Media | Articles

5 bits of race-car flair to elevate any engine bay

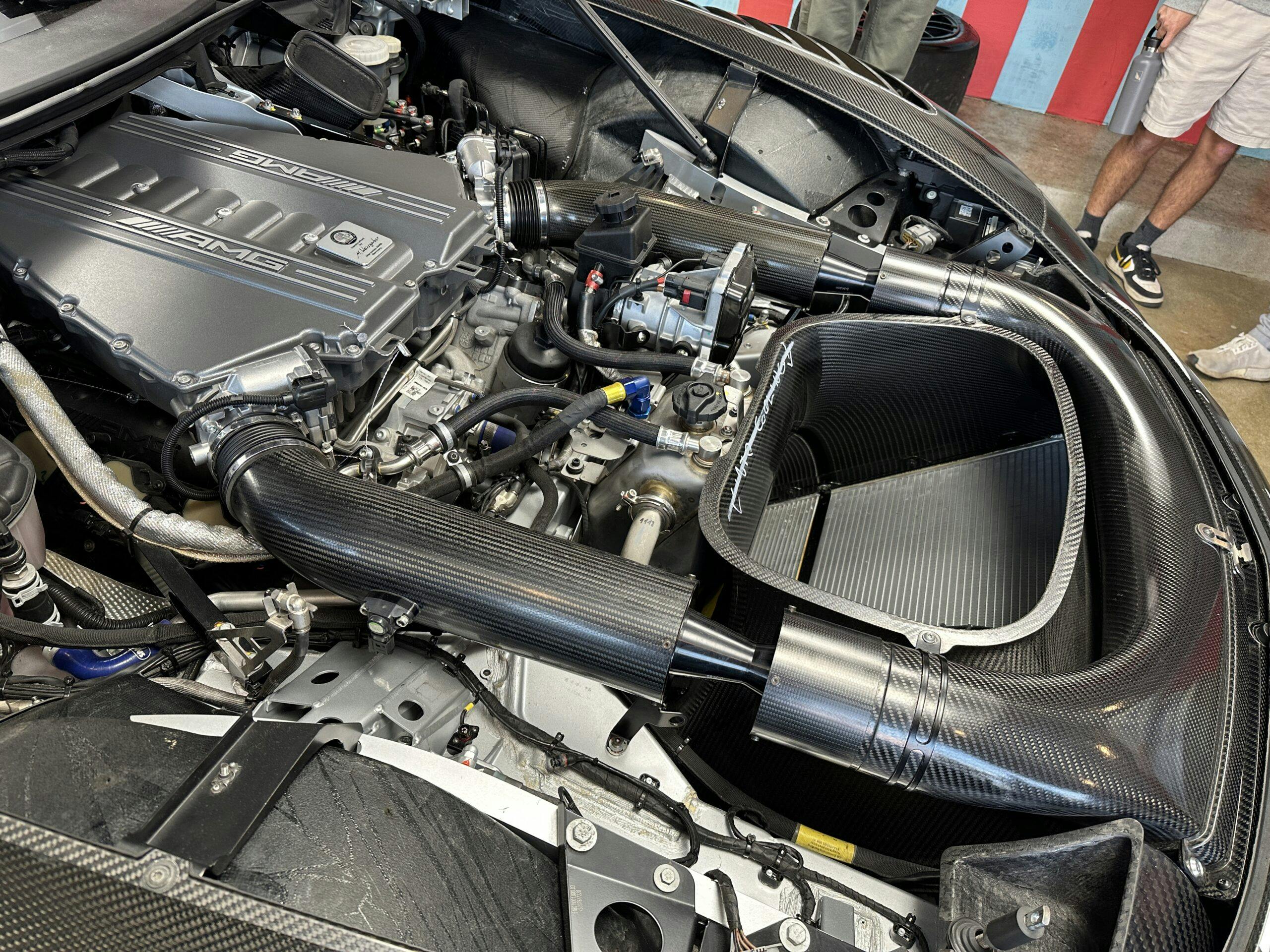

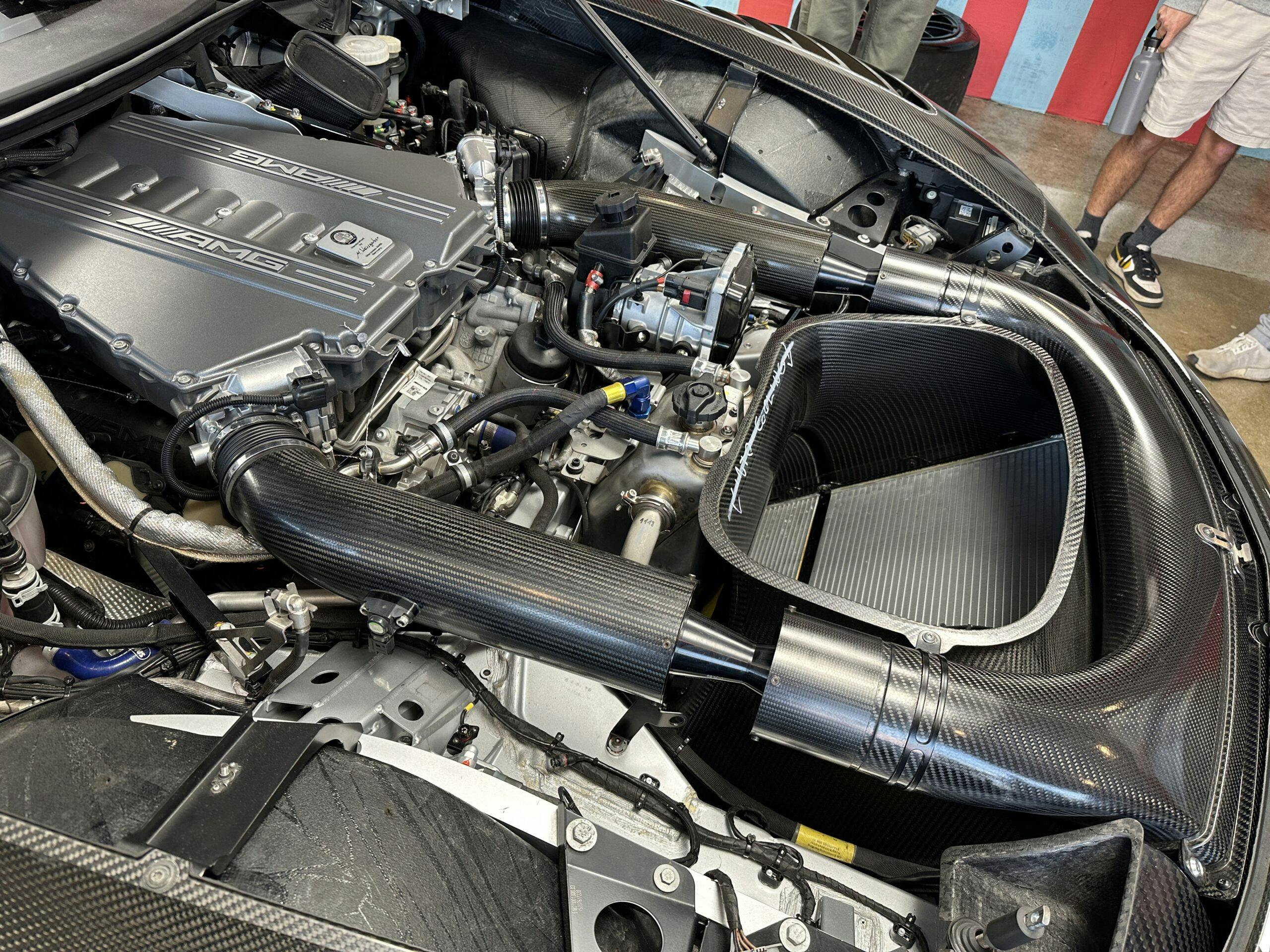

There is something about the prioritization of function over form in the engine compartments of most race cars that turns the spaces into art. Any detail-loving person can appreciate them, but especially DIY and at-home mechanics: These engine bays are often the antithesis of what we usually get to work on. Race machines are built with service in mind, and that focus removes a lot of frustration for the mechanic. (If you’ve ever broken a dozen plastic clips opening the access panel to do an oil change, you know what I mean.)

In the engine bays of race cars, function becomes attractive. With that in mind, I took a look at a few projects around my garage and found some cool bits of flair that give off just the right motorsports-inspired look.

Tidy organization

Engine compartments can be busy, with hoses and cables going this way and that for various pumps and control modules. In race cars, engine bays are laid out system-by-system, and this arrangement lends itself to a more thoughtful installation that maximizes function while minimizing space. In short, the engine bay is all tidied up.

