Media | Articles

Could 3D printing really help keep your vintage car on the road?

Fabrication techniques had been relatively stagnant for many years until 3D printing came along. The technology has advanced quickly, and now the home fabricator can reasonably use plastic 3D printing to make templates and parts for their own projects. If you are still fuzzy on how this tech could help you with your car, Davin and Matt take a deep dive into just how they’ve made parts for a few of our Redline Rebuild projects.

The concept of 3D printing is sometimes hard to grasp since it is the polar opposite of machining. Rather than starting with a large chunk of material and removing material until it reaches the desired size, it starts with nothing and creates the piece by stacking material up. This technique has its limitations, but solutions have been ironed out to overcome most of those hurdles.

To show the process from start to finish, Davin and Matt talk through their latest venture of creating a spacer to mount an additional pulley to the front of a 1951 Buick straight-eight crankshaft balancer. The rivets holding the balancer together complicated the issue of simply bolting on a new pulley, and rather than clearance the new pulley to fit around those rivets, Davin elected to go with a spacer to give the clearance required.

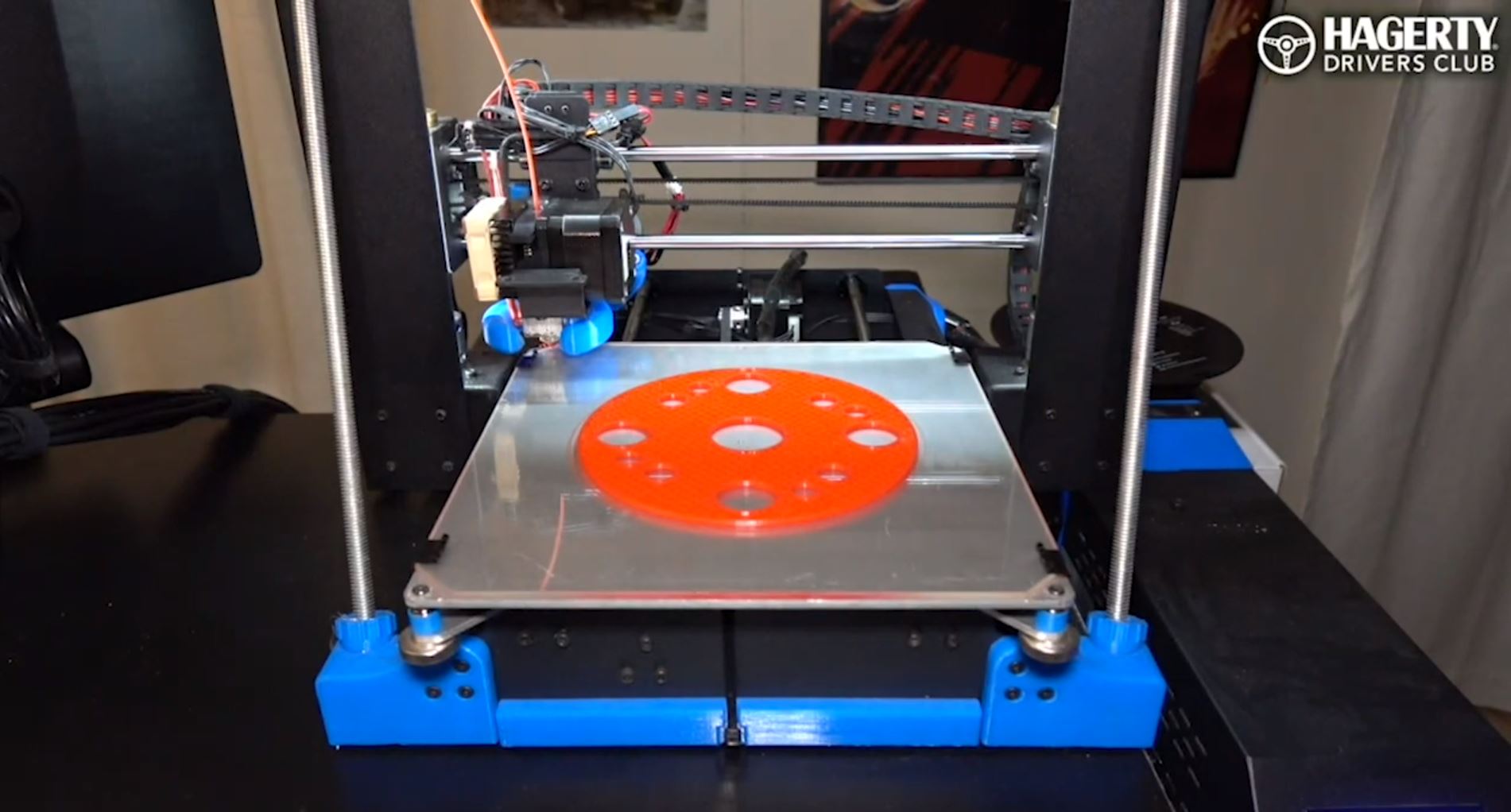

He designed the spacer in a simple CAD program and then shipped the file over to Matt, who rendered it into a file that his 3D printer could work with. From there the machine took over and artfully melted strands of PLA material into a form that Davin could use to confirm his part would work as he desired.

Marketplace

Buy and sell classics with confidence

This method of prototyping saves a significant amount of machine time—especially if the design does not work perfectly the first time, as this situation did for Davin. The design can be easily modified and reprinted with minimal investment and tooling cost. In an era when it is tough to get machinists to take on small projects like this, and when labor rates can be upwards of $80 an hour, this prototyping can keep you in good standing with your machinist.

Davin and Matt talk through the whole process in great detail, and if you are curious about how this technology is going to change the landscape of fabrication, you should absolutely give this livestream a watch from beginning to end.

Have you used 3D printing for any parts on your vintage car? Are you curious about how it could work? Leave us a comment below and tell us the project you think this tech might save.