Media | Articles

6 Cutting-Edge Innovations We Now Take for Granted

While it may seem like the car has been unchanged for decades at this point, with only bold new shades of gray and larger screens creating selling points and “value” for would-be buyers, the fact of the matter is there has been so much innovation over the years. However, much of it is taken for granted because just about every driver on the road today has little understanding of just how far the automobile has come. To provide a little perspective, here are six parts of a car that were revolutionary when they first debuted, but are now so common that they go entirely unnoticed.

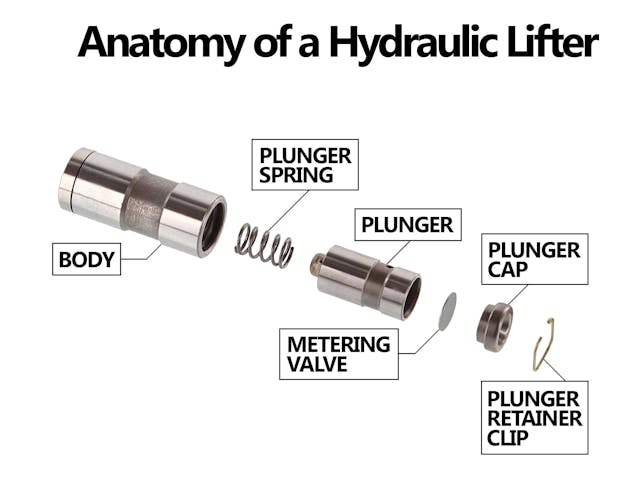

Hydraulic lifters

The way a lifter works by interacting with a camshaft to transform rotary movement into reciprocating movement is an under-appreciated aspect of an engine in my opinion. The forces, tolerances, and speeds involved are often difficult to grasp. Tolerances between the pushrod, rocker arm, and valve stem are tight enough that there needs to be a part that can take up the expansion and contraction that comes with the difference between cold and running temperatures.

Hydraulic lifters take that space up to help keep wear down and also make for a smoother and quieter-running engine. They are powered by the oil pump and hold oil pressure in them. Some lifters can leak down while in storage and make quite the clatter on startup until oil pressure builds fully. It is a price worth paying for not having to get the feeler gauges out every few oil changes.

Insert bearings

The many rotating parts inside an engine all need some type of bearing surface to maintain proper friction or lack thereof. When cars were overbuilt, it was common to pour the bearings into the block and connecting rods, making large and relatively soft bearings once machined to final dimension. It’s a time-consuming process though, and requires a lot more material than a comparable insert bearing.

The insert bearing is a much thinner shell of similar material that snaps into the engine block to create the perfect surface for the crankshaft to spin in. They’re also much easier to assemble than poured bearings, which is always appreciated.

