6 Final-Assembly Tips for Your Project

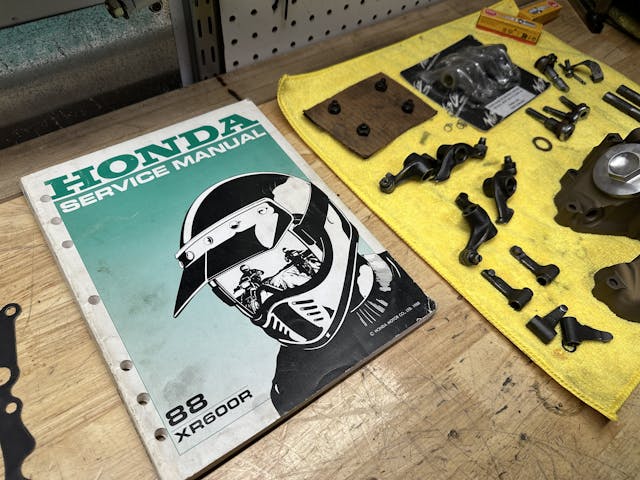

Anyone who works on cars likely has a favorite point in their projects. We might not even realize it, but there’s usually some task or process that we look forward to most. If we didn’t, well, we wouldn’t be doing this. For me, the tedious task of final assembly is one part I very much look forward to, and the engine of my 1988 Honda XR600R has finally reached that point. Here are six tips I’ve discovered that help me enjoy the time even more.

Understand your finishes

It’s likely that at least some of the parts and pieces to be assembled were painted, coated, polished, or otherwise finished in some way. Having to chase threads after a manifold or cover has already been installed is a pain at best and a cause for reversing course and disassembly at worst. Ensure all the parts are actually prepared for assembly before beginning.

Spread out

Final assembly is not the time to try to cram your work on just one corner of your workbench with a bunch of other stuff piled all around. It’s best to be able to look at all the parts before you, with nothing hidden in a pile to be found five steps too late. Create a nice open space where you can focus on the task at hand rather than trying to ensure you don’t topple the pile that belongs to your next project.

Keep your reference close

In that newly found space, make sure your shop manual or computer takes up residence within arms reach. Even with projects I’ve done a dozen times, it is nice to have a reference to eliminate second-guessing. Being able to check and confirm makes the whole process more relaxing and often a little quicker.

