Media | Articles

6 Cutting-Edge Innovations We Now Take for Granted

While it may seem like the car has been unchanged for decades at this point, with only bold new shades of gray and larger screens creating selling points and “value” for would-be buyers, the fact of the matter is there has been so much innovation over the years. However, much of it is taken for granted because just about every driver on the road today has little understanding of just how far the automobile has come. To provide a little perspective, here are six parts of a car that were revolutionary when they first debuted, but are now so common that they go entirely unnoticed.

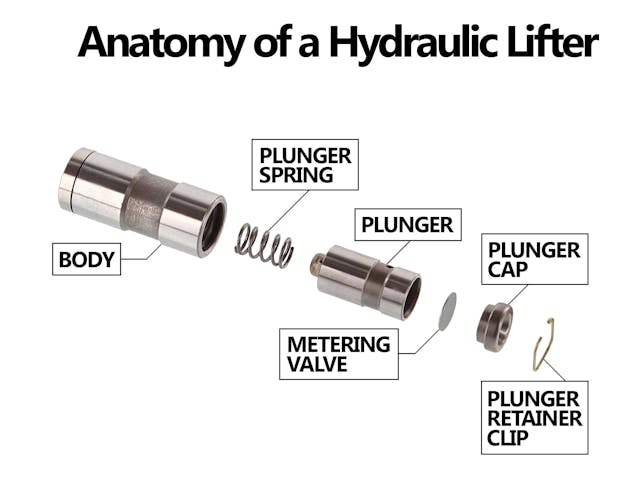

Hydraulic lifters

The way a lifter works by interacting with a camshaft to transform rotary movement into reciprocating movement is an under-appreciated aspect of an engine in my opinion. The forces, tolerances, and speeds involved are often difficult to grasp. Tolerances between the pushrod, rocker arm, and valve stem are tight enough that there needs to be a part that can take up the expansion and contraction that comes with the difference between cold and running temperatures.

Hydraulic lifters take that space up to help keep wear down and also make for a smoother and quieter-running engine. They are powered by the oil pump and hold oil pressure in them. Some lifters can leak down while in storage and make quite the clatter on startup until oil pressure builds fully. It is a price worth paying for not having to get the feeler gauges out every few oil changes.

Insert bearings

The many rotating parts inside an engine all need some type of bearing surface to maintain proper friction or lack thereof. When cars were overbuilt, it was common to pour the bearings into the block and connecting rods, making large and relatively soft bearings once machined to final dimension. It’s a time-consuming process though, and requires a lot more material than a comparable insert bearing.

The insert bearing is a much thinner shell of similar material that snaps into the engine block to create the perfect surface for the crankshaft to spin in. They’re also much easier to assemble than poured bearings, which is always appreciated.

Marketplace

Buy and sell classics with confidence

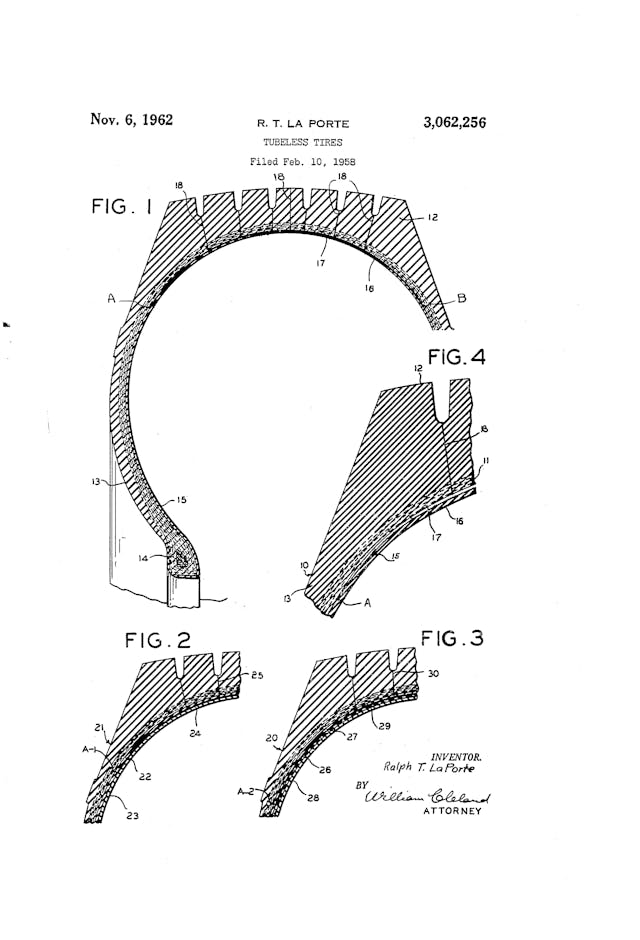

Tubeless tires

Modern tires are amazing; More durable with more traction than sometimes seems physically possible. The durability of a tire with no inner tube is a given these days, but certainly wasn’t always. Tubeless tires have been the standard since the mid-1950s, though the idea had been attempted earlier than that. The materials and design did not really work until the mid-1940s. The fact that tubeless tires only took a decade to become standard should say a lot.

