Media | Articles

6 Cutting-Edge Innovations We Now Take for Granted

While it may seem like the car has been unchanged for decades at this point, with only bold new shades of gray and larger screens creating selling points and “value” for would-be buyers, the fact of the matter is there has been so much innovation over the years. However, much of it is taken for granted because just about every driver on the road today has little understanding of just how far the automobile has come. To provide a little perspective, here are six parts of a car that were revolutionary when they first debuted, but are now so common that they go entirely unnoticed.

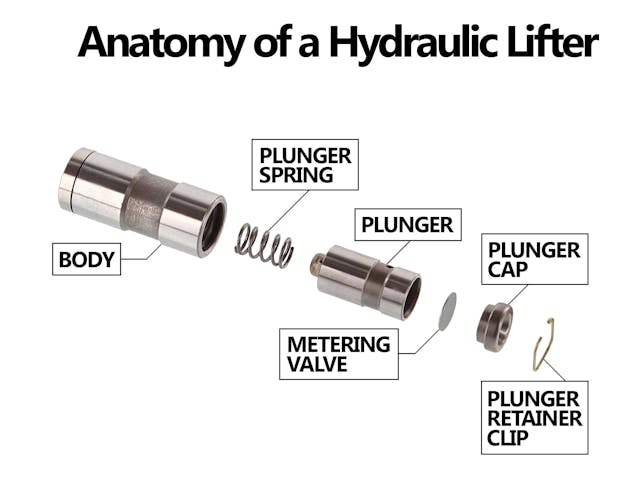

Hydraulic lifters

The way a lifter works by interacting with a camshaft to transform rotary movement into reciprocating movement is an under-appreciated aspect of an engine in my opinion. The forces, tolerances, and speeds involved are often difficult to grasp. Tolerances between the pushrod, rocker arm, and valve stem are tight enough that there needs to be a part that can take up the expansion and contraction that comes with the difference between cold and running temperatures.

Hydraulic lifters take that space up to help keep wear down and also make for a smoother and quieter-running engine. They are powered by the oil pump and hold oil pressure in them. Some lifters can leak down while in storage and make quite the clatter on startup until oil pressure builds fully. It is a price worth paying for not having to get the feeler gauges out every few oil changes.

Insert bearings

The many rotating parts inside an engine all need some type of bearing surface to maintain proper friction or lack thereof. When cars were overbuilt, it was common to pour the bearings into the block and connecting rods, making large and relatively soft bearings once machined to final dimension. It’s a time-consuming process though, and requires a lot more material than a comparable insert bearing.

The insert bearing is a much thinner shell of similar material that snaps into the engine block to create the perfect surface for the crankshaft to spin in. They’re also much easier to assemble than poured bearings, which is always appreciated.