Marketplace

Buy and sell classics with confidence

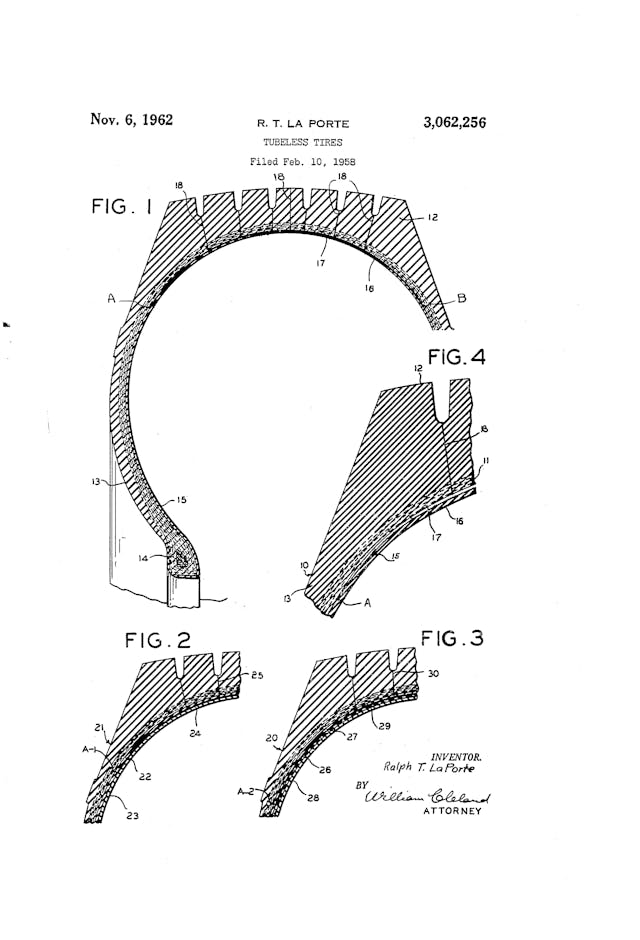

Tubeless tires

Modern tires are amazing; More durable with more traction than sometimes seems physically possible. The durability of a tire with no inner tube is a given these days, but certainly wasn’t always. Tubeless tires have been the standard since the mid-1950s, though the idea had been attempted earlier than that. The materials and design did not really work until the mid-1940s. The fact that tubeless tires only took a decade to become standard should say a lot.

Platinum spark plugs

Platinum and other rare earth materials changed the ignition world with their durability. Previously, the metal of choice was copper, which would erode from the arc and would often wear out in just a few years of regular driving. Platinum or iridium plugs, on the other hand, can last up to 100,000 miles.

Longer service intervals, and to a point separating the driver and mechanic into two people, were a side effect of better materials and processes being used during production. Modern cars can go tens of thousands of miles without even opening the hood, and that is mainly thanks to modern ignition systems and oils.

Cruise control

The concept of a self-driving car has likely been around since the second drive of the first car, although even a century later, that has proved to be a difficult problem to solve. However, engineers were able to at least remove one part of the equation and make long drives easier by having the vehicle hold speed on its own.

Early automobiles like the Model T Ford have cruise control baked in by how the machine operates; the throttle is a lever on the steering column that does not return to idle unless the driver moves it. Now systems incorporate a rife of sensors that not only hold the throttle input steady but also match that to vehicle speed and engine load which can make for a much more relaxing road trip.

With how interconnected the systems of modern cars are, cruise control is a matter of software today, not hardware. That usually makes it cheaper to incorporate on cars, which is why it’s now standard pretty much across the board. Once a luxury, now commonplace.

Disc brakes

Brakes are all about the relationship between friction and heat. More friction makes for quicker stopping but also creates more heat that needs to be dissipated. The wooden block pressed against a steel-rimmed wheel didn’t create a ton of friction, but it was better than nothing. Drum brakes were a massive step up, but disc brakes are the clear winner when it comes to balancing the two forces noted above. With modern materials, we have continued to evolve the design to the point that disc brakes are the standard on everything from economy cars to race cars at the 24 Hours of Le Mans.

There are certainly more, so tell us what you think is an amazing piece of technology that often gets overshadowed in modern cars. Leave your favorite in the comments below.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Pierce-Arrow introduced hydraulic valve lifters for 1933 in both their 8 and V-12. Regarding piston rings, don’t forget the finer tolerances in modern engines, improving metallurgy, and the cheapest motor oil of 50 years ago vastly better than the finest available in the ’40s.

A Texaco engineer told us in the late ’70s or 1980 that the black molybdenum/graphite chassis grease that replaced the orange fiber grease used into the ’70s was a factor of eight times better. It was first used in massive trucks in the hellish environment of stone quarries.

Pierce-Arrow introduced power brakes in their 1928 models. A Pierce engineer came up with the first power steering in 1926, but it did not appear until the ’51 Chrysler Imperial, in all Cadillacs for ’52.

Oldsmobile and Packard both introduced automatic choke for 1933. Chrysler used Warner Gear overdrive beginning in 1934, several years before the rest of the industry. The last generation Pierce-Arrow 8 & V-12 came standard with Warner R-1 overdrive, 1936-38. No GMobile offered overdrive ’til the ’55 Chevy, which V-8 development was overseen by Al Kolbe, who had previously worked on Packard’s 1932-39 V-12, as detailed by Don Sherman in the Hagerty article https://www.hagerty.com/media/automotive-history/chevy-small-block-the-little-engine-that-did/

Chrysler engineers brought a wrecked ’49 Cadillac ambulance into their lab, copied the new ohv V-8, same bore-stroke, bore spacing, compression but added hemi heads enabling 20 more hp but using regular gas instead of the Cad’s premium.