Organizing your car’s engine bay, whether or not it’s a race car, can be as simple as bundling wires into a proper loom or shortening unnecessarily long hoses. For my Corvair, tidying up meant removing the mechanical fuel pump and re-routing the fuel lines to remove clutter on top of the engine. This required very minimal fabrication: Though the four carbs might appear complex, they are mirrored side to side, allowing me to flip the stock fuel lines. Everything fits like it would from the Chevrolet factory, and I only had to put two 90-degree bends in a $10 generic steel pre-flared fuel line.

Safety wire

Since safety wire is the last step in any project—and one I am excited to do these days—just the presence of wire in the right place means a checkmark on my checklist. No need to rack my memory: If there’s no wire, the component is not ready —and I need to figure out why I left the job unfinished.

Science says a properly tensioned bolt will rarely loosen, but some positive retention of critical fasteners provides a warm security blanket to the mind of a detail-oriented gearhead: You know that piece of hardware is not going anywhere unless you let it. Safety wires entered my life when I first decided to try road racing and I’ve been breaking 1/16-inch drill bits putting them all kinds of places ever since.

With some attention to detail, the final product will be jewelry for your engine. Be sure to properly dress the cut ends, or your engine bay will hide a bunch of razor-sharp needles waiting to rip your hands open.

Labels or the lack thereof

For sponsored racers, brand names and logos matter. For the rest of us, they usually don’t, unless we are just bragging at the cruise-in. Between brand names and small labels identifying parts or need-to-know specifications, a race-engine bay can look either very cluttered or totally bare, devoid of any marketing whatsoever. Pick one look and try it out. Writing valve-lash specs on the valve covers or labeling fuel and oil lines all but guarantees correct assembly in any situation. They can be fun touches, too, especially if you enjoy silly easter eggs, like writing the solid-lifter valve adjustment specs on the valve covers that hide your hydraulic roller valvetrain. Posing? Yes, but also a harmless joke.

Breathers

Engines are all about airflow, and not just through the intake and exhaust. As the linear motion of the pistons is transferred into rotational motion by the crankshaft, pressure often builds inside the crankcase—pressure that is best relieved. Setting up appropriate breathers and ventilation can be easy and, if well thought-out, can still include modern crankcase-ventilation one-way valves.

Add some color

A little color contrast never hurt anything, and nothing makes a black-and-silver engine bay pop quite like a little gold—or whatever color you like. So many little details can be color-coded to make them disappear or become a feature. Valve covers and air cleaners are easy, but even hose ends, bits of wiring organization, and linkages can be snazzed up with subtle pops of color to really “bring the room together.” Be careful here though, as the look can get real gaudy real quick.

And just like that, you have an engine bay that is uniquely yours with a little race-car style mixed in—whether you need it or not.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Wait, so shrouding the coil in the skin from the can of your your favorite adult beverage is considered taboo?

GIGFY: Guinness Is Good For You…

Safety wire. In the mid 1050s I was stationed in Japan in a Marine all-weather squadron (Don’t ask, the planes were dinosaurs – but had the best flying radar in the Far East). In basic aircraft training, I had done rather well. “In the fleet,” my first assignment was in the on-the-line serviced of the F-3Ds – a choice role. My first task by the three-person team, was to replace the aircraft fuel pump. It is located in the belly of the plane. Access to the fuel bladder is via a 28″ by 28″ drop down panel. As the plane sits, that panel and fuel pump is 4 ‘ off the tarmac. At 6’ 4″, I had to work in a squat position – cramped. Did I mention that the fuel pump is held in place by perhaps 12 or 14 screws – each of which has to be safety wired? Proper procedure, as you know, it to wire at least 6 bolts with a single strand, “beautifully” twisted. Well, that ain’t what mine looked like. I was transferred to the night line within the week.

The Corvair…always the Corvair! Don’t you have a friend with a Vega you can photograph?

😉 Merry Christmas

Sounds like I need to make new friends!

I’m guessing the safety wire on your honda motor is some kind of requirtement at a street track some where. In all the off road racing I’ve done I’ve never had a problem with bolts coming loose. For amateur racers like me that had to be at work on Monday morning all this wiring would have slowed me down and kept me from getting my bkes servicing done. My motto has always been “serviceability above all” even above performance.

Well said Steven Adler! I’m also an A&P and have worked for Jaguar for nearly 50 years, (Jaguar, who used safety wire in numerous places on their cars well into the ’90s), and every time I see someone else’s ‘wire’ job I can’t help but scrutinize it. Rarely do I say to myself “nicely done”!

Hey Kyle, how about your plug wires? Wouldn’t some looms tidy things up a bit, and minimize the risk of rubbing on the belt?