Marketplace

Buy and sell classics with confidence

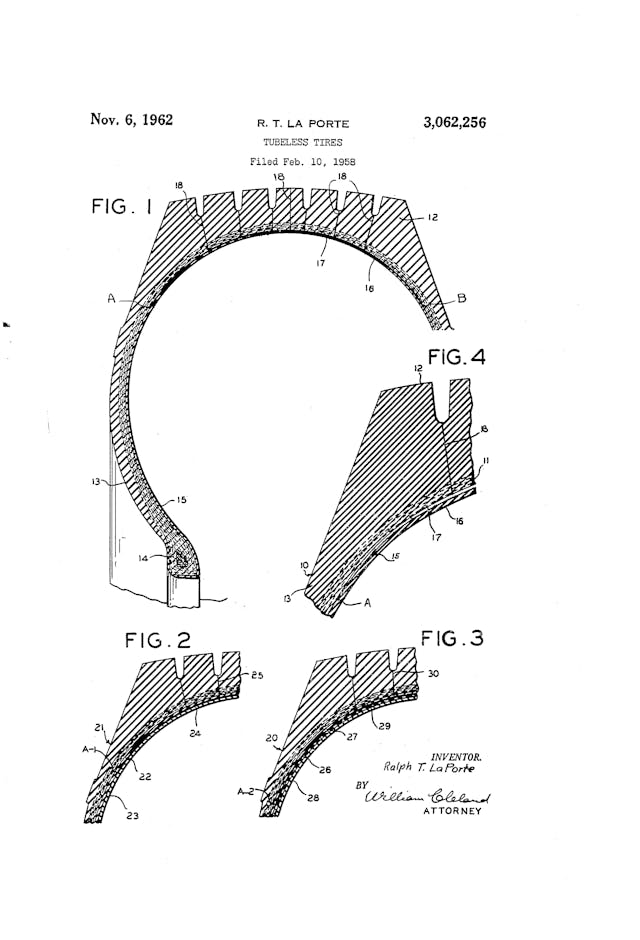

Tubeless tires

Modern tires are amazing; More durable with more traction than sometimes seems physically possible. The durability of a tire with no inner tube is a given these days, but certainly wasn’t always. Tubeless tires have been the standard since the mid-1950s, though the idea had been attempted earlier than that. The materials and design did not really work until the mid-1940s. The fact that tubeless tires only took a decade to become standard should say a lot.

Platinum spark plugs

Platinum and other rare earth materials changed the ignition world with their durability. Previously, the metal of choice was copper, which would erode from the arc and would often wear out in just a few years of regular driving. Platinum or iridium plugs, on the other hand, can last up to 100,000 miles.

Longer service intervals, and to a point separating the driver and mechanic into two people, were a side effect of better materials and processes being used during production. Modern cars can go tens of thousands of miles without even opening the hood, and that is mainly thanks to modern ignition systems and oils.

Cruise control

The concept of a self-driving car has likely been around since the second drive of the first car, although even a century later, that has proved to be a difficult problem to solve. However, engineers were able to at least remove one part of the equation and make long drives easier by having the vehicle hold speed on its own.

Early automobiles like the Model T Ford have cruise control baked in by how the machine operates; the throttle is a lever on the steering column that does not return to idle unless the driver moves it. Now systems incorporate a rife of sensors that not only hold the throttle input steady but also match that to vehicle speed and engine load which can make for a much more relaxing road trip.

With how interconnected the systems of modern cars are, cruise control is a matter of software today, not hardware. That usually makes it cheaper to incorporate on cars, which is why it’s now standard pretty much across the board. Once a luxury, now commonplace.

Disc brakes

Brakes are all about the relationship between friction and heat. More friction makes for quicker stopping but also creates more heat that needs to be dissipated. The wooden block pressed against a steel-rimmed wheel didn’t create a ton of friction, but it was better than nothing. Drum brakes were a massive step up, but disc brakes are the clear winner when it comes to balancing the two forces noted above. With modern materials, we have continued to evolve the design to the point that disc brakes are the standard on everything from economy cars to race cars at the 24 Hours of Le Mans.

There are certainly more, so tell us what you think is an amazing piece of technology that often gets overshadowed in modern cars. Leave your favorite in the comments below.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Safety glass is probably a good invention that has saved a lot of pain and injury. What is wrong with this web site with the ‘posting too fast’ nonsense?

Windshield washers and rear window defrosters. My dad’s bare-bones1964 Pontiac Tempest had neither. And let’s not forget all-season radial tires, which eliminated the need for snow tires in winter on practically all cars (with the notable exception of higher-priced performance cars for people who can afford two sets of wheels with winter and summer tires). Oh, and fuel injection!

“Copper” plugs did not have copper electrodes. All plugs have copper in them. The update was in the electrode material changing to platinum disks from some form of alloy or steel, which made them last longer. Its a common misnomer to call the old plugs “copper” when in reality they are all still copper with different more durable electrode material.

Multiple airbags. Safety is most important. Touch screen distractions a problem.

All steel bodies.