Platinum spark plugs

Platinum and other rare earth materials changed the ignition world with their durability. Previously, the metal of choice was copper, which would erode from the arc and would often wear out in just a few years of regular driving. Platinum or iridium plugs, on the other hand, can last up to 100,000 miles.

Longer service intervals, and to a point separating the driver and mechanic into two people, were a side effect of better materials and processes being used during production. Modern cars can go tens of thousands of miles without even opening the hood, and that is mainly thanks to modern ignition systems and oils.

Cruise control

The concept of a self-driving car has likely been around since the second drive of the first car, although even a century later, that has proved to be a difficult problem to solve. However, engineers were able to at least remove one part of the equation and make long drives easier by having the vehicle hold speed on its own.

Early automobiles like the Model T Ford have cruise control baked in by how the machine operates; the throttle is a lever on the steering column that does not return to idle unless the driver moves it. Now systems incorporate a rife of sensors that not only hold the throttle input steady but also match that to vehicle speed and engine load which can make for a much more relaxing road trip.

With how interconnected the systems of modern cars are, cruise control is a matter of software today, not hardware. That usually makes it cheaper to incorporate on cars, which is why it’s now standard pretty much across the board. Once a luxury, now commonplace.

Disc brakes

Brakes are all about the relationship between friction and heat. More friction makes for quicker stopping but also creates more heat that needs to be dissipated. The wooden block pressed against a steel-rimmed wheel didn’t create a ton of friction, but it was better than nothing. Drum brakes were a massive step up, but disc brakes are the clear winner when it comes to balancing the two forces noted above. With modern materials, we have continued to evolve the design to the point that disc brakes are the standard on everything from economy cars to race cars at the 24 Hours of Le Mans.

There are certainly more, so tell us what you think is an amazing piece of technology that often gets overshadowed in modern cars. Leave your favorite in the comments below.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Piston rings as good as we have today. Years ago it was common to re ring an engine. That was why so many cars at Indy carried ring sponsorship.

Vehemently disagree about modern rings. They are horrible, to say the least. Low tension rings have been the bane of engines last 15 or so years. Worked for Volvo for 15 years, independent shop last 10. Low tension rings, one part of the mandatory fuel milege recipe mandated by the EPA, have much less friction. That is why so many modern engines, from all makers, have oil consumption problems. Couple that with many cars not having dipsticks, lots of trashed engines from running low on oil. Many under 100k might burn 1 quart between 1 to 2k miles. You won’t see the smoke, but it also destroys the catalytic convertors, which are not cheap. 2k plus for them, especially if built into the exhaust manifolds. I remember the fix for Volvos was replacing the rings and or pistons, with normal rings! It is the 50s and 60s all over again as far as rings are concerned. My 89 Saab 900 Turbo, 220k, and 89 Volvo 240 wagon, 350K with normal rings, hardly use any oil at all. FWIW

Respectfully disagree.i grew up in the 70 s.it was common for an engine to need a rebuild at 80-90,000 miles. If I car made it to 100, 000 miles it was ready for the junkyard. With the Advent of chrome moly rings cylinder taper was much less apparent and it’s not uncommon for engines to go 200 or 300 thousand miles without needing major work.

I totally agree with you. l grew up in the 70s as well and my old 73 Dodge had 100,000 miles on it and it was done engine wore out and rusting to pieces. Later on in life I had a 2002 Chevy Silverado that I used as a work truck and put close to 300,000 miles on it before I traded it. Never did anything to the engine but an alternate r and the guy that bought it drove it for a couple more years.

I agree with EK. As a GM dealer technician for the last 20 years, and working at a machine shop in the late 90’s I’ve seen my share or piston rings through the years. The 70’s and prior wore out, by the late 80’s they were lasting pretty good. Late 90’s and early 2000’s were awesome and rarely had any ring issues. Then came low tension piston rings…no longer do engines last like they did or not use oil. We’re a relatively small dealer and we have 5 vehicles waiting on engines. We rarely replaced engines in 2005. Just sayin

Another vote for EK. How do I know? I have been the sad owner of two 2011 Honda v6 engines. In both cases the oil control ring issue was concealed through use of a secretive TSB until the extended warranty was expired.

It’s not unusual for a well look after Toyota to do 500ks or even a lot more from year 2000 onwards without even having the cylinder head off.

Funny, my 2009 matrix burned 1.5 quarts/1000 miles before 100K. Regular oil changes all its life. All mfg have issues with the low tension rings on some engines.