A perusal of 120 years of auto history shows a steady progression of refinement, tho’ to the chagrin of many of us who like d r i v i n g, a chief foci has always been on separating the motorist from that act.

This meandering overview brought to you by overpopulation’s resulting traffic limiting occasional romps in my immediate prewar authentically powered dragon to before 9am weekends.

Cruise control though on some cars is getting worse with paranoid radar cruise control systems that see your impending doom two blocks away you were never going to run into. I pretty much use good old regular cruise and skip the radar cruise. I think i know better than the computer what is going on in front of me.

Can’t argue with any of your selections. I would add air bags.

Except when the airbag throws shrapnel at you. OK so that’s not happening as much lately.

I HEARTILY disagree on airbags… They CAUSE injuries that COULD have been avoided… I got a concussion from a passenger side (I was driving) one, in a Honda FIT. Got zinged on RR by a woman running a light… I was securely belted in, and had no other injuries, but got serious headaches and other probs from that ^&$$@### airbag. Found out later,that Honda actually issued a recall, later on. NOPE, don’t like ’em – FASTEN YOUR SEATBELT… and make sure it’s TIGHT.

What about synthetic oil, easier starting and less wear especially in cold weather. And a call out for rtv for replacing the old rubber gaskets at the ends of intake manifolds.

You Gota add fuel injection and electronic ignition to the list; and paint. My 2002 envoy has sat out most of its life and the paint looks almost new ( under the dirt).

Clearly some rings are just bad. My 84 Olds 307 got a complete rebuild in 2017. On a 2019 trip to KS, the check engine light was on and off. When I got home the head gaskets and valve trains needed replacement. One side was warranted the other leater in 2022. By April 2023, time for smog check the #7 piston had collapsed. Another rebuild. Part quality was the determined issue. Hardened connecting rods replaced the old ones. The car runs much better than the 2017 rebuild. I will keep my fingers crossed and tightly on the wheel. I still stayed with the hydraulic Comp roller cam and rockers. It passed smog after de’tuning the crap.out of it. Thanks to The Arnold killing the Rolling 25 rule in Kommifornia.

I vote for Fuel Injection as being the major contribution to more reliable motoring.

Wow, Y’all have missed one of the biggest…Automotive Glass !!! Major Improvements

Glass has come a long way, great point!

Effective HVAC systems.

10’s of thousand of miles without opening the hood today? My car still needs an oil change every 5,000 miles or so.

Yours might, but some modern cars have 10,000-mile oil change intervals.

Electronic ignition. No more points, condensers, distributor caps, dwell meters.

Hoses are FAR better- mine are 15 years old and perfect!

Exhaust systems- same thing- 15 years and perfect!

Spark plug wires- again- 15 years and perfect!

All of the above used to be constant headaches “back in the day”

Go back to beginning with driving 30’s model vehicles and have seen many that got little past 20,000 miles before signs of burning oil with already great cylinder wear from ring wear. Up through the 60’s 100.000 miles on a set of rings was considered great. with the newer technology and better fuel mixtures of electronic fuel injection it is not uncommon to see engines well over 300,000 miles still running original rings. Today the problem lies more in auto weight vrs. displacement of engine. Trying to cram 300 H P out of a tiny 4 cylinder makes increased pressures in those cylinders. Even lower powered small engines in those heavy rigs they power are usually operating at max pressures and creating also more in cylinder heat which can damage ring seal. Super light pressures designed for race only engines are a totally different subject as they are not used in normally driven engines.

Intermittent wipers should be on this list. Driving a car in the past on bias ply tires with one speed wipers in the suburbs of Vancouver BC was a right of passage when I learned to drive.

No one has mentioned the metallurgy advances making exhaust system last forever. Used to need a new one every two years. Now one can sell a car after 15 years with the original exhaust.