer allowed in most States (if at all), plus a more toxic process so most chrome shops no longer use it.

0000 is good for windshields, water spots on glass & mirrors, etc. Be careful if you use on chrome.

For even finer work, use bronze wool. Softer than steel and the little bits left behind won’t rust. Marine supply shops should have it.

How have I made it this long not knowing bronze wool existed? Going to find some of that this weekend. Sounds nice to have around.

Bronze Wool (or even better sometimes, Brass Wool) is the greatest!

Great article.

Another tip regarding oven cleaner is to NOT use it on aluminum parts. It can be very corrosive and damage the finish.

I also like a bowl-type vibratory cleaner with Walnut shell for fasteners and small brackets, etc. Things look “still clean” instead of “just cleaned”.

A guy I met in Portland bought a used dishwasher for $30 on craigslist. Hooked it up to an on-demand water heater he got from a plumber who had removed it from a house being remodeled. I think he paid about $25 or so for it. He uses only low-sudsing liquid detergents with it, so it leaves no particle residue. Cleans the thickest gunk off of the parts before washing. Immediately after taking the parts out, while still warm he does a misting light machine oil spray or WD-40 to deal with remaining surface moisture issues or immerses more complicated parts in a bucket of light kerosene (or something) and lets them dry on a rack. Doesn’t clean all his parts with it, but as a final cleaning agent for a bunch of them, he says it does a pretty nice job. Told me he got the idea from a local transmission shop that uses a hot water/detergent commercial parts cleaner in its shop. I don’t know where he exhausts the dirty water, but apparently not into his septic tank. Never tried it myself, but it sounds quite plausible for someone with a fairly large shop.

I’ve heard of folks using “retired” dish washers before, but this is the best description of the process I’ve seen. It was always the flash rust that made me nervous about the idea, but it was never too big of a deal since I’ve never had the space for a dish washer in my shop anyway. Maybe one day.

An even better product than WD-40 or oil for rust protection is Break Free CLP. Available on Amazon in drip bottles or spray cans, it leaves a semi dry film that provides excellent rust protection.

Break Free CLP can also be found in the firearms department of most sporting goods stores and Walmart.

Some dishwashers recommend connecting a cold line water as they pre-heat the water internally before they run.

Be careful with simple green, it has a dulling effect on Aluminum and will dull paint. I used it on chassis of my car that had a nice finish from the factory. I noticed the finish became blotchy and dull. Took many applications of 3M swirl and scratch remover to take most of that out.

Simple Green does/did make an aircraft safe (aluminum) variant.

Yup. We used simple green as a substitute for stoddard solvent when it came out but then found it was corrosive on aircraft. https://www.amazon.com/Extreme-Aircraft-Precision-Cleaner-13406/dp/B001VXU7OE/ref=asc_df_B001VXU7OE?tag=bngsmtphsnus-20&linkCode=df0&hvadid=80195748927862&hvnetw=s&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4583795276202187&psc=1

I actually love cleaning parts. It’s a bit therapeutic. As per your points, as long as you are using the correct solvents and you are protected with gloves and eyewear you work away without having to think too much. And then there is sometimes that wonderful discovery that something is way better than you thought. The best part is that it means you are now past year down and into restoring. It’s a milestone! Keep scrubbing!

I also find cleaning and inspecting parts quite therapeutic. It also allows time to find things

that I might have overlooked by being in a hurry.

Hey, for my next cleaning project, wanna come by? I pay with beer

I feel the same way about firearms.

Atta Boy Robert!!!

And of you drop a tiny part and can’t find it you can shoot yourself!

Nuts and bolt cleaning is made easier with a good set of Thread chasers / cleaners. Got a Lang set for Christmas best present I got this year.

Good comment on chasers. I have often used a tap which is not a great idea for when only a chase is needed

On chrome besides using the variety of steel wool 0000 grade etc – I have also used coke and tin foil it really does clean the rusty chrome and leaves a nice shine all I did is use a clean cloth and wipe off the water i used to rinse off, when I was done. If you are cleaning other engine parts that have surface rust I have soaked it in coke over night then washed in dish detergent and rinsed in water and dried air dry. once dried applied a little WD40.

Loni, have you ever used bronze wool (boat supply companies)? It cleans chrome w/o scratching

chrome like steel wool. Tin foil is great too!

Haven’t heard of bronze wool before but will be looking into it now! Thanks for the heads up.

Good advice here; I didn’t know about Simple Green vs aluminum, though perhaps that’s because I rinse it well. I personally dislike having greasy or sticky or painted hands, so the cheap nitrile gloves are a Godsend. (Being a bit of a clean freak, I rarely have to deal with greasy or caked-schmutz parts, but I was taught to respect my hands.) When I have to disassemble an electrical system, I’ll draw a schematic if tagging seems insufficient, even though I have a shop manual for everything I own (which is a good double-check anyway).

Sometimes warm water and a microfiber towel is all you need. Sometimes Dawn helps.

In lieu of Coke, try white vinegar.

Apple cider vinegar works great for removing rust

I had a big jug of the cider vinegar only because it was extra in the house. Maybe its my imagination, but I think it derusts better than white vinegar. I could be crazy…ask my wife.

I bought a used Renegade parts washer several years ago! It saves a lot of time and is great for doing transmission cases and other large and small parts!

I use a mix of materials. Carb cleaner, Brake cleaner where appropriate. I have a pressure washer that I use often on my engine compartments and under chassis. I have never had a problem with electrical malfunctions, ever. Some of my cars I have had since new, now more than 30 years. Their engine compartments are sparkling. I use Simple Green Motorsports degreaser, as it doesn’t spot alloy or polished surfaces. Also, the Simple Green, and my pressure washer does an excellent job on rear axles. Again, no failures of gaskets, or any other part. I have found that proper maintenance, keeping things clean in the engine compartment and free of blow by oil, makes components last for decades, rather than a few years.

I tried something new for my last project, Dry Ice Blasting. AMAZING and very clean. All dirt/grease gone, no moisture residue. I did the undercarriage of one car, and a motorcycle in total. The frame paint was left intact, (but paint could be blasted off, if requested) surface rust gone, the alloy surfaces, even inside the fins, clean as factory fresh. Expensive, but worth it. I would use this process on any parts that can withstand pressure spray of the dry ice crystals.

Be careful with Simple Green, one formula attacks aluminum.