Agree with Tim

Agree fully. My 1998 Civic had 267k miles on the ticker when I sold it. Had my mechanic fully test the head gasket before I sold it. They said they put pressure on the cylinders in the AM and by lunch no pressure change. Over lunch they drew a vacuum and in an hour the vacuum held. Never burned oil either. Can’t say that for any of my Subaru’s!

Well my old 2014 silverado with its LV3 direct injection motor has 346kms and it never uses oil between its 6k oil changes,.neither do either of our buick 3.8 series 3 cars,. The only vehicle that uses oil is my 95 chev pkup 5.7 engine and by the time its down 1 liter of oil its time for an oil change at 6000k So i think you have different experiences than i do.

Gaskets and sealing in general. One of the reasons why modern engines rack up the miles they do is because we have gotten a lot better at keeping fluids where they belong

Great point!

You need to share that information with BMW.

It would not help! I’ve owned one BMW, an R1200RT Motorcycle. I had more things go wrong in 70K miles than most of my Yamaha bike have in 150K miles. My car is a Mercedes Benz, so it’s not a German thing, just BMW.

Dump it and get an older “airhead”… I have an’83 R100/RS,,, used to be an R80/RT… got bigger jugs, carbs and the RS front end… it goes and goes and goes… nothing breaks on an “airhead”

I was speaking more to the inability of BMW to keep oil inside its engines. I have a 2007 530i with 150,000 miles. So far, an oil pan gasket, two valve cover gaskets, and both profile gaskets on the oil filter manifold.

That would be at least $3,000 in repairs if I wasn’t able to do them myself. (The oil pan gasket is particularly onerous.)

Except BMW, at least the older ones I drive where the gaskets and cooling system parts need routine replacement. I’ve never figured out why they haven’t solved this problem as others certainly have.

Except for Subaru. Have spent $5k on head gaskets on 2/3 cars. And now have valve guide seals leaking which requires yet another head gasket. Why didn’t the DEALERSHIP replace the valve guide seals when they did the first head gasket job?

Electronic ignition systems and coil on plug tech, replacing distributors and all of the failure prone parts and wires. The serpentine drive belt, with continuous tensioner, replacing the nest of slipping drive belts. Struts / dampeners replacing short lived shock absorbers. LED lamps (all over the vehicle), and even silicone wiper blades. Comparing my first car in the ’70s to my current ones, it seems like regular maintenance (replacing all sorts of parts) is now just changing fluids.

I disagree with this serpentine belts being an improvement, one belt running everything instead of being able to get home if you loose the ac belt, or power steering….no limping a car along when everything stops working.

In approximately 1.5 million miles, I’ve never had a serpentine belt failure. Can’t say the same for V-belts.

The only serpentine belt issue I have experienced was on a 1986 Bronco, after a year or so it would start to squeal. I replaced that belt 2 or 3 times before I sold that vehicle.

I agree that the ignition system advances are a big leap forward. I am a Triumph owner, and my club does clinics every winter. One clinic is all about ignition system upgrades. Our tech gurus all recommend installing electronic ignition systems.

When it comes to sealing. After years of getting those SKF bearings ( at first for my skateboard ) and then later the obligatory accompanying CR seals one day I wondered – ‘What does CR stand for anyway?’ Chicago Rawhide. That shows you how long they’ve been around and how far we’ve come.

That’s an interesting tidbit of info!

My daughter works at an outfit that distributes oil seals and related. Her comment: “CR has turned into SKF- we have to special order the leather or felt seals into the US- They aren’t very popular.” Small wonder!!

Electronic fuel injection has been the major improvement responsible for today’s gas mileage and performance gains. Unfortunately it sometimes leaves us old-timers and back yard mechanics scratching our heads.

Touch screens – NOT It looks cool on the showroom floor but you must take your eyes off the road to use them.

I agree on touch screens. Distracted driving is a traffic violation almost everywhere yet are in virtually every new vehicle. Should auto makers be liable if you get a ticket or are involved in an accident due to distracted driving while using a touchscreen? Just a thought.

Pulling into a Toyota dealer to buy some OEM hoses (correct bends), I was decended upon by “The Vultures” (salesmen)… when I asked… “Got anything without a TV in the dash?” It got really quiet… Yep, they’re a BLATENT DISTRACTION, and should be REMOVED.

Agreed. Have you noticed how many accidents we now see are now rear enders? Distracted driving is at fault the majority of the time. Take the screens out of cars NTSB!

SOOOOOOO true

Hum, guess none of you guys are old enough to have to tune a car radio manually or change 8 track tapes or cassettes. I personally find steering wheel control switches and touch screens take much less time with eyes off the road than the stereo system was in my 67 Galaxie.

sorry Mike, i find that hard to believe. a touch screen demands you take your eyes off the road for an “extended” period of time while you navigate screens. the old analog radios, you need to glance at the radio while your hand finds the tuner knob, and your eyes remain on the road while tuning…..