Having witnessed a unibody Toyota Corolla sedan demolish then dislodge the body-on-frame Chev Impala V8 at a recent Rodney Fair, I would say that we should include the unibody design in this. Just don’t know who to thank.

The Model T throttle holds a constant throttle position. A cruise control holds a constant speed. Those are two vastly different things. When you drive a Model T on anything but a flat road (which I do for about 2000 miles a year) you are constantly moving the throttle to keep a constant speed.

Hmmm! For two out of the six:

Studebaker was one of the first – if not the first – mass-production cars to have insert main bearings. About 1931, if my sometimes fuzzy memory serves me correctly this time.

Studebaker was also the first North American car to have modern disc brakes as standard equipment – on Avantis. They were optional on any other of their cars. That was for the ’63 model year. Before Corvette!!

1949 Crosley beat Studebaker being both a NA manufacturer and standard equipment. They used not only modern type disc brakes on the front but disc brakes on the rear so it was one of the first vehicles with 4 wheel disc brakes. They were adapted from a Goodyear airplane design and used hydraulic actuation. Unfortunately, there was some severe corrosion issues due to salt on roads and salt not being used around airplanes, the parts just didn’t last long and it was abandoned in subsequent model years. I also saw that 1949 Chrysler Imperial had 4 wheel disc brakes standard but they didn’t use a caliper. That system is a disc of friction material like a clutch that clamps to metal rotor.

That’s all true, but l said “modern disc brakes” to denote a design that had the engineering integrity to be integrated into the mainstream industry on a “permanent” basis .

The Crosley discs were only hydraulic on the front (rod-actuated on the rear) and both the Crosley and the Chrysler deployments of disc brakes had issues to cause their makers to abandon them very quickly. They were just brave experiments that needed more work, like Reo’s automatic transmission and Chevrolet’s copper-cooled engine.

My 1940 Cadillac has a rudimentary cruise control–a wired-to-the-carb, independent-of-the-throttle cable that leads to a pull-out on the dash which when activated holds the throttle open.

Cup Holders?

How about knock sensors that allow timing instantly to adjust according to load and boost and improve fuel economy. And what about tire pressure monitors? And, have we forgotten about turbochargers? And, oh yes, how about the computers that make all of the above operate seamlessly?

All of these “Innovations” are at least 40 years old. Do we take them for granted? Do we take centuries-old alloy metals for granted? Sheesh, this article is really reaching for “innovations”. Iridium spark plugs are more of an innovation than platinum as they will often last 100k miles, twice as much as platinums did.

Not having access to Hagerty’s style book, I can’t say if the writers are obliged to translate dollars from 75 years ago into today’s inflated dollars — but the comparison is clearly flawed. My 1949 Suburban which sold for less than $2,000 doesn’t really compare to today’s $75,000 Suburban with all the features highlighted in this article. In ’49 the Suburban didn’t even have a radio, heater, turn signals or LED lights much less the alternator to run them! The bearing were poured and yes, I set the valve lash and point gap.

Let me throw in the dual master cylinder? Now if you blow a brake line you just may live a little longer.

And speaking of safety, how about airbags, 3rd brake light, collapsible steering column, seat belt, hazard lights, and padded dash?

I despise TPMs…. They get flakey, and are VERY expensive to replace… the parts are relatively inexpensive, but one must usually break the tire down to change ’em… a PITA, except for stupid little girls.

And speaking of safety…..how about the airbag, 3rd brake light, collapsible steering column, seat belt, padded dash, back-up lights, and 4-way flashers?

PLYMOUTH and DODGE had the 3td. brake light in the 40s… my beater ’47 Ply had one – a great idea, but NOT new.

Spark plugs’ life has been greatly extended due to the use of unleaded gas. Remember replacing all 8 every 10 to 12 thousand miles. Now, it’s only 4 or 6 never (because you sell the vehicle and let the next poor person pay to have an engine pulled to get at them).