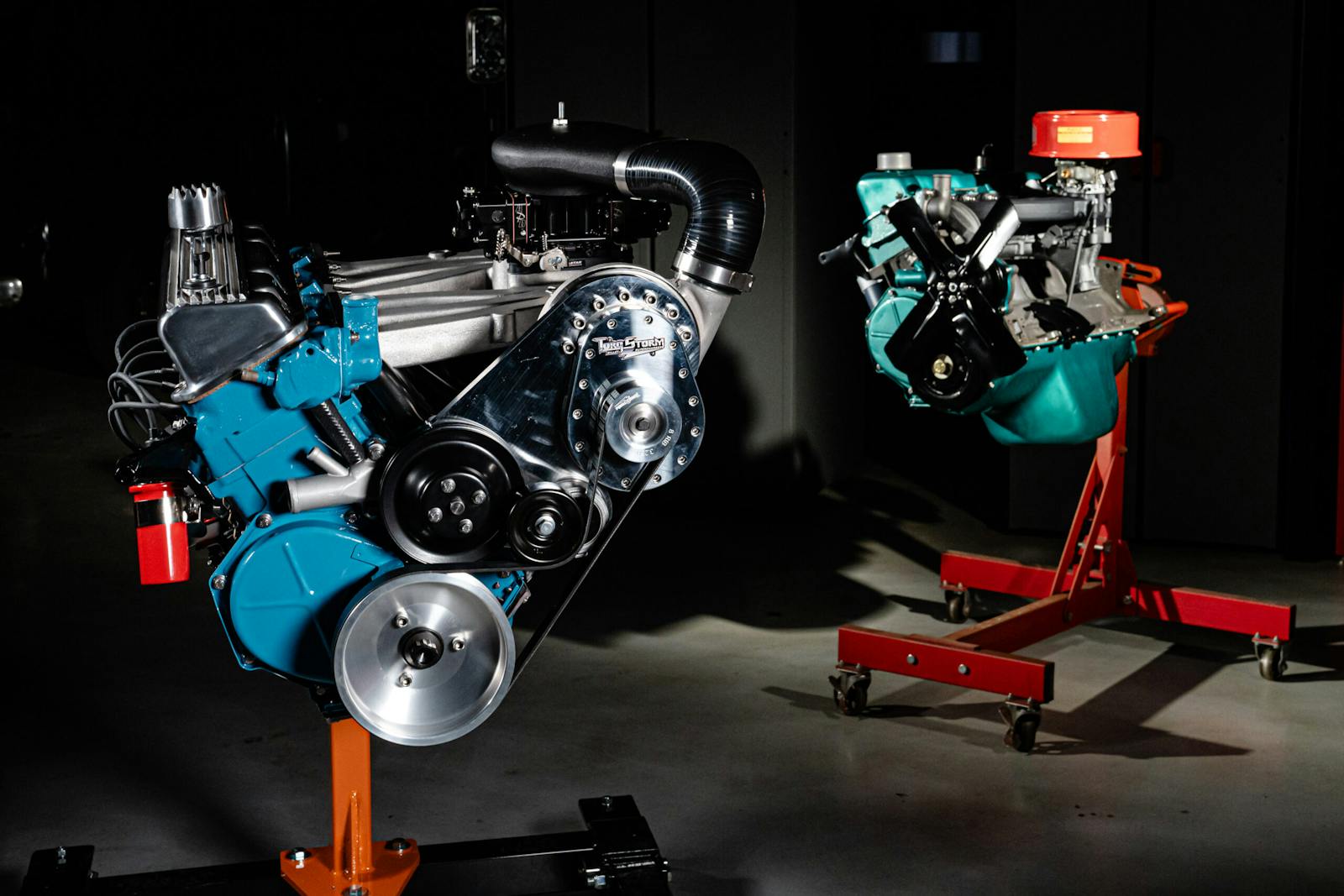

Use sub-assemblies

My XR600R engine has taken a year to evolve from the 14 boxes of parts that arrived in my shop to something that resembles the heart of a motorcycle. It came together in manageable sub-assemblies, each of which provided a nice sense of accomplishment as each was completed. The cam cover is a prime example: The rocker shafts, rockers, and more all needed to be carefully fit before the whole thing was carefully fitted to the cylinder head. I choose to tackle the assemblies one at a time. The clutch cover came together the other night—checking fit and double-checking all the appropriate seals ensures that when it mates up to the big thumper I’ll only have to do the job once.

Practice being lean

Space is at a premium in every shop, especially with a project blown wide open. That means storing a bunch of new bits and pieces is likely more of a hassle than it’s worth. Large manufacturing often functions on a “just in time” strategy to make the best use of space and materials. This means buying what you need in batches and having it arrive when you are ready for that task, no earlier. Often this means finishing one thing before moving to the next, but it also keeps me from tying thousands of dollars up in a half-done project, making it difficult to pivot if an opportunity comes up.

Keep it clean

It goes without saying, but letting dirt and grime into your project is counterproductive. You started this project to solve an issue, not to create more work for yourself, and putting dirty parts back together just gives you one more thing to take up your time. Keep any parts that are waiting for assembly covered or sealed to prevent other goings-on in the shop from getting them dirty. Just driving a car into my garage can put a surprising amount of grit into the air if the wind is going in the right direction, and it’s not worth having to step backward and re-clean parts I’ve already prepared or assembled.

The last about clean is very important. Not just dirt but anything that should not be inside the engine.