Fuel Injection; old concept that didn’t really work until the digital revolution (blast it’s dark soul!!) and of course emissions/CAFE standards enfod it’s development and universal application. As an old skool guy, I can’t work on it (and managed to crisp my first aftermarket set-up (initials F.T.) for an extra $350!! Carbs are weird and crude, but require no electronics beyond the choke heater — usually. Still, if you’ve ever tried to put a Honda CCCC carbureted system right (110 vacuum hoses, no number codes printed on the replacement ones that Greasy Gus put in a while back!) you might long for F.I. — or a Seppuku knife! Wick -he’s old!

Radial ply tires, invented by Authur Savage of firearms fame.

I remember back in the 1970’s, my company had a big push on driving safety because we had a fleet of cars for our service people. They sent out an “Automotive engineer” to talk to us about different safety advancements to assist us in driving safer. One thing he stressed over and over was those new “Radio Ply Tires” Yes RADIO! His primary thought was that they gave better gas mileage. Most of us stopped listening to him after that.

We’ve come along too late for self-starters and windshield wipers, then?

If we’re going back that far, we might as well throw in electric lights.

Some other parts that are not visible but have made a big difference in engine performance and durability are roller lifters for pushrod engines (which drasticaly reduce friction and extend camshaft life). Also powder metal connecting rods, which are much stronger than cast iron rods and cheaper to manufacture. How about cylinder heads with four valves per cylinder instead of two? Allows more airflow at higher rpms for more power. Tuned intake manifolds with motorized baffles in the runners to optimize air flow velocity at different speeds and loads. Hypereutectic alloy pistons, which are much stronger and more heat resistant than cast aluminum pistons, which makes them well suited for today’s high output engines. Anti-friction polymer coatings on some OEM piston skirts to reduce the risk of piston and cylinder scuffing after a cold start or if the oil runs low. Higher static compression ratios (up to 11 to 1 on many engines, and some even higher!) for more power and better fuel economy. Or engines such as Infiniti 2.0L VC_Turbo that has a variable compression ratio that changes depending on engine load and speed. We can’t forget multi-layer steel (MLS) head gaskets that essentially last forever (no more blown head gaskets). Also turbochargers, which are very common now and make little four-cylinder engines perform like a much larger V6 or even V8.

Anti lock brakes and traction control.

Power Steering. So nice on heavy duty trucks.

Best innovation by far is the Remote Start to run my heater in the cold Michigan winters. Live in the ice and snow and you’ll understand! You can have your cruise, PW/PL/P-seats, delay wipers, Pano Sunroof…etc. Just give me my Remote Start!!!

I would say the catalytic converter is totally overlooked. The number of cars in the road since these were factory installed in vehicles since 1975 has multiplied by 3 or 4 times. Without it we wouldn’t even be where we are now. It’s possible that cars would have been legislated off the roads completely due to gross pollution. Then we all would be writing in about putting Cragar SS wheels and white letter tires on our buck-boards.

Fred I owe you a coke – we were totally on the same wavelength at the same time!

I would say that the number of cars on the road since with these installed since 1975 is greater than a factor of 3 or 4, since the number on the road at the point they were first factory-installed was zero. 🙂 That humor aside, even expressed as a percentage of vehicles driven (or even more so as miles driven), I would bet that the number of miles driven by autos without cats today is very small even compared to total miles driven by all autos in 1974. What few pre-’75 cars are on the road today are surely driven far less than they would have been as daily drivers back in their day.

Lump together all of the improvements made in the name of cleaner emissions, and it’s massive. 1,000x less.

“More friction makes for quicker stopping but also creates more heat that needs to be dissipated.” The heat generated by the brakes is directly related to the speed and mass of the car, nothing else.

What about deceleration rate or pressure exerted on the pads against the rotors. More pressure = more friction = faster rate of deceleration = more heat

For Earth day I’ll toss in the catalytic convertor.

Reduced emission impact and better efficiency – ingenious!

The ‘Schrader Valve’ tire valve stem, or some slight variations thereof, was found on nearly every wheel of practically every model and make of automobile for about a century. (Bicycles, motorcycles, and trucks as well.) Perhaps the basic design has seen changes in relatively recent times with the development of TPMS (tire pressure monitoring systems), but on the outside, it still seems much the same valve.

Wish I could insert a photo here of my antique Schrader “Balloon Tire Gauge.” It has lots on machine engraving with various patent numbers, and identified as being manufactured by ‘A Schrader’s Son,’ Division of SCOVILL MFG.CO. INC BROOKLYN NY USA.

I HAVE one of those old Schrader gauges… It’s about 3/4″ in diameter, and about 3″ long…. My Uncle gave it to me, off the farm… silly thing still works!